Concentrating Solar Power Technologies.

advertisement

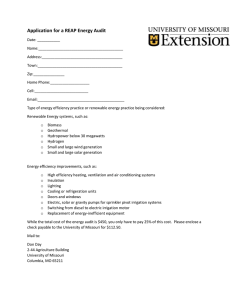

���� ������� ������� �� �������� � ��������� ������� ������� �� � ��� ���� ������ ���� ��������� ����� ����� � ��������� ������� ���� �������� ________________________________________________________________________________ �������������� ����� ����� ������������ � �� ��������� ���� � ������ ��������� ���� ����� �������� ����� ����� Concentrating Solar Power Technologies January 16, 2007 ICTP - Trieste presented by: Massimo Falchetta 2003-1 Overview of Presentation zBasics of CSP Technology zPerspectives of CSP Technologies zENEA R&D effort zENEA/ENEL demonstration plans ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Basics of CSP technologies CSP stands for “Concentrating Solar Power” A series of technologies that permit to convert sun’s energy to electric power by means of: ¾Concentration of solar irradiation by a series of mirrors or optical devices Î exploits only the “direct” part of irradiation ¾Production of high temperature heat, normally transferred to a Heat Transfer Fluid (air, diathermic oil, salt mixtures, steam …) ¾Generation of electricity by means of thermodynamic conversion ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Basics of CSP technologies Concentrating device Electric grid Electric Generator High temperature steam (400 –550 C°) Steam tubine ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Basics of CSP technologies Parabolic Trough Systems Source: solarpaces.org Source: CSP-GMI Initiative ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Basics of CSP technologies Central receiver or “Power Tower” systems Source: solarpaces.org Source: Sandia – Solar Two plant ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Basics of CSP technologies Paraboloic Dish systems Source: solarpaces.org Source: CESI - Eurodish ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Some more images Parabolic Troughs Source: Sandia – Kramer Junction ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Some more images Power Towers Source: Sandia – Solar Two ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Some more images Dish prototypes Source: Sandia - SunLab Source: Sandia ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Some more images Dish prototypes H2 production from natural gas. source: CSIRO (Australia) Source: web downloads ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Basics of CSP technologies CSP technology joins together three subsystems ¾ “Solar equipment” for high temperature heat production: similar to systems for process heat, but normally more demanding in terms of temperature (300 – 600 °C) ¾Heat transfer (and storage) equipment: similar to petrochemical plants ¾Conversion equipment: often similar to conventional fuel fired plants ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 CSP perspective CSP technology is technologically different with respect to photovoltaic thecnology (PV) z Similarities are found with respect to “concentrating PV” e.g. mirrors and solar tracking equipment; both exploit only the Direct component of the Solar Beam (Direct Normal Irradiation – DNI) zOther links exist in underlying technologies (e.g. materials for mirrors and selective coatings) ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 “Solar share” of CSP From the market point of view CSP technology and PV techology could be seen as “competitors”: but a deeper insight will show that: ¾PV plants are fit for a number of “diffused” industrial, residential and energy applications at most of the latitudes ¾ CSP plants are fit to high DNI (e.g. arid or “desert like”) situations for bulk electric energy production Therefore the two markets are not overlapping; a “solar alliance” can be more productive than a “solar competition” ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Comparison of CSP technologies Parabolic trough Tower Dish Process heat Grid connected H2 production Stand alone H2 production Max size (to date) 80 MWe 10 MWe 25 kWe Temp (proven) 400 °C 565 °C 700 °C Temp (target) 550 °C 1000 °C > 1000 °C El.efficiency 14-18 % 15-20% 30 % Status Commercially proven Prototype Experimental Applications Grid connected ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 LEC Assessment - CSP technologies Source: Sargent & Lundy Cost Assessment for NREL – NREL/SR-550-34440 ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 LEC targets - CSP technologies ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Proven Technolgy: SEGS plants SEGS: Solar Electric Generating System 9 plants at three locations (Daggett, Kramer Junction, Harper Lake), Mojave desert (CA) Individual unit size: 14 to 80 MWe Installed between 1984 and 1990 Total size: 354 Mwe Still operating: actual operator of units III to IX is FPL Energy; electricity customer is SCE ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Recent developments and launched projects zAPS Saguaro 1 MWe with oil filled parabolic trough and Organic Rankine Cycle (ORC) Temperature. 300 °C Developer: Solargenix (USA), customer Arizona Public Service Company (APS) completed april 2006 zNevada Solar One: 64 MWe parabolic trough, oil filled, 390 °C, steam rankine cycle Developer: Solargenix (USA). Construction started february 2006 zAndaSol: 2+2 50 MWe units, oil parabolic trough and molten salt storage Temp. 390 °C Location: Spain. Developer: SolarMillennium/ACS-Cobra (Germany/Spain) Construction of unit 1 started on June 19th 2006. ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Further Projects in Spain Spain is the most promising short term market for CSP Feed in law for solar – 2004: 18-20 €cent/kWh for CSP, 20 year 2010 Target: 500 MWe Iberdrola, Solucar, Solar Millennium have announced projects totalling over 1000 MWe Most projects are parabolic troughs; two projects are solar towers A number of projects will use molten salt Heat storage ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 CSP with Thermal storage Example of time shifting with 6 hour storage – source: U. Hermann, P. Nava Flagsol Trough Workshop in lake Tahoe, 2006 ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 CSP with Thermal storage Example of production with 12 hour storage – source: U. Hermann, P. Nava Flagsol Trough Workshop in lake Tahoe, 2006 ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Molten salt Heat storage for CSP Introduced at first in the 10 MWe “Solar Two” Power Tower (1996-1999). Advantages: Temperatures up to 565 °C Low cost energy storage Challenge Need of a additional Heat trace system for circuit priming and maintenance due to high melting temperature of the salt ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Molten salts vs. diathermic oil source: D. W. Kearney, ENEA-SunLab Workshop - 2006 ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Molten salts vs. diathermic oil – cost of storage source: D. W. Kearney, ENEA-SunLab Workshop - 2006 ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Integrated solar-combined cycle source: Solar Thermal Power Now – ESTIA/greenpeace ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Long term development of a EUMENA “Renewable network” Solar Hydro Wind Geothermal Source: DLR ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Long term development: Trans-CSP study Focus: Interconnection of electricity grids of Europe, Middle East, North Africa (EUMENA) region Scenario zCSP to supply firm capacity for base, intermediate and peak load in MENA zCSP to supply 700 TWh/year to Europe (15% of european electricity demand at 2050 zTransmission losses evaluated as 15% using HVDC lines; overcompensated by the high solar irradiance in MENA (300% than average Europe) Possible path of HVDC lines for massive export of CSP power to Europe. Source: Trans-CSP study - DLR ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Long term development: Trans-CSP study Source: Trans-CSP study - DLR ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Long term development: Trans-CSP study Possible path of HVDC lines for massive export of CSP power to Europe. Source: Trans-CSP study - DLR ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 ENEA R&D effort on High Temperature Solar In 2001 ENEA launched a programme on High Temperature solar thermal technology with two main goals: 1. Heat collection and storage for electricity production, using medium temperature (about 550°C) – CSP technology 2. Heat collection for direct hydrogen production, using high temperature (higher than 850°C). o 75 researchers are involved in this program o the R&D budget until now has been 17 Ml €. ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 ENEA development effort on CSP R&D on components and new concepts for CSP Experimental set-up for prototype evaluation Demonstration plant (Archimede) ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Financing of CSP development The following laws allow 100 % funding for the R&D and 40 % for the demonstration. ¾ Law 388/2000 ¾ Law 273/2002 ¾ DPCM 7 marzo 2003 The residual 60 % for demonstration will be supplied by the national electric utilitiy ENEL. 20.658 k€ 27.500 k€ R&D Archimede Power Plant 40% ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 R&D activities ENEA design introduces major improvements to the current technology: • Molten salt (KNO3 – NaNO3 “solar salt”) as Heat Transfer Fluid and for Heat storage • A new solar collector design • An innovative receiving tube design Solar collector Heat transfer fluid Heat storage Receiving tube 550°C Hot fluid Storage tanks 290°C Cold fluid Steam generator Power block ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 R&D activities The use of molten salt as Heat Transfer Fluid AND as heat storage medium permits the following advantages: •Higher steam temperature (540 °C instead of 390 °C) •No oil to salt heat exchanger •Much lower storage cost (half volume for the same size). Challenge: the entire network of pipes is filled with molten salt ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 New supporting structure ENEA Eurotrough USA-Kramer Junction ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 New Tracking system Hydraulic system Piston Contractor: Duplomatic ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 New receiver tube New coating New bellow COMPENSATION BELLOW 1 2 3 1. Steel pipe with spectrally selective coating 2. External glass pipe wit anti-reflective treatment 3. Absorbing material (getter) for void maintenance Metal-glass junction Involved enterprises: ITIV (MI), STEROGLASS (PG), CERAMIC LAYER STEEL PIPE Metallic layer ANGELANTONI (PG), POLO (FI), SAES GETTER (MI), NUOVA STEIM (TR), COMVAT (Switzerland) Components and assembly CETEV (AQ), Galileo Avionica (AQ), G.EMI. (RM), TFE (MI), CTS (TR) Selective coating ENEA “CERMET” SELECTIVE COATING: 1. High absorptance of solar spectrum (α > 94 %) 2. Low emittance in the infrared spectrum at high operating temperature (εmax < 14 % @ 580 °C ) Budget: 2,80 M€ ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 New receiver tube Designed for 550°C operating temperature Bellows Lab tests ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Sputtering machine for coating of receiver tube Contractor: Angelantoni Installed October 2005 - Commissioning December 2005 - Full operation March 2006 Budget: 3,54 M€ ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Solar Collector Assembly Test Loop (PCS) Involved enterprises : ALSTOM Power (MI), GECOP (RM) Construction Krohne Italia (MI), Friatec (Germania) Thermo Engineering (CR), Parcol (MI) Inox Impianti (MI), Eurochemicals (MI), Pompe Gabbioneta (MI) TECNOCOOP (PO), Nuova STEIM (TR) Components Maintenance Budget: 5,43 M€ Italian experience using molten salt in parabolic trough ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 ENEA-ENEL Archimede solar power plant A traditional oil electric generation plant was recently converted into a modern gas fired combined cycle plant at Priolo - Sicily Nominal electric power 760 MWe ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 “Archimede” project The plant is located nearby Siracusa, one of the most insolated Sicilians areas: 1725 kWh/m2 year of DNI kWh/m2 1750 1350 ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 “Archimede” project Integration between: Combined cycle Solar system ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Archimede solar project: first module Solar field Budget is 21 M€ Measured DNI is 1725 kWh/m2 year Equivalent capacity: 5 MWe Expected production: 10,8 GWhe Energy saving: 2.365 TEP/year Avoided CO2 emission : 7250 t/year Number of collectors: 72 Combined cycle ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 Archimede solar project: final stage Number of collectors: 318 Solar field area: 37.6 ha Equivalent Capacity: 28 MWe Peak Solar Thermal Power: 136 MW Thermal storage: 500 MWh Net yearly production: 54.2 Gwhe Net design total efficiency: 17.3% Primary energy saving: 11,835 tep/y Avoided CO2 emissions: 36,306 t/y ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 ITALIAN SOLAR ROADMAP Start-up Archimede power plant 2010 2009 Design and construction Archimede power plant 2008 2007 Agreement with ENEL (Italian electricity utilities) 2006 Experimental phase new components 2005 2004 Building test facility and main components 2002 Start-up of the project Start-up of the test facility (PCS) 2003 Design components and test facility (PCS) 2001 ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 2020 prospects Desert location (DNI = 2,900 kWh/m2 year), for each square km Plant with molten salt HTF and storage Peak capacity 75 MWe (*) Electric energy production 275 GWh/(km2 year) Equivalent hours 3660 Primary energy saved 60.000 t/(km2 year) Avoided CO2 emision 184.250 t/(km2 year) (*) Low specific peak capacity due to the presence of storage. ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 2020 prospects Desert location (DNI = 2,900 kWh/m2 year) target - for 100 MWe unit LEC evaluation – 2020 target Specific Investment cost: 1600 €/kWe Operative life: 25 years Interest rate: 7% Yearly O&M: 2% of investment cost LEC: 4,5 € cent/kWh (*) (*) This numbere is in agreement with data calculated in Assessment of Parabolic Trough and Power Tower Solar Technology Cost and Performance Forecast - Sargent&Lundy LLC Consulting Group per NREL - NREL/SR-55034440 - Oct. 2003 - staing a LEC in the range of 4.3 US cent/kWh(SunLab estimate) to 6.2 US cent/kWh (S&L estimate) ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007 CSP on the web For a deeper insight a nuber of docìuements can be retrieved from the following sites: www.solarpaces.org www.nrel.gov www.dlr.de/tt/trans-csp www.dlr.de/tt/med-csp http://www.enea.it/com/ingl/solarframe.htm http://www.enea.it/com/solar/doc/csp.pdf ICTP Experts meeting on “Science & Renewable Energy” – Jan 16 2007