d. Swivel-type pedestal 3.

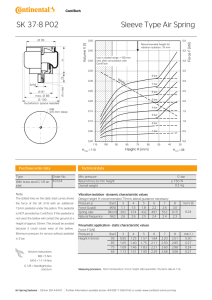

advertisement

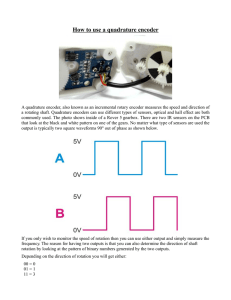

d. B. Swivel-type pedestal 3. Power Cabinet with Programmable Logic Controller (PLC) to control machine functions including safety interlocks (Siemens or equal). 4. Junction box for Hydraulic Power Unit, equipped with I/O hardware. 5. Linear Encoder to measure the position of the Machine Centers. 6. Rotary Encoder to measure the rotation of the Drive Rollers. Control Station Features 1. Touch screen shall utilize analog resistive technology, so it can be operated while wearing gloves. 2. Touch screen shall include virtual keyboard for manual entry of data including operator comments. 3. The angle of the pushbuttons on the Main Control Station shall be adjustable for ergonomic machine operation. 4. Absolute position feedback from the linear encoder shall eliminate the need to reference the position of the machine centers after cycling power to the machine. 5. Ethernet-based communications between the PLC, remote I/O, and the PC for connectivity and diagnostics. C. All push buttons, switches, and enclosures shall be NEMA 4 (IP 65) rated, and suitable for use in an environment with oils, coolants, and other non-corrosive liquids. D. The operator’s Control Station pedestal shall be capable of being rotated to a desired positon and locked into place. It is not necessary for the auxiliary Control Station to rotate. E. Operator-Machine Interface and Machine Control Requirements: 1. Computer specifications shall be Manufacturer’s standard offering (current at time of Bid) as to processor capacity and speed and hard drive capacity, with other requirements as follows: a. Rack-Mount Industrial Monitor and Touch Screen: i. Minimum 19” (diagonal measurement) ii. Thin-film transistor (TFT) active matrix liquid crystal iii. Native Resolution: SXGA (1280 x 1024 @ 60 Hz) iv. Contrast Ratio 1000:1 (static); 10,000,000:1 (dynamic) IFB NO. 016-002 WHEEL TRUING MACHINE TECHNICAL SPECIFICATIONS Page 33R of 56