FASS Fuel System Technical Guide

advertisement

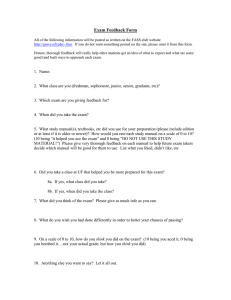

Technical Guide 08/15/14 1 Table of Contents Contact information…………………………………….3 Identifying your system………………………………..4-8 Model Number Serial number location Parts of your fuel system………………………………..9-14 Fuel pump diagram Wire harness schematics Fuel line diagram Servicing Your FASS or Fuel Pump Filters…………….15-18 Recommended Service Life Procedures for servicing your filters/separator How to prime your FASS system……………………….19 Trouble shooting………………………………..……….20-21 How to do a 5 gallon bucket test………………………..22 Electrical………………………………………………...23 ‘98.5-02 Hard Start Issues………………………………24-25 Fuel Leak………………………………………………..26 2 Contact us: Diesel Performance Products Inc. 16240 State Hwy O Suite B Marthasville, MO 63357 Phone: 636-433-5410 Fax: 636-433-5913 Email: techsupport@fassride.com When contacting FASS for technical assistance please have the Serial number of the pump ready. 3 Identify your Fuel system 4 DDRP/DMAX Series Serial number and model number on the DDRP or DMAX will be located on the motor casing of the fuel pump. 5 FA Series Serial number and model number on the Fuel pump series will be on the suction side of the pump next to the inlet(“T” port) of the pump. 6 Platinum Series Serial number and model number on the Platinum series will be located on the filter base, above the filter base and opposite of the truck frame rail. 7 Titanium/ Heavy Duty Series Serial number and model number on the Titanium or Heavy Duty series will be located on the filter base above the fuel filter. 8 Parts of your Fuel system 9 DDRP/DMAX Series Mounting bracket Fuel inlet( suction side of fuel pump) marked with “IN”. Located opposite of outlet. 12mm O-ring Outlet( suction side of pump). Marked with “OUT”. 12mm O-ring The weep hole is on opposite side of mounting bracket. Always be sure weep hole points down. Weep hole is for normal moisture to exit the motor Electrical plug, Green wire is ground and Red 10 FA Series Inlet( suction side of pump) Marked with a “T” for tank. 1/2” NPT The FA Series is factory preset for each truck, the pump is adjustable by using the regulator Outlet( pressure side of pump) Marked with an “E” for Engine. 1/2” Electrical plug, Green wire is ground and Red wire is power. Boost compensating port for high horse power applications Weep hole is for normal moisture to exit the motor casing. Weep hole must be facing down 1/8” NPT fuel pressure port 11 Platinum Series Engine feed ( pressure side) marked with an “E: for Engine. 3/8” NPT FASS return ( pressure side) Marked with a “R” for return. 1/2” male flare. 3/8” NPT fuel pressure port Fuel inlet( suction side). 3/8” NPT Electrical plug, Green wire is ground and Red wire is power. Fuel filter/water separator( pressure side) recommended to use at least a 3 micron filter or better 12 Titanium Series Electrical plug, Green wire is ground and Red wire is power. Engine feed ( pressure side) marked with an “E: for Engine. 3/8” NPT FASS return ( pressure side) Marked with a “R” for return 1/2” male flare. Fuel filter ( pressure side) recommended to use at least a 3 micron filter or better Fuel inlet( suction side) marked with a “T” for Tank. 3/8” NPT 1/8” NPT fuel pressure port Water separator ( suction side) recommended to us no more restrictive than a 10 micron filter 13 Titanium Series Electrical plug, Green wire is ground and Red wire is power. Engine feed ( pressure side) marked with an “E: for Engine. 1/2” NPT FASS return ( pressure side) Marked with a “R” for return 1/2” male flare. Fuel filter ( pressure side) recommended to use at least a 3 micron filter or better Fuel inlet( suction side) marked with a “T” for Tank. 1/2” NPT 1/8” NPT fuel pressure port Water separator ( suction side) recommended to us no more restrictive than a 10 micron filter 14 Heavy Duty Series Electrical plug, Green wire is ground and Red wire is power. Engine feed ( pressure side) marked with an “E: for Engine. 1/2” NPT FASS return ( pressure side) Marked with a “R” for return 1/2” male Flare. Fuel filter( pressure side) recommended to use at least a 3 micron filter or better Fuel inlet( suction side) marked with a “T” for Tank. 1/2” NPT 1/8” NPT fuel pressure port Water separator( suction side) recommended to us no more restrictive than a 10 micron filter 15 Servicing your FASS filters 16 Filter Intervals FASS DDRP/DMAX In line filter 4,000-6,000 miles* Refer to vehicle owners manual for factory fuel filter FASS FA Series Inline filter 4,000-6,000 miles* Refer to vehicle owners manual for factory fuel filter FASS Platinum Series In line filter 4,000-6,000 miles* Spin on fuel filter/water separator 15,000-25,000 miles* FASS Titanium Series Water separator 25,000-30,000 miles* Fuel filter 25,000-30,000 miles* FASS Heavy Duty Series Water separator 50,000 miles* Fuel filter 50,000 miles* *Intervals will depend on quality of fuel being used. FASS always recommends a fuel pressure gauge to monitor filter life. 17 How to change your filters Inline filter If possible crimp off suction line( line from tank to FASS pump) to prevent large fuel leaks Loosen hose clamps Using proper container pull fuel lines off each end of the fuel filter. Replace with new filter (from cross reference sheet) be sure to pay attention to flow of the filter Tighten hose clamps Remove crimps if used Prime pump Using proper container to catch fuel loosen a fitting on pressure side of and bump the starter, may need to do several times, do not let pump shut off until system is primed Tighten once fuel comes out Spin on water separator Using proper container to catch fuel, drain water separator and remove Replace with new water separator (from cross reference sheet) and follow directions on filter when installing 18 How to change your filters Priming Using proper container to catch fuel loosen fuel filter and bump starter, may need to do several times, do not let pump shut off until system is primed When the FASS motor changes tone tighten fuel filter Spin on fuel filter or fuel/water separator Using proper container to catch fuel drain or remove fuel filter Replace with new filter (from cross reference sheet) follow directions on filter when installing Priming Using proper container to catch fuel loosen fuel filter and bump starter, may need to do several times, do not let pump shut off until system is primed When the FASS motor changes tone tighten fuel filter 19 How to prime your FASS system DDRP/DMAX or FA Series Loosen a fitting on the pressure side of the FASS pump Using proper container to catch fuel bump the starter, may need to do several times, do not let pump shut off until system is primed When fuel starts to come out of line re-tighten Platinum, Titanium or Heavy Duty Series Leave water separator tight (Titanium and Heavy Duty) Loosen fuel filter so air can be pushed out Using proper container to catch fuel bump the starter, may need to do several times, do not let pump shut off until system is primed When pump motor changes tone and fuel begins to come out tighten fuel filter If the FASS pump will not prime proceed to 5 gallon bucket test to check for possible restrictions 20 Trouble shooting Pump will not turn on when key is on or truck is running Refer to electrical section and check relay After performing all test call FASS if issue is not fixed Pump drops fuel pressure under heavy throttle and low fuel levels Change your filters Refer to the 5 gallon bucket After performing all test call FASS if issue is not fixed Pump sounds like it is shutting ON and OFF or going up and down in tone Change your filters Refer to the 5 gallon bucket test Refer to electrical section After performing all test call FASS if issue is not fixed Pump is noisy Change your filters Refer to 5 gallon bucket test Refer to electrical section to see if motor is getting to many volts After performing all test call FASS if issue is not fixed 21 Technical Q&A Where to read fuel pressure? Use the “G” port on the FASS system or T into the supply line Noisy or grinding pump? First, check to make all rubber spacers have been properly installed. It could be cavitation, restriction or a bad motor. FASS recommends do the bucket test to see if noise goes away. I bought an aftermarket filter and the draw tube is to long. Some aftermarket filter depths are different than our filters. You can remove a 1/2” off the end of the draw tube and it should work properly. I am having priming issues. Suggest cracking the fuel filter and give the pump power. The pump should change tone once the system is primed, and at that point you need to tighten the fuel filter before fuel leaks out the filter. Refer to “how to prime you FASS.” My wiring harness is melting/popping fuses. A restriction can cause increased amperage on the motor, which could cause a wire to get hotter than normal or pop a fuse. Suggest changing the filter along with doing the bucket test to eliminate all restrictions which could cause high amperage. My pump doesn’t turn on and is locked up. First give a direct 12v source to eliminate the harness and/or ECM signal. If the pump is still locked up suggest checking the gear for any debris that might be stuck in the gear. WARNING: any seal broken to check for debris in gear without prior FASS approval will void the warranty. 22 5 Gallon Bucket Test Under the following conditions perform this test Low fuel pressure Lower fuel pressure with different fuel levels in fuel tank Inconstant fuel pressure Loss of fuel pressure Hard starts Losing prime Not priming properly Noisy pump Fuel pump sounds like it is turning ON and OFF How to do a 5 gallon bucket test Fill a clean 5 gallon bucket 3/4 the way with clean diesel fuel Pull suction line off fuel tank, this will be the line from the tank to the “T” port on the FASS pump Remove the FASS return line at the truck connection (Platinum, Titanium and Heavy Duty Series) Put both lines into bucket Prime the FASS pump Start truck and check pressure There only two factors that will affect this test The water separator or in line filter Suction line If doing this solves the issue you will need to install a suction tube or sump to eliminate the issue. If this does not fix the issue contact a FASS Tech 23 Electrical Many of the FASS units are equipped with a separate wire harness, which has a fuse and/or relay. To locate the fuse on all units other than DDRP, find where the red wire from the FASS is connected to the positive side of the battery or ignition switch. The fuse will be between the battery or ignition and relay. Remove fuse and inspect, if fuse is blown replace with same fuse. Be sure fuse terminals are clean of corrosion Be sure all connections are good and tight and free from corrosion Disconnect the FASS pump and using proper tools check for at least 12volts from the truck to the FASS How to jump the FASS relay Pull relay out of relay socket Locate pins 30 and 87 Using a piece of jumper wire connect terminals 30 and 87, this will supply a constant 12volts to the pump if the fuse is good. Checking trigger wire for relay For FASS models equipped with a relay, remove the relay and locate terminal # 85 Using a test light bump the starter, if light does not light up call FASS. Dodge 1998 1/2 and up will stay on for 25 seconds then shut off, Duramax will stay on at all times. 24 FASS is blowing Fuses All FASS systems will be supplied from the factory with an in line filter or water separator, a clogged filter can cause the motor on the FASS to over amp and blow a fuse. Be sure to check all electrical connections for a loose connection or corroded connection. Replace or repair as needed. If issue continues proceed to following test. Replace in line filter or spin on filter to check for possible restrictions. If issue continues proceed to following test. Once filters are changed refer to 5 Gallon bucket test to check for restrictions in fuel tank. If problem continues contact a FASS Tech. 25 Hard Starts (Dodge ‘98.5-’02) Answer the following questions Did the vehicle start fine without the FASS? Do you have high mileage on your VP44? Has your VP44 been subjected to 5psi or lower? Has your VP44 been subjected to a failing lift pump? Does it occur more frequently when conditions are hot? To test for a cracked diaphragm do the following when you know the truck will be hard to start Unplug the FASS pump Start the vehicle as soon as you enter the key into the ignition, shut vehicle down as soon as it starts. If the vehicle starts without issues there are two options Re-wire the FASS– refer to WH-1002 Hard start fix Install a Hobbs Oil pressure switch (Closed) into oil filter and wire ground from FASS harness to oil pressure switch. 26 Hard Start Fix 27 Fuel Leak Answer the following questions Do all male NPT thread fittings have thread tape on them? Are all fitting tight? Are all filters tight? In order to determine where the leak is the unit should be cleaned of with brake cleaner and allowed to dry. Then run unit on level ground without movement. Once it is determined that there is a leak from the FASS contact a FASS Tech. 28