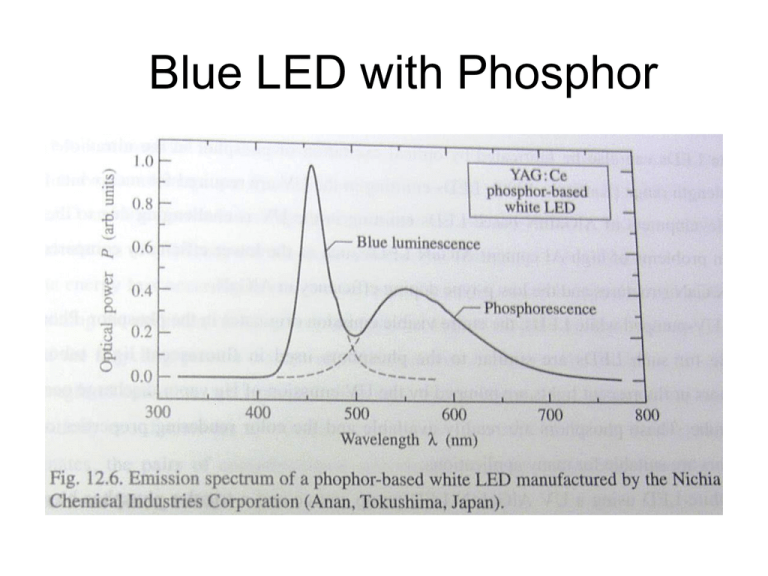

Blue LED with Phosphor

advertisement

Blue LED with Phosphor Illustration • A blue GaInN/GaN LED and a phosphor wavelength converter suspended in a epoxy resin make a white Light LED. • The thickness of the phosphor containing epoxy and the concentration of the phosphor determine the relative strengths of the two emission bands. 超高亮度半导体发光二极管(UHBLED)可定 义为其光通量大于250流明,高亮度发光二 极管(HBLED)可定义为其光通量大于50流明 而小于250流明,一般的LED可定义为其光通 量小于50流明;其光发射涉及粒子在多量子 阱能级间的跃迁,电子和空穴的复合,爱因 斯坦吸收、发射系数,内量子效率和外量 子效率的计算,提高量子效率的折射率匹 配方法,光频率转换和耦合的色图计算,和 智能控制及实际应用。 Blue LED Why is GaN? Blue LED 蓝光LED(1997) • 中村修二(Shuji Nakamura ,1954-)发明了第一个高强度的氮化镓 LED(LED是light emitting diode 的缩写),目前已大量生产。 • 当LED的蓝光部分地由荧光粉转化成黄光,蓝光黄光综合的效果成了 白光LED 的关键技术。他还发明了蓝光激光器。他得到了2006年 Millennium奖。 • 奖词说:“他是坚持和献身于研究工作并作出了重要突破的光辉榜样。 他带了极大的决心工作了几十年,即使试验重的挫折都未能阻止它达 到目的该领域的其他人认为它几乎是不可能的:用他自己的反应器系 统来开发固体材料,在他的氮化镓方案中,终于得到了产生蓝,绿和 白光的强大光源,也创造了蓝光激光器。” • 中村说:“为了持续我们民族的科学进步,我认为,要紧的是不仅是 科学专业的,而且要对所有的人进行更好的科学教育。” 1997年1月, 中村修二,史蒂芬P.DenBaars和詹姆斯S斯佩克在加州大学圣巴巴拉 分校宣布了氮化镓(氮化镓)激光器的开发,发射亮蓝紫外光脉冲光。 中村发明的蓝光激光器(BLD)和蓝光LED对节能环保的固态照明的 贡献是很大的。 不同环境下的照度 Efficacy Requirement US Department of Energy's stiff future targets, which include the goal of 150 lm/W at 2 A by 2012. According to him, hitting this milestone will require a hike in internal efficiency to 90%. Evolution of LED Electrical World ,1907 19 309 1928 Philosophical Magazine 6 1024 1951 Physical Review 83 603 White-light LEDs by using a blue GaInN chip to pump a wavelength-converting phosphor. Materials The performance of UCSB's LEDs have rocketed, thanks to improvements in the quality of m-plane material. UCSB's latest LEDs have a wider multiple-quantum-well (MQW) region than conventional c-plane devices, which boosts their efficiency. Non-polar LEDs show less of a decline in efficiency at higher drive currents than their conventional cousins. To compare the performance of this design with that featuring cladding layers, we have produced three different broad-area layers with growth conditions similar to those used for c-plane LEDs. Removing the AlGaN cladding layers from the laser has cut the threshold-current density by a factor of three and reduced the emitter's threshold voltage. Thermal management The luminous flux figures cited by LED manufacturers assume an LED junction temperature (Tj) of 25°C. LEDs are tested during manufacturing under conditions that differ from actual operation in a fixture or system. In general, luminous flux is measured under instantaneous operation (perhaps a 20 millisecond pulse) in open air. Tj will always be higher when operated under constant current in a fixture or system. Well-designed systems with adequate heat sinking will maintain Tj well below the manufacturer's rated maximum temperature (typically 125°C). Comparing LEDs to Traditional Light Sources Power Conversion for White Light Sources Light Output vs Junction Temperature Thermal Conductivities of Substrates What Determines Junction Temperature HBWLED at Different Operation Temperatures Light Output vs Junction Temperature Lumen Depreciation Comparison to Traditional Light Sources