Recovering Heat from Refrigeration Systems

advertisement

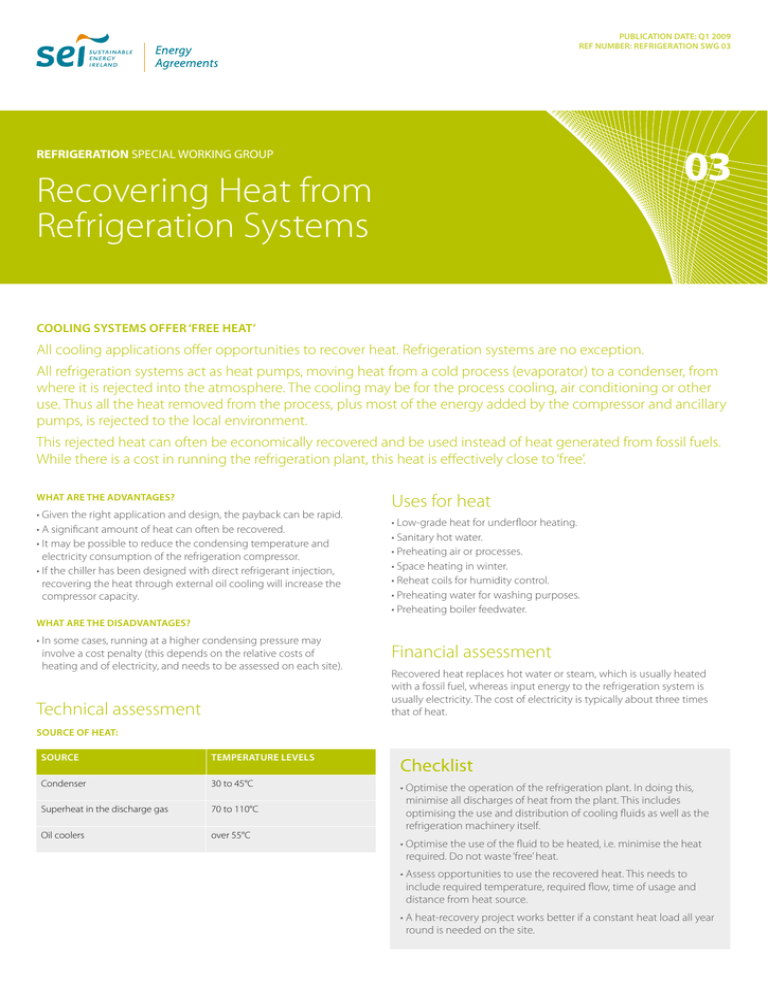

PUBLICATION DATE: Q1 2009 REF NUMBER: Refrigeration SWG 03 03 REFRIGERATION SPECIAL WORKING GROUP Recovering Heat from Refrigeration Systems Cooling systems offer ‘free heat’ All cooling applications offer opportunities to recover heat. Refrigeration systems are no exception. All refrigeration systems act as heat pumps, moving heat from a cold process (evaporator) to a condenser, from where it is rejected into the atmosphere. The cooling may be for the process cooling, air conditioning or other use. Thus all the heat removed from the process, plus most of the energy added by the compressor and ancillary pumps, is rejected to the local environment. This rejected heat can often be economically recovered and be used instead of heat generated from fossil fuels. While there is a cost in running the refrigeration plant, this heat is effectively close to ‘free’. What are the advantages? •Given the right application and design, the payback can be rapid. •A significant amount of heat can often be recovered. •It may be possible to reduce the condensing temperature and electricity consumption of the refrigeration compressor. •If the chiller has been designed with direct refrigerant injection, recovering the heat through external oil cooling will increase the compressor capacity. Uses for heat •Low-grade heat for underfloor heating. •Sanitary hot water. •Preheating air or processes. •Space heating in winter. •Reheat coils for humidity control. •Preheating water for washing purposes. •Preheating boiler feedwater. What are the disadvantages? •In some cases, running at a higher condensing pressure may involve a cost penalty (this depends on the relative costs of heating and of electricity, and needs to be assessed on each site). Technical assessment Financial assessment Recovered heat replaces hot water or steam, which is usually heated with a fossil fuel, whereas input energy to the refrigeration system is usually electricity. The cost of electricity is typically about three times that of heat. Source of heat: source temperature levels Checklist Condenser 30 to 45°C Superheat in the discharge gas 70 to 110°C Oil coolers over 55°C • Optimise the operation of the refrigeration plant. In doing this, minimise all discharges of heat from the plant. This includes optimising the use and distribution of cooling fluids as well as the refrigeration machinery itself. • Optimise the use of the fluid to be heated, i.e. minimise the heat required. Do not waste ‘free’ heat. • Assess opportunities to use the recovered heat. This needs to include required temperature, required flow, time of usage and distance from heat source. • A heat-recovery project works better if a constant heat load all year round is needed on the site. Heat Recovery Investigation notes tools / techniques Optimise the use, distribution and operation of refrigeration plant Ensure that the plant is already operating efficiently and that the waste heat really is waste and not the result of inefficiencies. 1. Minimise use of refrigerated fluids. 2. Minimise heat input into refrigerated systems from system auxiliaries such as distribution pumps. Examine waste heat streams in refrigeration plant(s) Quantify heat being rejected and verify against system COP balance. Include quantity of heat, its temperature and timing of its availability. 1. Measure air or water flow and temperature difference to calculate heat content. Quantify potential value of this heat Convert energy content to financial value based on the cost of thermal energy. This will give an indication of the potential for a heat recovery project. 1. Validate against total system electrical load and COP. Do the financial savings look attractive? 1. Take estimated future costs of energy into account. 2. Don’t forget to include CO2 emissions and their value if part of EU ETS. Examine uses for the waste heat Do you have a need for heat close to waste heat source? Do the timings match (heat storage may help but reduces economic attractiveness)? Ensure heating systems are running efficiently. 1. Potential uses: boiler water make-up heating, boiler combustion air pre-heating, HVAC fresh air pre-heating (cold weather only), wash water, others. Quantify useable heat and it’s value Quantify the amount of available heat that you will actually be able to use and put a financial value on it. 1. If heat source is not hot enough to heat to final temperature could it be used as a preheat source? No Interesting? Interesting? No End End Design and cost the necessary modifications to recover heat including heat exchangers, pumps, fans, pipes, ducts, wiring, controls as appropriate. Design heat recovery system financial appraisal Do the financial savings look attractive? No End Carry out a financial appraisal to compare the potential savings with costs and decide if they meet the organisation’s investment criteria. Develop and implement project Sustainable Energy Ireland Glasnevin, Dublin 9, Ireland Glas Naíon, Baile Átha Cliath 9, Éireann T. +353 1 8082100 F. +353 1 8372848 info@sei.ie www.sei.ie Sustainable Energy Ireland is funded by the Irish Government under the National Development Plan with programmes part financed by the European Union. 1. Simple payback, NPV, IRR