Quin Systems Limited

SRV-2 Issue F Hardware Manual

Issue 2

October 2004

MAN544

Important Notice

Quin Systems reserves the right to make changes in the products described in this

document in order to improve design or performance and for further product

development. Examples given are for illustration only, and no responsibility is assumed

for their suitability in particular applications. Reproduction of any part hereof without

the prior written consent of Quin Systems is prohibited.

Although every attempt has been made to ensure the accuracy of the information in this

document, Quin Systems assumes no liability for inadvertent errors.

Suggestions for improvements in either the products or the documentation are

welcome.

Relevant Directives

The product is designed to be incorporated into a system for the control of machinery,

and needs external equipment to enable it to fulfil this function. It must not be relied

upon to provide safety-critical features such as guarding or emergency stop functions.

It must not be put into service until the machinery into which it has been incorporated

has been declared in conformity with the Machinery Directive 89/392/EEC and/or its

relevant amendments.

The installation instructions in this manual should be followed in constructing a system

which meets requirements.

The product has been tested in typical configurations, and meets the EMC Directive

89/336/EEC, when fed from power supplies which meet 89/336/EEC and 92/31/EEC.

The product uses only low voltages, and is therefore exempt under 73/23/EEC as

amended by 93/68/EEC.

The product as normally supplied has low voltages accessible to touch, and must be

mounted within a suitable cabinet to meet any required IP rating to BS EN 60529.

Issue 2

SRV-2 Issue F Hardware Manual

Copyright Notice

Copyright © 2004 Quin Systems Limited. All rights reserved.

Reproduction of this document, in part or whole, by any means, without the prior

written consent of Quin Systems Limited is strictly prohibited.

Version History

Issue

Date

Update Reason

1

Aug 1996

(Board iss B)

2

Oct 2004

Covers iss E, iss F board

Amendment Record

Date

Issue

Amdt.

Copyright © 2004 Quin Systems Ltd.

Pages

By

Reason

Page iii

SRV-2 Issue F Hardware Manual

Page iv

Issue 2

Copyright © 2004 Quin Systems Ltd.

Issue 2

SRV-2 Issue F Hardware Manual

Contents

1.

Introduction

3

2.

Description of Operation

4

3.

Using The SRV-2 Module

5

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

5

5

6

6

6

6

6

7

7

8

4.

Configuration

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

5.

6.

General

Incremental Encoder Inputs

Link Encoder Output

Absolute Encoders

Analogue Outputs

Analogue Inputs

Relay Contacts

Serial Ports

CANbus Interface

Digital Inputs and Outputs

Processor Options : J1

Reset and watchdog enable : J2

Interrupt Configuration : J3

SSI Clock Signals : J4

Eprom Device Select : J5

Ram Device Select : J6

Spare Duart Inputs : J7

Serial Port A Overide : J8

Jumper Locations

9

9

9

9

10

10

10

11

11

12

Connections

13

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

13

14

14

14

15

15

15

16

18

Connector layout

Signal Names

Power Supplies

Serial Ports

CANbus Interface

Encoder Connections

Background Debug Connector

Screw Terminal Connections

CPLD Download

SRV2 Flashboot Sector

19

6.1

6.2

19

19

Switch-on Self-Test

Entry to Flashboot Diagnostics

Copyright © 2004 Quin Systems Limited

Page 1

Issue 2

SRV-2 Issue F Hardware Manual

List of Figures

Figure 1.

Encoder input circuits.

5

Figure 2.

Isolated inputs and outputs

8

Figure 3.

Interrupt Configuration : J3

9

Figure 4.

SSI Clock Signals : J4

10

Figure 5.

Eprom device select : J5

10

Figure 6.

Ram device select : J6

10

Figure 7.

Spare Duart Inputs : J7

11

Figure 8.

Serial Port A Override : J8

11

Figure 9.

Jumper locations

12

Figure 10.

SRV-2 layout

13

Table 11.

Serial port connections : ports A–B

14

Table 12.

CANbus connections

15

Table 13.

Encoder connections

15

Table 14.

Background Debug Connector

15

Table 15.

Back screw terminal connections

16

Table 16.

Bottom screw terminal connections

17

Copyright © 2004 Quin Systems Limited

Page 2

Issue 2

1.

SRV-2 Issue F Hardware Manual

Introduction

This document describes the Quin Systems SRV-2 two/three axis digital servo control

module, issue F. Earlier issues differ slightly, generally as noted.

The SRV-2 module is a complete control system for two or three servo motors. It is

designed for use in standalone applications. Its output signals are compatible with most

motor drive systems. Note that in most applications the high power drive system should

be selected for the particular motors used to provide the required system performance.

The SRV-2 module has its own processor with private program and data memory. It is

normally supplied with comprehensive firmware which performs all the real-time

functions and interfacing for the servo system. The module includes three inputs for

incremental position encoders and a buffered link encoder output, three analogue

inputs, three analogue outputs for the motors and a fourth for a monitor signal, sixteen

digital inputs, eight digital outputs, two serial ports, and a CANbus interface. All

encoder input signals and digital input/output signals are optically isolated. The serial

ports may be configured for either RS-232 or RS-485 operation.

Copyright © 2004 Quin Systems Limited

Page 3

Issue 2

2.

SRV-2 Issue F Hardware Manual

Description of Operation

This section gives a brief overview of the operation of the SRV-2 module.

The SRV-2 module has its own processor and memory which form a complete

microcomputer system. Together with the input/output facilities and the firmware

which is normally supplied, it is a complete two/three axis servo control system on a

single board. The module is designed for standalone use.

Each position encoder interface receives signals from an incremental encoder, 90

degrees out of phase (in quadrature). The phase of the two signals depends on the

direction of motion of the encoder. The interface converts the quadrature signals to up

and down count signals, which are counted by a counter circuit. The circuit multiplies

the encoder line count by four to get maximum position information from the encoder.

The encoder input circuits are fully isolated, and are designed for use with encoders

having complementary line driver outputs. The encoders require an external encoder

power supply. The module is intended for use with encoders providing signals A, B, Z,

and their complements; a total of six signals. The encoder input signals on channel 1

are buffered as the link encoder output, to allow separate units to share a common

encoder if required.

The local processor reads the up and down counts from the counters, and calculates the

current position of the encoder for each axis. It compares the current position with the

required position and calculates the position error. The position error is used to

calculate the demand signal for each motor, according to some control algorithm, for

example a PID 3-term control algorithm.

The calculated demand signal value for each channel is written to a 12-bit digital-toanalogue converter (DAC). The DAC output is scaled by an amplifier circuit to provide

a ±10V full scale output signal. This signal is output via a reed relay to the main drive

system for the motor.

The relays on the analogue outputs are controlled by three digital outputs. The relays

connect the drive system inputs either to the DAC outputs for normal operation, or to

0V to hold the motor stopped in an idle state. A second set of contacts from each relay

is brought out for external use, for example as a drive enable signal.

Other digital inputs and outputs are available and may be used for auxiliary inputs such

as limit switches or reference signals. These input and output lines are all optically

isolated, and are intended for use with 24V signals. They are suitable for direct

connection to programmable logic controller (PLC) systems. The digital outputs use

Darlington optical isolators, having a high current transfer ratio, and they can drive

loads up to a maximum of 100mA. Both inputs and outputs are protected against

reverse connection.

Copyright © 2004 Quin Systems Limited

Page 4

Issue 2

SRV-2 Issue F Hardware Manual

3.

Using The SRV-2 Module

3.1

General

The SRV-2 module is normally supplied with the Qmotion 2/3 firmware which

provides a high-level command set for controlling a servo system. This firmware

assigns certain functions to some of the SRV-2 input and output facilities, and these are

described below.

3.2

Incremental Encoder Inputs

The SRV-2 is normally supplied configured for use with incremental encoders. The

encoder input circuits are designed for use with encoders having complementary line

driver output signals. The encoder input signals are fully isolated, and the supply for the

encoders must be provided from an external power source. The input current into the

optical isolators is approximately 10mA. The module is shipped configured for use with

standard 5V encoder signals. The encoder input circuit is shown in the diagram below.

Note that the three red LEDs for each encoder light for the “off” polarity of the encoder

signals.

+5V

TLP115

1kΩ

Encoder

track A

Encoder A

100Ω

Encoder /A

0V

100Ω

1nF

100Ω

1nF

100Ω

Encoder 0V

Figure 1. Encoder input circuits.

The standard firmware assumes that encoder track A leads track B for positive

movement, although this is programmable.

Copyright © 2004 Quin Systems Limited

Page 5

Issue 2

3.3

SRV-2 Issue F Hardware Manual

Link Encoder Output

The link encoder output provides a buffered copy of the encoder input signals on

channel 1. This allows separate units to be connected together and share one encoder

without an external encoder splitter.

The encoder 0V supply common is available on the link encoder output connector, but

not the encoder +5V supply.

3.4

Absolute Encoders

On the SRV-2 module, provision has been made for using absolute encoders with a

synchronous serial interface (SSI). This option is selected by means of jumper links,

and replaces the normal incremental encoder feedback. The SSI input uses two twisted

pair RS-485 signals, one for the clock signal to the encoder (using the ‘A’ pair), and the

other for the serial data returned from the encoder (using the ‘B’ pair). The standard

firmware supports various different encoder resolutions, and either binary or gray code

data formats.

3.5

Analogue Outputs

The SRV-2 module has four analogue outputs. The output signals are 12bits resolution,

and range between ±10V. Three of these are used by the standard firmware as the speed

demand signals to the motor drive systems, and the fourth is available as a monitor

output signal. Outputs that are not used to drive motors may also be assigned as monitor

signals, which can be programmed for various functions. Each motor output signal is

taken through a reed relay which allows the output line to be switched directly to 0V.

This facility is used in the “motor off” state to force the output to 0V as a safe condition

when any error occurs.

3.6

Analogue Inputs

The SRV-2 module has three analogue inputs. The input signal range is ±10V, and the

analogue-to-digital converter has 12 bit resolution. The input signals are buffered by a

diferential amplifier, which provides good common mode noise rejection.

3.7

Relay Contacts

The relays are used to switch the main analogue outputs to 0V in the motor off state.

Each relay has a second set of changeover contacts, which change at the same time as

the main output is switched, and may provide an external indication of the motor off

state. This may be used to provide an inhibit signal to the motor drive system if

required.

The relay contact output connections are labelled in their unpowered (safe) state. This

is the same as in the motor off condition. The normally closed contacts are open when

the module is controlling the servo system, and closed when the module is in the motor

off state or is unpowered. The normally open contacts provide the opposite function.

Copyright © 2004 Quin Systems Limited

Page 6

Issue 2

3.8

SRV-2 Issue F Hardware Manual

Serial Ports

The SRV-2 module has two serial ports. Ports A and B are both used by the standalone

Qmotion 2/3 software; a SERVOnet slave uses port A only for initial configuration, and

port B for remote setup access for some types of drive. Each port is configured by the

software for either RS-232 or RS-485 signals as required, and multi-drop operation is

supported in RS-485 modes. The software control of port A may be overridden if

required for testing by changing the jumper link on J8.

3.9

CANbus Interface

There is an optional CANbus interface on the SRV-2 module. It uses the 9 way D type

socket at the bottom of the front panel, and the plug immediately above it, with all pins

linked pin-to-pin for looping the bus through. It is provided for both peer-to-peer

mapping between units and full master/slave operation with a separate host controller.

The CANbus interface requires an external 12 volt power supply to provide power to

the isolated transceiver device. It complies with the CAN in Automation (CiA) draft

standard DS102 Version 2.0, CAN Physical Layer for Industrial Applications.

Copyright © 2004 Quin Systems Limited

Page 7

Issue 2

3.10

SRV-2 Issue F Hardware Manual

Digital Inputs and Outputs

The SRV-2 module has sixteen digital input lines and eight digital output lines. These

may be individually set, cleared, or read via the standard firmware. They may also be

programmed for some predefined functions. Please refer to the appropriate Reference

Manual or User’s Guide for more details on programming the input and output lines.

The input lines are fully isolated, and must be used with an external logic supply,

normally +24V. The input current into the input optical isolators is approximately

10mA. The module is supplied configured for use with 24V signals, suitable for

signalling to a programmable logic controller. The input lines have a common 0V

connection, and are active-high.

The output lines are also fully isolated. Each output sources up to 100mA maximum.

The outputs have a common +24V connection, and are active-high. Protection diodes

are connected between each output and the +24V input/output supplies.

Typical circuits for the isolated digital input and output lines are shown below.

Machine SRV-2

Input circuit

SRV-2 +5V

SRV-2 Input 1

Input 1

SRV-2 0V

0Vio

Output circuit

SRV-2

Machine

SRV-2 +5V

SRV-2 Output 1

+24Vio

Output 1

0Vio

Figure 2. Isolated inputs and outputs

Copyright © 2004 Quin Systems Limited

Page 8

Issue 2

SRV-2 Issue F Hardware Manual

4.

Configuration

4.1

Processor Options : J1

Jumper J1 is provided for use with some processor test facilities. Fit a link 5–6, once

started, to stop the clock for JTAG test. No links should be fitted to J1 in normal

operation.

4.2

Reset and watchdog enable : J2

Jumper J2 provides a manual reset input, used during development, and enables the

hardware watchdog. Shorting J2 pins 1 and 2 resets the processor. If a link is fitted

between J2 pins 3 and 4 then the hardware watchdog is enabled. If no link is fitted then

the hardware watchdog is disabled. Currently the hardware watchdog is not available

and no links are fitted to J2.

4.3

Interrupt Configuration : J3

Jumper J3 is used to connect the various external interrupt sources to the seven local

processor interrupt inputs.

J3

/PFail : 1

/RefIRQ : 3

/RefIRQ : 5

/DuartIRQ : 7

/CanIRQ : 9

/CanIRQ : 11

/DuartIRQ : 13

/DuartIRQ : 15

/CanIRQ : 17

2 : /IRQ7

4 : /IRQ6

6 : /IRQ5

8 : /IRQ4

10 : /IRQ4

12 : /IRQ3

14 : /IRQ2

16 : /IRQ1

18 : /IRQ1

Figure 3. Interrupt Configuration : J3

The normal configuration is with the duart interrupt connected to /IRQ2 (link 13-14),

and the reference interrupt connected to /IRQ6 (link 4-3) when needed. The Mini

Machine Manager uses /IRQ4 ((link 9-10) for CANbus (SERVOnet); MiniPTS3

(Qmotion 3) uses /IRQ3 (link 11-12), while 2+1 (Qmotion 2) does not use CANbus.

Copyright © 2004 Quin Systems Limited

Page 9

Issue 2

4.4

SRV-2 Issue F Hardware Manual

SSI Clock Signals : J4

Jumper J4 connects the clock signals for the SSI absolute encoder option to the external

A and /A encoder connections on each channel. When an absolute SSI encoder is used

on a channel, two links are fitted to jumper J4 for that channel. Each channel may be

configured separately. The serial data output signals from each SSI encoder are then

received on the B and /B encoder input connections.

J4

SSICLK0 : 1

/SSICLK0 : 3

SSICLK1 : 5

/SSICLK1 : 7

SSICLK2 : 9

/SSICLK2 : 11

2 : ENC1A

4 : /ENC1A

6 : ENC2A

8 : /ENC2A

10 : ENC3A

12 : /ENC3A

Figure 4. SSI Clock Signals : J4

4.5

Eprom Device Select : J5

Jumper J5 selects the signals connected to pins 1 and 31 of the eprom or flash memory

devices IC9 and IC10. For 27C020 or similar eproms and 29F020 or similar flash roms,

link pins 1–3 and 2–4. For 27C040 eprom devices (512k×8) link pins 1–3 and 4–6. For

29F040 flash roms link pins 3–5 and 2–4.

J5

5V Pull-up : 1

IC9/10 pin 1 : 3

A18 : 5

2 : /WR

4 : IC9/10 pin 31

6 : A18

Figure 5. Eprom device select : J5

4.6

Ram Device Select : J6

Jumper J6 selects the signal connected to pin 30 of the SRAM memory devices IC12

and IC13. It allows pin 30 to be connected to either a high pull-up or address line A17

as required. For 128k×8 devices fit a link between pins 1 and 2. For 256k×8 or larger

devices (as for a Mini Machine Manager) fit a link between pins 2 and 3.

J6

5V Pull-up : 1

IC12/13 pin 30 :

A17 : 3

Figure 6. Ram device select : J6

Copyright © 2004 Quin Systems Limited

Page 10

Issue 2

4.7

SRV-2 Issue F Hardware Manual

Spare Duart Inputs : J7

Jumper J7 allows the unused inputs on the duart serial port device to be tied high or low.

The duart input pins are connected to a pull-up resistor network, and the jumper pad

allows them to be connected to 0V. Two of these lines are also connected to pins 3 and

7 of the serial eeprom devices IC6 and IC7, for configuration of device-dependent

options. J7 pins 1-2 or pins 3-4 may be linked to indicate NVM device types to some

software versions.

J7

Duart IP2 :

Duart IP3 :

NVM pin 3, Duart IP4 : 5

2 : 0V

4 : 0V

6 : 0V

NVM pin 7, Duart IP5 :

8 : 0V

Figure 7. Spare Duart Inputs : J7

4.8

Serial Port A Overide : J8

The serial ports on the SRV-2 module are configured by the software for RS-232 or

RS-485 as required, to reduce the number of jumpers that need to be configured by the

customer for different applications. Jumper J8 allows the software configuration for

port A to be overridden for testing. For normal operation under software control, link

J8 pins 1 and 2. To force RS-232 operation, link pins 2 and 3.

J8

Duart OP2 : 1

Port A select : 2

0V : 3

Figure 8. Serial Port A Override : J8

Copyright © 2004 Quin Systems Limited

Page 11

Issue 2

SRV-2 Issue F Hardware Manual

4.9

Jumper Locations

Top

S3

S2

S1

P2

J4

1

T1

T11

J2

1

J3

1

T4

1

S5

P4

P1

1

T5

1

J1

S4

J6

J8

1

1

J5

P3

J7

1

T6

1

T7

S6

T13

T2

T8

T9

T10

T3

Bottom

SRV-2 module - component side

Figure 9. Jumper locations

Copyright © 2004 Quin Systems Limited

Page 12

Issue 2

SRV-2 Issue F Hardware Manual

5.

Connections

5.1

Connector layout

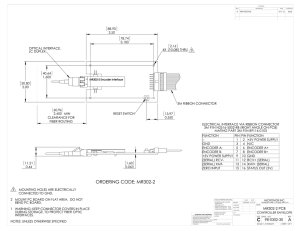

The SRV-2 board has several connectors. Two 9 way D sockets on the front panel are

used for serial ports. Port A is used for the main programming terminal, while port B is

used for options such as the Operator’s Panel or the Modbus interface. A 9 way D plug

and similar socket on the front panel are used for the CANbus interface. On the top plate

there are three 9 way D sockets for the three encoder inputs and a 9 way D plug which

provides a buffered output from the channel 1 encoder signals. Two part screw

terminals are used for all other signals, with the digital inputs and outputs at the back

of the unit on the left hand side, and the analogue inputs and outputs along the bottom

of the unit.

Encoder 3

Encoder 2

S3

S2

Encoder 1 Link encoder

S1

P2

T1

T11

Front

T4

Port B

S5

Back.

T5

Port A

S4

CANbus

P3

CANbus

S6

T6

T7

T13

T2

T8

T9

T10

T3

Figure 10. SRV-2 layout

Copyright © 2004 Quin Systems Limited

Page 13

Issue 2

5.2

SRV-2 Issue F Hardware Manual

Signal Names

On all signals, a ‘/’ prefix is used to denote an inverted or active low signal. For

example, the /VPA signal is the active low Valid Peripheral Address signal on the G64

bus.

5.3

Power Supplies

The +24V power supply to the SRV-2 module is connected via the 3 way screw

terminal connector T11 at the back of the unit. The +5V supply for the shaft encoders

is connected via T1, and the +24V i/o supply via T7. The relevant pins are as follows,

numbered from the top of each connector :

Unit supply :

+24V

0V

Earth

T11 pin 1

T11 pin 2

T11 pin 3

Encoder supply :

+5V

T1 pin 1

0V

T1 pin 2

Screen

T1 pin 3

I/O supply :

+24V

0V

T7 pin 1

T7 pin 2

Unit supply current is about 250 mA running, with an initial switch-on surge of up to 1

amp. Other supplies depend on connected devices: the unit internal loading of I/O

supply is 10 mA per ‘on’ channel.

5.4

Serial Ports

The following table shows the connections on the front panel 9 way D sockets for serial

ports A–B. Note that port C is no longer fitted.

Signal

Pin no.

Signal

Pin no.

RS-232

RS-485

1

High termination

6

2

TxD

7

RTS

/TxD

3

RxD

8

CTS

/RxD

4

Low termination

9

5

0V

Table 1: Serial port connections : ports A–B

Copyright © 2004 Quin Systems Limited

Page 14

Issue 2

5.5

SRV-2 Issue F Hardware Manual

CANbus Interface

The connections for the CANbus interface on the front panel 9 way plug are shown

below. Note that this complies with the CAN in Automation (CiA) draft standard

DS102 Version 2.0, CAN Physical Layer for Industrial Applications.

Pin no.

Signal

Pin no.

Signal

1

Reserved

6

GND

2

CAN_L

7

CAN_H

3

CAN_GND

8

Reserved

4

Reserved

9

CAN_V+

(7–13V)

5

CAN_SHLD

(screen)

Table 2: CANbus connections

Current consumption on the CAN_V+ (12 volt) rail is about 35 mA per node.

5.6

Encoder Connections

The table below shows the encoder connections for the Qmotion 2/3. Note that pin 4 on

the the channel 1 link encoder output plug does not have the encoder +5V supply

connected.

Pin no.

Signal

Pin no.

Signal

1

A

6

/A

2

B

7

/B

3

Z

8

/Z

4

+5VE

9

0VE

5

SCREEN

Table 3: Encoder connections

5.7

Background Debug Connector

The connections on the background debug connector P1 are given here.

Pin no.

Signal

Pin no.

Signal

1

/DS

2

/BERR

3

0V

4

/BKPT/DSCLK

5

0V

6

FREEZE

7

/RESET

8

IFETCH/DSI

9

+5V

10

IPIPE/DSO

Table 4: Background Debug Connector

Copyright © 2004 Quin Systems Limited

Page 15

Issue 2

5.8

SRV-2 Issue F Hardware Manual

Screw Terminal Connections

The back screw terminals provide connections for the power supplies and the digital

inputs and outputs.

Back screw terminals

Listed from top to bottom

Signal

1.1

+5V encoder supply

1.2

0V encoder supply

1.3

Screen/earth termination .

11.1

+24V supply

11.2

0V supply

11.3

Screen/earth termination .

4.1

0V i/o

4.2

Input 1:

4.3

Input 1:

4.4

Input 1:

4.5

Input 1:

4.6

Input 1:

4.7

Input 1:

4.8

Input 1:

4.9

Input 1:

4.10

+24V i/o .

5.1

0V i/o

5.2

Input 2:

5.3

Input 2:

5.4

Input 2:

5.5

Input 2:

5.6

Input 2:

5.7

Input 2:

5.8

Input 2:

5.9

Input 2:

5.10

+24V i/o .

6.1

0V i/o

6.2

Output 1:1

6.3

Output 1:2

6.4

Output 1:3

6.5

Output 1:4

6.6

Output 1:5

6.7

Output 1:6

6.8

Output 1:7

6.9

Output 1:8

6.10

+24V i/o .

7.1

+24V i/o .

7.2

0V i/o

Table 5: Back screw terminal connections

Copyright © 2004 Quin Systems Limited

Page 16

Issue 2

SRV-2 Issue F Hardware Manual

Note that the 24V power supply input is not isolated from the internal 5V supply, and

the 0V supply connection should normally be earthed. The 24V i/o supply is required

for correct operation of the motor enable relays, as it provides power to the relay coils.

The bottom screw terminals provide connections for the analogue inputs and outputs,

and the motor enable relays.

Bottom screw terminals

Listed from front to back

Signal

13.1

0V Operator’s Panel supply

13.2

+5V Operator’s Panel supply

2.1

Screen/earth termination

2.2

Analogue input 1–

2.3

Analogue input 1+

2.4

Analogue input 2–

2.5

Analogue input 2+

2.6

Analogue input 3–

2.7

Analogue input 3+

2.8

Analogue 0V

8.1

Analogue output 1

8.2

Analogue output 0V

8.3

Relay 1 n.o.

8.4

Relay 1 common

8.5

Relay 1 n.c.

9.1

Analogue output 2

9.2

Analogue output 0V

9.3

Relay 2 n.o.

9.4

Relay 2 common

9.5

Relay 2 n.c.

10.1

Analogue output 3

10.2

Analogue output 0V

10.3

Relay 3 n.o.

10.4

Relay 3 common

10.5

Relay 3 n.c.

3.1

Analogue output 4

3.2

Analogue output 0V

Table 6: Bottom screw terminal connections

All the screen connections are linked together to allow a single earth connection for all

the cable screens. They are not connected to the system internal 0V supply. A clean

separate earth connection is normally required to the 0V supply on terminal T11.2, or

to one of the analogue 0V points on T2.8, T8.2, T9.2, T10.2 or T3.2.

The supply connection for the Operator’s Panel on terminal block T13 is brought out

on pin 6 (0V) and pin 9 (+5V) of the 9 way D socket for serial port B. This allows a

single cable to be used to connect to the Operator’s Panel instead of a split cable with

wire tails to a separate external supply connection.

Copyright © 2004 Quin Systems Limited

Page 17

Issue 2

5.9

SRV-2 Issue F Hardware Manual

CPLD Download

The connector P4, behind the port B socket, connects to the programming chain for the

Lattice M4a CPLDs which implement much of the unit’s ‘hard’ logic. Pinouts are:

P4

+5 volts supply : 1

TDO : 2

TDI : 3

/ENABLE :

(no pin): 5

TMS : 6

0 volts: 7

TCK : 8

PLD download uses Lattice VM or PRO software with Lattice download pod, and a

‘chain’ command file to specify the JEDEC files and their order.

Some small amount of JTAG testing is possible from this connector, not using the

processor. This can verify some signal routes and displays, and read back the PLD

identity codes.

Prior to issue F the logic chips were programmed off the board and this connector did

not exist.

Copyright © 2004 Quin Systems Limited

Page 18

Issue 2

6.

SRV-2 Issue F Hardware Manual

SRV2 Flashboot Sector

The flashboot functions of the SRV2 perform a brief self-test before starting the PTS

code. Issue E/F also have features to enable firmware upgrade and for mode change

(SERVOnet or standalone) from the Toolkit 2000.

6.1

Switch-on Self-Test

The processor performs memory self-test following switch-on. The LED numeric

displays show testing status:

•

The restart reason (Reset Register value) is shown, prefixed r.

•

Test phases, steps 000, 001, and 002 are shown

•

Any address test error is indicated with letter A and the first failing bit number.

•

Any data test error is indicated with letter d and the first failing bit number.

•

On successful test completion the message rdy shows until the PTS code

indications appear.

In the event of test failure, the message hlt may show.

Normal start of the code then gives the serial-port ‘Copyright’ message and channel

checks; then data restore and channel status display.

6.2

Entry to Flashboot Diagnostics

The entry to flashboot code makes use of Toolkit 2000. From standard terminal,

Firmware Upgrade and choice of Version 2.x use the ZP command to switch the PTS

to the flashboot, at the same time as the terminal changes to 38400 baud. Or if there is

no live PTS, the terminal anyway selects 38400 baud. From there, user selection of

Unlock will await a PTS response to the UNLOCK string, then act as a terminal in the

faster flashboot mode. The flashboot Help prompt is given:

Flash Boot Version 2.2 05/19/00

> h

boot

Restart the processor

erase <start> <num> Erase <num> sectors from <start>

module [S or A]

Set module to Standalone or Axis

program

Program Flash memory

verify

Verify Flash memory

>

Commands can be shortened to an initial letter, so ‘b’ and return will restart, or ‘m a’

and return sets a unit to be an axis module.

Copyright © 2004 Quin Systems Limited

Page 19

Issue 2

6.2.1

SRV-2 Issue F Hardware Manual

Update Commands

This card has two byte-wide flash chips, to give a 16-bit memory bus access. For erase

program or verify the sector or base address is defined as a hexadecimal number of

64kbyte blocks per flash chip; but the numeric part of the file name extension defines

the start number of 64kbytes in total for a file download. Thus to erase from or write

starting at address $20000, the user would select sector 1 but a file with extension .b2

when prompted in response to the Erase or Program command.

As far as possible the user can upgrade a unit or change mode without needing any deep

understanding. The erase function is normally automatic before programming, and the

user is given a file already named, so need not know the details of sector numbering.

For a basic unit upgrade of version using Toolkit, the following steps are needed:

•

Select ‘Tools’, ‘PTS Firmware upgrade’, and choose Flashboot V2.x

•

If the terminal was not already live, select ‘Unlock’ and switch on when

prompted.

•

Select ‘Program’ and choose a file, then click ‘Download’. The toolkit issues

the necessary commands for erase and programming.

•

When complete, as indicated by the bar, ‘Close’ the download box.

To exit now back to PTS code:

•

Type ‘m’ and return to verify you have the correct mode.

•

Select ‘Restart’ to run the new PTS firmware just loaded.

6.2.2

Exit to PTS code

This uses the b command from the menu. ‘Restart’ on the Toolkit window toolbar will

give the b command and change the terminal baud rate back to 9600.

Copyright © 2004 Quin Systems Limited

Page 20

Issue 2

SRV-2 Issue F Hardware Manual

Index

A

absolute encoder input

analogue inputs

analogue outputs

auxiliary output

flashboot

force RS-232 on port A

6

6

6

6

I

15

12

J

B

background debug connector

board layout

C

CANbus

connections

configuration

connections

background debug

CANbus

encoder

power supplies

screw terminals

serial port

connectors

CPLD download

7

15

9

15

15

15

14

16

14

13

18

D

demand output

digital inputs and outputs

download

firmware

PLD

drive enable relay

6

8

20

18

6

6

15

5

6

5

6

10

F

firmware

firmware upgrade

upgrade

Copyright © 2004 Quin Systems Ltd

J1 : processor options

J2 : reset and watchdog

J3 : interrupt configuration

J4 : SSI clock signals

J5 : eprom device select

J6 : ram device select

J7 : duart inputs/serial eeprom options

J8 : serial port A override

jumper locations

8

8

9

9

9

9

10

10

10

11

11

12

L

line driver

link encoder output

5

6

M

E

encoder

absolute

connections

input circuit

link encoder output

sense

SSI

eprom device select : J5

input isolation

input lines

interrupt configuration : J3

19

11

5

monitor output

motor off relay

6

6

O

output isolation

output lines

output relay

8

8

6

P

power supply connections

processor options : J1

14

9

R

ram device select : J6

relay contacts

reset and watchdog : J2

RS-232

RS-485

10

6

9

7

7

20

Page 21

Issue 2

SRV-2 Issue F Hardware Manual

S

screw terminal connections

self-test

serial eeprom options : J7

serial port A override : J8

serial port connections

serial port

signal names

software

spare duart inputs : J7

SSI clock signals : J4

SSI encoder

Copyright © 2004 Quin Systems Ltd

16

19

11

11

14

7

14

5

11

10

6

Page 22