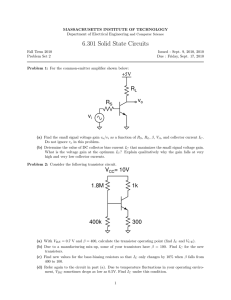

Equation - Electrical and Computer Engineering

advertisement