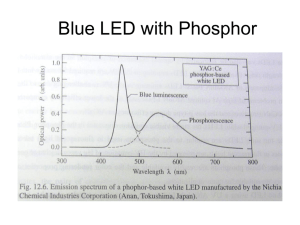

Solid-state lighting—a benevolent technology - ECSE

advertisement