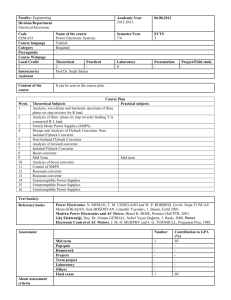

as a PDF

advertisement

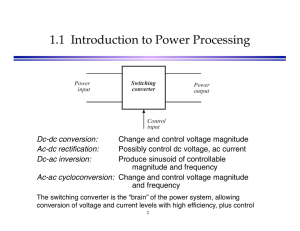

Lecture 1: August 23, 2010 Introduction to Power Electronics ECEN 4797/5797 Robert W. Erickson University of Colorado, Boulder Fall 2010 1 Introduction to Power Electronics ECEN 4797/5797 • Instructor: Prof. Bob Erickson – – – – – Office: ECOT 356 Telephone: (303) 492-7003 Email: rwe@colorado.edu Office hours: Th 2:00 - 3:30 pm, W 3:00 - 4:00 pm Telephone office hours: M 3:00 - 4:00 pm • Course web site: – http://ece.colorado.edu/~ecen5797 – Includes lecture slides, handouts, homework assignments, links to online lecture files • Textbook: – Erickson and Maksimovic, Fundamentals of Power Electronics, second edition, Springer, ISBN 0-7923-7270-0. • Prerequisite: – A 3-4 semester sequence of undergraduate EE circuits and electronics courses (at Univ. of Colorado: ECEN 3250) 2 Coursework in Power Electronics at the University of Colorado • Power electronics courses – ECEN 4797/5797 (this course): Intro to power electronics (Fall) – ECEN 5807 Modeling and Control of Power Electronics Systems (Alt Spring semesters, including S 11) – ECEN 5817 Resonant and Soft-Switching Techniques in Power Electronics (Alt Spring semesters, including S 12) – ECEN 4517/5517 Power Electronics Laboratory (Spring) • Professional Certificate in Power Electronics – ECEN 5797, 5807, and 5817 • Formats for this course – On-campus, for senior or graduate credit – Web-based lectures (visit the CU Anywhere website at http:// caete.colorado.edu/courses/onlineaccessdetails.aspx) 3 Grading • Homework – – – – – – Due at beginning of class on date listed on Lecture Schedule web page Late homework not accepted Homework counts 50% of grade You may speak with others about the homework, but turn in your own work Password-protected solutions on web site Homework and exam problems of additional depth and complexity for those earning graduate credit; separately graded • Exams – – – – Midterm exam: one-week take-home exam, 17% of grade Final exam: five-day take-home exam, 33% of grade See course schedule page for dates See course vitals page for details 4 Off-campus students • Assignment due dates – One week grace period allowed for all assignments and exams – Late homework not accepted beyond the one-week grace period • How to submit your work: mail, email, or fax – Fax option: ECEE Department fax 303-492-2758. On cover page, clearly direct to Prof. Erickson. – Email: send to Prof. Erickson at rwe@colorado.edu Scan instructions: black-and-white (no grayscale or color!), 200-300 dpi, with all pages in a single pdf file. Other file/scan formats not accepted. – Mail: send to: Prof. R. Erickson, ECEE Department, University of Colorado, Boulder CO 80309-0425. Must be postmarked by due date. • Exam options – Send email to Prof. Erickson on your desired start date. Prof. Erickson replies with exam as email attachment. You fax or email completed exam directly to Prof. Erickson by due date. No Educational Officer (EO) required. – Second option: your company EO receives the exam from CAETE, then administers the exam to you. 5 Key dates • Drop deadlines – September 8: last day to drop the course and receive full tuition refund, with no “W” grade appearing on transcript – October 6: last day to drop the course without petitioning the Deans office • Tentative exam dates – Midterm exam: 1 week take-home exam. For on-campus students: handed out Oct. 22, due in class on Oct. 29. One week grace period allowed for CAETE students. – Final exam: Five day take-home exam. For on-campus students: handed out Dec. 10, due in Prof. Ericksons office on Dec. 15. One week grace period allowed for CAETE students. • Grades assigned in December appear on your permanent university transcript • Campus holidays – Labor day: Sept. 6 – Fall break / Thanksgiving holiday: Nov. 22-26 6 Chapter 1: Introduction 1.1. Introduction to power processing 1.2. Some applications of power electronics 1.3. Elements of power electronics Summary of the course 7 1.1 Introduction to Power Processing Power input Switching converter Power output Control input Dc-dc conversion: Ac-dc rectification: Dc-ac inversion: Change and control voltage magnitude Possibly control dc voltage, ac current Produce sinusoid of controllable magnitude and frequency Ac-ac cycloconversion: Change and control voltage magnitude and frequency 8 Control is invariably required Power input Switching converter Power output Control input feedforward feedback Controller reference 9 High efficiency is essential 1 = Pout Pin 0.8 1 –1 Ploss = Pin – Pout = Pout 0.6 High efficiency leads to low power loss within converter Small size and reliable operation is then feasible Efficiency is a good measure of converter performance 0.4 0.2 0 0.5 1 Ploss / Pout 10 1.5 A high-efficiency converter Pin Converter Pout A goal of current converter technology is to construct converters of small size and weight, which process substantial power at high efficiency 11 + – Devices available to the circuit designer DT Resistors Capacitors Magnetics 12 T s s Linearmode Switched-mode Semiconductor devices + – Devices available to the circuit designer DT Resistors Capacitors Magnetics Signal processing: avoid magnetics 13 T s s Linearmode Switched-mode Semiconductor devices + – Devices available to the circuit designer DT Resistors Capacitors Magnetics Power processing: avoid lossy elements 14 T s s Linearmode Switched-mode Semiconductor devices Power loss in an ideal switch + Switch closed: v(t) = 0 Switch open: i(t) = 0 In either event: p(t) = v(t) i(t) = 0 Ideal switch consumes zero power 15 v(t) – i(t) A simple dc-dc converter example I 10A + Vg 100V + – Dc-dc converter R 5 V 50V – Input source: 100V Output load: 50V, 10A, 500W How can this converter be realized? 16 Dissipative realization Resistive voltage divider I 10A + Vg 100V + – + 50V – Ploss = 500W R 5 V 50V – Pout = 500W Pin = 1000W 17 Dissipative realization Series pass regulator: transistor operates in active region + I 10A 50V – + Vg 100V + – linear amplifier and base driver Ploss 500W –+ Vref R 5 V 50V – Pout = 500W Pin 1000W 18 Use of a SPDT switch I 10 A 1 + + Vg 100 V 2 + – vs(t) R – vs(t) – Vg Vs = DVg switch position: DTs 0 (1 – D) Ts t 1 2 1 19 v(t) 50 V The switch changes the dc voltage level vs(t) Vg Vs = DVg switch position: DTs 0 (1 – D) Ts t 1 2 1 DC component of vs(t) = average value: Vs = 1 Ts Ts vs(t) dt = DVg 0 20 D = switch duty cycle 0 D 1 Ts = switching period fs = switching frequency = 1 / Ts Addition of low pass filter Addition of (ideally lossless) L-C low-pass filter, for removal of switching harmonics: i(t) 1 + Vg 100 V + – + L 2 vs(t) C R – Pin 500 W v(t) – Ploss small Pout = 500 W • Choose filter cutoff frequency f0 much smaller than switching frequency fs • This circuit is known as the “buck converter” 21 Addition of control system for regulation of output voltage Power input Switching converter Load + + – v H(s) – Transistor gate driver Error signal ve Pulse-width vc G (s) c modulator Compensator (t) dTs Ts –+ vg i Reference vref input t 22 Hv Sensor gain The boost converter 2 + L Vg 1 + – C R V – 5Vg 4Vg V 3Vg 2Vg Vg 0 0 0.2 0.4 0.6 D 23 0.8 1 A single-phase inverter 1 Vg + – vs(t) + 2 – + v(t) – 2 1 load “H-bridge” vs(t) t 24 Modulate switch duty cycles to obtain sinusoidal low-frequency component 1.2 Several applications of power electronics Power levels encountered in high-efficiency converters • less than 1 W in battery-operated portable equipment • tens, hundreds, or thousands of watts in power supplies for computers or office equipment • kW to MW in variable-speed motor drives • 1000 MW in rectifiers and inverters for utility dc transmission lines 25 A laptop computer power supply system Inverter iac(t) vac(t) ac line input 85–265 Vrms Display backlighting Charger Buck converter PWM Rectifier Boost converter Lithium battery 26 Microprocessor Power management Disk drive Power system of an earth-orbiting spacecraft Dissipative shunt regulator + Solar array vbus – Battery charge/discharge controllers Dc-dc converter Dc-dc converter Payload Payload Batteries 27 An electric vehicle power and drive system ac machine Inverter ac machine Inverter control bus battery μP system controller + 3øac line 50/60 Hz Battery charger DC-DC converter vb – Low-voltage dc bus Inverter Inverter ac machine ac machine Variable-frequency Variable-voltage ac 28 Vehicle electronics A standalone photovoltaic power system The system constructed in ECEN 4517/5517 Power Electronics and Photovoltaic Systems Laboratory 29 1.3 Elements of power electronics Power electronics incorporates concepts from the fields of analog circuits electronic devices control systems power systems magnetics electric machines numerical simulation 30 Part I. Converters in equilibrium Inductor waveforms vL(t) Averaged equivalent circuit RL t –V 1 iL(t) 2 0 + Vg – V L Vg + – R – iL Predicted efficiency 100% –V L DTs V I 1 iL(DTs) I iL(0) D' : 1 D'Ts DTs switch position: D' RD + – Vg – V D' VD D Ron 0.002 90% 0.01 Ts 80% t 0.02 70% 0.05 60% 50% RL/R = 0.1 40% Discontinuous conduction mode 30% Transformer isolation 10% 20% 0% 0 0.1 0.2 0.3 0.4 0.5 D 31 0.6 0.7 0.8 0.9 1 Switch realization: semiconductor devices The IGBT collector Switching loss iA(t) transistor waveforms Qr Vg gate iL vA(t) 0 0 emitter t Emitter diode waveforms Gate iL iB(t) vB(t) 0 0 t n p n n n- p area –Qr n –Vg minority carrier injection tr p pA(t) = vA iA area ~QrVg Collector area ~iLVgtr t0 32 t1 t2 t Part I. Converters in equilibrium 2. Principles of steady state converter analysis 3. Steady-state equivalent circuit modeling, losses, and efficiency 4. Switch realization 5. The discontinuous conduction mode 6. Converter circuits 33 Part II. Converter dynamics and control Closed-loop converter system Power input Averaging the waveforms Switching converter Load gate drive + vg(t) + – v(t) R feedback connection – (t) compensator pulse-width vc Gc(s) modulator dTs Ts v averaged waveform <v(t)>T s with ripple neglected voltage reference vref vc(t) (t) actual waveform v(t) including ripple –+ transistor gate driver t t t t Controller L Small-signal averaged equivalent circuit vg(t) + – + – 1:D Vg – V d(t) I d(t) D' : 1 + I d(t) C v(t) – 34 R Part II. Converter dynamics and control 7. Ac modeling 8. Converter transfer functions 9. Controller design 10. Input filter design 11. Ac and dc equivalent circuit modeling of the discontinuous conduction mode 12. Current-programmed control 35 Part III. Magnetics n1 : n2 transformer design iM(t) i1(t) i2(t) the proximity effect LM R1 R2 layer 2 current density J Rk 4226 0.1 2616 2616 2213 2213 1811 0.08 0.06 1811 0.04 0.02 0 50kHz 100kHz 200kHz 250kHz 400kHz Switching frequency 36 500kHz 1000kHz Bmax (T) Pot core size 3622 25kHz 2i –i layer 1 transformer size vs. switching frequency –2i ik(t) : nk 3i layer 3 i d Part III. Magnetics 13. Basic magnetics theory 14. Inductor design 15. Transformer design 37