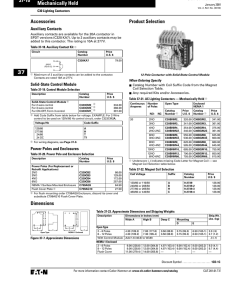

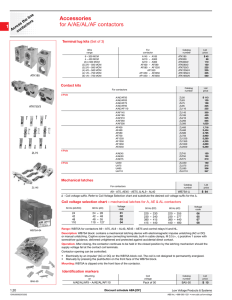

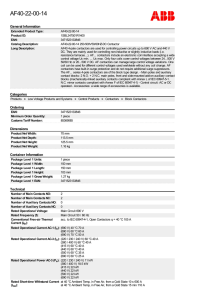

R.. Series Contactors R1400, R1700, R2100

advertisement