Bridges 2 Confernce Paper - Rama VIII- James Lee

advertisement

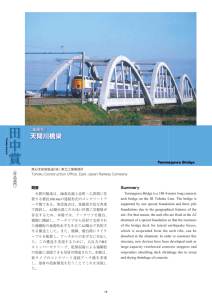

-1 unfactored dead load = 186 kNm the Proceedings of Bridge Engineering 2 Conference 2009 April 2009, University of Bath, Bath, UK A CRITICAL ANALYSIS OF THE RAMA VIII BRIDGE, BANGKOK J.S. Lee1 1 Undergraduate Student – Civil Engineering, University of Bath Abstract: This paper presents a critical assessment of the Rama VIII Bridge, crossing the Chao Phraya River in Bangkok. Included are sections relating to bridge aesthetics, structural design, and construction. Various design load models are also formulated using the British Standard (BS) relating to bridge design (BS 5400). These are used to analyse the structural performance of the bridge in regards to BS specified limit state design. Keywords: Rama VIII, Asymmetric, Cable-Stayed, Inverted-Y Pylon, BS 5400 1 General Information Bangkok is said to have an official population of 8 million, however due to unregistered migrant influxes’ it is estimated at 15 million. This places a huge demand on public infrastructure and congestion is rife. The Chao Phraya River runs through central Bangkok separating east from west. 4 bridges existed over the river but this was not enough causing some of the cities worst congested areas. The Bangkok Metropolitan Association (BMA) commissioned a 5th bridge at what was believed to be the worst traffic bottleneck as a measure of relief. This would become the Rama VIII Bridge, named after the brother of the current King of Thailand. Feasibility studies started in 1995 but economic reasons shelved the project until 1998. Construction started in 1999 and the bridge opened in 2002. Design criteria set by the BMA required the bridge to be cable-stayed but with only 1 tower so not to overshadow historically important structures on the eastern bank (The Bank of Thailand and a Palace). Rama VIII is a 475m long, asymmetric cable-stayed bridge, supported by a 160m tall, inverted-Y pylon. The bridge has a 300m main span and three land spans; two 50m back spans and one 75m anchor span (as seen in Fig. 1). Rama VIII provides a low level river crossing with a 10.4m vertical clearance. Two planes of stays support either side of the main span, whilst one centrally arranged plane is used to anchor the pylon. The bridge is designed for both vehicular and pedestrian traffic, with the main span having two traffic lanes and a 5.3m sidewalk in each direction [1].1 2 Aesthetics During the 20th century Engineer Fritz Leonhardt proposed 10 rules, each relating to an area of bridge aesthetics that he believed needed fulfilling to create visually appealing bridges. Obviously design is subjective and obeying these rules doesn’t ensure beautiful bridges, but does give a good platform on which to base an objective analysis. 1 James S. Lee – jsl21@bath.ac.uk 50m P45 P42 Anchor Span =75m 50m 20m 27@10m =270m Tower Height =161m P41 Back Spans =100m P39 Main Span =300m Figure 1: Elevation Showing General Arrangement [1] Figure 2: Rama VIII at Night [1] It is generally accepted that the most important aspect of bridge aesthetics is fulfillment of function. If this is done simply and efficiently a designer can show how a bridge works and impart a sense of stability on the user, creating a positive first impression. For cable stayed bridges apparent structural simplicity is easily portrayed, through easy to see load paths (i.e. deck supported by the pylon through the stays). There is often a danger of bridges with poor aesthetics being built as they tend to be primarily designed in elevation. The view when travelling across a bridge is that which is most commonly seen so it is essential that thought is put into this view. On Rama VIII the stays regularly span from either side of the main deck converging upwards towards the leg of the Y pylon. Doing this has helped impart a sense of stability by creating a closed triangular shape which is inherently stronger than if the stays were separated and the section open. Asymmetric cable-stayed bridges have to avoid looking like they may overturn due to a heavy looking main span. On Rama VIII carefully chosen proportions have avoided this. The size and amount of stays anchoring the pylon looks sufficient to be able to provide restraint. Also the main span deck has been kept particularly slender. The use of a thin light fascia edge beam helps this effect. The proportions of the slender deck do not look out of place as the amount of stays creates deck spans that don’t appear to have an excessive length. The sleek and slender deck has also allowed the pylon to be kept slender. Even though the pylon looks slender a good structural hierarchy has been implemented causing it to appear much stiffer and heavier than that it is supporting. As previously mentioned a thin fascia edge beam with a darker fascia below helps the deck to look lightweight. The stays have been painted gold differentiating them from the deck and pylon plus have been given a smooth finish aiding the slender appearance. The change of material at the pylon to concrete with a matte finish accentuates its strength, stiffness and ability to fulfill its function. Other areas of the design have been refined to try and improve the aesthetic qualities of the bridge. The tower has a tapered cross section refining it in a way popular with the ancient Greeks. This stops it from looking top heavy. At the base of the Y’s legs there is a concrete detail designed to look like an Elephant’s foot. I like this detail as it adds interest to the structure whilst adding a sense of resistance from overturning at the base of the slender tower. This detail draws inspiration from nature satisfying several of Leonhardt’s criteria at once. The detail also reflects Thai culture which was particularly important to the designers as previous structures have not been well received for having a too ‘clean European’ design. Figure 4: Elephant Foot Detail Figure 3: Bridge shows Good Structural Hierarchy [1] A distinct amount of effort has been placed into keeping a good sense of order within Rama VIII. This reduces the amount of any unnecessary lines and edges keeping the structure as simple as possible. Elegant clean structural lines run throughout the bridge keeping its order. The design has been refined so that the fascia is carried uninterrupted from the west anchorage to the east side of the river, minimizing optical discomfort. This is done by hiding necessary but protruding items such as corbels and stay anchorages with the tower or bridge deck as required. With cable stayed bridges it can be easy to break order often unknowingly. As mentioned bridges are primarily designed in elevation, but when viewed from oblique angles cables can appear to cross destroying the order of a bridge. This can be prevented to a certain extent and methods of doing this have been adopted. Firstly the stays supporting the main span are arranged in a semi-fan configuration. This is a less structurally efficient system than the optimum fan arrangement, but the aesthetic benefits, particularly with respect to order justify this. The design refinement of having an inverted-Y tower where the pairs of stays converge and meet at single point also helps with views from oblique angles. On the anchor span there is only one plane of cables so this problem is avoided. Refinement has also been attempted through the addition of the audacious Lotus inspired observation tower and ornamental access piers (as seen in Fig. 3). These items may help the bridge to be received locally, but it is my opinion that they are a bit garish. I also believe the bridge to be poorly integrated into its environment. Cable-stayed bridges look good over wide spans of water so the aesthetics are added to with this, but the tall, linear concrete pylon looks completely out of place compared with its small surroundings. One tower may have been required so not to overwhelm important buildings on the east side of the river but resulted in creating a massive structure on the west. Colour has been used within the structure to make it seem more ‘jewel-like’. This has been done by painting the stays gold and adding several gilded elements to the tower (bands around the legs and the vertical stripe on the Y). This can be seen especially well at night when careful lighting upwards from the bridge deck is reflected of the gold elements, creating what I believe to be the best view of the bridge. Finally Leonhardt said bridges have to have both the closely linked properties of character and complexity. These are somewhat achieved by having the stays arranged in a double plane on the main span and in a single plane on the anchor span. This creates a particularly interesting effect when crossing the bridge and makes the user think about why this change may be occurring. Character is a hard quality to define. I believe that this bridge has it but I am unsure why. Possibly it is due to the somewhat overpowering tower however badly integrated it may be. The tower stands alone not being rivaled in size or stature by anything around (see Fig. 2). A true test of character is how the building is received by the general public. Local Appreciation has been high with the bridge becoming a notable tourist attraction and even being featured on a banknote. 3 Structural Description 3.1 Structural Strategy As is the case with asymmetric bridges, Rama VIII has a long main span which acts as if to overturn the pylon, developing bending moments within. Traditional symmetrical cable-stayed bridges have spans of a similar weight creating a balance and reduction of bending in the pylons. As Rama VIII doesn’t have this, moments need to be reduced in another way. Below is a description of the structural strategy implemented in the Rama VIII Bridge. This is by no means comprehensive but does give an idea of the force transfer involved. The main span (and loads upon it) is supported by stays, with a regularly spacing of 10m. Load is carried via tension in the stays to the pylon. This direct load path is an advantage for cable-stay bridges (over suspension) greatly stiffening up the structure. The stays are in a semi-fan layout on the main span causing both a horizontal and vertical force to act upon the pylon. The vertical force places the pylon in compression. Closely spaced main span stays reduce bending in the deck allowing it to be kept light and slender. This adds flexibility to the structure which is needed to cope with seismic loading that may occur. Tension in the stays also places horizontal compression within the bridge deck, increasing with each stay towards the pylon. The deck is designed carry both bending and axial force. The bridge is less structurally efficient than if a complete fan system were used. Fan systems locate all of the stays at one maximum eccentricity, meaning greater cable inclinations and smaller horizontal components of force acting on the pylon and in the deck. This reduced deck compression then allows smaller/lighter decks to be used, in turn reducing the size of the stays needed. As mentioned the stays place horizontal, longitudinal loading upon the pylon. Fully anchored backstays appose this force. The stays are the main stabilizing element of this structure. The backstays are tensioned so that under deadweight bending moments within the pylon are reduced as much as possible. Imposed loading placed upon the main span is resisted by tensile forces in the backstays, keeping pylon bending to a minimum. Torsion produced by unsymmetrical loading on slender decks is a possible problem. The inverted-Y pylon allows the stays to meet, increasing the bridges structural performance. With cables spanning down to either side of the main span a closed section is created, increasing the torsional stiffness of the bridge. 3.2 Pylon Design Features The pylon is the primary load bearing element of any cable-stayed bridge, carrying compression applied by vertical force from the stays. Rama VIII’s pylon is built of reinforced concrete with sections of posttensioning. The use of concrete was a specified design criterion for aesthetics but provides structural benefits. The pylon has a rectangular cross section throughout of sufficient size to provide the required stiffness along the length of the tall tower. Longitudinally the pylon has a constant width of 7m. Along the upper section of the pylon the transverse width tapers from 5 to 7.5m. This increase is necessary to cope with high transverse bending demands at the interface with the legs. The legs also taper with a width of 5.4m at the interface down to 4m at the base. This reduction in width minimizes the amount of bending attracted to the base of the legs [2]. The tower legs are not tied together by the deck causing thrust at the base. This is resolved by an 8m wide, 1m deep beam between under each leg. Two diaphragms are in place at the upper section/leg interface. These tie the structure together aiding the transfer of lateral force. This adds a great deal of rigidity to the pylon and is especially important in the ability of the pylon to resist wind/seismic loading. Usually stays are anchored into the side of a pylon facing the span in which they are placed, requiring tie elements to transfer tension across the structure. In Rama VIII the upper 14 of the 28 sets of stays are all anchored into the main span wall. This is structurally efficient as it allows forces to directly oppose each other. Some bending is generated in the main span wall but small amounts of post-tensioning can solve this [1]. Corbels are cast into the tower to support bearing loads from the deck. Horizontal and vertical potbearings are placed here. The horizontal bearings allow longitudinal movement which is important for affects such as those due to temperature. The vertical bearings carry transverse seismic/wind forces out of the flexible deck into the much stiffer pylon [2]. 3.3 Deck Design Features Figure 5: Force Distribution within the Bridge Transverse loading upon the bridge from actions such as wind are resisted solely by bending of the pylon about its transverse axis. Usually backstays are anchored into the ground. A different approach was taken on Rama VIII as they are anchored into the ‘anchor span’. This is a purposely heavy section of deck to stop uplift from the stays. In turn uplift from the stays is used to support the deck. Three different types of deck are used throughout the structure, however the deck has still been design as one continuous structural element. The main span is a steel-concrete composite deck, used for a reduction in selfweight. The deck is 29.2m wide accommodating two lanes of traffic and a sidewalk in each direction. Two primary steel girders, 1.6m deep, run longitudinally along the main span. 1.3m deep floorbeams span between these at 5m centres creating a steel grid [1]. Precast concrete panels (250mm deep) span between the floor beams. The benefit to using precast panels is the ease of installation and assured build quality. Composite action is achieved through cast-in-place infill strips connecting shear studs (welded to the girder) to the slabs via its reinforcement. The integration of composite action has a positive affect on the design of the bridge. Composite action allows the concrete to participate in bending. This along with the concrete helping to carry axial compression in the deck (from stays), reduces the size of the steel required in the main span. A further size reduction of the steel was obtained through designing the webs in accordance with BS 5400 [1]. This allows web buckling to occur, providing account is taken of axial load shed to boundary elements (i.e. the concrete deck). Concretes compression carrying ability again proves a benefit. Figure 6: Section of the Main Span Deck The anchor span consists of a 10m wide, 9m deep post-tensioned box spine. Ribs are placed at 5.4m centers along the length of the span to provide the required width to the deck. Precast concrete panels span between the ribs and match those in the main span deck. The uplift of the stays is resisted by the self weight of this span along with some extra ballast. All of the weight couldn’t be initially placed in the span as it would have governed the pile design. To solve this, reducing the size of the foundations, the box was filled with concrete during main span construction allowing it to act as a counterbalance. The two 50m back spans are similar in construction to the anchor span, but as no stays are anchored in this span the central spine is only 2.5m deep. 4.1 Pylon Foundations A group of 18, 1.5m diameter, 55m deep bored piles are placed under each leg. The two groups are tied together by an 8m wide, 1m deep tie-beam. The main function of the piles is to carry the large compressive load at the base of the tower into the ground. Wind, seismic and asymmetric imposed loading can cause bending to develop within the pylon in both the longitudinal and transverse directions. The pylon must be connected to the pile group with full moment and shear connections to transfer these forces into the ground. With this the pile group can resist any lateral loads, overturning moments or uplift that may occur. The ultimate capacity of each pile has been calculated as 31MN [2]. As the soil is poor in end bearing it only provides 5MN of the resistance. The majority of resistance comes from skin friction along the length of the piles (26MN). Skin friction resists both downwards and upwards loading by the same degree. Any uplift that may arise can be resisted through this. As mentioned it is possible for both longitudinal and transverse moments to need to be resisted by the piles. An effort has been made to minimize these, reducing the required pylon size. Firstly the centre of mass of the pile groups and tower legs have been offset, counteracting dead load moments [1]. As previously mentioned the legs of the pylon have been tapered reducing the moment attracted to the foundations. Piles within soils consisting of layers of soft clays and sands have an increased risk of settlement. This is due to the pressure from the piles causing consolidation in the soil. Settlement levels must be checked as significant amounts may possibly have a catastrophic affect on the stability of the bridge. The equivalent raft method can used to estimate pile settlement. 4.2 Pier Foundations The system of cable stays is constructed using 1770 MPa prestressing strands. The closest main span stays are constructed using 11 strands increasing to 65 for the longest backstays [3]. On each side of the pylon 28 stays (or pairs of) are anchored along its height. Dampers are fitted on all stays to minimize problems due to vibrational affects. Two types of dampers are used. Standard neoprene dampers are used for all backstays and the first 10 main span stays. On the longer main span stays where the deck is more susceptible to vibrational affects specially developed shear dampers are provided. The bridge is also supported at piers 39, 41, 42, and 45 (Fig. 1) which each have their own smaller foundation. Each of these foundations consists of 4, 1.5m diameter piles (55m deep under P39/41, 41m deep under P42/45). The piers have a relatively simple engineering role primarily being required to carry vertical loads from the deck to the foundations. They also need to provide the necessary torsional restraint to the deck and resist any horizontal loads applied to it. Connections of the deck to the piers are either fully pinned or on longitudinal bearings so no moments are carried from the deck to the piers. This along with any loading upon them being significantly smaller than that of the pylon has led to the design of much smaller foundations. 4 Foundations 5 Bearings and Expansion Joints Rama VIII has several groups of pile foundations along it length, the main of which are under the pylon. Bangkok is situated upon a floodplain with underlying strata consisting of soft clays and sands to depths of 1000m so expansive foundations are required. Pot bearings have been used to connect the bridge deck to the piers/pylon. Bridge bearing are used to transfer loads and movements from the deck into the piers (and pylon) then foundations. Primarily they allow rotation at the joints in order for the connections to be considered as pinned. 3.4 Cable-Stay Design Features Varying temperatures cause a bridge to expand/ contract. This movement needs to be allowed so not to induce large thermal stresses within the bridge deck. Expansion joints have been placed at Piers 39 and 45 to accommodate for any movement. The bearings at piers 39, 41 and the pylon allow the horizontal movement required by temperature changes. Longitudinal fixity is achieved at pier 42 where no horizontal movement can occur [2]. anchorages were pre-welded to the top of the girders. For the majority of the segments a typical erection sequence was used and repeated until the main span (and the bridge) was complete. However the first two girder sections were installed differently. The first stay only provides support at the end of the second segment so temporary falsework was used to provide support during construction for the first segments. Great care was taken to align these correctly. 6 Construction The first step in the construction process was to cast the pile foundations. This was done using the Continuous Flight Auger (CFA) process. A hollow stemmed auger is bored to the required depth in the ground. Once reached, high slump concreted is pumped through the centre of the auger, as it is withdrawn. Soil is also removed during withdrawal. Upon withdrawal reinforcement cages are placed into the piles aided by the use of a vibrator. CFA piles are effective for use on soft ground as they cause minimal ground disturbance. Following this the pylon and piers were constructed, none of which are situated within the channel of the river. This saved a substantial amount of time and money as no cofferdams were required during construction. The reinforced concrete piers were built using the common technique of casting within timber formwork. It is likely that this will have been built on site, possibly being reused for several piers. The pylon was jump-formed. This involved concrete being poured into formwork which got jacked further and further up the pylon as the concrete hardened below. The steel reinforcement and prestressing was continuously erected and the pylon got taller. Concrete was poured, and the formwork raised in 4m lifts. As Fig. 7 shows two sets of formwork were used on the inclined legs. These merged into one along the upper section of the pylon. Once the pylon was complete there was a period of time before stays were attached. It is this period of time that is likely to have governed its structural design. Strong wind/seismic forces could have induced bending within the pylon that the stays would help resist once installed. Next the decks were constructed, with the anchor and back spans before the main. These are pre-cast, post-tensioned sections which were craned into place. As previously mentioned concrete ballast is placed inside the anchor spans to provide a downwards force to resist uplift from the stays. This was not originally placed in the anchor span but pumped in gradually during construction to counteract the weight of the main span. If all the ballast were all in place initially it would have governed the design of the foundations [2]. As with a large number of cable-stayed bridges, Rama VIII’s main span was constructed using the suspended cantilevered method. This allowed the deck to be built progressively out from the pylon. The main span consists of 29, 10m long girder segments, each consisting of; 2 primary longitudinal girders, 2 floorbeams 5m apart, and a steel sidewalk attached to the side of each girder. These were formed offsite and delivered by barge. The main stay Figure 7: Jump-Formed Pylon, Girder Section Lifting The first stage of the erection sequence was to install and fully stress the anchor stay opposing the stays supporting the section of main span being installed. The stays are placed into pre-assembled anchor bodies in the pylon and decks. Next the girder was lifted by cranes to deck level off its delivery barge. The section was aligned and bolted together through splice plates. Following this the front stays were installed, again into pre-installed anchor points. They were initially stressed to a level known as stage 0. If at any point during construction the level of stress in the stays dropped below 20kN construction was stopped as they provided insufficient counter-balance loads [3]. Lifting pre-cast deck panels into place on top of the floorbeams was the next step. To account for this extra weight the stays were then stressed to an intermediate level, stage 1. To connect the deck and girder segments the concrete infill strips were then cast. Finally the cables were stressed to their final level finishing the erection sequence. The underside of the main span is enclosed by fiber reinforced concrete panels. These give the bridge a clean aesthetic and create an access area for maintenance and inspection. They also shield the steel from the aggressive Bangkok environment. The installation of these panels was several segments behind that of the girder. 7 Loading This paper analyses loads in accordance with BS 5400-2:2006. BS 5400 considers the main loads that may act upon a bridge such as Dead, Super-Imposed Dead, Live, Wind and Temperature then groups them into 5 combinations (as set out later in this section). Bridges need to be designed under both Ultimate Limit State (ULS) and Serviceability Limit State (SLS) conditions. The requirements for each are distinctly different and this needs accounting for. Varying partial safety factors γfl and γf3 as set out in BS 5400 help do this. γfl is a partial load factor whilst γf3 accounts for inaccuracies in the bridge analysis. Through stipulating an elastic bridge analysis γf3= 1.10 at ULS and 1.00 at SLS will be used throughout, whilst γfl varies with the 5 load combinations. With Rama VIII having three decks, three different sets of deck loading need to be analyzed. As the main span is the only section of deck directly supported by stays loading will be analyzed for this section alone. 7.1 Dead Load Dead loads are those of permanent structural elements that are unlikely to be replaced over the life of a bridge. The weight of the main span girder (steel and concrete) and pylon will be assessed. The weight of the stays is neglected for the assessment. The pylon is a reinforced concrete box with a maximum Cross-Sectional Area (CSA) equal to 24.8m2. Assuming this doesn’t alter and that the weight of concrete =24kNm-3 the dead-loads can be calculated: Pylon Dead-Load = 595 kNm-1 height The 29.2m wide deck is constructed of girder sections (as described in section 3.3). The main beams have a top flange 700mm wide and 30mm thick, a bottom flange 1300mm wide and 100mm thick and a 14mm thick web [2] giving a CSA = 0.172m2. The transverse beams are smaller with a CSA = 0.06 m2. With the weight of steel taken as 77kNm-3 the following loads were calculated: Main Beams = 26 kNm-1 length Transverse Beams = 22 kNm-1 length Concrete Deck = 138 kNm-1 length Total Dead Load Main Span Girder Section = 186 kNm-1 length Dead load is constant for all load cases so we can always take γfl= 1.15 at ULS and 1.00 at SLS. 1.15 is used at ULS as such a large percentage of the total load is due to concrete. particularly heavily loaded. The design brief states that 1.3 times the loading suggested by design codes should be used, this will be considered. BS 5400 uses the concept of notional horizontal lanes. Rama VIII has an approximately 8.7m wide carriageway in each direction, corresponding to 3 notional lanes each 2.9m wide (clause 3.2.9.3.1). Two main traffic loads (HA and HB loading) act upon highway bridges. HA loading is a uniformly distributed load applied over a bridge. Clause 6.2.1 states that for bridges with a length between 50 and 1600m that HA loading is equal to: 1 W = 36( ) 0.1 L = 20.35kNm-1 x 1.3 (1) -1 = 26.5kNm length per notional lane A Knife-Edge Load (KEL) of 120kN must also be applied to each notional lane. This is a point load placed at one location along the length of a lane where it will cause the worst effect. Full HA and KEL are applied to two of the notional lanes whilst 1/3 of the value is applied to the rest of the lanes (placed to create the most onerous effect). HB loading represents an abnormal truck load on the bridge. Clause 6.3.1 states that each truck axel represents a 10kN point load for each unit of HB loading, with full loading being 45 units i.e. 450kN per axel. The inner axel spacing can be varied depending upon what causes the worst effect as Fig. 8 shows. In this instance it varies between 6 and 11m dependant upon whether hogging or sagging is being considered, 6m for sagging (all in one span) and 11m for hogging (spread equally over a support). 7.2 Super-Imposed Dead Load These are dead loads acting upon a structure from objects which do not serve a structural purpose. Objects of this type are likely to change several times over a bridges life. This gives rise to a tendency for layers of road surface to be built up. Also, the possibility of fill becoming saturated and objects possibly being replaced with something of a different weight make superimposed dead loads difficult to predict. This is reflected by high values of γ fl= 1.75 at ULS and 1.20 at SLS. A 200mm layer of hardcore fill (density = 1920kgm-3) and a 100mm layer of asphalt (density = 2300kgm-3) have been assumed, along with an allowance of 1.0kNm-2 for services and street furniture. Total Super-Imposed Dead Load = 205 kNm-1 length 7.3 Primary Live Loads Primary live loads are vertical loads from traffic and pedestrians upon the bridge. In Thailand trucks are Figure 8: Variable Axel Width HA HA HA HA 1/3HA 1/3HA 1/3HA 1/3HA Figure 9: HA and HB Load Distribution As the notional lane width is less than 3.5m the HB load straddles two lanes. This gives the load distribution for HA and HB loading as shown on plan above. For both HA and HB loading γfl and γf3 vary dependant upon the load combination. Rama VIII has a 5.3m walkway in each direction so pedestrian loads must also be considered. For bridges in excess of 36m length the pedestrian load is equal to k x 5.0kNm-2: k= ( HAUDL × 10) = 0.36 ( L + 270) (2) Pedestrian Load = 9.5 kNm-1 length walkway As the walkway has both foot and cycle access and is wider than 2m the pedestrian load can be reduced by 15% for the first meter over a 2m width and by 30% for any width over this. For simplicity an average load over the width of each walkway can be calculated (2 walkways in total). Av. Pedestrian Load = 8.0 kNm-1 length per walkway 7.4 Secondary Live Loads Various secondary live loads can also arise due to traffic. Centrifugal loads must be applied to bridges with a radius of curvature less than 1000m. The curve on Rama VIII is shallow so this is ignored. Longitudinal loads due to braking/acceleration forces need considering. BS 5400 Clause 6.10.1 states that for the HA load type a nominal load of 8kNm-1 along the loaded length +250kN or a maximum load of 750kN must be applied longitudinally. The maximum is exceeded in this instance so a value of 750kN is used. For the HB load type breaking/acceleration loading is taken as 25% of the nominal HB loading, applied between 8 wheels of two axels. As the HB load is taken as 450kN per axel a longitudinal force of 225kN is applied along the bridge. 7.5 Wind Loading As Rama VIII is outside of the UK and has a span greater than 200m, wind loadings obtained from BS 5400 are not strictly applicable. However they still can be used to give an idea of the loads upon the bridge. In situations such as this the aerodynamic stability of the bridge would be confirmed though wind tunnel testing. Through information obtained by wind tunnel testing the fiber-reinforced composite panels, placed upon the underside of the deck, were designed to make it as aerodynamic as possible, relieving the load it feels. Reduced wind loading is another benefit of having a slender deck. This is primarily due to the wind having a smaller area to act over but also through the reduction of a decks coefficient of drag. As mentioned it is likely that wind loading upon the pylon during the construction stage would have played a large part in its structural design. Wind loading in accordance with BS 5400 is based upon 120 year wind speeds at a height of 10m above the ground. Wind loads acting upon both the pylon and deck must be considered. The first step in finding wind loads is to calculate the wind gust speed (vc) acting upon a bridge. The mean hourly wind speed (v) for Bangkok was not readily available therefore has been conservatively assumed as 30ms-1. The height of the deck above ground ≈ 15m, but the pylon height alters. For simplicity an average pylon height of 80m will be used. For a 300m long bridge the wind coefficient (K1) = 1.39/1.71 (Deck/Pylon), funneling factor (S1) = 1.00/1.00 and gust factor (S2) = 1.07/1.42: vc = v K1 S1 S2 = 44.6 ms-1(Deck) (3) = 72.8 ms-1(Pylon) The transverse wind load (Pt) acting at the centroid of the element under consideration, is a function of Pressure Head (q), area (A) and coefficient of drag (CD). As the deck is 2.4m deep it has an approximate area of 720m2 along its length. The 29.2m wide deck has a d/b = 12.1, corresponding to a CD = 1.00. The pressure head is found using Eq. (4): q = 0.613vc2 = 1219 Nm-2 (Deck) (4) The transverse wind load is then calculated using: Pt = q A1 CD = 878kN (5) -1 Transverse Deck Wind Load = 2.9 kNm length Both transverse and longitudinal (PL) wind loads act upon the pylon. With tapering sections in both directions finding accurate wind loads can become complicated. As the section is almost square a worst case wind loading will be calculated an applied in both directions. If the 161m high pylon is assumed to have a 7m width in both directions, an area of 1200m2 and CD = 1.90 a value for pressure head can be calculated: q = 0.613vc2 = 3248 Nm-2 (Pylon) PT/L = q A1 CD = 7408kN (6) -1 Pylon Wind Load = 46.0 kNm height Wind can also cause uplift or a downwards force to act over a bridge deck. This force is calculated using the plan area of the deck (= 8760m2) and a lift coefficient (CL = 0.25) as shown below: Pv = q A3 CL = 2670kN (7) -1 Vertical, Deck Wind Load = 8.9 kNm length Wind loads are combined in the following ways; Pt alone, Pt with ± Pv, PL alone, 0.5Pt with PL ±0.5Pv. 7.6 Temperature Loading Varying temperatures will cause a bridge to expand/contract in both the longitudinal and transverse directions. Usually this movement is allowed through expansion joints and bearings along the bridge. If these get blocked they can restrain the deck from movement, inducing thermal stresses with it. Bridges are designed to 120 year return temperatures. Two effects of temperature change need to be considered, the first being when one temperature acts uniformly over the whole bridge. It is also possible for there to be a variation in temperature between the top and bottom of the deck inducing bending stresses within. In this section I will analyze the stress induced longitudinally along the deck by a constant temperature. Through looking at the climate data for Bangkok I believe it acceptable to assume a temperature range of +5 to +40°C. If there is a temperature change of ±20°C the change in length of the bridge will be: ε = α ∆T where α = 12x10-6°C-1 for steel/conc (8) ε = 240µε δ=εL (9) δ = 0.072m = 72mm As the bridge is designed to act compositely a thermal stress will be induced in both the steel and concrete. Assuming full restraint of the bridge deck the stresses induced in the main section (either tension or compression) along its length are: σ C/T = ε x E (10) C/T -2 Thermal Stress - Steel, σ = 48Nmm Thermal Stress - Concrete, σ C/T = 7.2Nmm-2 7.7 Seismic Loading Bangkok is an area of low-to-moderate seismicity with approximately 20 earthquakes being recorded over the last 200 years. No record of any significant damage occurring during any of these quakes exists. However the soft soils and deep pile foundations cause the design spectral input to increase to such a level that seismic effects need to be considered [2]. As the UK is not a seismic area British Standards have no guidance on seismic loading. If a full analysis of the Rama VIII Bridge were to be conducted provisions from a design code such as AASHTO would need to be used. 7.8 Fatigue Loading It is likely that the concrete pylon will undergo some degree of creep caused by sustained periods of stress. Creep occurs over a significant period of time (20-30 years), but it is estimated that 75% occurs within the first year. Consequences of creep include increased deflections, a reduction in prestress and redistribution of internal forces. Creep and shrinkage of a composite deck as used in Rama VIII would lead to axial load being redistributed from the concrete into the main steel girder beams. To combat this the precast deck panels were stored for 90 days before being installed [1]. Steel is not susceptible to creep but is to stress relaxation, particularly in stays and steel prestressing tendons. Stress relaxation in the stays will causes them to lengthen. This is only likely to cause serviceability issues (i.e. increased deflections) but in extreme circumstances could cause the pylon to become destabilized. Elastomeric dampers are placed upon the stays in Rama VIII to compensate for this [3]. If the affects of stress relaxation become too large the stays will need to be re-tensioned or possibly replaced. Prestressing tendons also loose prestress during loading. Both concrete creep and stress relaxation play a part in this, along with the shrinkage of concrete and other possible causes under special circumstances. The initial tensioning stress can be reduced by up to 30% so needs to be considered and accounted for during the design process. 7.9 Load Combinations BS 5400 groups the previously described loads into 5 combinations which need to be checked at both ULS and SLS. These are shown below: 1. Permanent Loads plus Primary Live Loads 2. Combination 1, plus Wind and temporary erection loads (if any) 3. Combination 1, plus Temperature and temporary erection loads (if any) 4. Permanent Loads, Secondary Live Loads and associated Primary Live Loads 5. Permanent Loads, plus loads due to friction at supports Section 8 (Strength Analysis) uses the appropriate safety factors γfl and γf3 to combine the loads and form the most onerous effects on various parts of the bridge. The loads obtained are used to check the capacity of the structure. 8 Strength This section aims to analyze the strength of several parts of the Rama VIII Bridge using the ULS philosophy. A worst case set of forces is obtained from the loadings in section 7 (Note: γf3= 1.10 at ULS). 8.1 Strength of the Deck Whilst in operation a bridge deck will be subject to axial force, bending and torsion. For the purpose of this analysis several assumptions have been made. Firstly the main girder beams are continuous with rigid support provided from stays at every 10m. The stays would actually provide elastic support so the stresses in reality would be slightly larger than those obtained here. Secondly it is assumed that the two main girder beams will carry all of the longitudinal bending in the main span. Fig. 10 shows a simplified cross section of the main span deck that will be used for analysis purposes. Torsion is developed from asymmetric loading. Open sections (as often is the case in cable-stayed bridges) have a low torsional rigidity. As Rama VIII’s cables converge this is increased but torsion may still be an issue. However torsion has been neglected in this analysis. Figure 10: Approximated Main Girder Section As the deck is continuous both sagging and hogging moments will form within it. Steels properties are isotropic so it can carry both equally well but they each need to be assessed to find which has the greatest magnitude. Load combination 1 is likely to induce the greatest moments in the deck. Here Permanent and primary live loads are considered. Fig. 11/12 shows how loads would be arranged within each span to induce the greatest moments. Figure 11: Load Distribution for Maximum Sagging Figure 12: Load Distribution for Maximum Hogging Load patterns as seen in Fig. 9 are complex and would be analyzed using a computer. However the deck can be analyzed with relative ease if no HB loading is applied and the two lanes of full HA loading are arranged symmetrically about the deck. It is for this variation of load case 1 that the bridge deck will be analyzed. Using the loads shown in Table 1 and the unfactored dead load = 186 kNm-1 the moments in the deck can be found. Table 1: Loads – Case 1 Load: γfL Factored Load Dead 1.15 213 kNm-1 Super – Imposed Dead 1.75 359 kNm-1 Live: Full HA (2 Lanes) 1.5 39.8 kNm-1 1/3 HA (4 Lanes) 1.5 13.3 kNm-1 Pedestrian 1.5 24 kNm-1 Total: 729 kNm-1 A factored knife edge load (180kN and 60kN) must also be applied in each notional lane at one point along the length of the bridge. The results obtained give a maximum sagging moment = 7.96 MNm and hogging moment = 8.10 MNm. From this the bending stress within the section can be found using Eq. 11: My = 54Nmm-2 (11) σ= I Transverse wind loading acting upon the main span would cause bi-axial bending within the deck. This would be checked using load case 3. The maximum force in the stays and ultimately the maximum compression in the deck is found when the full factored load is placed over the whole length of the bridge rather than in selected spans. The vertical reaction at each of the 28 sets of supports can be taken as 7290kN. The inclination of the stays changes along the length of the bridge but through taking the angle of the central most stay and applying it to them all a fair approximation of the compression in the deck can be obtained. With the angle of the central stay taken as 37.5° the compressive force from a single pair of stays = 9500kN, making the total compressive force in the deck = 266MN. If we make the assumption that the load has spread out equally over the complete area of concrete/steel section we can obtain a value for the level of compressive stress in the deck as shown in equation (12). The C.S.A. for the section is 7.65m2: F -2 (12) σ = = 34.8 Nmm A By totaling the stresses we can find the total level of stress within the deck. Thermal stresses are included with a factor of γfL = 1.3 applied (note that live loads would have a smaller safety factor when temperature is considered so the stresses obtained are conservative). Total Stress - Steel, σ = 151.2Nmm-2 Total Stress - Concrete, σ = 44.2Nmm-2 Extra stress due to torsion, transverse wind etc. will need to be added to these totals. Concrete with a cylinder strength of 55Nmm-2 and S355 steel [2] have been used so the stresses obtained show an understressed deck for this load case. 8.2 Strength of the Stays The maximum tensile force is induced within the stay with the smallest angle of inclination. This is the stay that spans the longest from the pylon. This stay hits the deck at an approximate angle of 27.3° and supports an ≈ 7290kN reaction, making the tension in the stay = 15890kN. Ref. [3] states that each strand has an ultimate tensile strength of 265.5kN. The longest stays each contain 73 strands, giving a tensile strength = 19382kN, with two stay supporting each section of deck. Equation (13) shows that the level of stress within each stay is at an acceptable value. Unity Factor = 15890 =0.41 ( 2 × 19382) (13) 8.3 Strength of the Pylon The compression within the pylon can be found using an average value of 11975kN for the level of tension within each stay, and 595kNm-1 height for the unfactored dead load of the pylon. To check the capacity of the pylon bending within it will need to be analyzed under all loading conditions, including wind and seismic in every direction. 9 Serviceability Designing bridges to comply with SLS criteria is as equally important as for ULS conditions. Excessive deflections may not pose a threat to the stability of a bridge but is likely to put people off wanting to use it. Deflections of cable-stayed bridges due to permanent loads can be controlled through tension in the stays. Equation (14) shows an approximate value for the level of deflection within a 10m span between stays. It has been assumed that the girder sections are simply supported between the stays for conservatism. Using the same load case as in section 8 the SLS load long the length of the bridge = 495 kNm-1 with a 120kN KEL load placed at the centre of the span. 5wL4 PL3 = 2.7 + 0.1 = 2.8mm (14) δ= + 384EI 48EI The level of deflection obtained is minimal for a 300m long bridge and would not be noticed. Once again this value may be lower than what would realistically occur due to the distance between rigid supports being 300m and the intermediate stay supports being elastic. However the value is so small the actual deflections are still unlikely to cause an issue. The bridge will also deflect laterally from wind blowing upon the side of the deck. The aerodynamic shape of the underside of the deck will help to minimize this. 10 Natural Frequency Lessons have been learnt from past events and dynamic effects due to vibrations are checked for all bridges. Primarily this is a serviceability check to ensure that no discomfort if felt (particularly by pedestrians) when crossing a bridge. Both low and high frequency vibrations can cause problems so a check is conducted to ensure that a bridges natural frequency lies with an acceptable range of 5 – 75 Hz. If a bridge vibrates at its natural frequency it can cause large oscillations of the bridge deck. It is at this point when a bridge has serviceability issues and faces the risk of collapse. If the natural frequency is below 5 Hz it is at risk of being matched by people walking across the bridge or by wind (if around 1 Hz). If this occurs consideration needs to be placed into limiting the maximum acceleration of the bridge to within limits set out it BS 5400. When above 75 Hz the frequency is unlikely to cause collapse but may create unpleasant physiological effects. The natural frequency of a bridge deck can be calculated using Eq. (15). It calculates the frequency of a section, taking into account its end conditions using a coefficient kn. It is again assumed that the deck is continuous over rigid supports (stays). The frequency will be calculated for a 10m girder section between stays. The support provided by the stays is considered to be clamped. Two types of end conditions exist, clamped-clamped between stays (kn = 22.37 [7]) and clamp-pinned on the end spans (kn = 15.42 [7]). It is the end spans that will have the lowest frequency. For the girder section I = 0.120m4, m = 39.9x103kgm-1 and E = 200x109Nm-2: k EI (15) fn = n 2π mL4 f0 =27.6 Hz (clamped – clamped) f0 = 19.0 Hz (clamped – pinned) The values obtained lie within acceptable limits but are higher than what would realistically be achieved. The stays are not rigid supports but elastic allowing a limited movement causing the deck/stay system to vibrate as one. 11 Durability Durability is a key concern for all bridges. As is the norm for most bridges, Rama VIII has a design life of 120 years, set under the assumption of regular maintenance. The enclosed space on the underside of the main span provides access for maintenance, where the girder section can be inspected for corrosion. The enclosure also provides a dehumidified atmosphere and reduced environmental exposure, greatly reducing the risk of corrosion. The main span steel is still painted with a protective coating to reduce this risk further. Corrosion of steel cables is another concern. Four barriers are used to protect the stays from the elements. Firstly each strand within every stay is galvanized. They are then waxed and coated in a protective layer of polyethylene. Finally the stays are cased inside a HDPE sheath. This allows replacement of individual strands if required. The stays anchorages are one of the key areas that require regular maintenance. In the anchor span where the back stay anchorages are hidden from sight, access can be achieved through the central spine beam running along the said span. Inspection of movement joints and bearings is also needed to ensure the do not become blocked restraining deck movement. 12 Vandalism Small scale vandalism is a problem in Bangkok. This is in the magnitude of graffiti and not at a level which would cause anything more than superficial damage to the Rama VIII Bridge. It is not impossible to imagine a vehicle being purposely being crashed into one of the piers or the pylon. Both elements will have been designed to be robust enough to withstand the necessary impact loads. The threat of terrorism is becoming more and more of an issue. Rama VIII is fairly modern so it is likely that it will have been designed to withstand some degree of blast loading. 13 Future Changes As Rama VIII is effectively performing its required task with no reported operational problems it is difficult to suggest future changes. The increasing level of congestion in Bangkok will require further capacity to cross the Chao Phraya River at some point in the future. Widening of Rama VIII is one solution to this problem. The location of the pylon and where the stays meet the deck make this difficult to do but there is precedence. The likely way in which this would be done is to replace the cantilevered walkway with a larger stiffer cantilevered section. This solution is not realistic and you can tell that the bridge was not designed to be widened. The extra load would change the back staypylon-main span equilibrium resulting in further design work. The most practical solution to the problem is likely to be the construction of a new bridge at some point along the river. References [1] Heidengren, C.R., 2003. Rama VIII – Regal Crossing, Civil Engineering Magazine, Vol.73, No.7, pp. 34-43. [2] Torrejon, V.E., Berman, D.W., Design of Rama VIII Bridge in Bangkok, Thai Engineering.com, [Online]. [3] Lengweiller, R., Kaufmann, E., 2002. Rama VIII Bridge in Bangkok: Construction and Stay Cable System, JKR Seminar, Kuala Lumper Aug 2002, [Online]. [4] BS 5400-2:2006, Steel, Concrete and Composite Bridges – Part 2: Specification for Loads, BSI. [5] Walther, R., 1999. Cable Stayed Bridges 2nd Ed., Thomas Telford Publishing. [6] Leonhardt, F., 1982. Bridges, The Architectural Press. [7] Davison, B., Owens, G.V., 2003. Steel Designers Manual 6th Ed., Blackwell Publishing.