(TYPE B40) BOX BEAM DETAILS PRESTRESSED CONCRETE BB

advertisement

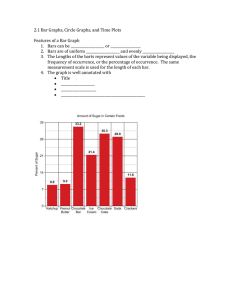

3'-11 ƒ" 1 Bars Z are required for beams topped with a 3'-7 ƒ" 2" 1'-2" 3" 1'-2" 2'-3 ƒ" Void 12" Max Spa (Typ) tendon 4" 2 11" 6 with Bars N interior diaphragms. A 2'-3 • " 4 Extend beam 5 90° at conventional Interior Bents. Ends of beams shall be vertical at Abutment backwall and Inverted Tee Bent Stems. Optional locate between strands Blockouts required at ends of all beams. reinforcement into blockouts. Drain holes ~ 6 chamfer 3 Showing void modification required in exterior beams not topped with a Min 5" cast-in-place concrete slab. strip 5" See standard BBRAO for void modification dimensions. 8 7 5" 1'-0" 5" D See "Blockout, Interior Diaphragm, and Drain Details". 5" 3'-4" N Place drain holes (1" Dia PVC Sch 40 Pipe) as shown in all beam void corners including each side of 2 Tendon hole Form 3" Dia See standard BBPT for details. 3 C L Transverse Based on 150 pcf weight density of concrete. Weight of end blocks and interior diaphragms is not included. 5" C C U 8 Add chamfers as shown when beam length is over 100 ft. Locate drain holes at toe of chamfers. U N TYPICAL SECTION ~ TYPE 4B40 4'-11 ƒ" U 4'-7 ƒ" 2" 3" 5" 2" 3'-3 ƒ" Void 5" 3" B PARTIAL PLAN 5 •" Bars D ~ 7 Eq Spa (Typ) (Showing Type 4B40) Z 2" Z 1 Z 1 1 2" Clr C Top cast (webs and top beam flange) is placed. Vibrate as required to ensure consolidation between the two casts. 1 ‚" clear cover to reinforcement is required unless noted otherwise. See standard BBRAS or BBRAO for railing anchorage at bridge edges to be cast in beams. Optional 5" chamfer 8 strip locate between strands An equal area of welded wire reinforcement (WWR) meeting the requirements of ASTM A1064 may be substituted for Bars A, B, C, and D. These details are applicable for skews up to 30 3 degrees only. Chamfer bottom beam corners ƒ" or round to C U C.G. of a ƒ" radius. U HL93 LOADING Beam SHEET 1 OF 3 TYPICAL SECTION ~ TYPE 5B40 M Bridge Division Standard BEAM PROPERTIES "e" Yb The flange) must remain plastic until the second stage Void 2 5" Yt All reinforcing steel concrete in the first stage cast (bottom beam Drain holes ~ U Use Class H (HPC) if Two-stage monolithic casting is required. Bott D Slab 5 • " Cover 1 • "Clr 1'-0 • " Use Class H concrete. Slab B Designed according to AASHTO LRFD Specifications. must be Grade 60. 2'-5 • " 1 5" Z 5" A 2'-3 • " 3'-4" Blockout 4 Tendon hole GENERAL NOTES: required elsewhere in plans. 5" tendon 2 1'-0" 4 6 1'-0" Blockout 7" Internal Void B C L Transverse C L Transverse End of Cover D 11" 3" 4" A 1'-4" Min Type 4B40 5 PRESTRESSED CONCRETE Type 5B40 over 100 feet 100 feet or less N BOX BEAM DETAILS over 100 feet (TYPE B40) 100 feet or less 8 8 C.G. of strands Bars M ~ 1 •" C ELEVATION Area in 2 Y top in Y bott in FILE: I DATE: The use of this standard is governed by the " Texas Engineering Practice Act" . No warranty of any M ~ space of this standard to other form ats or for incorrect results or dam ages resulting from its use. kind is m ade by TxDOT for any purpose whatsoever. TxDOT assum es no responsibility for the conversion U B holes in interior beams. Slab 1 See "Blockout, Interior Diaphragm, and Drain Details". 5 • " Z 3" C L Transverse 2 ES = D Cover Slab A beams in staged constructed bridges. Top 12" Max Spa Cast interior diaphragms in exterior beams and beams that serve temporarily as exterior Void 3 •" 8 ‚" DISCLAIM ER: tendons. 2" Clr 8 ‚" Bars N ~ 2 ‚" See span details for number and spacing of transverse Z 1 1 Z 1'-0 • " 2 ES = Post-tensioning tendons are required for beams not topped with a Min 5" cast-in-place concrete slab. 39 Spaces at 6" = 19'-6" 2" 3 •" Bars D ~ 5 Eq Spa 8 ‚" Bars U ~ 2 ‚" 2 2'-5 • " 2 ES = cast-in-place concrete slab only. 3" 12" Max Spa 5 •" Bars C ~ 2 ‚" 5" Bott 1 5" Cover Bars Z 2" 6" Max Spa 1 • "Clr Bars A & B in 4 918.8 21.31 18.69 943.8 1044.8 1069.8 21.63 21.07 21.36 18.37 18.93 18.64 BB-B40 bbstds04.dgn FILE: C TxDOT 176,607 180,159 215,300 219,007 957 983 1,088 1,114 December, 2006 DN: TxDOT CONT SECT CK: TxDOT JOB DW: TxDOT CK: TxDOT HIGHWAY REVISIONS Weight7 lb/ft 01-12: Bars Z. DIST COUNTY SHEET NO. Bars A & B N 12 12" Max Spa Bars C 12" Max Spa 39 Spaces at 6" = 19'-6" 2" Eq Spa Bars AL, CL & U at 6" Max & M ,M CC U 8 = 1 ‚" •" C L Transverse tendon 2 AL 9 CL 9 Z 1 5 Eq Spa rs Ba ES 2 U 5" AA CC A N 10 MM Spa Bars M or C Bottom 4 5 7 8 11 11 8 7 5 4 Strands 11 SECTION THRU BLOCKOUT ~ TYPE 4B40 (Showing End Mat Reinforcing) N 12 D 7" M or MM 2" MM U Z 3" 0 Skew Angle 1 B PARTIAL PLAN ~ 15° SKEW Bars A & B Bars U & Z 6" Max Spa 1 12" Max Spa Bars C U 12" Max Spa 39 Spaces at 6" = 19'-6" 5" C L Transverse tendon Z CL 9 2 1 10 Bottom MM Spa Bars M or = ES " ‚ " 8 • 1 AL 9 6" U Eq Spa at 6" Max Bars AL, CL & U , CC s U r & Ba MM C or CC 5 Eq Spa (Showing Type 4B40) (use for skew angles of 15° or less) 2 5 9 4 8 13 13 12 9 12 Strands 11 5 8 4 SECTION THRU BLOCKOUT ~ TYPE 5B40 U (Showing End Mat Reinforcing) D 1 Bars Z are required for beams topped with a cast-in-place concrete slab only. 2 Post-tensioning tendons are required for beams not topped with a Min 5" cast-in-place concrete slab. See span details for number and spacing of transverse tendons. Cast interior diaphragms in exterior beams and beams that serve temporarily as exterior beams in staged constructed bridges. Interior Diaphragm, and Drain Details". MM Form 3" Dia holes in interior beams. See "Blockout, See Standard BBPT for details. 9 Cut as required to maintain one inch clear between bars. C N 10 Bars M may be adjusted vertically as required SHEET 2 OF 3 HL93 LOADING to avoid pretensioning strands in web. Bridge Division Standard A 11 See standard BBND or appropriate Prestressed Concrete Box Beam Standard Designs sheet for AA PRESTRESSED CONCRETE locations of pretensioning strands. 12 For Type 4B40 Box Beams: BOX BEAM DETAILS Bars N may be reduced to 4 bars per row CC (TYPE B40) when beam design contains fewer than 22 strands. In this case, place Bars N at the 5-6 and U 8-9 strand locations. For Type 5B40 Box Beams: 3" Z B 1 Bars N BB-B40 may be reduced to 5 bars per row when beam design contains fewer FILE: 0 DATE: The use of this standard is governed by the " Texas Engineering Practice Act" . No warranty of any C or CC U D of this standard to other form ats or for incorrect results or dam ages resulting from its use. kind is m ade by TxDOT for any purpose whatsoever. TxDOT assum es no responsibility for the conversion U DISCLAIM ER: D M or MM 7" Bars U & Z 6" Max Spa 1 Skew Angle bbstds04.dgn FILE: PARTIAL PLAN ~ 30° SKEW (Showing Type 4B40) (use for skew angles greater than 15° and less than or equal to 30°) than 28 strands. In this case, place Bars N at the 4-5, 9-10 and 14-14 strand locations. C TxDOT December, 2006 DN: TxDOT CONT SECT CK: TxDOT JOB DW: TxDOT CK: TxDOT HIGHWAY REVISIONS 01-12: Bars Z. DIST COUNTY SHEET NO. 2'-8 ƒ" cos 0 Type 4B40 2'-8 ƒ" Type 4B40 Type 4B40 2'-8 ƒ" (Max) Type 5B40 3'-8 ƒ" (Max) 3'-8 ƒ" 3'-8 ƒ" Type 5B40 cos 0 Type 5B40 9 1'-6" (Min) C L Interior Diaphragm and C L 1 •" Diameter hole 1'-10" 3'-0" Bars CL 3'-0" Bars AL 1'-10" Bars CC 3'-0" Bars C Bars AA 1'-10" End of Void Min BARS A & C (#4) BARS AA & CC (#4) 6" Beam Length minus 3" Type 4B40 3'-4" Type 5B40 4'-4" Permiss Splice Fascia side 3" 4 †" 3" 6" 2'-2" Min BARS D (#5) See Detail "A" of exterior beam BARS AL & CL (#4) 6 • " 1'-4" between " -0 t 1' ou k c o 4 Bl (Typ) 2" ) yp (T Limits strands " 10 Locate Permissible splices to BARS B (#4) BARS E (#4) be placed in middle third of span BLOCKOUT, INTERIOR DIAPHRAGM AND DRAIN DETAILS 2'-7 •" Type 5B40 3'-7 •" 6" Type 4B40 3" 6 •" 3" 2'-7 •" formed recess ~ 6" 7" 4" square 6 •" 6" (Showing 30° skew) taper sides Type 4B40 cos 0 3'-7 •" ˆ" per inch F E BARS F (#4) cos 0 Type 5B40 BARS M (#4) 5" (Typ) 13 ANCHORAGE DETAIL DETAIL A " ƒ 7 14 1'-3" 4 •" POST-TENSION 2'-6 • " 14 BARS MM (#4) Type 4B34 2'-8 ƒ" Type 5B34 3'-8 ƒ" 1'-5" 1'-1 •" BARS N (#4) BARS U (#4) 9" 8" 5 • " 1'-3" 5 •" cos 0 1'-3" 5 •" F 1'-8 • " E 5 • " of this standard to other form ats or for incorrect results or dam ages resulting from its use. Block 0 BARS Z (#4) 1 1 Bars Z are required for beams topped with a cast-in-place concrete slab only. At fabricator's option, Bars Z 2 transverse tendons. See span details for number and spacing of Cast interior diaphragms in exterior beams and beams that serve temporarily as exterior beams in staged constructed bridges. 3" Dia holes in interior beams. Details". 3 pairs may be fabricated using Post-tensioning tendons are required for beams not topped with a Min 5" cast-in-place concrete slab. Form one continuous bar. If this option is used, Bars B at Bar Z locations (only) may be omitted. See "Blockout, Interior Diaphragm, and Drain See standard BBPT for details. Place drain holes (1" Dia PVC Sch 40 Pipe) as shown in all beam void corners including each side of interior diaphragms. SHEET 3 OF 3 HL93 LOADING See "Blockout, Interior Diaphragm, Bridge Division Standard and Drain Details". 4 Blockouts required at ends of all beams. Extend beam reinforcement into blockouts. 9 Cut as required to maintain one inch clear between bars. 13 5" (Typ) or sufficient depth to provide 1" Cover on cut-off tendon. PRESTRESSED CONCRETE BOX BEAM DETAILS See BBPT for details. 14 Dimension will vary slightly with skew. (TYPE B40) Adjust as necessary. BB-B40 bbstds04.dgn FILE: FILE: C TxDOT DATE: The use of this standard is governed by the " Texas Engineering Practice Act" . No warranty of any 3 0 kind is m ade by TxDOT for any purpose whatsoever. TxDOT assum es no responsibility for the conversion bottom slab (parallel to beam ends) 2 of beam DISCLAIM ER: Drain holes in Bars A Top edge December, 2006 DN: TxDOT CONT SECT CK: TxDOT JOB DW: TxDOT CK: TxDOT HIGHWAY REVISIONS 01-12: Bars Z. DIST COUNTY SHEET NO.