Lemur Manual - Boca Systems

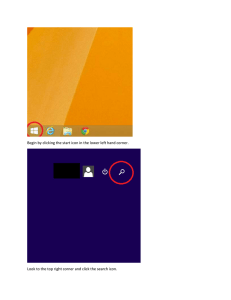

advertisement