Infrared Thermography for Electrical Condition Monitoring

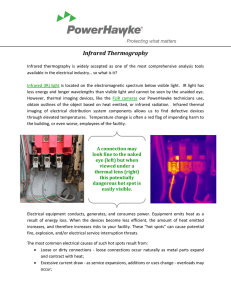

advertisement