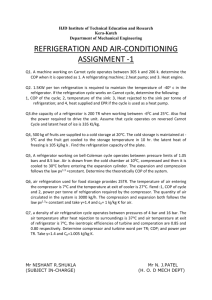

Investigation of Heat Recovery in Different Refrigeration System

advertisement