Surge Protection Devices for Facility Engineers And Electricians

advertisement

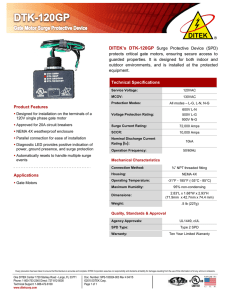

Surge Protection Devices for Facility Engineers And Electricians Peter Walsh, PE 1 Today’s Information ● History of SPD Protection ● Why Specify an SPD? ● Codes and Standards ● Specifications ● Q&A 2 1 What Products are We Discussing Today? Specification Products ● STXT Intended for Service Entrance Protection ● STXP Larger Distribution Panels / Branch Panels ● STXR Branch Panels, Control Panels, Equipment 3 What Products are We Discussing Today? General and OEM Products ● STT ● End use equipment ● Listed Type 1 ● OEM or Retrofit Applications ● ST Pluggable and Modular- OEM Applications ● End use equipment ● UL Recognized ● OEM Applications 4 2 What’s Inside? MOV Disk Eutectic Solder: Melts away and releases arc shield when the MOV senses thermal runaway Arc Shield: Provides isolation of electrical contact during and after low level or short circuit faults TPMOV: Patented thermally protected MOV 5 How the Surge-Trap Operates Surge Trap in normal operating conditions or as over voltage condition first begins. Surge Trap as thermal protection contact begins to operate and arc shield begins to move. Surge Trap as thermal protection contact completely separates and arc shield continues to isolate. Surge Trap in open state, with arc shield completely closed and visual indicator present. 6 3 History of Surge Protection Secret Magic Until Mid 1980’s – Not any way to verify marketing claims – Any manufacturer could claim anything – More than 25 small companies making products and claiming theirs was the only one that had the most important “X” performance – Most of the products would burn up under certain conditions – Switchgear companies faced large claims when the SPDs failed internally to their switchgear 7 History of Surge Protection Responsible SPD Manufacturers and Switchgear Companies agreed to cooperate to develop UL Standard 1449 – Original edition required a least minimal safety tests Mersen (Ferraz Shawmut) started to develop the TPMOV responding to new OEM interest in safety (We have 12 years experience making TPMOVs) Battle lines were drawn between the old-school anythinggoes SPD manufacturers and the safety conscious performance verified companies Eventually the industry adopted third party (UL) verified testing for safety and performance 8 4 What Is a Surge? ● ● ● High amplitude at least 2X greater than the normal voltage with short duration. It can be thousand of volts Can be positive or negative polarity What the difference between transients and noise? ● Transient: ● Noise: Greater than 2X system RMS voltage Less than 2X system RMS voltage Millionths of second 9 9 What Does a Good SPD Prevent? -Insulation Breakdown 500% X 120V RMS X 1.414 = 850V Peak for 0.01 cycles 10 5 Surge Greater than the Insulation Rating X 11 Overview of the Risk Never before have we seen so many Drives, PLC’s, Microprocessor based machine controls on the manufacturing floor. To prevent damaging voltage problems proper surge protective devices need to be used in a cascaded method throughout the facility. It’s a common misunderstanding SPD’s are used for lightning protection while in reality 80% of all overvoltage problems are caused within a facility from equipment. (Commercial, Industrial, Institutional) 12 6 Effects of Surges? Electronics can’t tolerant Surges- Three Ds Disruption - Lockups, Downtime & Interruption costs, Computing / operating glitches and errors Degradation – To electronics, Damage to motor insulation Destruction - Failed electronics, ballasts, motors, controllers 13 MOV - Metal Oxide Varistor Varistor - variable resistor Semiconductor; generally zinc oxide Connects parallel to load (not series) Thickness determines clamping voltage Diameter determines current capacity MOV symbol 50 kA 10 kA 14 14 7 MOV - Metal Oxide Varistor At Low voltages: very high impedance, ≈109Ω Threshold voltage: resistance approaches 0Ω – Overvoltage diverts through MOV as current – Voltage is “clamped” as energy is transferred to other side of MOV(s) MOV does not ‘absorb’ surge, however, I2R heat is retained Bidirectional – Operates same for positive or negative surges Creates a momentary short-circuit to pass transient energy to earth; analogous to water heater pressure relief valve + + 15 15 SPD Operation and TPMOV Technology: SPDs are parallel connected devices that sense overvoltage conditions and create a momentary path to ground redirecting harmful overvoltage energy. Think of it as a pressure relief valve in a water system, relieving the pressure then resetting itself but in an electrical system. SPD 16 8 Codes & Standards changes are driving an industry UL 1449-3rd (Sept 2009) edition has significant product testing changes that has caused an industry to redesign most of their products. The changes are difficult to pass and have created third party verification of product claims. Products that comply are required to have the newer UL holographic label on the product. We’re in an education stage with electrical inspectors and insurance inspectors UL 3rd edition is only product compliance that should be specified 17 Q Why did UL revise the standard? & A Reported catastrophic product failures of surge protection devices derived an initiative at UL to revise its UL 1449 2nd Edition safety standard. Pictures of non fused and non thermally protected MOV based surge products. Products were tested under the new requirements of UL1449. The MOVs saw sustained over voltage conditions and were forced into thermal runaway. Molten metal oxide was expelled, plastic case ruptures occurred and significant black smoke was present during testing. Internal versus External SPDs? 18 9 UL 1449 THIRD Edition Combines TVSS and Surge Arresters into one UL Standard, UL 1449 3rd Edition renamed: Surge Protective Devices (SPDs) Effective: Sept 29, 2009 SPD Surge Arresters TVSS ●New Voltage Protection Ratings (VPRs) replacing old-style …Suppressed Voltage Ratings (SVRs) ● New Endurance In nominal ratings ●New safety SCCR values ●New Application SPD Types: Types 1, 2, 3 & 4 19 19 What Does the Management Want? Safety – UL Listing – Sufficient SCCR value Protection of Equipment from Surges – Low Voltage Protection Rating VPR Endurance – High Nominal Current Rating In Independent third party testing of marketing claims – UL Testing and Listing 20 10 Protective Test Format Changed to VPR New Testing uses Six (6) Times More Energy • As a surge amplitude goes up, clamping voltage goes up too • Specs become obsolete • Need new VPRs in specs 3000A 500A Old – 6kV / 500A Suppressed Voltage Ratings (SVR) New – 6kV / 3,000A Voltage Protection Ratings (VPR) 21 21 UL 1449 Protective Ratings Voltage Protection Ratings (VPR’s) 3,000A test impulses – Uses 6” lead lengths from outside of enclosure – UL specified waveshapes – UL specified oscilloscope settings & probes Directly comparable results Posted on every SPD’s UL label Discrete VPR categories of 500, 600, 700, etc….volts Verifiable on UL.com 22 22 11 UL 1449-3 Endurance Nominal Current Testing – In - (Nominal Discharge Current) - Duty Cycle Testing -15 of 8x20μs surges through every mode of three samples used for VPR testing -- New Concept to USA – (Originated from IEC 61643) Type 1 – 20kA or 10kA Type 2 – 20kA, 10kA, 5kA or 3kA Type 3 – 3kA Type 4 – Based on intended usage as Types 1, 2 or 3 UL 96A Master Label requires 20kA In from Type 1 or Type 2 SPD 23 23 These Ratings Have Similar Units Nominal In - (Nominal Discharge Current) -Mersen Spec Grade Devices are 20kA SCCR -Mersen Spec Grade Devices are 200kA Surge Rating Mersen Spec Grade Devices are 50kA, 100kA, or 200kA+ 24 24 12 Some Terms Not Fixed Yet ● Joule ratings were never defined by UL, IEEE, or industry • Although the Joule game appears to be over, be aware: • No standard exists and never has, no test program or measurement exists • Many ways to manipulate ratings – be careful • Use the new data from the new UL testing ● Surge Ratings are not Defined 50kA, 200kA, 400kA • Historically it was the MOV Supplier Rating • Many companies are stretching their MOV Ratings 25 25 How Does One Select SPD Maximum kA Ratings? Subjective & Delicate: • Sometimes Based on Ampacity of Gear: - Presumption that larger gear has more valuable equipment Larger Panel Ampacity: 4000A-3000A: 3000A-2000A: 2000A-1200A: 1200A-800A: 800A-400A: 400A-50A: SPD kA: 400kA-300kA 300kA-250kA 250kA-150kA 200kA-100kA 150kA-50kA 100kA-50kA Careful: 1.) More valuable equipment might be on smaller panels 2.) Surges do not differentiate based on panel size 26 26 13 Verifying at www.UL.com Click Certifications Category Code #’s: VZCA for SPDs 27 27 2008 NEC – Key Points SCCR labeling consistent with location in distribution system: 285.6 - “The SPD shall be marked with a short circuit current rating (SCCR) and shall not be installed at a point on the system where the available fault current is in excess of that rating. This marking requirement shall not apply to receptacles.” 28 14 NEC – Key Points ● “285.5 Listing. An SPD shall be a listed device.” ● Note: UL will always have a UL Holographic label showing “SPD” on a SPD Product that is UL Listed 29 30 30 15 2008 NEC – Key Points “285.3 Uses Not Permitted. An SPD shall not be installed in the following: On ungrounded systems, impedance grounded systems, or corner grounded delta systems unless listed specifically for use on these systems.” 31 31 NEC Locations for SPD Type: Retrofit OEM Equipment UL Recognized SPDs Are Only for OEM Installation 32 16 Example Lightning Protection System UL 96A Conductor connecting all metals and grounds per UL 96A and NFPA 780 Lightning Rod 33 Applications • XT Series –Listed Type 1 SPD • Service Entrance Gear • Main Distribution Panel Board • XP Series – Listed Type 1 SPD • Distribution Panels, • Motor Control, Automation Control • Larger Equipment, Drives • XR Series , Listed Type 1 SPD • End Use Equipment • ST Series –UL Recognized Type 4 SPD • HVAC – 4X enclosure • STT Series – Listed Type 1 SPD • End Use equipment • Indoor use •Pluggable and Modular • Inside Control Panels • OEM based equipment 34 17 Applying & Selecting SPDs Effective Facility Protection - Factors to Consider Positively ID the Electrical System (480V 3-phase isn’t enough) Proximity in Facility (Service is different than downstream) Modes of Protection Cascading SPDs Locating & Placement of SPDs Installed Clamping Voltage (Short Leads) Redundancy = Longevity (kA ratings for redundancy & longer life – to a point) Power + phone/data/network = Complete Protection 35 35 Engineering Factors to Consider ▀ Whole Facility -Tends to be a coordinated approach by controlling ‘outside’ surges coming ‘in, and ‘inside’ surges, moving throughout Point of Application – Specific piece of equipment – Usually, a modest SPD works fine – Protecting upstream panel usually works better and protects other equipment at same time-Cascading 36 36 18 Cascade Protection Dist Panel Meter Svc. Disc. Main Panel 10m (30feet) Trans Type 1 Type 2 NEC & UL Types Type 3 37 37 Noise Filtering Textbook Low-Pass filter Simple, first order L-N capacitive filters UL1283 & MIL STD 220B Beware: – Ratings often derived by including 100’ of lead length – Impressive names for basic functionality All “track” sinewave All “fill in” notches 38 38 19 Diagnostic Features LED indicators) – sometimes one per unit, or one per phase (Some brands are idiot lights, and/or do not monitor all MOVs) Audible Alarm – makes sound if problem Form C Dry Contact – changes state to trigger indication elsewhere (building management) 39 39 Why Mersen SPDs: • TPMOV- Superior Diagnostic Monitoring XT XP Too many SPDs have insufficient monitoring Examples: • LEDs illuminate when power is present • Only a portion of MOVs are monitored • Few SPDs monitor N-G (because its hard) • SPD can be mostly dead, yet customer thinks it’s A-OK good (especially SPDs with longer warranties) XR TAC switch on each individual MOV – triggered by mechanical contact with slide gate 40 40 20 Warranty on Specification Grade SPD Products ●STXT 10 Year Specific Warranty ●STXP 10 Year Specific Warranty ●STXR 2 Year Specific Warranty 42 42 ● All Products UL Listed to UL 1449 except Pluggable and Modular which are Recognized to UL 1449 ● Full Range of Products ● Smallest Footprints available ● TPMOV Technology Provides ● ● ● ● ● ● Industry leading performance Enhanced personnel Safety Product Reliability Eliminates Need for Upstream OCP Arrestor Grade MOVs Diagnostic Monitoring 54 21 Today’s Information ● History of SPD Protection ● Why Specify an SPD? ● Codes and Standards ● Specifications ● Q&A 55 Surge Protection Devices for Facility Engineers And Electricians Questions? 56 22 Your Electrical Protection Resource Peter Walsh, PE -Senior Field Engineer 23