Tr i path Technol ogy, I nc. - Appl i cati on Note

DO’S AND DON’TS WHEN DESIGNING FOR EMI COMPLIANCE

Application Note – AN17

Rev 1.0 – November 2001

INTRODUCTION

The goal of this application note is to provide a simple guideline to help design digital amplifiers

that comply with the EMI governing standards. This document will not go into detail on the

theoretical aspects of EMI containment techniques. Please refer to Tripath application note,

AN11, for theoretical background information of EMI containment when using Tripath amplifiers.

The best time to begin considering EMI effects are at the start of the system design. Radiated

and/or conducted emissions can cause the system to fail. Radiated emissions occur when the

EMI escapes through the enclosure. Conducted emissions occur when the input and output

signals are not properly terminated. Both radiated and conducted emissions must be contained

in order for the system to comply with the EMI regulations. There is no checklist of items that can

guarantee a system will pass all of the EMI regulations. But if the guidelines as mentioned in this

application note are carefully followed there is a good chance that the digital amplifier system will

pass the EMI regulations without PC board revisions.

RECOMMENDED DO’s

•

•

•

•

•

1

Enclose the system in a metal box that is electrically conductive. A metal box can

eliminate any noise from radiating outside. The EMI can escape through large holes and

slots in the metal box. Avoid large thin slots on the enclosure. Screws and rivets that are

electrically conductive should be used on all the lap joints to avoid thin slots on the

enclosure.

If the box requires painting or anodizing, a masking process should be used to improve

the electrical conduction on all of the joints.

Attach the metal box to the main ground. The power supply ground should always return

to a single point close to the main AC rectifier. This point is the star ground. Connect

this star ground point to a single point on the metal box. This connection to the box

should be a mechanically solid and an electrically low impedance connection. This can

be done with screws and buswire, braid wire, or copper tape. In systems that use a

power cord with an earth ground connection, this connection can be attached to the

chassis at the same single point on the metal box.

The power supply decoupling capacitors for the amplifier must be located as close to the

amplifier as possible.

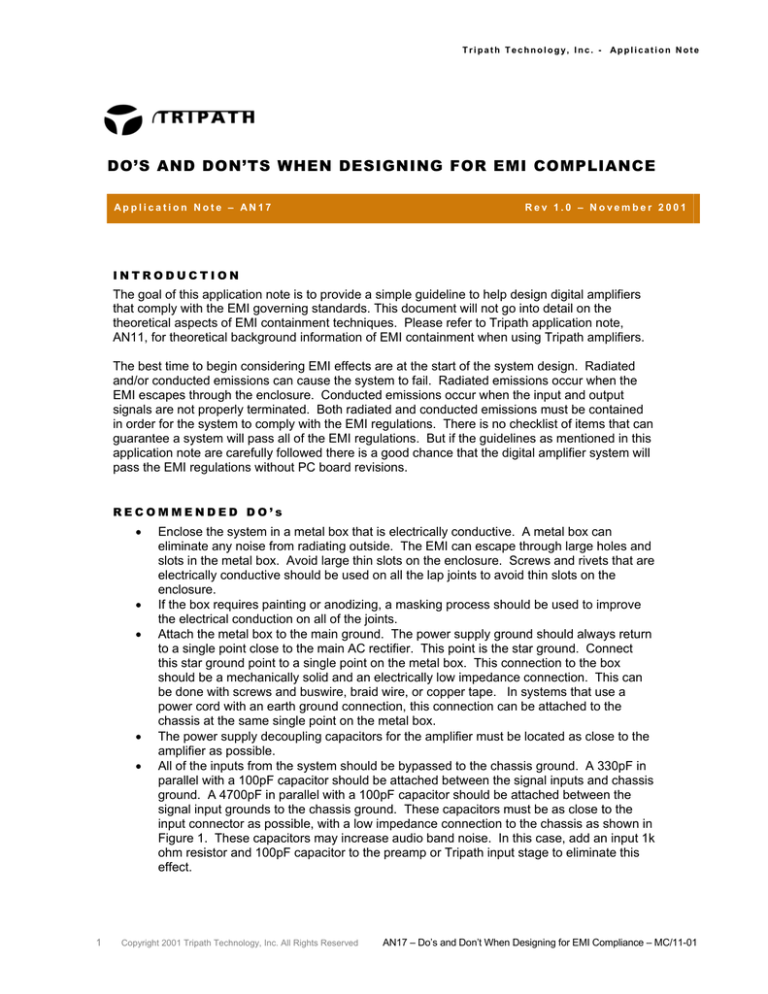

All of the inputs from the system should be bypassed to the chassis ground. A 330pF in

parallel with a 100pF capacitor should be attached between the signal inputs and chassis

ground. A 4700pF in parallel with a 100pF capacitor should be attached between the

signal input grounds to the chassis ground. These capacitors must be as close to the

input connector as possible, with a low impedance connection to the chassis as shown in

Figure 1. These capacitors may increase audio band noise. In this case, add an input 1k

ohm resistor and 100pF capacitor to the preamp or Tripath input stage to eliminate this

effect.

Copyright 2001 Tripath Technology, Inc. All Rights Reserved

AN17 – Do’s and Don’t When Designing for EMI Compliance – MC/11-01

Tr i path Technol ogy, I nc. - Appl i cati on Note

Metal box

C1

100pF

C2

330pF

R1

1k

Input Connector

C3

100pF

Preamp or Amplifier Input

C9

100pF

C4

4700pF

Figure 1

•

The AC line input should have a line filter in series with the power supply. The EMI can

conduct through the AC line power cord if a line filter is not used. If the line filter is

located on the PC board, as opposed to an “off the shelf” line filter, it should be located

as close to the chassis as possible. If this is not possible, the AC power cord may need

to be shielded. See Figure 2. A typical line filter configuration is a differential capacitor,

common mode choke, and common mode capacitors.

AC Power Cord

AC Power Cord

Line Filter

Shield

Line Filter

Metal Enclosure

M etal Enclosure

Figure 2

•

2

All of the speaker outputs from the system should be bypassed to the chassis ground.

Attach 100pFand 4700pF capacitors in parallel from the output to the chassis ground as

shown in Figure 3. These connections must be as close to the output connectors as

possible with low impedance connections to the chassis. Both of these capacitors should

Copyright 2001 Tripath Technology, Inc. All Rights Reserved

AN17 – Do’s and Don’t When Designing for EMI Compliance – MC/11-01

Tr i path Technol ogy, I nc. - Appl i cati on Note

be used for the initial evaluation. In most cases a single 4700pF capacitor is sufficient

and the extra capacitors may be removed one at a time from the design for cost

reduction.

Metal box

C5

100pF

C6

4700pF

+ Speaker Out

- Speaker Out

100pF

C7

•

•

•

•

•

•

4700pF

C8

Figure 3

Other outputs such as line level or subwoofer line level outputs should be bypassed to

the chassis ground with a 100pF capacitor and a 50 ohm series resistor.

For systems that require output power greater than 100W per channel a separate metal

box can be used to enclose the output connectors on the inside of the system. This

internal metal box must have a low impedance connection to the chassis. This will further

shield the outputs from radiating the EMI outside of the system.

For Tripath Amplifier systems that use the TA3020 or TA010X, where external MOSFETs

are required, use low dielectric constant insulators to prevent the switching noise from

coupling onto the heat sink. Aluminum Oxide insulators or polyester film thermally

conductive insulators (such as Poly-Pad K-10 from The Bergquist Company at

www.bergquistcompany.com) can be used with the MOSFETs. Both of these insulators

reduce radiated EMI from the chassis. These insulators also improve the overall

performance of the Tripath Amplifiers.

Whenever possible use toroid core inductors. Toroid core inductors emit less energy

than shielded bobbin core inductors.

Run traces of equal and opposite currents in parallel. For example run the VCC and

GND traces in parallel. This will cancel any radiated energy. If fly leads are used for high

current connections twist together the opposite currents. For example twist together VCC

and GND or twist together the positive and negative speaker outputs.

Use the ground plane to fill in any unused portions of the PC board. This ground plane

should be connected to the power ground at the main star point.

RECOMMENDED DON’TS

•

3

If slots are used on the box to increase airflow inside the system, do not use slots greater

than 2 cm. in length. (See Figure 4)

Copyright 2001 Tripath Technology, Inc. All Rights Reserved

AN17 – Do’s and Don’t When Designing for EMI Compliance – MC/11-01

Tr i path Technol ogy, I nc. - Appl i cati on Note

<2cm .

Figure 4

•

•

•

•

•

4

Do not attach the Tripath amplifier device directly to the metal box that houses the

system. For amplifiers using TA3020 or TA010X which requires external MOSFETs, do

not attach the MOSFETs directly to the metal box.

Do not use single sided PC boards with Tripath amplifiers.

If buswire is used to connect the star ground point to the box do not use wire thinner than

16 gauge.

Input signal traces should be routed as far away from the output stage as possible.

If the system has an AM/FM tuner module along with the Tripath amplifier, do not mount

the tuner module next to the output inductors. The AM/FM tuner module should be

mounted as far from the power amplifier as possible. Always use shielded AM/FM tuner

modules.

Copyright 2001 Tripath Technology, Inc. All Rights Reserved

AN17 – Do’s and Don’t When Designing for EMI Compliance – MC/11-01

![[ ] [ ] ( )](http://s2.studylib.net/store/data/011910597_1-a3eef2b7e8a588bc8a51e394ff0b5e0e-300x300.png)