Technical leaflet FWPC FWPS FWS FWP

advertisement

FWPC/FWPS/FWS/FWP

PLATE EXCHANGERS FOR INSTANTANEOUS DOMESTIC

HOT WATER PRODUCTION IN BLOCK OF FLATS

FWPC: instantaneous DHW calorifiers, with a low

primary temperature return for condensing boilers

up to 750 kW

FWPS: instantaneous DHW calorifiers, with

integrated preheating loop (solar or heat pump) for

boilers up to 217 kW

FWS

Instantaneous DHW.

For connecting to a boiler with an

exchanged outpout of 50 to 750 kW

FWS: primary storage calorifiers for

instantaneous domestic hot water production

employing a heat exchanger in the form of an

integrated coil, for boilers up to 280 kW

FWP: instantaneous DHW calorifiers, with low Δ

of temperature for boilers up to 650 kW

FWPC

FWPS

FWP

FWPC: Range of calorifiers for instantaneous domestic hot water production,

constructed using a movable plate exchanger on a base. Thanks to a primary

return temperature to 30°C, it is possible to optimise the efficiency of the

condensing boiler systems for domestic hot water (DHW) flow rates, at 60°C,

of up to 13 m3/h and powers up to 750 kW.

FWPS: Range of instantaneous domestic hot water calorifiers with solar or

heat pump preheating system, for DHW flow rates at 60°C of up to 5.5 m3/h

and powers up to 217 kW.

D

H

(Qi¡la¡f_

HUJL

\

$

$

%

&

'

(

)

*

FWPC/FWPS equipped with primary

pumps class A, with energy efficiency

index EEI < 0.23

Legionella

EQUIPMENT

FWS: Range of calorifiers for instantaneous domestic hot water production,

combining primary storage and the production of DHW in the same volume,

optimising the efficiency of the system by solar of heat pump preheating

and a condensing boiler contribution, for DHW flow rates at 60°C of up to

2.5 m3/h and powers up to 280 kW.

FWP: range of calorifiers for instantaneous domestic hot water production

with a primary having a 't of 25 K, for DHW flow rates up to 11 m3/h and

outputs up to 650 kW.

CONDITIONS OF USE

Primary circuit

Working temperature:

- FWPC: 70/30°C

- FWPS 70/20°C

- FWS: 70/20°C

- FWP: 70/50°C

Max. operating temperature:

- FWPC/FWPS/FWP: 110°C

- FWS: 90°C

Max. operating pressure:

- FWPC/FWPS/FWP: 10 bar

- FWS: 6 bar

Secondary circuit

Working temperature: 10/60°C

Max. operating temperature: 90°C

Max. operating pressure:

- FWPC/FWPS/FWP: 10 bar

- FWS 750: 7 bar

- FWS 1500: 10 bar

PRESENTATION OF THE RANGES

RANGES FWPC/FWPS/FWP

Our ranges of instantaneous DHW calorifiers are all constructed

using a removable plate heat exchanger, mounted on a rigid

frame to be installed on the ground. They are equipped with

a double primary pump and with a mixing valve installed and

connected on the autonomous regulation. The assembly is tested

and delivered, ready to use on a film-wrapped pallet, to be

connected to a heat generator.

¹ FWPC

70°C

0

2

4

6

8

10

12

14

16

18

20

22

FWPC

70°C

24

0

30

l

FW_F0003B

Low-temperature DHW calorifiers for use with a condensing

boiler. The primary return temperature, fixed at 30°C,

ensures the condensation function of the boiler, which enables

a considerable reduction in energy consumption; the integrated,

ultra-responsive and precise regulation contributes actively to

these energy savings - see page 10.

30°C

¹ FWPS

70°C

FWPS

70°C

0

0

2

4

6

8

10

12

14

16

18

20

22

24

30

FW_F0004B

Multi-energy DHW calorifiers for use with renewable energy

preheating of the solar or heat pump type. The primary return

temperature, fixed at 20°C, ensures maximum efficiency of the

renewable energy contribution to the system, controlled by the

integrated, ultra-responsive and precise regulation - see page 11.

l

20°C

¹ FWP

>70°C

6A

0

FWP

30

l

FW_F0002B

DHW calorifiers for use with conventional boilers or an urban

heat network with low 't or primary (wood-fired boiler for

example), allowing simple integration into any existing system see page 12.

RANGE FWS

¹ FWS

FWS

FW_F0013

Multi-zone DHW calorifiers which can be connected to all types

of generators, with the option of connecting a solar energy

or heat pump circuit. It is composed of a buffer tank with

temperature stratification and heat exchanger in the form of a

high-performance stainless steel coil incorporated in the tank. see page 13.

2

CHOICE OF DHW PRODUCTION PRINCIPLE

FW

50°C

FW_F0014

The domestic hot water system must be chosen in full knowledge

of the facts, in order to ensure continuous DHW availability at the

desired flow rate and:

- In the individual residence, at the desired temperature in

order to ensure the comfort wished for by the user - for those

establishments requesting it, at the temperature required to

avoid proliferation of legionella and set by the DUT. One of the

recommendations for health institutions, schools, public buildings,

etc. is that the DHW production be instantaneous, i.e. without

storage, and that the return temperature of the recirculation loop

on the plate heat exchangers be maintained at above 50°C.

The estimate of the DHW requirement is important for

defining the system and its components.

Our FW and other calorifier products respond to these

prerogatives:

- The FWS combines instantaneous DHW production with primary

storage in the same volume.

- The FWPC, FWPS and FWP are defined for instantaneous DHW

production.

¹ DHW production using plate heat exchangers

Instantaneous DHW production

Semi-instantaneous DHW production

Solution involves storing the domestic hot water immediately

or rapidly meeting large needs and is therefore subject to the

constraints relating to legionella: minimum storage temperature,

superheating cycle, periodic cleaning of the tank, etc. It is also

applicable for replacement of components in boiler rooms and

our products are entirely suitable for this purpose.

Benefits of instantaneous DHW production with primary storage

- Also enjoy the advantages of semi-instantaneous DHW

production, including reduced generator power and/or

allowing it to shutdown or at least decrease its temperature

when DHW is not being drawn,

Advantages of our product solutions

- delivers significant productivity gains in DHW production by:

• limitation of the Primary inlet temperature required to 70°C,

• a primary return temperature allowing condensation of the

boiler and/or effective integration of renewable energies in

the system (FWPC/FWPS),

FW_F0015

FW

FW_F0015

FW

For new installations or major renovations, we advise against

semi-instantaneous systems with DHW storage in favour of

instantaneous DHW production systems with primary storage

(solution ).

- Removes any risk of the presence of legionella in the DHW

distribution, while ensuring that a suitable quantity is available

at the desired temperature.

• precise control of the system with Class A, low consumption,

modulating primary pumps, having energy efficiency index

EEI < 0.23.

Note: In this document, we will only describe this type of

instantaneous DHW production system although, of course,

we have products for all types of installation.

3

CHOOSING THE DOMESTIC HOT WATER CALORIFIER

The domestic hot water calorifier must be chosen in full knowledge

of the facts in order to ensure permanent DHW availability at the

desired temperature.

It is therefore important accurately to determine the DHW needs

necessary to meet this requirement, which depends largely on the

number of people living in the home and their consumption habits.

It will also depend on the risk of legionellosis, which would direct

the choice towards a calorifier with instantaneous DHW production

(solution we recommend).

Below are a number of points which may help you in this choice :

DETERMINING YOUR DOMESTIC HOT WATER NEEDS

Determining these needs will condition :

- The choice of the DHW calorifier’s capacity;

- The power of its exchanger;

- And possibly the power of the generator with which it is

combined.

Actual needs will therefore have to be determined for a given

temperature over a given duration (hour/day) and the peak

flows (litre/minute) assessed according to DHW use at a given

moment. In collective housing, it will also mean factoring in

simultaneous use.

METHODS FOR DETERMINING YOUR DHW NEEDS

¹ Using the “DHW Needs” software available in our “DIEMATOOLS” offer

This software (or any other software which you may have

acquired) will offer you an effective guide in assessing your needs.

¹ Other methods

- Using the tables below, it is possible to approximate your daily

domestic hot water needs.

Station

to be supplied

Sink

kitchen

Sink

+ washbasin

+ shower

Number of

people

1-2

3-4

1-2

3-4

5-6

Important:

To determine the capacity of the DHW calorifier, it is necessary

to factor in any peak flows caused by simultaneous use at

different draw-off points in addition to these daily needs.

As for the calculation of the installation, this will have to be

made in accordance with prevailing standards.

Station

to be supplied

Washbasin +

small bathtub

Sink

+ washbasin

+ bathtub

Daily DHW needs

(L to 60°C)

30 to 40

40 to 50

75 to 95

120 to 170

150 to 190

Number of

people

1-2

3-4

1-2

3-4

5-6

Daily DHW needs

(L to 60°C)

50 to 75

80 to 120

90 to 150

150 to 240

145 to 340

Note: These tables do not cover multi-jet shower (艐 50 L/min) or «spa» type

bathtubs

Special cases: domestic hot water requirements in the tertiary sector

Hotels with no restaurant

Restaurants

Hotel categorie (number of stars)

DHW needs at 60°C (L/room/day)

no*

65

1*

75

2*

100

3*

135

4*

150

Campings

Restaurant

Canteen Restaurant

DHW needs at 60°C

(L/cover)

5

12

Restaurant

gastronomic

Breakfast

20

3

Hairdressing salons

Campings

DHW needs at 60°C (L)

by

location

45

camper

12

Number of basins

3

4

DHW needs at 60°C (L/day)

700

1000

Collective housing - Health - Sports and other Complexes

DHW

needs at

60°C

Collective housing Retirement Hospitals

Home

F1 F2 F3 F4 F5 home and clinics disabled

L/day

L/bed/day

50 75 100 150 200

40

50

100

Gyms

Stadiums

30

45

Plant

Military

swimming

Offices

Internat

barracks

pool

(cloakroom)

L/person/day

20

30

Example:

The DHW needs of a building with 21 apartments, comprised in the following manner:

3 one-room apartments, thus 3 x 50 L

5 two-room apartments, thus 5 x 75 L

7 three-room apartments, thus 7 x 100 L

thus: i.e.: Total maximum daily DHW: 225 L at 60°C

4 four-room apartments, thus 4 x 150 L

2 five-room apartments, thus 2 x 200 L

}

4

30

5

20

CHOICE OF THE DHW PRODUCTION SYSTEM AND TYPE OF CALORIFIER

CONNECTION PRINCIPLE OF A BOILER (OR CASCADE OF BOILERS) TO A FWPC, FWPS OR FWP CALORIFIER

To ensure optimum operation of the FWPC, FWPS or FWP with

a boiler, it is essential to decouple the calorifier circuit from the

boiler; this can be done through a disconnecting cylinder which

will provide total satisfaction for the operation of the FWPC,

FWPS and FWP. By contrast, there will be a tendency to request

repetitive heating of the boiler if it is not continuously maintained

at the DHW setpoint temperature to ensure water draw-off or

to maintain the temperature of the recirculation loop.

FW

6A

0

30

FW_F0016A

l

Solution not recommended with FWPS or FWPC

Since our boilers have distinct features for heating and

DHW production, with lowering and/or modulation of the

temperatures according to the demand, we recommend the

installation of primary storage in place of a disconnecting

cylinder in order:

- to allow the operation of the boiler at lower temperatures for

heating than for the production of DHW

- to allow and to favour condensation with the FWPC, FWPS

and FWS

- to allow shutdown at night or outside of periods when DHW is

being drawn-off from the boiler, to reduce the consumption for

maintenance

- to avoid frequent or repetitive restarts during very low drawoff of water and/or for temperature maintenance in the

recirculation loop.

FW

6A

0

30

FW_F0016A

l

Optimisation of condensation

To ensure the DHW needs by reducing as much as possible the

time for the boiler to raise the temperature and to condense

we recommend the installation of a reversal valve with

thermostatic control on the boiler outlet, which will switch

over this valve to the top of the primary storage when the inlet

temperature to the valve has reached the DHW setpoint of the

boiler.

FW

70°C

0

0

2

4

6

8

10

12

14

16

18

20

22

24

30

FW_F0023

l

Recommended solution

This principle (establishment of a primary storage) will be

adopted for all these configurations in collective housing,

retirement homes, hospitals, etc., with a DHW setpoint of 70°C

for the boiler, in order to both ensure a secondary outlet

temperature to the DHW heat exchanger of 60°C and, above

all, to protect the heat exchanger from lime scale deposits

that largely occurs at temperatures greater than 75°C at the

secondary level. This low temperature of 70°C implies a slight

oversizing of the plate exchanger but is offset by gains in terms

of energy consumption and maintenance.

DEFINITION OF THE COMPONENTS OF A DHW PRODUCTION SYSTEM

To ensure correct functioning of the system and to meet the needs

of the installation, the components should be defined as follows:

햲 DHW calorifiers FWPC, FWPS, FWP and FWS:

Refer to the maximum instantaneous flow rates given on

page 12.

햳 Boiler output:

The boiler power should be equivalent to at least that of

the DHW calorifier selected. The boiler will also be sized to

ensure that the heating and DHW needs are met.

Remember: Our boilers are modulating and thus incorporate

output reduction allowed by the primary storage on the

calorifier.

햴

Primary buffer volume:

To be defined as a function of the boiler power; see following

page.

5

CHOICE OF THE DHW PRODUCTION SYSTEM AND TYPE OF CALORIFIER

Definition of the buffer volume to be associated with the FWPC, FWPS and FWP calorifiers

The table below indicates the advised primary buffer volume to

This volume takes account of the boiler connection to our buffer

install according to the power of the plate exchanger or DHW

tanks in the PSE range (see page 15) either at 3 points with

flow required.

zone reversal valve as recommended above, or on the midpoint

connection for the boiler contribution.

Boiler output range

DHW flow rate with ' 50 K

⭐ 120 kW

⭐ 170 kW

⭐ 260 kW

⭐ 400 kW

⭐ 600 kW

⭓ 750 kW

⭐ 2.1 m3/h (35 L/min) (1)

⭐ 3.0 m3/h (50 L/min)

⭐ 4.5 m3/h (75 L/min)

⭐ 6.9 m3/h (115 L/min)

⭐ 10 m3/h (170 L/min)

⭐ 13 m3/h (215 L/min)

Buffer volume recommended with

FWPC

FWPS with solar

500 L

500 L + 1, 500 L solar (⬍ 30 m2 collectors)

750 L

750 L + 2 ,000 L solar (⬍ 40 m2 collectors)

1,000 L

1,000 L + 2 ,500 L solar (⬍ 50 m2 collectors)

1,000 L

2 ,000 L + 3, 000 L solar (⬍ 60 m2 collectors)

2,000 L

3,000 L

-

FWP

500 L

500 L

500 L

750 L

1,000 L

2,000 L

(1) In this flow range, it is possible to ensure DHW production using calorifiers with integrated buffer volume: FWS 750 and FWS 1500

DHW PRODUCTION WITH CONDENSING BOILER WITHOUT RENEWABLE ENERGIES

¹ With DHW calorifier FWPC

21

7

7 1 2

3

4

2

6

4

8

12

10

14

16

18

20

22

10

24

30

l

70°C

124

27

9

166

32

9

AD212

27

30

9

29

28

16

C230 ECO

26

PSE

FWPC

50

9

FW_F0017A

0

0

18

In this scenario, we recommend DHW

calorifiers from our FWPC range, which

ensure a return at 30°C during water

draw-off. This allows condensation to be

optimised for the boiler and thus provides

energy savings of up to 7 % more than

for a conventional instantaneous DHW

production.

Thanks to the modulating pumps fitted to

our FWPC, electrical consumption is also

reduced by more than 50 %.

Coupled with our condensing boilers, this

provides the most economic instantaneous

DHW production that can be installed in

low energy consumption buildings, without

risks to health and with simple maintenance

and easily accessible use.

System optimisation

21

7

7 1 2

3

4

10

0

2

4

6

8

10

12

14

16

18

20

22

24

0

30

l

124

27

9

AD212

166

32

9

27

16

C230 ECO

PSE

EC680

50

9

Key: see page 15

6

46

18

26

FWPC

30

29

9

28

FW_F0018A

70°C

The reversal valve with its sensor (package

EC 680 - optional, see page 9), connected

on the outlet of the FWPC calorifer, allows:

- Optimisation of the stratification in the

bottom of the buffer volume, - to promote

condensation during restarts of the DHW

heating

- avoidance of reheating of the bottom of

the buffer tank by the recirculation loop.

DHW PRODUCTION WITH CONDENSING BOILER AND RENEWABLE ENERGIES

THE USE OF RENEWABLE ENERGIES DIRECTLY REDUCES THE VOLUME OF THE BOILER’S PRIMARY BUFFER

¹ FWPC calorifier + reversal valve (package EC 680), optional, see page 9

112a

131

21

7

1 2

7

3

4

10

2

0

6

4

8

10

12

14

16

18

20

22

24

0

30

l

70°C

124

27

AD212

AD250

166

9

32

9

27

30

29

9

28

16

C230 ECO

26

PSE

50

9

FWPC

EC680

AD 276

112b

CCI

18

AD 275

CAN BUS

230V

50Hz

24V

OU

132

FW_F0019A

DKCS

8-30

39

PGA38

The boiler is connected on the buffer tank with a

boiler return on the lower volume corresponding to

the renewable energy contribution zone. The upper

part of the storage tank (DHW boiler sensor in the

upper part, outside the renewable energy zone)

allows optimum functioning of the FWPC/boiler

combination as previously described, while allowing

a low temperature renewable energy contribution

of the solar or heat pump type to the bottom of

the buffer volume.

The cold return (30°C) from the FWPC allows,

via the 3-way reversal valve (package EC 680

- optional), a renewable energy contribution

in all scenarios in the event of water draw-off.

This solution is used for a renewable energy

contribution that is rapid and higher in temperature

because of the relatively low volume to be heated

and that actively contributes, in a simple way, to

temperature maintenance of the recirculation loop

which often represents a significant yet poorly

identified source of energy consumption.

SOLAR ENERGY ON A SPECIFIC DEDICATED BUFFER VOLUME

¹ FWPC calorifier + reversal valve (package EC 680) and preheating sensor (package EC 681), optional, see page 9

This solution involves connecting the

21

7

112a

FWPC (or FWPS) directly to the buffer

7 1 2

3

131

volume of the boiler and connecting

4

the primary solar tank in series to the

10

renewable energy zone of the boiler

70°C

124

9

buffer volume.

32

Note: An expansion volume is not

AD212

166

9

27

27

30 29 9

recommended for a renewable

28

16

energy contribution with heat pump.

26

C230 ECO

PSE

FWPC

The dedicated renewable energy

EC680

50

EC681

9

18

volume in the boiler buffer tank being

Diemasol A

sufficient for the proper functioning

of the system. In this case, the boiler’s

*

DHW sensor will have a dedicated

112b

DKS

volume (at the top). In all other cases,

132

8-20

the boiler’s DHW sensor remains in the

renewable energies volume.

* - DHW sensors supplied:

*

0

2

4

6

8

10

12

14

16

18

20

22

24

0

30

l

FW_F0021A

230V

50Hz

- with FWPC

- with DIEMASOL regulation

PS

¹ FWPS DHW calorifier

112a

131

21

7

7 1 2

3

4

10

0

2

4

6

8

10

12

14

16

18

20

22

24

0

30

l

70°C

124

27

9

32

166

AD212

9

26

27

16

PSE

C230 ECO

29

9

28

FWPS

50

9

30

*

18

*

* - DHW sensors supplied:

- with FWPC

- with DIEMASOL regulation

Key: see page 15

112b

PSE

DKCS

8-30

132

FW_F0020A

230V

50Hz

This solution involves connecting

the FWPS to the upper part of the

boiler buffer volume and connecting

the primary solar buffer tank in

series to the renewable energy zone

of the solar buffer volume. Given

the low temperature (20°C) at the

outlet of the FWPS exchanger, the

solar contribution will be almost

continuous, even with very little sun.

This solution allows passage

through the solar buffer volume

to recuperate solar energy if it is

contributed or, if there is no solar

contribution, short-circuiting of this

tank to go directly to the boiler

buffer volume (boiler DHW sensor

at the top of the renewable energy

zone).

7

DHW PRODUCTION WITH CONDENSING BOILER AND RENEWABLE ENERGIES

¹ FWS DHW calorifier

The upper part (DHW) of the FWS

can be loaded by boilers installed in

cascade supplying the heating circuits

and the DHW circuit connected to

the heating collector. The solar circuit

is connected to the lower part of

the tank for DHW preheating (or

DHW heating if the solar back-up is

insufficient). A heating circuit can be

connected to S1/S2 for a swimming

pool, for example.

The FWS can operate without a

renewable energy input (diagram

on p. 14) or with renewable energy

contribution to its buffer volume

(diagram opposite) or with a specific

solar buffer volume at the bottom of

the FWS (see FWPS diagram, p. 7).

For more details, see the DIETRISOL

technical sheet for collectives.

112a

131

DKCS 8-50

21

2

1

2

1

FWS

11

7

109

27

8

MCA

9

9

132

35

S1

13

33

28 29 30

S3

112b

16

16

FW_F0024

S2

Note: Our DHW calorifiers from the FWS range are suitable for

replacing the 3 ranges FWPC, FWPS and FWP, but only for low

DHW throughputs limited to 2.5 m3/h

DHW PRODUCTION ECS WITH CONVENTIONAL BOILERS

¹ FWP DHW calorifier

21

1

2

7

3

4

6A

0

30

l

10

27

166

16

50

32

9

9

Key: see page 15

8

18

27

PSE

FW_F0022A

9

AD212

26

FWP

30

29

9

28

The calorifiers from our FWP

range are characterised by a high

return temperature that does not

allow condensation. This solution is

reserved for replacements of existing

conventional boilers or heat networks.

Management of the primary buffer

tank is ensured by the boiler’s DHW

sensor located in the bottom of the

buffer tank. The buffer tank pump

should be sized according to the

useful power of the boiler, to ensure

the setpoint temperature at the boiler

outlet.

PLATE EXCHANGERS FOR INSTANTANEOUS DHW OF THE FWPC RANGE

DESCRIPTION – STRONG POINTS

The DHW calorifiers from the FWPC range consist of a

removable plate exchanger on a base with double modulated

primary pump (pump with energy efficiency index EEI < 0.23 ),

reactive 3-way mixing valve, and proactive regulation unit for a

constant and instantaneous DHW temperature regardless of the

flow rate (up to 13 m3/h at 60°C).

- Compact, robust and reliable product, mounted and wired

in the factory, supplied tested in accordance with the EU

directives 73/23EC and PED 97/23EC Article 3.3

- Unique primary flow rate control concept to ensure a low

return temperature (30°C) in order to optimise condensation in

the boiler.

- Operates with a primary at 70°C to limit scaling in case of very

hard water

- «Plug & Run» control for autonomous proactive control of the

calorifier in instantaneous or semi-instantaneous mode. With

ECO and BOOSTER functions, alarm reporting, anti-clogging,

permutation of the pumps, thermostat, emergency and other

tests for simple use and self-adapting to the various installations

- ModBus RTU communication for cascading or remote access

with recording of the mode of operation.

MAIN DIMENSIONS

FWPC 200

FWPC 400, 600, 800, 900

B

A

420

143

1

2

1

4

4

1183

1535

1535

92

92

2

1224

880

880

240

97,5

203

140

335

C

92

240

500

530

818

839

97,5

140

FW_F0011

FW_F0010

3

3

F

500

D

E

335

Key

햳 Primary outlet:

- FWPC 200: Rp 1

- FWPC 400, 600, 800, 900: R 1 1/2

햴 Cold water inlet: Rp 2

햵 DHW outlet: Rp 2

햲 Primary inlet:

- FWPC 200: Rp 1

- FWPC 400: Rp 1 1/4

- FWPC 600, 800, 900: Rp 1 1/2

(mm)

FWPC 400

FWPC 600, 800, 900

A

415

504

B

871

979

C

662

692

D

575

585

E

585

591

F

203

232

TECHNICAL SPECIFICATIONS

Primary circuit:

- Working temperature: 70/30°C

- Max. operating temperature: 110°C

- Max. operating pressure: 10 bar

Type preparer DHW

Number of plates

Outlet

Primary flow

Primary circuit manometric height available

Instantaneous DHW flow

Secondary circuit water resistance

Shipping weight

Secondary circuit (DHW):

- Working temperature: 10/60°C

- Max. operating temperature: 90°C

- Max. operating pressure: 10 bar

FWPC 213-100 223-200 429-300 449-400 637-450 849-550 961-650 997-750

13

23

29

49

37

49

61

97

kW

100

200

300

400

450

550

640

750

m3/h

2.2

4.2

6.7

8.0

10.2

12.1

14.1

15.1

kPa

38

7

13

5

40

29

10

7

m3/h

1.7

3.4

5.2

6.9

7.7

9.5

11.0

12.9

kPa

11

9

13

8

15

15

14

11

kg

184

195

209

230

239

253

263

293

PACKAGING

FWPC

Package No.

213-100

EC 667

223-200

EC 668

429-300

EC 669

449-400

EC 670

637-450

EC 671

849-550

EC 672

961-650

EC 673

997-750

EC 674

OPTIONS

3-way 2-position valve - Package EC 680

Allows you to manage the renewable energy

contribution on the FWPC. It is supplied with a dip

sensor and an attachable sensor.

3-way valve preheating sensor - Package EC 681

Can be used to replace the attachable sensor

supplied with package EC 680 in order to provide

a more accurate temperature for managing

reversal of the valve.

9

PLATE EXCHANGERS FOR INSTANTANEOUS DHW OF THE FWPS RANGE

DESCRIPTION – STRONG POINTS

The DHW calorifiers from the FWPS range consist of a

removable plate exchanger on a base with double modulated

primary pump (pump with energy efficiency index EEI < 0.23 ),

reactive 3-way mixing valve, and proactive regulation unit for a

constant and instantaneous DHW temperature regardless of the

flow rate (up to 5.5 m3/h at 60°C).

- Compact, robust and reliable product, mounted and wired

in the factory, supplied tested in accordance with the EU

directives 73/23EC and PED 97/23EC Article 3.3

- Unique primary flow rate control concept to ensure a low

return temperature (20°C) in order to maximise the renewable

energy contributions.

- Operation with a primary at 70°C to limit scaling in case

of very hard water and incorporates a reversal valve for

management of the renewable energy contribution

- «Plug & Run» control for autonomous proactive control of the

calorifier in instantaneous or semi-instantaneous mode. With

ECO and BOOSTER functions, alarm reporting, anti-clogging,

permutation of the pumps, thermostat, emergency and other

tests for simple use and self-adapting to the various installations

- ModBus RTU communication for cascading or remote access

with recording of the mode of operation.

MAIN DIMENSIONS

FWPS 200

FWPS 400

415

FWPS 200

1005

420

143

2

2

1

2

1

4

4

1535

1326

1535

92

2

92

1246

1224

FW_F0007A

3

240

97,5

3

203

140

500

530

818

839

335

662

92

240

97,5

FW_F0008A

880

880

140

335

203

500

575

700

779

Key

햲 Primary inlet:

- FWPS 200: Rp 1

- FWPS 400: Rp 1 1/4

햳 Primary outlet:

- FWPS 200: R 1

- FWPS 400: R 1 1/2

햴 Cold water inlet:

- FWPS 200: Rp 2

- FWPS 400: Rp 2

햵 DHW outlet:

- FWPS 200: Rp 2

- FWPS 400: Rp 2

TECHNICAL SPECIFICATIONS

Primary circuit:

- Working temperature: 70/20°C

- Max. operating temperature: 110°C

- Max. operating pressure: 10 bar

Type preparer DHW

Number of plates

Outlet

Primary flow

Primary circuit manometric height available

Instantaneous DHW flow

Secondary circuit water resistance

Shipping weight

Secondary circuit (DHW):

- Working temperature: 10/60°C

- Max. operating temperature: 90°C

- Max. operating pressure: 10 bar

FWPS

kW

m3/h

kPa

m3/h

kPa

kg

235-100

35

103

1.8

53

1.8

9

204

PACKAGING

FWPS

Package No.

235-100

EC 675

261-200

EC 676

497-300

EC 677

OPTIONS

3-way valve preheating sensor - Package EC 681

Can be used to replace the attachable sensor

supplied with the FWPS, in order to provide

a more accurate temperature to manage the

reversal valve.

10

261-200

61

191

3.4

19

3.3

13

229

497-300

97

317

5.6

19

5.5

8

271

PLATE EXCHANGERS FOR INSTANTANEOUS DHW OF THE FWP RANGE

DESCRIPTION – STRONG POINTS

The DHW calorifiers from the FWP range consist of a

removable plate exchanger on a base with double conventional

primary pump, 3-way primary mixing valve and regulation unit

ensuring a constant DHW temperature in instantaneous or semiinstantaneous mode, for flow rates up to 11 m3/h at 60°C

- Compact, robust and reliable product, mounted and wired

in the factory, supplied tested in accordance with the EU

directives 73/23EC and PED 97/23EC Article 3.3

- Classic plate exchanger concept for the replacement market

with primary temperatures above 70°C on boilers with constant

temperature and/or a hot-water loop

- Intelligent control for operation in instantaneous or semiinstantaneous mode. With ECO and BOOSTER functions, anticlogging, permutation of the pumps, thermostat, anti-legionella

treatment (temp. > 70 °C), and history

- Self-adapting to all conventional installations in the replacement

market.

Note: For major renovations we recommend our FWPC and

FWPS models, favouring energy savings.

MAIN DIMENSIONS

FWP 100

FWP 200 and 600

D

358

358

112

155

1

2

1

4

145

2

H

4

755

70

880

90

FW_F0009A

525

3

165

95

60

145

240

140

335

450

735

250

690

3

FW_F0012

1055

97,5

263

500

C

A

733

B

Key

햲 Primary inlet:

- FWP 100: Rp 1 1/4

- FWP 200: Rp 1 1/2

- FWP 600: flange DN 50

햳 Primary outlet:

- FWP 100: Rp 1 1/4

- FWP 200: Rp 1 1/2

- FWP 600: flange DN 50

햴 Cold water inlet:

- FWP 100: Rp 1 1/4

- FWP 200 and 600: Rp 2

햵 DHW outlet:

- FWP 100: Rp 1 1/4

- FWP 200 and 600: Rp 2

(mm)

FWP 2…

FWP 6…

H

1440

1462

A

480

543

B

910

1082

C

593

830

D

593

745

TECHNICAL SPECIFICATIONS

Primary circuit:

- Working temperature: 70/50°C

- Max. operating temperature: 110°C

- Max. operating pressure: 10 bar

Type preparer DHW

Number of plates

Outlet

Primary flow

Primary circuit manometric height available

Instantaneous DHW flow

Secondary circuit water resistance

Shipping weight

Secondary circuit (DHW):

- Working temperature: 10/60°C

- Max. operating temperature: 90°C

- Max. operating pressure: 10 bar

FWP 113-50 127-100 147-150 215-200 221-250 227-300 231-350 257-450 647-500 657-550 657H-650

13

27

47

15

21

27

31

57

47

57

57

kW

50

100

150

200

250

300

350

450

500

550

650

2.8

4.5

5.8

10.1

10.8

12.0

13.9

14.5

18.7

19.4

15.2

m3/h

kPa

6

13

13

25

32

27

9

12

9

6

20

0.9

1.7

2.6

3.4

4.3

5.2

6

7.7

8.6

9.5

11.2

m3/h

kPa

6

5

4

4

3

3

3

2

3

3

15

kg

84

88

94

215

220

225

227

234

270

279

279

PACKAGING

FWP

Package No.

113-50

EC 656

127-100 147-150 215-200 221-250 227-300 231-350 257-450 647-500 657-550 657H-650

EC 657

EC 658

EC 659

EC 660

EC 661

EC 662

EC 663

EC 664

EC 665

EC 666

OPTIONS

Insulation for plate exchangers:

- FWP 100: Package EC 678

- FWP 200 and 600: Package EC 679

11

DHW PERFORMANCES OF THE PLATE EXCHANGERS FWPC/FWPS/FWP

¹ FWPC: - with instantaneous DHW temperatures 10-60°C

FWPC

213-100

223-200

429-300

449-400

637-450

849-550

961-650

997-750

Primary Primary temperature 65°C Primary Primary temperature 70°C Primary Primary temperature 80°C Primary Primary temperature 90°C

flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop

m3/h

m3/h

m3/h

m3/h

kW

L/min

kpa

kW

L/min

kpa

kW

L/min

kpa

kW

L/min

kpa

2.2

100

29

11

2.9

163

47

19

3.3

227

65

37

4.2

200

57

9

4.7

267

77

16

4.4

328

94

23

6.7

300

86

13

7.0

413

118

23

7.1

508

146

35

8.0

400

115

8

8.0

507

145

12

8.0

613

176

18

10.2

450

129

15

10.5

595

171

29

12.5

845

242

58

12.1

550

158

15

13.8

788

226

29

13.8

971

278

44

14.1

640

183

14

14.5

860

246

22

14.5

1053

302

34

15.1

750

215

11

15.5

1000

287

14

15.6

1209

347

19

- with instantaneous DHW temperatures 10-55°C

FWPC

213-100

223-200

429-300

449-400

637-450

849-550

961-650

997-750

Primary Primary temperature 65°C Primary Primary temperature 70°C Primary Primary temperature 80°C Primary Primary temperature 90°C

flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop

m3/h

m3/h

m3/h

m3/h

kW

L/min

kpa

kW

L/min

kpa

kW

L/min

kpa

kW

L/min

kpa

3.1

120

38

13

3.3

150

48

20

3.1

200

64

30

3.1

240

76

51

4.7

183

58

9

4.4

219

70

13

4.4

282

90

21

4.4

335

107

30

6.9

280

89

13

6.9

335

107

17

6.9

430

137

31

7.1

525

167

46

8.0

356

113

8

8.0

420

134

11

8.0

530

169

16

7.9

620

197

22

12.0

449

143

21

12.2

545

174

30

12.5

725

231

53

12.5

875

279

77

13.2

530

169

16

13.5

645

205

24

13.6

835

266

40

13.7

1005

320

58

14.6

597

190

14

14.7

715

228

19

14.7

917

292

32

14.4

1095

349

45

15.6

702

224

8.3

15.5

830

264

11

15.6

1055

336

18

15.5

1225

390

24

¹ FWPS: - with instantaneous DHW temperatures 10-60°C

FWPS

235-100

261-200

497-300

Primary Primary temperature 65°C Primary Primary temperature 70°C Primary Primary temperature 80°C Primary Primary temperature 90°C

flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop

m3/h

m3/h

m3/h

m3/h

kW

L/min

kpa

kW

L/min

kpa

kW

L/min

kpa

kW

L/min

kpa

1.2

58

17

1

1.8

103

30

9

2.3

116

33

1

3.4

191

55

13

4.1

203

58

1

5.6

317

92

8

-

- with instantaneous DHW temperatures 10-55°C

FWPS

235-100

261-200

497-300

¹ FWP:

FWP

113-50

127-100

147-150

215-200

221-250

227-300

231-350

257-450

647-500

657-550

657H-650

Primary Primary temperature 65°C Primary Primary temperature 70°C Primary Primary temperature 80°C Primary Primary temperature 90°C

flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop

m3/h

m3/h

m3/h

m3/h

kW

L/min

kpa

kW

L/min

kpa

kW

L/min

kpa

kW

L/min

kpa

2.2

115

37

2

3.2

183

58

4

4.1

209

67

2

4.1

240

77

3

6.1

319

102

2

6.1

366

117

3

-

- with instantaneous DHW temperatures 10-60°C

Primary Primary temperature 65°C Primary Primary temperature 70°C Primary Primary temperature 80°C Primary Primary temperature 90°C

flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop

m3/h

m3/h

m3/h

m3/h

kW

L/min

kpa

kW

L/min

kpa

kW

L/min

kpa

kW

L/min

kpa

2.6

50

15

6

2.6

75

20

12

2.6

100

28

23

4.6

100

28

5

4.6

155

45

11

4.6

207

60

19

5.5

150

43

4

5.5

215

62

9

5.5

280

80

14

10.7

200

57

4

10.7

320

92

13

10.7

430

124

24

11.5

250

72

3

11.5

360

103

12

11.5

485

140

23

13.2

300

87

3

13.2

458

132

10

13.2

610

176

18

14.0

350

100

3

14.0

526

152

8

14.0

700

202

15

14.9

450

128

2

14.9

667

192

5

14.9

858

247

8

19.7

500

143

3

19.7

770

221

6

19.7

1010

289

11

20.5

550

158

3

20.5

835

239

5

20.5

1090

312

9

15.2

650

187

15

15.2

915

255

26

15.2

1120

320

40

- with instantaneous DHW temperatures 10-55°C

FWP

113-50

127-100

147-150

215-200

221-250

227-300

231-350

257-450

647-500

657-550

657H-650

12

Primary Primary temperature 65°C Primary Primary temperature 70°C Primary Primary temperature 80°C Primary Primary temperature 90°C

flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop flow Output DHW flow Sec. pressure drop

m3/h

m3/h

m3/h

m3/h

kW

L/min

kpa

kW

L/min

kpa

kW

L/min

kpa

kW

L/min

kpa

2.6

42

13

5

2.6

58

19

10

2.6

83

26

20

2.6

108

35

29

4.6

93

30

5

4.6

123

39

9

4.6

175

56

17

4.6

220

70

26

5.5

130

42

4

5.5

175

56

8

5.5

245

78

13

5.5

308

99

21

10.7

175

55

5

10.7

250

80

10

10.7

363

116

21

10.7

468

149

34

11.5

201

63

5

11.5

282

90

10

11.5

408

130

20

11.5

525

167

32

13.2

263

83

4

13.2

365

116

8

13.2

514

164

16

13.2

654

208

25

14.0

310

98

4

14.0

421

134

6

14.0

591

188

13

14.0

747

238

21

14.9

419

133

2

14.9

532

170

4

14.9

729

232

7

14.9

910

290

11

19.7

470

150

3

19.7

618

197

5

19.7

860

274

9

19.7

1080

344

21

20.5

512

163

3

20.5

655

209

4

20.5

912

290

8

20.5

1130

360

13

15.2

635

200

16

15.2

765

244

22

15.2

965

305

22

15.2

1155

368

52

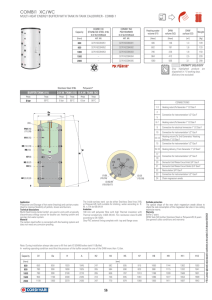

INSTANTANEOUS DHW CALORIFIERS FWS

DESCRIPTION – STRONG POINTS

Multi-zone steel calorifiers for production of instantaneous DHW,

to which all types of boiler can be connected and with the option

of connecting a solar circuit.

The main applications of this tank can be found in the service

sector: retirement homes, hospitals, schools, etc. where

prevention of legionella is essential. It is comprised of:

- a stratification storage tank

- an exchanger in the form of a high performance stainless steel

coil incorporated in the tank for the production of DHW:

• FWS 750: annealed stainless-steel tube, DN 32, with 1“

connection (7 bar),

• FWS 1500: 2 rigid, 1“ stainless-steel tubes individually

connected to the same circuit or to separate

circuits (10 bar).

MAIN DIMENSIONS (mm AND INCHES)

FWS 750

FWS 1500

Ø 950

Ø 1200

13

1

1

300

430

1

13

1

1

2

2

2

Ø 750

3

4

4

6

5

9

6

7

7

884

770

659

302

8

119

9

3

2160

3

270

9

6

6

1970

1277

1007

645

FWS_F0001

5

9

9

8

1080

150

4

395

4

7

7

9

7

8

8

292

180

FWS_F0002

3

611

1151

2190

Ø 1000

1945

2020

1482

2

35

12

Key

햲 Domestic hot water outlet

햳 Boiler inlet

햴 Boiler return (maxi solar)

햵 Solar circuit inlet

햶 Solar volume input

햷 Boiler return (mini solar)

FWS 750

Rp 1

R 1 1/4

R 1 1/4

R 3/4

R 3/4

R 1 1/4

FWS 1 500

R1

R 1 1/2

R 1 1/2

R 1 1/2

R 1 1/2

햸 Domestic cold water inlet

햹 Solar circuit outlet/drainage

Boiler outlet if no solar circuit

햺 Sensor tube Ø

햾 Thermometer

햿 Air vent

FWS 750

Rp 1

FWS 1 500

R1

R 1 1/4

R 1 1/2

20 mm

Rp 3/4

Rp 3/8

16 mm

R2

TECHNICAL SPECIFICATIONS

Operating pressure:

- tank: 6 bar

- DHW exchanger : FWS 750: 7 bar

FWS 1500: 10 bar

Model

FWS 750

Total storage volume

l

700

Total solar storage volume maxi/mini

l

380/230

DHW coil capacity

l

50

10 (single coil)

DHW exchange surface

m2

Exchange power maxi

kW

195

DHW coil pressure drop at

bar

0.2/0.8/2.0

2 m3/h / 4 m3/h / 6 m3/h

3

4

5

6

¼ DHW flow (with primary flow…) m3/h

Primary inlet temp.

°C 70 80 90 70 80 90 70 80 90 70 80

at temp.

outlet

Exchanged output

kW 143 186 - 171 - - 192 - - - DHW = 45°C Flow per hour at 'T = 35 K (1)

l/h 3513 4567 - 4216 - - 4729 - - - Primary inlet temp.

°C 70 80 90 70 80 90 70 80 90 70 80

at temp.

outlet

Exchanged output

kW 100 153 203 118 182 241 134 204 270 148 228

DHW = 60°C Flow per hour at 'T = 50 K (1)

l/h 1721 2629 3500 2043 3140 4143 2308 3518 4653 2554 3916

Cooling constant

Wh/24h.K.l

0.14

Net weight

kg

260

Max. operating temperature:

- tank: 95°C

FWS 1500

1440

860/700

86

11 (double coil)

280

0.1/0.5/1.0

90

90

-

3

4

5

6

70 80 90 70 80 90 70 80 90 70 80 90

170 201 - 196 239 - 211 262 - 223 274 4176 4938 - 4815 5872 - 5184 6437 - 5478 6731 70 80 90 70 80 90 70 80 90 70 80 90

117 179 220 139 203 261 154 217 288 160 227 301

2012 3078 3783 2390 3491 4488 2648 3732 4953 2772 3904 5176

0.15

320

(1) boiler connected in 햳 and 햹 (without solar)

13

INSTANTANEOUS DHW CALORIFIERS FWS

INSTALLATION WITH 2 FWS… CALORIFIERS CONNECTED IN PARALLEL

27

4

18

50

9

27

27

27

16

37

37

37

37

37

FWS_F0006A

37

17

Key: see page 15

The FWS connects to the boiler like a

calorifier with coil. The boiler reheats

the hot water storage volume, which

then provides heating of the DHW

exchanger for instantaneous DHW

production.

The DHW sensor circuit is placed in the

lower 1/3 of the FWS calorifier, for

which the set point should be adjusted

to 10 K above the desired DHW

temperature at the calorifier outlet.

The storage volume compensates for

low usage and for the revival time of

the boiler during the times of largest

demand. The choice of boiler power

should be made with respect to the 't

that it allows.

PRESSURE DROP ACCORDING TO THE DHW EXCHANGER FLOW

kPa

Comment :

The maximum permissible flow through the DHW exchanger on

the FWS 750 is 4800 l/h (80 l/min) because of the noise in the

exchanger.

Loss of pressure

200

180

160

FSW 750

140

*

FSW 1500

120

100

80

* 2 exchangers connected in parallel

40

20

0

0

10

20

30

40

50

60

70

80

90

100

110

Water

output

l/min

FWS_F0005

60

CONTINUOUS PERFORMANCE

FWS 750

y

ar

im t

pr tpu 3 /h

3

/h FWS 750

ou m

m

in

45 4

/h

Continuous performance

3

3

6

m

kW

5

45

60

m

/h

DHW flow per hour (l/h) at

6500

t

tle $C

ou in

60

tic re

es atu

m r

45

do pe

m

te

200

3

3m

/h

6000

5000

4500

80

60

r

ratu

3500

e

ry

ima

pr

100

mp

t te

inle °C

in

3000

1500

50

30

40

50

60

70

C330/630 ECO

(1)

3000

2500

2000

2500

2000

20

3500

4000

e

70

10

4000

5500

90

175

150

4500

6t primary

in (K)

1500

1000

FWS_F0007B

250

Example: GTU C 330 with

- DHW need: 3000 l/h

- Target DHW outlet temp.: 60°C ('T DHW: 50 K)

¹DHW setpoint temp. 70°C above primary inlet temp.: 80°C

Min. required boiler output: 175 kW. Primary flow rate required

to fill the tank: 3.8 m3/h, 'T primary: 40 K

¹Boiler selected: GTU C 337… with 193 kW

Recalculated primary flow with 'T primary of 40 K: 4.2 m3/h

Note: max. flow rate through the DHW exchanger: 4800 l/h

C230 ECO, MC..

GT..., DTG ...

FWS 1500

DHW flow per hour (l/h) at

Continuous performance

kW

FWS 1500

/h

6

m

p

o r im

in utpu ary

m3 t

/h

3

3

45

5

m

60

300

3

d

te om

m e

pe st

ra ic o

tu u

re tle

in t

$C

4

250

45

216

m

5500

6500

3

/h

6000

5500

200

80

4500

3000

2500

2000

1500

50

(1)

20

C230 ECO, MC..

GT..., DTG ...

14

30

37

40

50

4000

3700

3500

3000

100

C330/630 ECO

4500

5000

3500

prim

10

5000

4000

re

ratu

pe

m

t te

inle °C

ary in

70

8000

7000

3m

90

60

6000

7500

/h

60

150

8500

60

70

6t primary

in (K)

2500

2000

1500

1000

FWS_F0008A

/h

350

Example: C 330 ECO with

- DHW need: 3700 l/h

- Target DHW outlet temp.: 60°C ('T DHW: 50 K)

¹DHW setpoint temp. 60°C above primary inlet temp.: 80°C

Min. required boiler output: 216 kW

Primary flow rate required to fill the tank: 5 m3/h, 'T primary:

37 K

( 'T primary max. 25 K for C 330 ECO)

¹Boiler selected: C 330-280 ECO… with 280 kW

Recalculated primary flow with 'T primary of 25 K: 9.6 m3/h

(1) the max. primary 'T permitted on these boilers ensures that

they are protected against insufficient water supply.

PRIMARY STORAGE INSTANTANEOUS DOMESTIC HOT WATER TANKS PSE

DESCRIPTION

- Storage tanks in very thick sheet with interior coating in

rustproof paint

- The tank has multiple connection points

- Insulation in 100mm thick in mineral wool with external skin in

polystyrol

MAIN DIMENSIONS (mm AND INCHES)

ØK

ØL

100

A

45°

ØJ

B

,5°

22,5°

ØJ

22

ØJ

1

Ø··

G

H

F

D

PSE

500

750

1000

2000

3000

A

1950

1853

2206

2171

2172

C

Key

I

B

1557

1448

1801

1686

1607

FW_F0001A

E

햲 Sensor tube

C

790

630

730

910

790

D

340

350

350

400

480

E

990

830

930

1100

9990

F

290

300

300

350

430

G

1040

880

980

1160

1040

H

940

780

880

1060

940

I

390

400

400

450

530

ØJ

R 1 1/2

R 1 1/2

R2

R2

R 2 1/2

ØK

830

990

990

1300

1600

ØL

630

790

790

1100

1400

TECHNICAL SPECIFICATIONS

Max. operating pressure: 6 bar

Model

Capacity

Maintenance consumption at 't = 45 K

Shipping weight

Max. operating temperature: 95°C

PSE

L

kWh/24h

kg

500

500

3

115

750

750

3,5

160

1000

1000

3,8

195

2000

2000

5

330

3000

3000

6,5

536

PACKAGING

PSE

Package No.

500

EC 640

750

EC 641

1000

EC 643 + EC 644

2000

EC 645 + EC 647

3000

EC 649 + EC 650

Key for the installation diagrams

1

2

3

4

7

8

9

10

13

16

18

Heating flow

Heating return

Safety valve 3 bar

Pressure gauge

Automatic air vent

Manual air vent

Isolation valve

3-way mixing valve

Flush valve

Expansion vessel

System for filling the heating circuit

21

26

27

28

29

30

32

33

39

46

50

Outside sensor

Load pump

Non-return valve

Domestic cold water inlet

Pressure reducer

Sealed sanitary safety device calibrated to 7 bar

DHW loop back pump

DHW sensor

Injection pump

3-way 2-position directional valve

Disconnector

109 Thermostatic mixer valve

112a Solar collector sensor

112b Solar DHW tank sensor

124 Thermostatically controlled distribution valve

131 Collector field

132 Complete solar station with DIEMASOL control

system

133 Interactive remote control

166 Storage tank pump

15

INFORMATION ON THE PREVENTION OF SCALDING BY DOMESTIC HOT WATER AND THE DEVELOPMENT OF LEGIONELLA

To restrict the development of bacteria, the temperature of the hot

water distributed must be at least 60°C on leaving storage and,

if the installation includes a recirculation loop, the return water

temperature must be at least 50°C. In all cases, users must be

protected against the risk of scalding at the draw-off points where

the temperature of the water drawn off must not exceed 50°C.

RECOMMENDATION REGARDING SCALDING

Scalding caused by domestic hot water is a common accident

which has serious consequences, particularly because of its

potential extent. Around 15% of scalds are thought to be caused

by the domestic hot water temperature being to high, occurring

principally in the bathroom.

Room not intended for ablutions

Network

supply

point

Room intended for ablutions

KEY

T $C ) 60 $C

T $C ) 60 $C

T $C ) 50 $C

Draw-off point at

NO PARTICULAR RISK

from legionella

Draw-off point at

RISK

from legionella

Area subject to prescriptions

in the example

8980F229

Cold water

Domestic hot water

production

Source : excerpt from a draft DGS circular

RECOMMENDATION REGARDING LEGIONELLA IN STORAGE SYSTEMS AND DISTRIBUTION NETWORKS

Annex 1 : minimum duration of the daily increase in the water

temperature in storage equipment, excluding preheating

calorifiers

Minimum time for which the

temperature must be increased (min)

Water temperature (°C)

2

4

60

Higher than or equal to 70

65

60

temperature must be higher than or equal to 50°C at all points

in the distribution system with the exception of the final supply

pipes. The volume in these final supply pipes must be as low as

possible and at all times less than or equal to 3 litres ;

- When the total storage volume is higher than or equal to

400 litres, the water contained in the storage equipment,

excluding preheating calorifiers, must:

• Always be at a temperature higher than or equal to 55°C at

the equipment outlet ;

• Or be raised to a sufficient temperature at least once every

24 hours. Annex 1 gives the minimum water temperature

maintenance time to be respected.

Example 2 : storage tanks present in the distribution system

Network

supply

point

Cold water

Domestic hot water

production (without storage)

DE DIETRICH THERMIQUE

S.A.S. with corporate capital of 22 487 610 €

57, rue de la Gare - F – 67580 Mertzwiller

Tel. +33 3 88 80 27 00 - Fax +33 3 88 80 27 99

www.dedietrich-heating.com

8980F229

Legionella is caused by the inhalation of water spray

contaminated by legionella. Water temperature is a significant

factor in preventing the development of legionella in distribution

networks as the Legionella bacterium multiplies significantly in

water presenting temperature of between 25 and 43°C.

In order to limit the risk connected to the development of

legionella in domestic hot water distribution systems to which

draw-off points which may be at risk at likely to be connected,

the following requirements must be respected when using

domestic hot water production and distribution systems and

during the 24 hours proceeding their use :

- When the volume between the distribution point and the

most distant draw-off point is more than 3 litres, the water

Storage tank

T > 55 $C at the network

supply point or increased in

temperature on a daily basis

10/2014 – 300030548 – 347.555.559 Strasbourg Companies Register – Document not contractually binding - Printed in France - OTT Imprimeurs 67310 Wasselonne - 142735

Example 1

1 . In order to limit the risk of being scalded :

- in rooms intended for ablutions, the maximum temperature of

the domestic hot water is set at 50°C at the draw-off points ;

- in the other rooms, the maximum temperature of the

domestic hot water is limited to 60°C at the draw-off points ;

- in the kitchens and laundries of establishments open to the

public, the temperature of the water distributed may be

raised to a maximum of 90°C at certain points which are

indicated by special warning signs.