GMOOR v9.41 - Site moved to

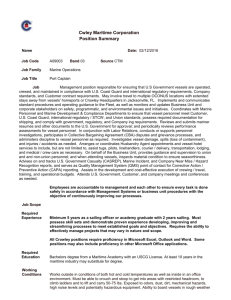

advertisement