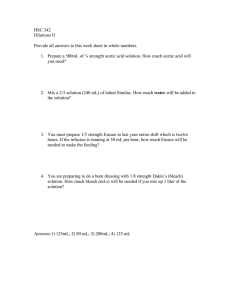

A Stabilized Bromine solution that offers: • Improved - ICL-IP

advertisement

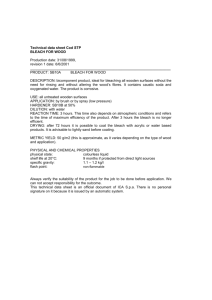

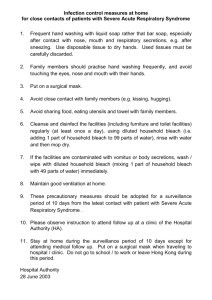

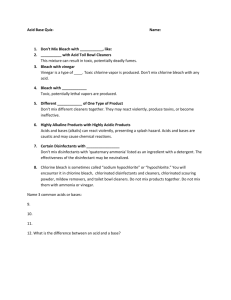

A Stabilized Bromine solution that offers: • Improved Performance • A Chlorine-free / Chloride-free system • Very High Product Stability • Minimal Equipment Investment • Ease of operation • A product specifically designed for the disinfection of Cooling Towers and Industrial Water Systems. The demand for biofilm control is growing rapidly, and Oxidizing biocides are playing a major role in combating this problem on a global scale. • Industrial plant processes are increasing their productivity and in turn becoming very sensitive to biofilm formation. It is therefore imperative that they have the best bio-film control. • E nvironmental laws are now more demanding than ever, and restrictions are increasing (e.g. Legionella risk, Health issues). • Energy- and water- saving strategies now require better bio-film control. •O xidizing biocides do not circum to any resistance phenomena that conventional biocides seem to suffer; their residues (which are linked to their performance level) are very quickly formed and easy to measure. •O xidizing biocides have therefore become a product of choice when selecting a biocide program for any cooling system. 1.2. Features of Bromosol versus other technologies Product Bleach NaBr + Bleach BCDMH Other Stab. Br Bromosol Oxide. content 10 to 15% Same as bleach 55% 6,07% 7,6% Chlorine- and Chloride-free No No No YES Cost Efficiency Poor at pH 7 and + Good Good Very Good Very Good Stability Poor Poor High High High Equipment investment Low Medium Medium Low Low Handling Easy Less Easy Less Easy Easy Easy Safety rather safe less safe dust rather safe rather safe No Note: incorrect handling of any biocide can always lead to dangerous situations. Always handle biocides with care. 1. Product Advantages EFFICIENT, CL-FREE, LOW INVESTMENT COSTS, STABILITY, SIMPLICITY 1.1 Introduction on the bromine chemistry The advantages of Bromine vs. Chlorine in water treatment microbial control applications, have been known for many years. The main benefit is that hypobromous acid is much more efficient than hypochlorous acid in neutral to alkaline conditions. The more alkaline the system is, the more cost effective it becomes, as illustrated in the graph below. • T he second advantage is that the bromamines formed during the reaction of hypobromous acid with the organic materials are excellent biocides in their own right. The bromamines degrade rapidly into harmless residues; this however is not the case with chloramines. Bromine chemistry clearly provides a cost-effective advantage without any environmentally adverse residues. • S ince the 1990’s, several types of bromine systems have been developed in the market, competing with the traditional Bleach/chlorine chemistry: • NaBr (mixed with bleach, will generate hypobromous acid), • BCDMH in tablet or granules dissolved in water, releases hypobromous and Hypochlorous acid • Other Stabilized Bromine (stabilised all-in-one solution of NaBr + bleach). Fig. 2: Biocide efficiency (in %) against bacteria at different concentrations (initial contamination: 1*107 CFU/ml) Volatility Bromosol has a very low volatility, ensuring that the active component will stay in the water for much longer periods. Efficiency comparison (tests on biofilm, pH 7,0) Fig. 1: Comparison of different biocides efficacies against bacteria at concentrations of 1.0 and 2.5 ppm. All biocides concentrations units are given as ppm as Cl2. Stability comparison (at different storage temperatures) The graph demonstrates the exceptional stability of Bromosol during storage. Stored at 40°C, NaOCl will lose 30% of its activity in 7 days; whereas Bromosol will only loose around 4% in 33 days. The above results clearly highlights the advantages of using Bromosol instead of the mixture Nahypo+NaBr. Compatibility with scale and corrosion inhibitors Bromosol has been proven to have a much lower reversion of phosphonate-based scale inhibitors than Bleach or Bromine. Bromosol has little or no reactivity with corrosion inhibitors. If you would like to achieve lower chloride levels Cooling tower manufacturers usually recommend a maximum level of chlorides that should not be exceeded in the recirculation water. The reason is that stress corrosion can be generated in some of the construction materials in the tower. Stress corrosion will eventually destroy components of the tower thereby substantially increasing maintenance costs. Using Bromosol will help to reduce the amount of bleach required by a considerable amount, thus, getting the chloride concentration to the right levels without much effort. When the storage temperature of Na-hypochlorite is high (over 30°C) and the usage of Nahypo is low In these situations, even if used on its own or in combination with NaBr, the Na-hypochlorite is going to lose its activity rather quickly. You may have doubts about the efficiency of the program and visit the plant more often to adjust the dosages to compensate the loss of the active ingredient. Using Bromosol would make the application safer and easier, with less frequent visits to the installation to carry out the task of adjusting the dosage. 2.1. Bromosol’s application Bromosol is a stabilised bromine solution free of Cl (chloride- & chlorine-free). Its strong oxidizing power works by destroying or disrupting bacteria’s membranes (generating holes and leaks in the membrane); it also blocks their enzymatic activity. Yeasts, Fungi and Algae are also controlled by Bromosol. If dosed correctly, there are no micro-organism that can resist Bromosol. As it is easily degrades into non-toxic and non-harmful components, it does not create any threat to the effluent plant or the environment. Bromosol is a liquid formulation that is usually added to the circulation point of a water system. The dosage ranges from 5 to 10 ppm (mg/L) , based on the volume of the system, and the dosing strategy can be intermittent (1-3 times / day). Very difficult cases will need 10 to 50 Litres per 1,000 m3. It is quite possible that higher doses are initially required, but once that the system is back under control, Bromosol’s dosage rate can be optimized and managed accordingly. Bromosol can be used on its own, or in combination with conventional Na-hypochlorite. Nevertheless, the dosage of those conventional biocides can be significantly reduced, offering a better environmental profile. Example of typical dosing - when applied in combination with Na-hypochlorite (Cooling tower): - On a daily basis, apply bleach for several hours (4-7 hours) in order to achieve 0,3 – 0,5 ppm of free chlorine in circulation. - Once per week (sometimes once in 2 weeks) apply 5-10 ppm Bromosol (mg/L in volume); this amount is added in addition to the daily bleach usage and can be introduced in a 2-3 hour period with a pump (or in slug dose, manually). 1.3. Some specific instances where Bromosol shows great advantages When bleach on its own is not able to maintain the required levels of free chlorine. Bleach on its own is a very commonly used in cooling water systems. Quite often, and especially during the summer months, bleach cannot reach the level of free chlorine required (0,5 – 1,5 ppm. as free chlorine during a few hours/day). Whatever the reason is (higher demand / degassing during the storage), the Bleach program needs to be supported and Bromosol is an excellent partner in this instance. After adding a few doses of Bromosol, with the bleach program running under normal conditions, you will very quickly be able to detect much higher concentrations of free chlorine in the water. Once you have reached this stage, Bromosol will even allow you to reduce the dosage levels of bleach, while still getting adequate chlorine levels. Although bleach is a relatively cheap product, reducing the dosage of bleach has several advantages e.g. reduced corrosion, reduced alkalinity and savings on pH control, lower conductivity etc’. .... In low volume systems, the investment for 2 pumps and a mixing system (NaBr + Bleach) is not cost effective. For low chemical usage applications (vacuum pumps, small cooling towers) , you might favour a “oneproduct” system where only one pump is required to dose the biocide into your water system. In addition, due to long storage times at the plant, Bleach will de-gas and loose some of its reactivity. You may find that to overcome this, you will need to overdose with Bleach to be able to convert all the NaBr. Bromosol offers the easy option of using only one product and just one pump; no need to adjust any ratio between two products: the reactivity is ready to be harnessed – just pump and go ! . Bromosol offers also a much higher stability than bleach. Several useful benefits that you might want to consider... If you already use stabilised bromine but are looking for a more advantageous product Bromosol offers several advantages over other existing stabilised bromine solutions: - It has a much higher activity ratio - this will have a significant impact on the product handling costs, and you will be able to reduce supervision in the field related to product handling and spend more time on value added duties. - It is Cl-free (chlorine & chloride free) - Due to its unique patent-protected process, ICL is the only manufacturer that, is able to provide a Cl-free stabilised bromine product. If you would like to have more stable halogen measurements Dissolution of BCDMH is very sensitive and can depend on the water temperature. Cl2-content of Bleach varies with temperature and storage times (which will affect bleach only or a bleach + NaBr system). As it is very stable, Bromosol provides a stable and constant active bromine ratio that helps you stabilise your process, avoiding any ambient temperature (seasonal) related variations. 3. Production Sites And Contacts 3.1/ The production sites ICL is the only manufacturer to provide a chlorine and chloride-free stabilised bromine solution. The production technology is unique and patent-protected. Bromosol is manufactured at Terneuzen (The Netherlands, Europe) or at Wei Hai (Shandong province, China). 3.2/ Contacts lists For info please contact: Mr. Ron Guy, Phone +972 8 6297 525 E-Mail: ron@icl-ip.com 2.2. Bromosol’s properties Specifications Active ingredient Concentration A stabilised chlorine-free bromine solution 17.0 % (+/- 0.9) as Br2; 7,6% (+/- 0.4) as Cl2 Other properties Appearance Density pH Freezing point Flammability Incompatibility acids. Clear Yellow-Orange solution. 1400-1500 kg/m3 >12,5 (neat) Starts to freeze below -15°C Non-flammable is a strong oxidizer and should not be stored near reducing agents or strong Viscosity 12,5 cp @ 15°C (20,0 cp @ 3°C ) Solubility in water Completely soluble in water, in all proportions CompatibilityDuring normal use, concentrations of Bromosol solutions are compatible with commonly used materials of construction in cooling systems. In its neat form, Bromosol is compatible with polypropylene, high density polyethylene, Teflon®, polyvinyl chloride and Viton®. Storage Bromosol should be stored in a cool, dry, well-ventilated area, away from fire and reducing agents. Bromosol has a suggested storage limit of six months and evolves nitrogen gas during storage. 2.3. Delivery Bromosol is supplied in jerry cans of 20 kg, 200 kg drums and 1250 kg IBCs. 2.4/ Bromosol’s complementarity In order to reach a higher efficiency, other biocides (like BCDMH : DBNPA bleach) can be added in the process to complement the Bromosol system BCDMH, DBNPA and bleach (in cooling tower systems) offer good synergy with Bromosol. In cases of DBNPA applications, the levels of continuously dosing of halogens should not be too high (not exceeding 2-3 ppm as free chlorine).