A New Multilevel Topology For Induction Motor Drive

advertisement

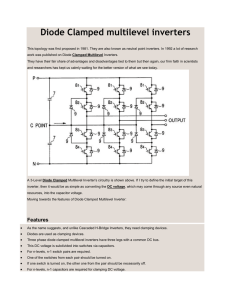

International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 2, Issue 12, December 2012) A New Multilevel Topology For Induction Motor Drive k.Srinivas1, k. Ramesh babu2, CH. Rambabu3 1,2,3 Department of Electrical and Electronics Engineering, Sri Vasavi Engineering College, Tadepalligudem (A.P), India They generate smaller Common Mode (CM) voltage, thus reducing the stress in the motor bearings in addition using ophisticated modulation methods CM voltages can be eliminated. They can operate with a lower switching frequency. Three different topologies have been proposed for multilevel inverters: Diode Clamped (Neutral Clamped), Flying Capacitor and Cascaded Multi cell separate dc sources, in addition several modulation and control strategies have been adopted for multilevel inverters [1] In the higher levels large number of components are require such as Clamping diodes (for NPC), Clamping capacitors (for FC ), number of DC sources (for cascaded H-Bridge) and Complicated PWM strategies. But in this paper proposed topology require fewer components, free from voltage imbalancing problems and reduced complexity when compared to other topologies.[2] Abstract— Use of multilevel inverters has become popular in recent years for high power applications and an effective and practical solution for increasing power and reducing harmonics of AC waveforms. By synthesizing the AC output voltage from several levels of DC voltages, stair case output waveform can be produced. This allows for high output voltage and simultaneously lowers the stress on the semiconductor device, complexity of control and introduce voltage unbalancing problems. In this paper the proposed topology requires less number of switches, free from voltage imbalancing problems and reduced complexity when compared to other topology of available multilevel inverters Neutral Point Clamped and Flying Capacitor. This topology shown the requirement of components and compared to other topologies to show the superiority. The simulation results of proposed topology three phase five-level and seven-level multilevel inverter fed induction motor drive are verified using MATLAB. The THD between five-level and sevenlevel inverter is compared it can be observed that in the higher levels THD is reduced. II. NEW MULTILEVEL TOPOLOGY Keywords— Multilevel inverter, new multilevel topology, spwm In ordinary multilevel inverters specified switching devices are used to generate multilevel positive and negative half cycles or multilevel sinusoidal wave form. In this paper as shown in the block diagram of fig.1 the proposed topology generate multilevel positive half cycle only, no need to generate negative half cycle. The positive half cycle can be converted in to negative half cycle by means of full bridge converter. So in the proposed topology the requirement of switching devices are reduced to generate multilevel sinusoidal wave form.[3],[4]. I. INTRODUCTION In recent years, industry has begun to demand higher power equipment, which now reaches as the megawatt level. Controlled Ac drives in the megawatt range are usually connected to the medium voltage grids (2.3, 3.3, 4.16, or 6.9kv). For these reasons, a new family of multilevel inverters has emerged as the solution for working with higher voltage levels [1]. In a medium voltage and high power applications two level inverter have some limitations in operating at high frequency mainly due to switching loses and constraints of devices voltage\ power ratings [6] For a medium voltage grid it is troublesome to connect only one power semiconductor switches directly. As a result, multilevel power converter structure has been introduced as an alternative in high power and medium voltage situations [7, 8, and 9]. The most attractive features of multilevel inverters are as follows. They can generate output voltage with extremely low distortion. They draw input current with very low distortion. DC Power supply Positive level generator Full Bridge Converter PWM controller Fig.1 Block diagram of New Multilevel Topology 323 Load International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 2, Issue 12, December 2012) Operation of three phases Five-level multilevel inverter using New Multilevel Topology for induction motor drive: Operation of new topology can be explained with the help of fig.2 and Table.1. By proper switching combinations of the switches S1 to S4 the positive half cycle can be generated. Switches SH1 and SH2 are complementary in full bridge converter, similarly SH2 and SH3 are also complementary. When SH1 and SH2 are switched on together positive half cycle can be obtained to the load. When SH3 and SH8 switched on together positive half cycle to be converted in to negative half cycle to the load. This topology requires half of the fundamental output whereas output for negative half cycle is automatically generated by switching of full bridge converter. The proper switching combination of switches S1 to S6 as shown in Table.2 the positive half cycle can be generated. This positive half cycle can be converted in to negative half cycle by means of full bridge converter circuit. In seven level inverter modified full bridge converter circuit is used to reduce the switching devices requirement. Generally in fig.2 full bridge converter need 12 switches to generate positive or negative half cycle. In seven level inverter circuit of fig.3 modified full bridge converter need only 10 switches to generate positive and negative half cycle to the load. When compared to other available topologies of multilevel inverters as shown in Table.3 this new topology require less device count. Fig.2 Simulink diagram of Five-level multilevel inverter for Induction motor drive TABLE1 Switching states for five level inverter Fig.3 Simulink diagram of Seven-level multilevel inverter for Induction motor drive Output voltage S1 S2 S3 S4 0 0 1 1 0 Vdc 0 1 0 1 2Vdc 1 0 0 1 TABLE.2 Switching states for Seven-level inverter Operation of three phases Seven-level multilevel inverter using New Multilevel Topology for induction motor drive: The new topology of seven level inverter is shown in Fig.3. 324 Output voltage S1 S2 S3 S4 S5 S6 0 0 1 1 0 0 0 Vdc 0 1 0 1 0 0 2Vdc 1 0 0 0 1 0 3Vdc 1 0 0 0 0 1 International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 2, Issue 12, December 2012) TABLE.3 Number of components for three phase inverter Inverter Type NPC Flying capacitor Cascaded H-bridge New topology Main switches 6(N-1) 6(N-1) 6(N-1) 3((N-1)+2) Main diodes 6(N-1) 6(N-1) 6(N-1) 3((N-1)+2) Clamping diodes 3(N1)(N-2) 0 0 0 DC bus capacitors 3(N-1) 3(N-1) 3(N-1)/2 (N-1)/2 Flying capacitors 0 3(N-1)(N2) 0 0 Total numbers 3(N2+2N3) 3/2((N-1) 27/2(N-1) (13N+33)/2 The five-level Phase voltage is shown in fig.6 (b). The fig.6(c), (d), (e) are the Induction motor RYB currents in Amperes, speed in R.P.M and Electromagnetic Torque in Newton meter respectively. Line current (A) Fig.5 (a) Phase voltage (V) Fig.5 (b) (N+8)) IRYB (A) III. SIMULATION RESULTS In the proposed topology, in the carrier based implementation, the phase disposition PWM scheme is used. In phase disposition technique the carrier wave form are in phase with reference wave form. The proposed topology will require (N-1)/2 carriers only and are just positive as shown in fig.4. Fig.5 (c) Speed (R.P.M) Fig.5 (d) Electromagnetic Torque Te (N*m) Fig.4: Phase disposition PWM The performance of three phase induction motor fivelevel inverter is shown in fig.5. The Line current is shown in fig.5 (a). The five-level Phase voltage is shown in fig.5 (b). The fig.5(c), (d), (e) are the Induction motor RYB currents in Amperes, speed in R.P.M and Electromagnetic Torque in Newton meter respectively. Similarly the performance of three phase induction motor seven level inverter is shown in fig.6 The Line current is shown in fig.6 (a). Fig.5 (e) Fig.5 Simulation Results for Three-phase 5- level inverter induction motor load 325 International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 2, Issue 12, December 2012) TABLE 4: Modulation Index Vs THD of five-level and seven-level inverters Line current (A) Modulation Index THD of five-level THD of sevenlevel 1.0 12.48 8.94 0.9 17.32 16.84 0.8 24.41 22.26 0.7 26.28 19.49 0.6 18.72 17.24 0.5 20.10 16.47 0.4 34.37 25.36 0.3 36.21 26.42 0.2 37.84 27.92 Fig.6 (a) Phase voltage (V) Fig.6 (b) IRYB (A Fig.6 (c) Speed (R.P.M) Fig.6 (d) Electromagnetic Torque Te (N*m) Fig.7 THD Vs MI of five and seven-level inverter Fig.6 (e) V. CONCLUSION Fig.6 Simulation Results for Three-phase 7- level inverter induction motor load In this paper, a new multilevel topology in five-level and seven-level inverter fed induction motor drive is implemented. In seven-level inverter circuit modified full bridge converter is used for reducing the switching devices and higher reliability. Here SPWM controller has less complexity when compared to other topologies. The THD is compared of five-level and seven-level inverters. IV. THD COMPARISION The comparison between the THD of both three phase five-level and seven-level inverter with respect to Modulation index is shown in fig.7. It can be observed that in the higher levels the THD of the multilevel inverter is reduced. 326 International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 2, Issue 12, December 2012) Authors‘ Profile It can be observed that in the higher levels THD is reduced. The simulation results of proposed topology of three phase five level and seven level inverter fed induction motor drive are verified using MATLAB Mr. k. srinivas received the Bachelor of Technology degree in Electrical & Electronics Engineering from JNTU Kakinada in 2008. Currently he is pursuing master in technology in Sri Vasavi Engineering College, Tadepalligudem, A.P. His areas of interests are in Power Systems, Power Electronics REFERENCES [1 ] J.Rodriguez, J.-S Lai and F . Z Peng , ‗‘Multilevel inverters : a survey of topologies, controls, and applicatiosn,‘‘ IEEE Trans. Ind . Electron., vol .49, pp.724-738, 2002. [2 ] J.S Lai and F. Z. Peng, ‗‘Multilevel level converters –A new breed of power converters ,‘‘ IEEE Trans . Ind . Applicat., vol . 32 , pp .1098-1107, May/June 1996. [3 ] E.Najafi, A.H.M.Yatim and A.S. Samosir. ―A new topologyreversing voltage (RV) for multi-level inverters.‖ 2nd International conference on power and energy (PECon 08),pp 604-608, December 2008 Malaysia [4 ] Hemant joshi, P.N Tekweni and Amar Hinduja. ‖Multilevel inverter for induction motor drive : using reversing voltage topology‖ 978-14244-7398@2010 IEEE [5 ] Performance evaluation of inverted sine PWM Technique for an Asymmetric cascaded multilevel inverter. © 2005 - 2009 JATIT [6 ] Jose Rodriguez, Leopoldo G. Frequelo, Samir Kouro, Jose I. Leon, Ramon C. Portillo, Ma Angeles Martin Prats and Marcelo Perez.―Multilevel Converters: An Enabling Technology for Highpower Applications‖ IEEE Proceedings, vol. 97, no. 11, pp17861817, Nov2009. [7 ] J.S Lai and F. Z. Peng, ‗‘Multilevel level converters –A new breed of power converters ,‘‘ IEEE Trans . Ind . Applicat., vol . 32 , pp .1098-1107, May/June 1996. [8 ] J.Rodriguez, J.-S Lai and F . Z Peng , ‗‘Multilevel inverters : a survey of topologies, controls, and applicatiosn,‘‘ IEEE Trans. Ind . Electron., vol .49, pp.724-738, 2002. [9 ] L. M. Tolbet, F. Z . Peng, and T. G Habetler, ‗‘Multilevel converters for large electric drives, ‗‘ IEE Trans. Ind . Applicat., vol, 35, 36-44, 1999. Mr. K. Ramesh Babu received the Bachelor of Technology degree in Electrical & Electronics Engineering from JNTU in 2007 and Master‘s degree from JNTU Hyderabad in 2010. Currently, working as an Assistant Professor in Sri Vasavi Engineering College, Tadepalligudem, A.P. His areas of interests are in power systems, Power electronic control of drives. Mr. Ch. Rambabu received the Bachelor of Engineering degree in Electrical &Electronics Engineering from Madras University, in 2000 and Master‘s degree from JNTU Anantapur in 2005.He is a research student of JNTU Kakinada. Currently, he is an Associate Professor at Sri Vasavi Engineering College. His interests are in power system control, Power Electronics and FACTS 327