Luminous Efficiency Enhancement of Organic Light

advertisement

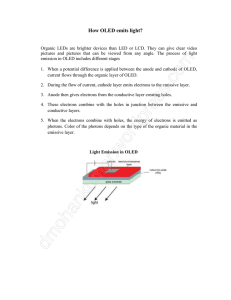

Luminous Efficiency Enhancement of Organic LightEmitting Diodes by an External Electron Source Chi-Shing Li, Shui-Hsiang Su*, Tzu-Min Lin , Hsiang-Yu Chi and Meiso Yokoyama Abstract-The external electron source is used to enhance the luminous efficiency of organic light-emitting diodes (OLEDs). Based on the electrons emission characteristics of carbon nanotubes (CNTs), an OLED combined with a CNTs template is proposed. Electrons emitted from the CNTs template impact the Al cathode layer of an OLED device and transport arriving at the emission layer. Balanced recombination of electrons and holes occurs in the OLED and the luminous efficiency can be enhanced by 50%. I. INTRODUCTION Organic light emitting diodes (OLEDs) have been attracting attention because of their advantages in emission in a wide visible region and for application in flat-panel displays driver at low voltage. Improvements have been made since the first efficient organic light-emitting diode was reported in the late 1980s [1]. There have been various efforts to increase the efficiency of OLED [2]. Using multi-layer structures, low work function cathodes and proper injection configuration can be greatly improved the performance of OLED. However, the extraction efficiency is related to the intrinsic photoluminescence efficiency of the organic material and to the output coupling efficiency of the sandwiched indium-tin-oxide (ITO)/organic layers [3, 4]. In fact, in the multi-layer organic structure, holes and electrons not balanced was the principal factor to affect the luminous efficiency. In order to improve the performance of the OLED, the external electron source of CNTs cathode was proposed [5-7]. By using the CNTs cathode as electron sources inject electrons into the organic thin film. One of the authors had been report the similar structure and named field emission organic light emitting diode (FEOLED) [8]. However, by using the external electron to enhance the luminance efficiency of OLED has not yet been report. In this paper the fabrication and emission characteristics of the OLED also discussed, in terms of external electron sources to supplement the electronic components of the OLED. II. EXPERIMENT Fig. 1 shows the chemical structure of the organic materials investigate and the device configurations. All of the organic layers were deposited onto an ITO-coated glass substrate (7 Ω/ □ ) by vacuum vapor deposition at a pressure of 5 × 10−6 Torr. All authors are with the school of Department of Electronic Engineering, IShou University, Kaohsiung County, Taiwan *Contacting Author: Shui-Hsiang Su is with the School of Department of Electronic Engineering, I-Shou University, Kaohsiung County, Taiwan (phone: 886-7-657-7711; email: shsu@isu.edu.tw). CNT-base filed emitter cathodes have been fabricated by using the spray method. The 1,2-dichloroethane (DCE) solvent is used to disparate the CNTs by sonication. Adhesion between CNTs and ITO glass substrate was resolved by introducing glass frit in the DCE/CNTs solution. After that, the spray technique is introduced to fabricate CNTs field emitters, followed by heat treatment. After the OLED device has been done, the cathode (Al) of OLED was faced toward the CNTs cathode and setting in a vacuum chamber (<5 × 10-6). This triode structures, measurement and control by using standard commercial electronic components. A keithley model 2400 was provided the OLED, and a keithley model 237 was used to control the voltage between OELD anode plate and CNTs cathode, to generate an additional electrical field to attract the electrons to the OLED cathode (Al). The EL spectrum and luminance– current–voltage characteristics were measured and recorded by use of the TOPCON SR-1 spectrometer. In this system, the CNTs cathode emission electrons were generated with the electric field to attract and accelerate, which were accelerated toward the OLED and had to supplement the electrons. III. RESULTS AND DISCUSSION Fig. 2 plots the I-L-V characteristics of the OLED device with the switch of Sw1=close and Sw2=open. The luminance of the OLED is 550 cd/m2 at 10 V. The OLED will burn down at a driving voltage more than 10 V. Experimental results reveal that unmatched energy barriers exit at the interfaces of layers resulting in an imbalance in electrons and holes concentrations in the emission layer. The most situations are holes more than the electrons. Therefore, external electrons emitted from the CNTs template outside of the OLED are suggested to supplement the electrons to enhance the efficiency of electron-hole recombination. A CNTs template is used as a cathode in the study and it can emit a high electron current density of 10 mA/cm2 at 1.4 V/μm. It is attributed to the CNTs have perfectly dispersed on the template and glass frit has held all the CNTs tight after annealing process. The inset in Fig. 2 shows the mapping of CNTs and quite good dispersion can be observed. The CNTsbased template is very suitable to be the external electron source. In order to promote the efficiency of OLED, the exterior electron source enters from the outside of OLED to further supplement electron. The VEL of OLED is fixed at 8 V and the luminance is 184 cd/m2. At the same time, Va is turn on (Sw2=close) to induce the field emission electrons from CNTs cathode. The external electrons have initially impacted the Al cathode layer of an OLED and transport toward the ITO anode. It has provided more electrons for the recombination with holes in the organic light emission layer. Fig. 4 shows the luminous characteristics of a green-OLED. At the same driving voltage of 8 V, the luminance has arisen from 184 cd/m2 to 300 cd/m2. The improvement has been attributed to the more balanced hole-electron recombination in the emission layer of an OLED. ITO m-MTDATA (40 nm) NPB (20 nm) Alq3 (60 nm) LiF (0.7 nm) Al (30nm) Va e IV. CONCLUSIONS This study has successfully used a CNTs template to act as an external electron source in the OLED. Under an electrical field driving, electrons emitted from the CNTs templates compensate for the lack of electrons in an OLED and completely recombine with the holes in the emission layer. Balanced recombination of electrons and holes occurs in the OLED and the luminous efficiency can be enhanced by 50%. The construction presented here is a very promising technique for OLED device applications. Sw2 - - e e - VEL - e Sw1 CNT CNTs cathode Fig. 1 The layer structure of a field-emission organic light-emitting device (FEOLED) and the configuration adopted in this study. ACKNOWLEDGMENT The authors would like to thank the National Science Council of the Republic of China, Taiwan, for financially supporting this research under Contract No. NSC 98-2221-E214-003-MY3. The authors would also like to thank the MANALAB at ISU, Taiwan. Fig. 2 I-L-V characteristics of organic light-emitting diodes. (Sw1:close, Sw2:open) REFERENCES [1] C. W. Tang and S.A. Van Slyke, “Organic electroluminescent diodes.” Appl Phys Lett., vol. 51, pp. 913–915, September 1987. [2] M. A. Baldo, D. F. O'Brien, Y. You, A. Shoustikov, S. Sibley, M. E. Thompson, and S. R. Forrest, “Highly efficient phosphorescent emission from organic electroluminescent devices,” Nature, vol. 395, pp. 151-154, September 1998. [3] I. Schnitzer, E. Yablonovitch, C. Caneau, T. J. Gmitter, and A. Scherer, “30% external quantum efficiency from surface textured, thin-film lightemitting diodes.” Appl. Phys. Lett., vol. 63, pp.2174, October 1993. [4] M. H. Lu and J. C. Sturm, “External coupling efficiency in planar organic light-emitting devices.” Appl. Phys. Lett., vol. 78, pp. 1927, March 1993. [5] W. A. Deheer, A. Châtelain, D. Ugarte, “A carbon nanotube field-emission electron source.” Science, vol. 270, pp. 1179 – 1180, November 1995. [6] W. B. Choi, D. S. Chung, J. H. Kang, H. Y. Kim, Y. W. Jin, I. T. Han, Y. H. Lee, J. E. Jung, N. S. Lee, G. S. Park, and J. M. Kim, “Fully sealed, high-brightness carbon-nanotube field-emission display.” Appl. Phys. Lett., vol. 75, pp. 3129-3131, November 1999. [7] J. M. Bonard, J. P. Salvetat, T. Stockli, W. A. Deheer, L. Forro, and A. Chatelain, ”Field emission from single-wall carbon nanotube films.” Appl. Phys. Lett., vol.73, pp. 918-920, August 1998. [8] C. S. Li, M. Yokoyama, and S. H. Su, “Efficiency enhancement of fieldemission organic light emitting diodes using a dynode structure.” Electrochemical and Solid-State Letters, vol.11, pp. 1-3, July 2007. Fig. 3 The J-E characteristics of CNTs-based emitters. (Inset) CNTs Mapping results from a CNTs-base template. (Sw1:open, Sw2:close) Fig. 4 The characteristics of the field-emission organic light-emitting device (FEOLED). (Sw1:close, Sw2:close)