Plastic Fiber Components (PFC)

Application Note 5342

Introduction

Optical-Mechanical Design

Optical communications offer important advantages

over electrical transmission links. The following characteristics make the technology particularly attractive for a

wide range of applications:·

The product range builds upon proven fabrication technology 5 mm LEDs. The task of coupling the device to the

fiber is given over to the housing, the design is shown in

Figure 8a.

• Insensitivity to electromagnetic interference·

A particular advantage of the Avago PFCs is the housing

aperture into which a standard plastic fiber (external

diameter of 2.2 mm) may be introduced without having

to remove the cladding. This has the additional benefit of

automatically aligning the fiber on the chip.

• Voltage decoupling between emitter and detector·

• Security against tapping·

• No sparking at fiber ends or breaks·

• No ground loops

Yet despite the many potential application areas arising

from these advantages, the use of optical glass fiber is

restricted due to its relatively high cost. Where demands

are for medium bit rates and distances, by far the more

cost effective solution today is offered by Plastic Optical

Fiber (POF) in combination with Avago Plastic Fiber Components (PFC) emitters and detectors. These low cost

components permit the use of plastic fibers even in the

most cost-sensitive applications, such as:

• Industrial and medical networks

• Motor controls, links between power and control units

• Replacement of connections with copper wire and

optocoupler (within cabinets)

• High voltage optocouplers

• Automotive bus applications

• Building information and control systems

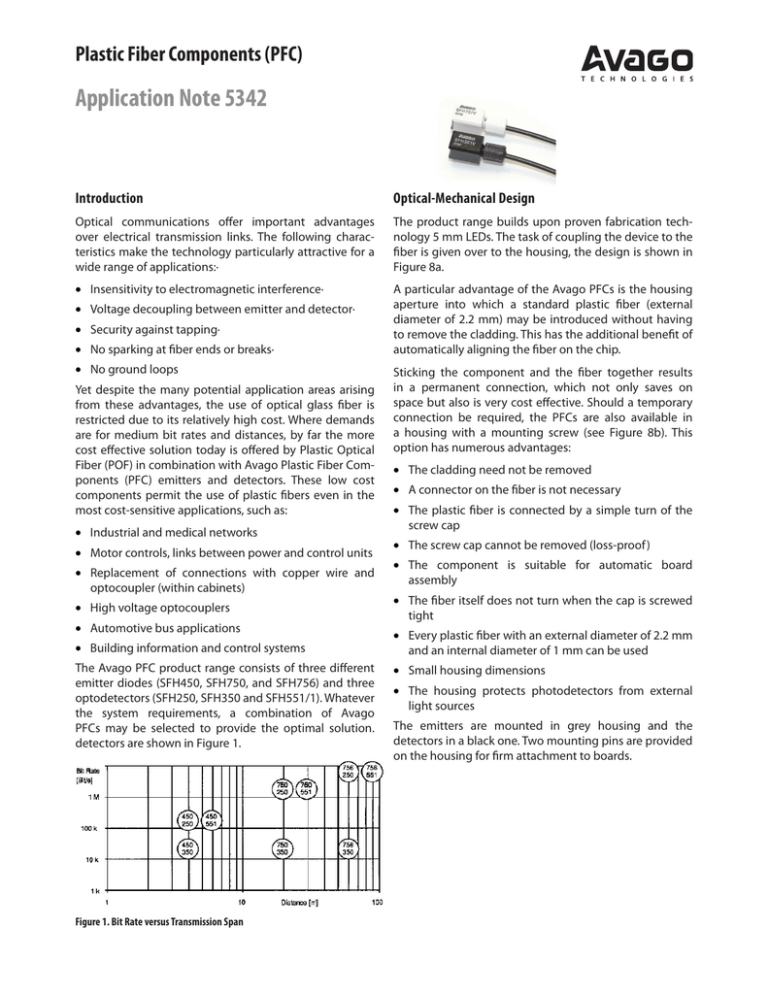

The Avago PFC product range consists of three different

emitter diodes (SFH450, SFH750, and SFH756) and three

optodetectors (SFH250, SFH350 and SFH551/1). Whatever

the system requirements, a combination of Avago

PFCs may be selected to provide the optimal solution.

detectors are shown in Figure 1.

Figure 1. Bit Rate versus Transmission Span

Sticking the component and the fiber together results

in a permanent connection, which not only saves on

space but also is very cost effective. Should a temporary

connection be required, the PFCs are also available in

a housing with a mounting screw (see Figure 8b). This

option has numerous advantages:

• The cladding need not be removed

• A connector on the fiber is not necessary

• The plastic fiber is connected by a simple turn of the

screw cap

• The screw cap cannot be removed (loss-proof )

• The component is suitable for automatic board

assembly

• The fiber itself does not turn when the cap is screwed

tight

• Every plastic fiber with an external diameter of 2.2 mm

and an internal diameter of 1 mm can be used

• Small housing dimensions

• The housing protects photodetectors from external

light sources

The emitters are mounted in grey housing and the

detectors in a black one. Two mounting pins are provided

on the housing for firm attachment to boards.

Electrical and Optical Characteristics of PFCs

Table 2. Parameters of PFC Photodetectors

Both the emitters and detectors display the same electrical characteristics of standard optoelectronic devices.

They may be operated in a temperature range of –40° C

to +85° C.

Characteristics of the Emitter Diodes

Different technologies employed in chip fabrication

lead to significant variation in parameters for the various

emitter diodes. All the emitters distinguish themselves in

offering high output power coupled into the plastic fiber,

low fiber attenuation and long lifetimes. Table 1 gives

a summary of the most important device parameters,

where Pin is the output power coupled into the fiber,

and tr and tf are the rise and fall switching times for the

optical signal.

Table 1. Parameters of the PFC Emitters

Sensitivity 660 nm

(950 nm)

SFH350

Phototrasistor

0.25 (0.3)

80 (120)

Switching Level

SFH551/1

Integrated

Photodetector

Unit

A/W

6

µW

Phototransistor SFH350

The phototransistor SFH350 is a very cost effective photodetector. In operation it yields a high output current

even at low optical input power. Its performance is

limited by low switching speeds. The external base

connector on the SFH350 may be used to divert current

using a base-emitter resistor, with the following advantages:

Part

SFH450

SFH750

SFH756

Unit

• Reduction of the collector-emitter cut-off current

Wavelength

950

660

660

nm

• Reduction of the switch off time

Typ. Pin(IF = 10 mA)

90

9

200

µW

tr 10%/90%

1000

120

80

• Suppression of noise signals and signals with low

power

tf 90%/10%

1000

50

80

ns

As the temperature coefficient is positive for phototransistors, this in some measure compensates for the

negative coefficient of the emitter diodes, assuming that

the ambient temperature of the emitter and receiver are

the same.

The SFH450 emits in the infrared range, whereas the

SFH750 and SFH756 emit visible light in the red range,

namely at 660 nm, which is optimal for plastic fiber. The

choice of emitter for a particular application is dealt with

in Systems with PFC Diodes (page 5), where system issues are

discussed.

The output power coupled into the fiber is measured

using a standard plastic fiber of numerical aperture 0.47

and length approximately 30 cm, for a forward current of

10 mA. It should be noted that this power is not transmitted over long distances. As a consequence the first few

meters of a long length of fiber appear to have higher attenuation (see Connecting the PFCs to the Fiber Emitter, page 6).

The optical power does not rise linearly over the entire

operating range. At low currents the optical power rises

more than proportionately with the current; at higher

currents, saturation sets in.

With respect to the effect of device temperature, all

emitter diodes have negative temperature coefficients.

As a result the output power coupled into the fiber

decreases at higher temperatures.

Characteristics of the Photodetectors

Within the PFC range, three photodetectors are available:

a fast PIN-Photodiode (SFH250), a phototransistor

(SFH350) and an integrated photodetector with TTL-output (SFH551/1).

The main parameters of the photodetectors are summarized in Table 2.

2

Part

SFH250

PINPhotodiode

Photodiode SFH250

The photodiode SFH250 has a switching time of 10 ns

(with 50 Ω for Popt = 50 µW), which makes it the fastest

available detector. When driving a load of greater than

200 Ω, the capacitance of the diode also determines the

switching time.

Temperature dependence of IP is less than that for a phototransistor. The photodiode SFH250 has lower, negative

temperature coefficients for wavelengths of 565 or 500

nm. At 950 nm wavelength, the coefficient becomes

positive.

Digital Receiver SFH551/1

A simple design of the electronic circuitry is an essential

step for the implementation of low cost optical links. In

many cases optical emitters can be directly driven by

logic gates through a resistor for adjusting the current.

On the receiver side, however, a special low-noise

amplifier is required due to the small photocurrent. Thus,

receivers with integrated preamplifiers have succeeded

to realize simple and low cost transmission links.

For this purpose Avago offered the SFH551 (not for

new design), which stood the test in many applications.

Now this receiver is replaced by the upgrade version

(SFH551/1) which is compatible in pinning and identical

in most of its properties. It was the goal of the SFH551/1

development to improve its performance with respect

to noise and dynamics. The features of the SFH551/1 are

now discussed in detail.

Principle of the Digital Receiver

An integrated optical receiver in an optical transmission

system (Figure 2) comprises the following units:

Using a built-in lens, the light leaving the plastic fiber is

focused onto the photodiode of the IC. The photodiode

integrated in the device converts the received light into

photocurrent.

The preamplifier converts the photocurrent into voltage.

Usually, a transimpedance amplifier is applied. A resistor

in the amplifiers feed-back loop determines the currentvoltage conversion. To avoid pulse disturbance, the

amplifier has to offer a linear performance over the entire

power -range of the received light.

The comparator following the signal path converts the

signal to a logic signal. Here, the preamplifiers output

voltage is compared to a reference voltage and the

decision to set the output high or low is made. As the

signal may be noisy, a (small) undefined voltage range

occurs around the reference level. Typical input signals

go through this range very fast and no degradation

of the output signal can be observed. However, if the

signal slowly increases towards the decision threshold,

the output can run into undefined states. Thus, noise

peaks may occur with amplitudes reaching the switching

threshold of the following stages.

To remove this effect, the SFH551/1 is equipped with

a Schmitt trigger which works with different thresholds. If the output is ’off’ a high signal level is required

for switching to the on-state, whereas a lower level has

to be reached to switch back to the off-state. Therefore,

the probability is greatly reduced that small noise signals

cause unwanted switching errors.

Vref

Vcc

Data

Vcc

GND

Figure 2. Optical Transmission Line with Integrated Optical Receiver

Vref

Vcc

Schmitt-Trigger

Data

Vref

Vcc

Differential

amplifier

Cref

Figure 3. Circuitry of the SFH551/1 with Built in Schmitt Trigger

3

TTL-Output

Inverting ooopopr

GND

How the DC-Coupled Receiver with a Fixed Threshold

Works

The form of the signal that is internally delivered from

the transimpedance amplifier to the decision circuit considerably determines the performance of the receiver.

This form itself is determined by the optical receiver

signal and its processing in the preamplifier.

The received optical signal is determined by the following

items:

• Bias light caused by scattering or residual emission of

the transmitter in the switched off state

• Rise and fall times depending on the transmitters

control signal, the transmitter’s speed and possibly

effects from the transmission link

• Pulse amplitude depending on emission power and

the loss of the optical transmission link.

The preamplifier integrated in the SFH551/1 is designed

for wide bandwidth. Consequently no considerable disturbance occurs within its linear working range.

Depending Where the Fixed Decision Threshold Crosses...

If the input signal is too small and does not reach the

decision threshold, the decision circuit does not change

its output state. A short peak exceeding the threshold

results in a correspondingly short output pulse.

If the level of the input signal is very high this results in

early transition to the on-state and a delayed transition

to the off-state. Consequently, the delay of the electrical

signal caused by the falling edge of the optical signal is

longer than the delay of the rising edge (optical signal).

If the transmitter signal is DC-biased (at logical zero) or

additional light hits the receiver, the noise signal is shifted

to the decision threshold. In the case of the SFH551

(without Schmitt trigger) unwanted pulses may occur

at the output. Using a SFH551/1 with its built-in Schmitt

trigger eliminates this problem.

Highly biased signals (at logical zero) cause permanent

switching to the on-state and therefore prohibit data

transmission for both the SFH551 (not for new designs)

and the SFH551/1.

4

The effects described above demonstrate, that the performance of the optical receiver can only fully be described

if the level and form of the optical input signal are taken

into account.

Limits of the Receiver Operation

Dynamic range:

An important figure for the application of an optical

receiver is the dynamic range, defining the range

between smallest and highest signal level in which

perfect operation is assured.

As described above noise pulses can occur at the receiver

output:

• If no light is received (negative peaks on high level)

• If the input power is close to or below the specified

limit of 4 µW (positive peaks on low level)

As these noise pulses occur randomly, they are hard to

detect, requiring a modern storage oscilloscope.

The measurement has shown, that the receiver switches

at an input level as low as 2 µW. In order to avoid noise

as described above, a switching level of 4 µW for nearly

error free operation has been specified in the data sheet.

SFH551/1: minimal light power

As described above, the SFH551/1 contains a Schmitt

trigger. To ensure safe operation, the limit of the switching-threshold was shifted to 5 μW. Compared to the

SFH551 this appears as a lower sensitivity, but taking

the very low bit error rate into account the transmission system can be reliably operated with less system

margin. Due to possible coupling losses, a value of 6 μW

is specified in the datasheet.

On request a low cost option (SFH551/1 -2) with

switching level < 10 μW is available.

SFH551/1: maximal light power

The SFH551/1 offers a considerably increased dynamic

range. Using conventional plastic fiber transmitter diodes

overdriving is practically impossible. Depending on the

system application a limit is given by pulse disturbances

in time depending on the pulse form and increasing with

the input level at high input power. It is recommended

not to exceed a signal level of 400 μW. For higher levels

the pulse form has to be checked in the circuit individually.

Hints for the Application in an Electronic Circuit

Systems with PFC Diodes

Power supply

Plastic Optical Fiber (POF)

For printed circuit board mounting it has to be taken

into account that the SFH551 and SFH551/1 are fast electronic circuits. A blocking capacitor (100 nF) is obligatory

for the SFH551 (not for new designs) and recommended

for the SFH551/1. As both circuits can be operated at 5

V voltage, a noisy power supply can be connected via

a resistor building a low pass filter together with the

capacitor. Despite this means, the full output level can be

reached, if the pull up resistor is connected to Vcc.

The most common type of fiber consists of a polymethylmethacrylate (PMMA) core approximately 970 µm thick

with 30 µm thick cladding made of fluoride-containing carbon polymer. Given the refractive indices of the

core and cladding are 1.492 and 1.417 respectively, the

numerical aperture is 0.47 and the fiber acceptance angle

56°. With a PVC or PE protecting sheath the POF has a

total diameter of 2.2 mm.

How to select the pull-up resistor

To keep the current consumption low, a high value

within the possible range is usually chosen. For very

fast systems it might be important to work with the

minimal value. The calculation of the minimal value,

however, should not be performed with the maximal

output current. For the SFH551 (not for new designs) the

minimal value is 330 Ω (VCC = 5 V). The SFH551/1 can also

be operated with this value, although 390 Ω is recommended here.

Signal Delay

The redesign of the receiver has resulted in a small

increase of the delay times. This becomes clear if the

pulse form of the SFH551/1 is taken into account. The

rising edge is fast and; the delay time increases only for a

very small light power.

Figure 5 shows that the delay of the electrical signal

caused by the falling edge of the optical signal is longer

than the delay of the rising edge (optical signal).

These fibers are obtainable from many manufacturers. The CUPOFLEX fibers, data for which is given in the

appendix, are typical of the POFs available.

The appendix also gives the typical attenuation as a

function of wavelength. Of the two attenuation minima

in the visible spectrum, the one in the red region at = 650

nm is suitable for distances up to 100 m. Due to the low

quantum efficiency of the green emitter, the attenuation

minimum at 570 nm is unsuitable for communications

applications. Moreover, the switching times of the red

emitters are significantly lower, and the degradation is

less than for green emitters. In spite of the high attenuation of POF in the IR-spectrum (4 dB/m), infrared emitters

(SFH450) can still produce sufficient power levels at the

fiber end over a few meters to be of practical use.

Plastic optical fiber made of PMMA can be used in

ambient temperatures of –20° up to +85° C. For lower

temperatures (down to –50° C) the constraint of mechanical flexibility has to be taken into account. Fibers

for higher temperatures, up to 100° C, such as those

necessary for automotive applications, are in development.

When using POF, the bend radius should not be less than

20 mm, as otherwise the fiber attenuation increases.

Smaller radii are possible using fibers with higher

numerical aperture.

250

Light off [ns]

Light on [ns]

tphl, tplh [ns]

200

LED Driving Current

tpLH

Figure 4. Definition of the Delay Times

5

100

50

Output

tpLH

150

0

6 45 84 123

161

200

239 277 316 355

Popt (µW)

394

432

471

Figure 5. Measured Signal Delay vs the Level of Received Light. SFH756 on

the Transmitter Side

Treatment of Fiber Ends

Detector

Due to the thick diameter of POF it is easier to handle

than glass fiber. Thus for very short distances where

plenty of allowance has been made for attenuation, it is

possible to cleave the fiber using a sharp edged blade.

For longer stretches wet polishing the fiber end with

600 grain sandpaper yields greatly improved results.

To achieve very flat surfaces at the fiber ends, the fiber

should be cut with a blade heated to 160 - 180° C or the

clean cut fiber end may be pressed for 2 - 4 seconds on to

a plate heated to 100 - 140°C. Avago recommends that

the manufacturer recommendations be followed.

Due to the lens of the detector’s housing, virtually all the

input radiation is focused on to the chip.

Connecting the PFCs to the Fiber Emitter

When current flows in the forward direction the emitter

diode emits optical radiation. The task of the housing

is to bundle the output radiation so that the greater

portion of it is coupled into the fiber. The components

are intended for use with plastic fibers and thus the data

regarding optical coupling into and out of the fiber refers

to standard plastic fiber with a core diameter of 1 mm

and a numerical aperture (NA) of 0.47. So that as much

as possible of the radiation emitted within this angle falls

upon the fiber, the radiation is concentrated on the fiber

using a built-in reflector and a lens.

The chip in the SFH756 is a large area radiating chip with the

bonding ball in the centre. Therefore not just one position

between chip and fiber core (indicated by the lens) is

possible for optimum coupling, as shown in Figure 6.

Dimensioning the Emitter Driver and the Detector

The Emitter Driver

The emitter is stimulated into emission by current

flowing in the forward direction. There are several possibilities for the design of the driver circuit, which has

the task of adjusting and stabilizing the current flow. In

Figure 7 the basic types of driver circuits are given.

In the simplest example (Figure 7a) the emitter diode

is connected in series with a resistance Rs to the supply

voltage Vs. The current If is dependent of the forward

voltage Vf of the diode:

If = (Vs – Vf )/Rs

The diode may also be driven using the output transistor

of a TTL gate or a separate driver transistor (Figure 7b), in

which case the collector-emitter voltage should be taken

into account. In this configuration the current passed

through by the transistor is given as:

If = (Vs – Vf – Vce)/Rs

In order to keep the current and thus the optical power

constant, it is preferable to control the current flow

(Figure 7c). For this example, as with the others, it is

necessary to ensure than sufficient voltage is provided.

One of the diagrams in the emitter data sheet shows

the dependency of the forward voltage Vf on the

current. Since Vf may reach 3 V for currents of 300 mA,

the maximum duty cycle may be limited by the supply

voltage.

Lens

Light Emitting Area

Figure 6. Lens Position in the Transmitter

In Characteristics of the Emitter Diodes (page 1) it was already

pointed out that the optical power which can be coupled

into the fiber is measured using a standard plastic

fiber with a numerical aperture of 0.47 and of length

approximately 30 cm. The power defined in this way

is not transmitted along large lengths (> 3 m) of fiber.

For long stretches of fiber the first meters therefore

apparently exhibit a higher level of attenuation. This can

be taken into account by adding 2 dB to the attenuation

incurred due to the length of the fiber itself.

Another important parameter when dimensioning the

driver is the permissible pulse load. It is clear from the

relevant diagram in the data sheet, that in regard to

power loss, peak currents of up to 1 A are possible for

short duty cycles. Whether this peak current can be used,

depends on the available supply voltage.

Figure 7. Types of Emitter Diode Driver Circuits

6

Detector

Recommendations for Mounting

When dimensioning the detector it is necessary to

establish the dynamic range, ie. the relation between the

minimum current required and the maximum permissible current.

When soldering it should be ensured that the components is not overheated. Given a distance of 2 mm

between the component and the soldering point, when

using a soldering iron the maximum permissible temperature is 300° C for at most 3 s. In the case of flow and dip

soldering the maximum temperature is 260° C for up to a

5 s period.

System Planning

In order to demonstrate the process of system planning,

an example of the design of an optical transmission

system over a long distance using the SFH551/1 detector

will be discussed.

According to the data sheet, the SFH551/1 detector has

a dynamic range of around 18 dB. This range must be attributed to the various levels of attenuation along the

fiber and the tolerance of the emitter power.

Attenuation in plastic fiber over long distances for light of

wavelength 660 nm is of the order 0.3 dB/m. However the

first section of fiber exhibits higher attenuation (around

2 dB additional to the regular losses in the first meters).

Since the emitter power is measured and specified using

a short length of fiber, the effect needs to be taken into

account (see Connecting the PFCs to the Fiber Emitter, page 6 ).

The following example demonstrates how a PFC system

with a length of 50 m should be driven:

Table 3 Planning of a Transmission Line

Detector power

22.0

dBm

50 m distance at 0.3 dB/m

15.0

dB

Additional attenuation of first few meters

2.0

Needed emitter power without tolerances

5.0

dBm

Further effects which contribute to the reduction of the

operating range:

Temperature (–20 to 45°C)

1.0

Aging

2.0

Range of emitter power distribution

1.5

Emitter power

0.5

dB

dBm

Thus the configuration in this example requires at

minimum an emitter 890 µW output power achievable

with SFH756 driven by 50 mA peak current.

For easy planning SFH551/1 with SFH756 the following

table for recommended drive current in SFH756 may be

used:

Table 4 Easy Planning of a Transmission Line SFH551/1 with

SFH756

7

Maximum Length

10m

20m

30m

40m

50m

Needed Peak Current

5 mA

10 mA

20 mA

30 mA

40 mA

When soldering particular care should be taken so that

the component is not subject to any mechanical stress.

When bending the connection pins, the packaging

should not be loaded in any way.

The soldered components may be cleaned using organic

solvents, with an alcohol base, a base of certain fluorohydrocarbons or a mix of the two. Under no circumstance

should solvents or solvent mixtures be used which

contain chorohydrocarbons or ketones, since these can

attack or dissolve the housing.

Reliability

Degradation

For optoelectronic emitters, the emitted radiation power

reduces over the component’s lifetime. This effect is

known as ageing. It is dependent on the technology of

the diode system, the load current If and the ambient

temperature TA.

If one defines the failure criteria as a 50% (–3 dB) fall in

output power relative to the start value, the lifetime of

the PFC emitter is more than 105 khours.

Emitter Diode Permissible Current Load

When the emitter diode is in operation most of the

electrical input power (Uf x If ) is converted into heat.

The temperature of the semiconductor chip and the

packaging rises as a consequence. On grounds of reliability, the chip should not be heated above the

maximum permitted for the depletion layer. This in

turn yields a maximum power loss, dependent on the

ambient temperature, which cannot be exceeded (refer

to the relevant data sheets). These values are valid for DC

operation.

Significantly better operating conditions are possible

by using the emitter diodes in pulse operation, as the

average power decreases inversely proportional to the

duty cycle. However this means that the maximum

forward current If can be increased for shorter pulse

widths and/or longer duty cycles, as shown in the Permissible Pulse Load plot in the data sheets. These plots give

the maximum permissible forward current dependent on

the pulse width for an ambient temperature TA of 25° C.

The duty cycle parameter D (ratio of pulse width to cycle

period) given as D = ‘n/T. For very short pulse widths (10

s) and small duty factor (1:200) a current up to 20 times

greater than the maximum direct current is permissible

for PFC emitter diodes. Even in the range of 100 ms and

a duty cycle of 1:5 a doubling of the forward current may

be reached, thereby raising the power coupled into the

fiber by a factor two with the SFH450 and a factor 2.5

with the SFH750 in comparison with DC operation.

Permissible Mechanical Load

The fiber optic components SFH250, SFH350, SFH450,

SFH750, SFH756 and SFH551/1 are designed in such a

way, that they can cope with a heavy mechanical load, as

required in automotive applications. The following tests

have been successfully conducted on all the above components:

• Oscillation test (according to DIN IEC Teil 2 - 6, Test Fc)

• Schock test (according to IEC 68-2-27, Test Ea)

In these tests diodes were employed with a fiber of approximately 5 cm in length. They were soldered to a

board and subjected to oscillations and schocks (single

impulses) in the three orthogonal axes. The oscillation

frequency was varied between 10 and 500 Hz with an acceleration of 5 g’s.

Package Outlines

.093

(2.35) .087

Surface not flat

Anode

.100 (2.54)

Cathode

.181

(4.6 )

.071

(1.8) .047

.187

(4.75) .177

.307 (7.8)

.201 (5.1)

.295 (7.5)

1.142 (29)

.354 (9.0)

1.063 (27)

.323 (8.2)

.217 (5.5)

a.SFH250, SFH750, SFH450

.362(9.20)

346 (8.80)

.953 (24.20)

.937 (23.80)

(9.00)

(8.60)

.138 ±.020

(3.5 ±.5)

.024 (0.60)

.024

(0.60) .016

.300

(7.62)

Screw-on

connector

b. SFH350V

Figure 8. Design of the PFC Housing

8

.200

(5.08)

.100

(2.54)

Dimensions in inches (mm)

Disclaimer

The information herein is given to describe certain components and shall not be considered as a guarantee of

characteristics.

Terms of delivery and rights to technical change reserved.We hereby disclaim any and all warranties, including but

not limited to warranties of non-infringement, regarding circuits, descriptions and charts stated herein.

Warnings

Due to technical requirements components may contain dangerous substances. For information on the types inquestion please contact your nearest Avago Technologies Office.

Avago Technologies Components may only be used in life-support devices or systems with the express written

approval of Avago Technologies, if a failure of such components can reasonably be expected to cause the failure

of that life-support device or system, or to affect the safety or effectiveness of that device or system. Life support

devices or systems are intended to be implanted in the human body, or to support and/or maintain and sustainand/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons

maybe endangered.

Information

For further information on technology, delivery terms and conditions and prices please contact your nearest

Avago Technologies Office (www.avagotech.com).

For product information and a complete list of distributors, please go to our web site:

www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies in the United States and other countries.

Data subject to change. Copyright © 2005-2010 Avago Technologies. All rights reserved. Obsoletes AV01-0746EN

AV02-2647EN - September 16, 2010