Design of a Modified Slip Casting Procedure for the Single Step

advertisement

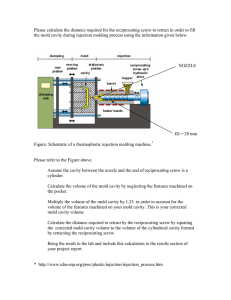

Design of a Modified Slip Casting Procedure for the Single Step Manufacture of

Sealed Silicone Balloons

THESIS

Presented in Partial Fulfillment of the Requirements for the Degree Master of Science in

the Graduate School of The Ohio State University

By

Michael W. Hudoba, B.S.

Graduate Program in Mechanical Engineering

********

The Ohio State University

2011

Master's Examination Committee:

Dr. Blaine Lilly, Advisor

Dr. Jose Castro

Copyright by

Michael W. Hudoba

2011

Abstract

Many applications in engineering and medicine require a flexible, ‘bag-like’

device that can withstand large amounts of internal and external pressure. In medicine,

these devices are used to control the pressure of urethras and blood vessels in urethral and

vascular occlusion procedures, respectively. Currently these devices are made by

stacking two flat sheets of silicone and gluing them together at their edges. This

eliminates the benefit of silicon’s high strength, and the strength of the device becomes

limited by the properties and application of the glue. This report outlines the research

and approach of using platinum cure silicone to make a one-piece, hollow device capable

of withstanding significant internal and external pressures. An apparatus was designed to

manufacture these devices, and a full factorial experiment was implemented to help

define the manufacturing parameters. Success was defined by enclosure of the void as

well as uniformity of the device along each of its faces. This report will outline the

procedural and technical specifics needed to create the devices. The results of these

findings can not only improve the success rate of certain procedures already using similar

devices (vascular and urethral occlusion), but can be implemented to improve any

process where a strong, flexible part with an internal void is required.

iii

Dedication

This document is dedicated to my greatest influence, my father;

And to my biggest fan, my mother

iv

Acknowledgments

I would like to thank the Ohio State University, especially the mechanical and

aerospace engineering department, for helping me develop the skills necessary to grow as

an engineer through my undergraduate and master’s degrees.

I would like to thank Josh Hassenzahl, Chad Bivens, and Neil Gardner, staff

members at the Ohio State University, for their support and assistance in manufacturing

processes used in this thesis.

I would like to thank Dr. Chris Adin, who developed the hydraulic urethral

occluders, for allowing me to help with the redesign of his device. Without Dr. Adin,

none of this would have been possible. It was a pleasure to work with him over the past

several years.

I would like to thank my family; my mother Marilyn, my father Russell, and my

brother Doug. Their continuous encouragement, love, and support are the motivation that

drives me toward success. My mother is my biggest supporter, and she always makes me

realize that I am capable of anything I put my mind to. My father has always inspired me

to strive for greatness, as I attempt to emulate his success. My brother Doug has always

been my role model and my best friend. I am where I am today because of them, and I

will continue to succeed because of their support.

v

Finally, I would especially like to thank my advisor, Dr. Blaine Lilly. Over the

past few years Dr. Lilly has become an advisor, a supporter, and a friend. Dr. Lilly’s

enthusiasm as a teacher sparked my interest in product design, research, and education.

He was very influential throughout my master’s program, and prepared me for my future

as a PhD candidate. I would not be the engineer I am today without his guidance and

support, and for that I am forever grateful.

vi

Vita

November 28, 1986 .......................................Born – Youngstown, Ohio

2005................................................................Canfield high School

September, 2009 ...........................................B.S. Mechanical Engineering, The Ohio

State University

2009 to present ..............................................Graduate Teaching Associate, Department

of Mechanical Engineering, The Ohio State

University

Fields of Study

Major Field: Mechanical Engineering

Specialization: Design and Manufacturing

vii

Table of Contents

Abstract .............................................................................................................................. iii

Dedication .......................................................................................................................... iv

Acknowledgments............................................................................................................... v

Vita.................................................................................................................................... vii

Fields of Study .................................................................................................................. vii

Table of Contents ............................................................................................................. viii

List of Tables ..................................................................................................................... xi

List of Figures ................................................................................................................... xii

List of Appendix Figures .................................................................................................. xv

Chapter 1:

Introduction and Objectives .......................................................................... 1

1.1 Introduction ............................................................................................................... 1

1.2 Canine Incontinence .................................................................................................. 2

1.3 Handmade Hydraulic Urethral Occluders ................................................................. 5

1.4 Thesis Objectives .................................................................................................... 11

Chapter 2:

Technical Background ................................................................................ 14

2.1 Similar Product Investigation .................................................................................. 14

viii

2.1.1 U.S. Patent #4592339 – Gastric Banding Device (4) ....................................... 15

2.1.2 U.S. Patent #5449368 – Laparoscopic Adjustable Gastric Banding Device (5)

................................................................................................................................... 16

2.1.3 U.S. Patent #4632114 – Urethral Sphincter Cuff (6) ....................................... 17

2.2 Process Investigation ............................................................................................... 18

2.2.1 Injection Molding ............................................................................................. 18

2.2.2 Slip Casting....................................................................................................... 22

2.3 Material Investigation ............................................................................................. 25

Chapter 3:

Occluder Design.......................................................................................... 28

3.1 Design Development ............................................................................................... 28

3.2 HUO for use in Process Development .................................................................... 33

3.3 Dacron Infusion ....................................................................................................... 36

Chapter 4:

Process Design ............................................................................................ 44

4.1 Mold Development .................................................................................................. 44

4.2 Process Development .............................................................................................. 46

4.3 Evolution from HUO to Generic Silicone Balloon ................................................. 57

Chapter 5:

Optimization Strategy ................................................................................. 64

5.1 Full Factorial Experiments ...................................................................................... 64

5.2 Developing Treatments and Treatment levels ......................................................... 65

ix

5.3 Running the experiments ......................................................................................... 72

5.4 Full Factorial results ................................................................................................ 76

Chapter 6:

Conclusions and Future Work .................................................................... 89

6.1 Conclusions ............................................................................................................. 89

6.2 Future Work ............................................................................................................ 95

Appendix A: MATLAB Code ......................................................................................... 97

Calculate avg. and SD of mass and volume .................................................................. 98

Calculate avg. and SD of lumen area ............................................................................ 99

Plot wall thickness of devices from full factorial experiment ..................................... 100

Appendix B: Gimbal Drawings ..................................................................................... 103

Appendix C: Mold Procedure ........................................................................................ 113

C1: Preparing the mold .............................................................................................. 114

C2: Creating the Flow Tube ....................................................................................... 114

C3: Mixing of Silicone A and B Components ........................................................... 114

C4: Applying the Silicone to the Mold Cavity........................................................... 115

References ....................................................................................................................... 117

x

List of Tables

Table 5.1: Full Factorial Design ...................................................................................... 73

Table 5.2: Enclosure of Experimental Devices................................................................ 78

Table 5.3: Visual Uniformity of Experimental Devices .................................................. 80

Table 6.1: Average Enclosure and Visual Output Values for Treatment A .................... 90

Table 6.2: Average Enclosure and Visual Output Values for Treatment B..................... 91

Table 6.3: Average Enclosure and Visual Output Values for Treatment C ..................... 91

Table 6.4: Average Enclosure and Visual Output Values for 8 different Parameter

Combinations .................................................................................................................... 92

Table 6.5: Treatment Levels Producing Most Successful Results ................................... 93

xi

List of Figures

Figure 1.1: Implantation of HUO....................................................................................... 4

Figure 1.2: Handmade HUO .............................................................................................. 5

Figure 1.3: Failure of Handmade HUO .............................................................................. 6

Figure 1.4: Handmade HUO Mass against Average Mass ................................................ 7

Figure 1.5: Handmade HUO Volume against Average Volume ....................................... 8

Figure 1.6: ImageJ Program to Measure Internal Lumen Area ....................................... 10

Figure 1.7: Internal Lumen Area of Handmade HUOs.................................................... 11

Figure 2.1: Gastric Banding Device................................................................................. 15

Figure 2.2: Laparoscopic Adjustable Gastric Banding Device ........................................ 16

Figure 2.3: Urethral Sphincter Cuff ................................................................................. 17

Figure 2.4: Mold Design with Inclusion of Tongue (Single Mold Half) ......................... 19

Figure 2.5: Slip Casting Procedure (Drain Slip Casting) ................................................. 24

Figure 3.1: Proposed Design 1 ......................................................................................... 28

Figure 3.2: Proposed Design 2 ......................................................................................... 29

Figure 3.3: Proposed Design 3 ......................................................................................... 31

Figure 3.4: Proposed Design 4 ......................................................................................... 31

Figure 3.5: Proposed Design 5 ......................................................................................... 32

Figure 3.6: Proposed Design 6 ......................................................................................... 32

Figure 3.7: Solid Model for Injection Molded Device .................................................... 34

xii

Figure 3.8: Solid Model with Extension Link ................................................................. 35

Figure 3.9: Teardrop Shape of Occluder.......................................................................... 36

Figure 3.10: Pressure Distribution of Donut-shaped Pressure Vessel ............................. 37

Figure 3.11: Cylindrical Pressure Vessel ......................................................................... 39

Figure 3.12: Creep Apparatus .......................................................................................... 41

Figure 3.13: Channel for Dacron Infusion ....................................................................... 43

Figure 3.14: Example of Device Infused with Dacron .................................................... 43

Figure 4.1: Silicone Mold Cavity..................................................................................... 44

Figure 4.2: Initial FDM Mold .......................................................................................... 46

Figure 4.3: Injection Method ........................................................................................... 47

Figure 4.4: Modified Syringe ........................................................................................... 48

Figure 4.5: Exit Port of Syringe ....................................................................................... 49

Figure 4.6: Successful Void A ......................................................................................... 50

Figure 4.7: Successful Void B ......................................................................................... 50

Figure 4.8: Device with Improved Uniformity of Wall Thickness .................................. 51

Figure 4.9: Sliced Open Device with Improved Uniformity of Wall Thickness ............. 52

Figure 4.10: 5 RPM 12 VDC Motor ................................................................................ 53

Figure 4.11: Assembly Drawing of Gimbal Device ........................................................ 54

Figure 4.12: Gimbal and Heat Gun Molding Setup ......................................................... 57

Figure 4.13: HUO with no Dacron or Injection Port ....................................................... 58

Figure 4.14: HUO with Dacron and Injection Port (A) ................................................... 58

Figure 4.15: HUO with Dacron and Injection Port (B) ................................................... 59

xiii

Figure 4.16: Plastic Mold Cavity ..................................................................................... 60

Figure 4.17: Enlarged Aluminum Mold Cavity ............................................................... 61

Figure 4.18: Weld-line Issue ............................................................................................ 62

Figure 4.19: Repeatable Sealed Silicone Balloon ............................................................ 63

Figure 5.1: Mold Cavity Horizontally Oriented in Gimbal ............................................. 68

Figure 5.2: Mold Cavity Vertically Oriented in Gimbal.................................................. 70

Figure 5.3: Experimental Matrix for Full Factorial Experiment...................................... 72

Figure 5.4: Orientation of Mold Cavity in Compartment for B- Treatment Level .......... 75

Figure 5.5: Orientation of Mold Cavity in Compartment for B+ Treatment Level ......... 75

Figure 5.6: Visual Uniformity Values (from left to right) of 1, 2, and 3 ......................... 79

Figure 5.7: Parameter Set 1 .............................................................................................. 81

Figure 5.8: Parameter Set 2 .............................................................................................. 82

Figure 5.9: Parameter Set 3 .............................................................................................. 83

Figure 5.10: Parameter Set 4 ............................................................................................ 84

Figure 5.11: Parameter Set 5 ............................................................................................ 85

Figure 5.12: Parameter Set 6 ............................................................................................ 86

Figure 5.13: Parameter Set 7 ............................................................................................ 87

Figure 5.14: Parameter Set 8 ............................................................................................ 88

Figure 6.1: Face Thickness of Run Parameter 4 ............................................................... 93

Figure 6.2: Run Parameter 4 - Device 6 .......................................................................... 94

Figure 6.3: Run Parameter 4 - Device 14 ........................................................................ 94

xiv

List of Appendix Figures

Figure B 1: Gimbal Base................................................................................................ 104

Figure B 2: Gimbal BaseTop ......................................................................................... 104

Figure B 3: Gimbal BaseVert ........................................................................................ 105

Figure B 4: Gimbal RingHorizontal .............................................................................. 105

Figure B 5: Gimbal RingVert1 ...................................................................................... 106

Figure B 6: Gimbal RingVert2 ...................................................................................... 106

Figure B 7: Gimbal RingShaftTop ................................................................................. 107

Figure B 8: Gimbal RingShaftBottom ........................................................................... 107

Figure B 9: Gimbal SleeveBearing ................................................................................ 108

Figure B 10: Gimbal InnerShaft .................................................................................... 108

Figure B 11: Gimbal MoldCavitySlot ........................................................................... 109

Figure B 12: Gimbal MotorPlate ................................................................................... 109

Figure B 13: Gimbal Motor ........................................................................................... 110

Figure B 14: Gimbal InnerBottom ................................................................................. 110

Figure B 15: Gimbal ConductingRing ........................................................................... 111

Figure B 16: Gimbal ConductingRing2 ......................................................................... 111

Figure B 17: Gimbal BrushHousing .............................................................................. 112

xv

Chapter 1: Introduction and Objectives

1.1 Introduction

The medical field is an industry that benefits greatly from the contributions made

from design engineers. From instruments and implants to diagnostic and life-support

machines, engineers play a key role in designing the equipment used in medicine.

Many implant applications in medicine require ‘bag-like’ devices that are solid, onepiece plastic objects that can be filled with fluid. Examples include vascular or urethral

occluders – devices that are capable of controlling the pressure and thus the flow of blood

or urine in a blood vessel or urethra, respectively. There are many processes in

manufacturing that are used to create a void within an object, such as lost-wax or blow

molding. These processes, although very effective in many situations, are not the best

choice when designing medical implant devices. With lost-wax, for example, the

additional material in the manufacturing process (the wax that is dissolved away) is not

implantable and should not be mixed with implant grade plastics. Blow molding is a very

commonly used process for creating hollow parts; however, the process requires an

opening into the cavity for gas injection. The bag-like implant devices needed for

vascular or urethral occlusion require a completely closed void capable of being filled

1

with a pressurized fluid, which are left in the body cavity. Any leakage of the fluid from

the occluder is clearly not acceptable.

The purpose of this thesis was to develop a process for fabricating one-piece silicone

occluders. The immediate application area for this project was to design a urethral

occluder for use in alleviating canine incontinence. Incontinence in female dogs typically

occurs after spaying, due to a lack of pack pressure in the urethra. Using the urethral

occlusion problem as the foundation, a process was designed that is capable of creating a

solid, one-piece silicone occluder that can hold saline solution for long periods of time

without leakage. Although the design described here was intended specifically as a

urethral occluder, the process can potentially be adapted for molding hollow silicone

parts for varied applications.

1.2 Canine Incontinence

Canine incontinence is the term used to describe the inability of a dog to control the

flow of urine through its urethra. This condition is most commonly seen in spayed

female dogs. Urethral sphincter mechanism incompetence (USMI) is seen in 13.6% to

20.1% of dogs following a hysterectomy (1). Although this condition is not fatal, it is

very detrimental to the quality of life for both the dog and its owners.

There are multiple devices and procedures that can be used to deal with or even cure

USMI. One of these options is a surgical treatment in which the anatomic position of the

bladder neck and pelvic urethra is altered causing what is known as urethral bulking.

Unfortunately, restoration of continence prior to these procedures only occurred in about

2

14% to 56% of dogs in clinical studies (1). Another option includes the administration of

estrogen or a-adrenoceptor agonists. These drugs, however, must be given 2 or 3 times a

day for the remainder of the dog’s life and do not guarantee curing the USMI (2).

A third option involves the implantation of a hydraulic urethral occluder (HUO). An

HUO is a device that wraps around the urethra and then is filled with a saline fluid. The

volume of saline used to fill the HUO determines the pressure on the urethra. In humans

with incontinence, these devices are dynamically controlled by the patient, giving them

the ability to release fluid to lower the pressure and allow for urination. In canines,

however, the pressure in the devices must be static. A pressure has to be found that will

restrict urine flow during everyday activity, yet will allow nature urine flow when the dog

desires. Figure 1.1 is an intraoperative photograph showing the surgical placement of an

HUO in a dog (3). In this figure, the white arrowhead shows the HUO, which is wrapped

around the right caudal branch (white arrow) of the portal vein (PV). The location of the

gallbladder (GB) is also indicated.

3

Figure 1.1: Implantation of HUO

These HUOs, shown in Figure 1.2, are currently fabricated one at a time by a

laborious manual method. Because the fabrication process used to manufacture the

devices is not automated, the quality of the devices is inconsistent, which can lead to

failure of the device after surgery, necessitation a second operation to replace the

defective device. Clearly, a need exists for a manufacturing procedure that can produce

devices in standard sizes, reliably.

4

1.3 Handmade Hydraulic Urethral Occluders

Figure 1.2: Handmade HUO

As shown in Figure 1.2, the HUO (indicated by the arrow in the bottom right of

the figure) is connected via a tube to a valve (indicated by the arrow at the top of the

figure). During the HUO implant procedure, the valve is implanted underneath the skin.

The valve is used to inject or extract saline fluid. The amount of saline fluid injected in

the device controls the pressure of the occluder, and thus the pressure of the urethra.

The handmade HUOs are created by first taking two flat pieces of silicone sheet

and placing them on top of one-another. Then, the manufacturer adds a silicone adhesive

to the edges of the sheets to glue the two halves together. This gluing process is done by

hand. The manufacture of HUOs using manual methods leads to several problems with

the devices. These problems include device reliability, variation of the size of device,

and variation of the internal lumen area of the device.

After implementation, the stresses seen in the HUO over the course of its lifetime

are significantly less than the stress limit of the silicone used to make the device. Device

5

failure, however, can occur at the seams where glue is used to secure the silicone halves

together. This can be due to the strength of the glue, the amount of glue used (which

varies due to the manual nature of the application), or a combination of both. This lack

of reliability led to failure of devices in two of the first five dogs involved in a clinical

study at the University of Florida (1). Figure 1.3 shows an example of a leaking HUO.

The leak, shown at the top of the device, occurred at the glued seam.

Figure 1.3: Failure of Handmade HUO

Device-to-device variability is another important drawback with handmade

HUOs. A sample of ten handmade HUOs was measured to obtain their mass and

volume. Mass was measured using a small scale, and volume was measured using a

volume displacement technique. The average mass of the ten HUOs was found to be

3.548 g, and the average volume was 1.71 mL. Figure 1.4 and Figure 1.5 show the

masses and volumes of each HUO against the average value, respectively. As seen in the

6

figures, the standard deviation from average of the mass was low (SDmass = 0.0786 g), but

the standard deviation from average of the volume was slightly more significant (SDvolume

= 0.2025 mL).

Average mass of Handmade HUOs

3.7

3.65

3.6

mass (g)

3.55

3.5

3.45

3.4

3.35

3.3

0

1

2

3

4

5

6

Occluder

7

8

9

10

Figure 1.4: Handmade HUO Mass against Average Mass

7

11

Average Volume of Handmade HUOs

2.1

2

1.9

Volume (mL)

1.8

1.7

1.6

1.5

1.4

1.3

1.2

1.1

0

1

2

3

4

5

6

Occluder

7

8

9

10

11

Figure 1.5: Handmade HUO Volume against Average Volume

Even more critical to the success of the device than its mass and volume is the

internal lumen area. The internal lumen area is defined as the cross-sectional area

enclosed by the HUO when the HUO is sutured closed. The canine urethra travels

through the lumen. As the HUO is filled with saline fluid, the internal lumen area

decreases until it is the same size as the cross-sectional area of the urethra. From this

point, any additional volume of saline fluid added will increase the pressure on the

urethra. Variability in the manually fabricated HUOs leads to inconsistent base-line

lumen areas, which results in a lack of correlation between volume of saline injected and

urethral pressure for like-sized urethras.

8

The program ImageJ was used to calculate the base-line internal lumen area

(base-line defines the size of the internal lumen area of an empty HUO with no saline

fluid). Ten devices (different from the mass/volume analysis) were used to calculate the

variance in lumen area. Each device was sutured closed and placed in a test tube holder,

with the lumen area perpendicular to the axis of the test tube holder. Images of each

device were captured individually, with the presence of a reference measurement (a

millimeter ruler). ImageJ was then used to physically outline the lumen area, after which

the program calculated the area in pixels2. Using the reference image of the ruler, pixels2

were then converted into mm2. Figure 1.6 shows how ImageJ was used to obtain the

measurements; the yellow outline was drawn by hand onto the photograph of the HUO.

9

Figure 1.6: ImageJ Program to Measure Internal Lumen Area

To improve accuracy, each area was outlined and measured three times, and the

recorded area was the average of the three measurements. After measuring all ten HUOs

(30 total measurements), the average internal lumen area was found to be 28.8105 mm2.

Figure 1.7 shows a plot of each HUOs lumen area against the average value. As

displayed in the figure, there is a large standard deviation for internal lumen area for the

handmade HUOs (SDlumenarea = 6.2568 mm2).

10

Average Lumen Area of Hand-made HUOs

40

Area (mm2)

35

30

25

20

15

0

1

2

3

4

5

6

Occluder

7

8

9

10

11

Figure 1.7: Internal Lumen Area of Handmade HUOs

Both variability and non-reliability of handmade HUOs were the motivating factors

driving this research. Creating devices that are both reliable and consistent were two of

the important thesis objectives, which are described in the following section.

1.4 Thesis Objectives

The objectives of this research evolved throughout the life of the project. Initially,

the research focused on specifically designing a HUO to be used to cure canine

incontinence. Accordingly, the objectives were initially based around the design of the

HUO:

11

Design a clasping mechanism to eliminate the need for sutures

Develop adjustability so the device can be used on a wide-range of dog

sizes

Improve reliability reduce variability by designing the device to be

injection-molded

Research began with focus on the third objective – designing the device to be

injection-molded. After working with the material and becoming familiar with its

properties and molding characteristics, it became clear that injection-molding of platinum

cure liquid silicone might not be the best solution.

With injection-molding no longer a viable option, a new method of HUO

fabrication needed to be developed. Research began on a manufacturing method known

as slip casting, and this investigation led to the evolution of the research objectives for

this thesis. At this point, focus moved from specifically designing an HUO to designing

a manufacturing procedure for creating sealed silicone balloons. This approach is more

general and is relevant to a variety of needs both in and outside of the medical field. The

‘process-based’ objectives are described here:

Design the procedure for a modified slip casting method to create sealed

silicone balloons

Determine the parameters that have an effect on the manufacture of the

device

12

Develop a full factorial experiment to test how each parameter effects the

device

From the experiment, determine the best process and parameters for

manufacturing sealed silicone balloons

13

Chapter 2: Technical Background

2.1 Similar Product Investigation

There are many products in existence today that function in a similar manner to the

HUO devices. To aid in the improved design of the HUOs, research was done on a

number of patents for devices that control flow either by controlling the pressure or the

size of the cross-sectional area of the flow path.

The following devices were investigated to aid in the design of the HUO. Each of

these devices is designed to alter the flow through a pathway. The first two devices

control flow into the stomach by changing the cross-sectional area of the stomach

opening. The third device controls flow of urine by controlling the external pressure of

the urethra. Each device was investigated to determine both functionality as well as their

method of latching and adjustability.

14

2.1.1 U.S. Patent #4592339 – Gastric Banding Device (4)

Figure 2.1: Gastric Banding Device

Functionality – Used to treat morbid obesity by wrapping around the top of the stomach.

This creates a stoma opening that is smaller in cross-sectional area than the natural

opening of the stomach.

Latching Method – Similar to a belt. The narrower end slides into the slot at the wide

end and is pulled through. Excess length of the narrow end is cut and sutured to the band.

Adjustability – Size is controlled upon implantation. To create a smaller stoma opening,

the ‘belt’ is pulled tighter.

15

2.1.2 U.S. Patent #5449368 – Laparoscopic Adjustable Gastric Banding Device (5)

Figure 2.2: Laparoscopic Adjustable Gastric Banding Device

Functionality – Serves the same function as the gastric banding device above, only this

device can be implanted laparoscopically.

Latching Method – A flap at one end is inserted into a slot at the other end. A pin then

slides through a hole in the flap and the slot to lock them together. The pin is then

screwed into place to secure the band.

Adjustability – Size is controlled by the location of the slot relative to the flap. This size

is static and cannot be changed.

16

2.1.3 U.S. Patent #4632114 – Urethral Sphincter Cuff (6)

Figure 2.3: Urethral Sphincter Cuff

Functionality – Used to treat incontinence in humans. The cuff wraps around the urethra

and is filled with a fluid to control the pressure within the urethra. This device is similar

to the HUOs being designed in this thesis, however, the pressure exerted on the urethra

by the sphincter cuff is dynamic - the patient can control the fluid in the device by

squeezing a diaphragm (not pictured) which will add or extract fluid from the cuff.

Latching Method – Holes (left end) are placed on pins (right end) and snap into place.

Silicone adhesive is used on the pegs to lock the device into place.

Adjustability – As displayed in the image, the device has many holes similar to belt

loops to control the size of the device. This size adjustment is done intraoperatively, and

cannot be changed once it is locked into place.

17

2.2 Process Investigation

2.2.1 Injection Molding

Injection molding is a very versatile process that can be used for the manufacture of

endless types of plastic parts. There are many different types and methods of injection

molding, and each type serves a specific purpose. Injection molding methods that result

in parts with internal voids were examined to determine their usefulness in the

manufacture of the HUOs. The methods investigated include injection molding with the

use of a solid inner core, injection molding with a fusible core, and gas-assisted injection

molding.

The first injection molding process that was considered involved designing the mold

cavity with a ‘tongue’ portion that would create the cavity within the device. Figure 2.4

shows an example of a possible mold half with the inclusion of the tongue cavity.

With

this method, plastic could be injected at the top of the mold and flow around the tongue

portion of the mold, creating the cavity. When the device solidifies, it could be slid off of

the tongue and the open end (created from the bottom of the tongue portion that is

connected to the mold) can be glued together using a silicone adhesive.

18

Figure 2.4: Mold Design with Inclusion of Tongue (Single Mold Half)

The main advantage of this method would be that it could be done using standard

injection molding techniques and equipment. The disadvantage is the lack of strength

that comes from gluing the edge closed, which far outweighs the process’ advantage.

One of the objectives of this thesis is to increase the mechanical reliability of the devices

by eliminating the need to glue the edges of the device together. This ensures that the

strength of the device is based entirely on the properties of the silicone instead of the

properties and application of the silicone adhesive. The device will only be as strong as

its weakest section, so any gluing (even though the gluing was reduced 75%) would

defeat the purpose of the re-design.

Fusible core injection molding (also known as lost or soluble core injection molding)

is a process used to design hollow parts, which is precisely what the HUO is. The device

is created first by designing an insert which is a temporary core made from a material

19

with a low melting point. Examples of these materials include a tin-bismuth alloy, wax,

or a thermoplastic. The insert is placed inside of the mold, and the liquid silicone

material flows into the mold and around the temporary core. After solidification of the

silicone, the core is melted or chemically dissolved and drained, leaving behind a hollow

device.

An interesting phenomenon occurs with fusible core injection molding. Since the

melting point of the core is lower than the melting point of the silicone, it would seem

that during injection the liquid silicone would cause the core to melt. However, due to

high thermal diffusivity, large thermal inertia and latent heat of possible core materials,

the insert remains solid during the injection phase.

An advantage to the fusible core injection molding process is that the secondary step

of gluing is eliminated and the solid device is molded in a single step (the core must still

be dissolved with an additional step, but the actual device is created in a single step). The

elimination of glued edges would increase the mechanical reliability of the occluder.

Also, HUOs already have a hole used to inject or extract saline fluid. This hole could

initially be used to drain out the melted core during the lost wax procedure.

An additional advantage is that most of the temporary core materials can be re-used

and recycled. This means that the addition of a core would not significantly increase the

overall amount of material (and thus overall cost) necessary for the process.

There are certain disadvantages in using fusible core injection molding for the

purpose of manufacturing HUOs. First, appropriate core materials would have to be

investigated and tested. Silicone is a very unique plastic material; much consideration

20

would be needed to find a core material that has the appropriate mechanical and chemical

properties. These considerations come from the fact that the device is made from implant

grade silicone. Implant grade silicone is made to be safely implanted inside of a living

body for extended periods of time. With fusible core injection molding, one would also

have to ensure that the core material would not degrade or change the chemical properties

of the implant grade silicone.

Another disadvantage is that fusible core injection molding is a very expensive

process. The injection molding machine would not need to change, but the mold would

need to be designed in such a way so the temporary core can be inserted into the mold

cavity prior to injection. And although the injection molding of the device is completed

in a single step, the addition of a melting station would need to be implemented to

remove the temporary core from each device. This increases cycle time, equipment

needs, and energy cost.

The final injection molding process that was initially examined was gas-assisted

injection molding. Gas-assisted injection molding is a unique form of injection molding

in which the plastic is injected into the mold cavity and is followed by injection of a gas

that hollows out the center of the device. The typical gas used in this type of molding is

nitrogen, mainly because of its lack of reactivity with most polymers, its availability, and

its low cost. When the gas is injected into the core, it fills the thicker areas of the part

because this is where the plastic material remains liquid the longest. Thus, for the HUOs,

the walls of the device would solidify first and allow the nitrogen gas to expand

throughout the center of the device leaving behind a cavity.

21

The advantage to gas-assisted injection molding is that the device can be completed

in a single step. No additional gluing or melting stations would be needed, as with the

other injection molding procedures. This would help with mechanical reliability, as well

as mass production efficiency.

The disadvantage of gas-assisted injection molding is that a unique injection molding

machine would be needed. The machine would need to first inject the molten silicone,

and then inject the compressed gas through the sprue. This would initially require a

larger investment. However, after the initial investment, since the cost of the nitrogen is

low and the process can be completed in a single step, the per-part price would remain

low and the product process would be efficient and reliable. Although a viable option,

the high cost due to equipment requirements of gas-assisted injection molding limited its

applicability at this level of the research.

2.2.2 Slip Casting

The three possible manufacturing methods described above are all variations of the

basic injection molding process. The main problem with injection molding methods for

this application did not even become evident until the silicone material was chosen and

experimented with. Platinum cure silicone is an extremely viscous substance that does

not flow well. While heat can be added to decrease the viscosity, the addition of heat

greatly reduces the working and curing time of the silicone. Two specific problems arose

when attempting to use an injection molding procedure. First, the act of injecting the

liquid silicone was extremely difficult. The injection cavity either had to be very large,

22

or the injection force needed to be significantly high. Secondly, once injected into the

cavity the liquid silicone would not separate from itself to coat the inner walls of the

cavity and leave a void. Instead, the silicone would cohere as a single solid piece. A

third indirect problem with injection molding of silicone is the upkeep and maintenance

of the injection molding machine. The liquid silicone leaves some of itself behind on

anything it comes in contact with, and it is very difficult to clean/remove. Upkeep of the

injection molding machine would include a very tedious process of cleaning the injection

port to ensure that no silicone is left behind to harden inside the machine. Because of

these issues, alternatives to the initial injection molding manufacturing method needed to

be investigated and considered.

A method of manufacturing known as colloid casting was investigated to determine if

it could be beneficial to the design and manufacture of the HUOs. A colloid is defined as

a substance microscopically dispersed evenly throughout another. This sounds similar to

platinum cure liquid silicone rubber – even amounts of Part A and Part B are mixed

together. Once mixed, the material cures and solidifies. Typically, ceramics are the

materials used in colloid casting procedures. Although silicone is obviously not a

ceramic, two types of colloid casting were investigated to see if the procedure could be

modified for the manufacture of the HUOs.

The most common form of colloid casting is known as slip casting. Slip casting is

used to produce items such as tableware, structural tubing, and a variety of automotive

and biomedical components. The procedure begins with the pouring of the aqueous

23

material (known as a slip) into a permeable mold that has the shape of the desired part.

Next, one of the three following methods is used:

Drain slip casting – The slip material is cast for a limited amount of time to

form a wall layer of desired thickness. After the desired wall thickness is

reached, the slip material is then drained from the mold (Figure 2.5) (4).

Solid slip casting – The slip material is continuously added until a solid cast of

desired thickness is formed. No additional material exists to drain.

Vacuum slip casting – A vacuum is applied to the mold to increase the rate of

filtration

Figure 2.5: Slip Casting Procedure (Drain Slip Casting)

A second form of colloid casting is known as centrifugal casting. Centrifugal casting

is similar to slip casting, except coating the walls of the mold and separating the colloid

material is assisted by centrifugal motion. Centrifugal casting will push all of the liquid

material outward from the axis of rotation. Thus, if the axis of rotation is defined as the

24

axis of the desired part, then all of the material will be pushed to the outer walls leaving a

voided inner core.

By themselves, none of the above described methods would work for the manufacture

of an HUO for this research, either due to the specific procedure or limiting factors such

as equipment availability and cost. However, information learned from injection molding

in combination with the slip and centrifugal casting procedures led to the development of

the modified slip casting method that was used throughout the experiment to create

devices. The specifics of that procedure are outlined in chapter 4, Process Design.

2.3 Material Investigation

An important step in the development of the HUOs is determining the material to be

used in manufacture. The manufacturing process for making the hand-made HUOs

begins with sheets of solid silicone, yet the modified design of the HUOs requires the use

of platinum cure silicone that begins as a liquid. Aside from having an initial liquid state,

the other important characteristic required of the material is that it is implantable in a

living body.

Silicones have inherently low toxicity, which presents low risk for biological

reactions. For this reason, they have gained recognition and acceptance in a wide range

of industrial and medical applications. There are three ‘types’ of FDA tested silicones

(5), with each level of silicones undergoing more rigorous testing. The first type is ‘food

grade’ silicones. These are not accepted as usable silicones for medical applications.

The next type is ‘USP Class 6’ silicones. These silicones are typically used for

25

packaging drugs and food. Although more pure than food grade silicones, USP Class 6

silicones are still not acceptable for implantable devices. For an implant application, one

must use the third class of silicone known as ‘medical grade’ or ‘implant grade’ silicone.

These silicones go through rigorous biological testing and are rated by the FDA to be

used in medical procedures, including implantation devices.

Material investigation led to an implant grade silicone supplier, Applied Silicone

Corporation. After the development of a non-disclosure agreement, Applied Silicone

Corporation assisted in determining an implant grade silicone for manufacture of the

HUOs. The material chosen was Applied Silicone Implant Grade Liquid Silicone Rubber

30 (LSR 30). LSR 30 is a two part pourable silicone elastomer that has been rated as

implant grade by the FDA. The material is a two part, 10:1 mixture (10 parts A 1 part B

by mass or volume) with a 30 durometer, Shore A hardness.

Although ideal for the application, LSR 30 is not ideal for research purposes for a

number of reasons. First, the cure time was extremely high. The mold, although solid

after about 24 hours, remained tacky for a few days. Complete cure and total

solidification was not reached until approximately 72 hours after mixing. Since dozens

of parts needed to be made for experiment and testing procedures, a 3 day cure time was

too long for the purpose of this research. In addition to the long cure time, LSR 30 has an

extremely high price. A 1.1 lb kit of liquid silicone rubber cost approximately $250, and

thus it would not have been a monetarily viable option to use the LSR 30 in dozens of

trial runs and experiments.

26

For these reasons it was critical to find an alternative material to use throughout the

test phase of the research. The mold company Perma-flex assisted in determining a

research material. Perma-flex recommended using a silicone known as DragonSkin 30

(DS 30). DS 30 is a two part, 1:1 mixture (1 part A 1 part B by mass or volume) with a

hardness rating identical to that of LSR 30. DS 30 is chemically very similar to LSR 30

and behaves in a very similar manner. The main difference is that DS 30 has not

undergone the rigorous purity testing procedures that would qualify it as medical or

implant grade. For this reason, the price of DS 30 is a fraction of LSR 30’s price. The

other advantage is that DS 30 cures much more quickly, having an average cure time less

than 24 hours. For this reason, DS 30 was used throughout the course of the research.

27

Chapter 3: Occluder Design

3.1 Design Development

Before the focus of the thesis evolved to generic silicone balloon devices, the initial

objectives were focused on improving the already existing HUO design. The initial

proposed designs focused on two objectives: designing a latching mechanism to

eliminate the need for sutures and making the device intraoperatively adjustable so that it

would fit dogs of various sizes.

The initial six designs are shown in the following six figures. Each design was rated

in terms of its latching mechanism and adjustability.

Figure 3.1: Proposed Design 1

28

Figure 3.2: Proposed Design 2

Figure 3.1 was a very simple model focused on creating a latching mechanism to

replace the need for sutures during implantation. The principle of the design is simple: a

‘stretch-fit’ is used to lock the device on itself. A hole in one end of the device is

stretched over a ‘hook’ like extrusion at the other end. Once the hole is stretched over the

hook, the hoop stress seen in the device ensures that it will stay together. To unlock the

device, one would have to pull in the opposite direction of the forces seen within the

device until the hook is released from the hole. This is not something that would happen

naturally, ensuring that the device stays locked.

Although the design in Figure 3.1 offered a solution to the latching mechanism, it did

not serve to solve the adjustability problem. Figure 3.2 is a design that uses the basic

principles of the previous design, yet it provides a choice of holes to lock into the hook.

Each hole would correspond to a different circumference length, making the device

capable of fitting a variety of dogs.

29

The main problem with the previous design is that if a smaller size is desired, then the

excess length of the HUO is left hanging tangent to the circular occluder. Although

technically speaking this device is adjustable, it is not desirable to have excess length of

the HUO hanging off of the urethra. The following two designs kept the ‘stretch-fit’

principle for the locking mechanism from the first two designs but attempted an

alternative adjustment method to eliminate any overhang seen in design 2.

The designs in Figure 3.3 and Figure 3.4 attempted to solve the adjustability issue by

placing a slit at one end that goes all the way through the device. In each design, the

portion at the left of the drawing does not contain a silicone bag. Instead, this flat piece

can be slid into the slot at the opposite end of the device and then placed on the

appropriate hook (depending on desired size). The excess length that remains tangent to

the HUO in Figure 3.2 is now forced to remain circular, following the shape of the rest of

the device. The designs in Figure 3.3 and Figure 3.4 are the same, except that the former

uses a hole and hook latching method and the latter uses a tab and slot latching method.

30

Figure 3.3: Proposed Design 3

Figure 3.4: Proposed Design 4

The next two designs used a latching mechanism different from the ‘stretch-lock’

method seen in the previous designs. In the design depicted in Figure 3.5, one end of the

device has a single opening referred to as the sleeve. The other end of the device slides

into the sleeve. The adjustment of this device is simple: sliding the one end farther into

the sleeve will result in a smaller circumference. The latching method relies on the

pressure exerted by the saline fluid filling the device. The entire length of the device has

31

a saline bag, even the portion that enters into the sleeve. When the device is filled, the

expansion of the saline bag will secure the one end in the sleeve.

Figure 3.5: Proposed Design 5

The design in Figure 3.6 is the same as the design of Figure 3.5; only this design

adds the concept of a zip tie to aid in locking the device in place. In this design, the

expansion of the saline bag still secures itself within the sleeve but additional latching

support is added by a series of holes and angled notches on the sleeve and opposite end,

respectively.

Figure 3.6: Proposed Design 6

32

These initial design ideas focused on two of the three initial thesis objectives;

designing a device that can be secured without the use of sutures and designing it to be

adjustable. After the development of these initial ideas, the research shifted to focus on

the third and final of the initial objectives which was to design the device to be injectionmolded. Research into an injection-moldable design led to the modification of the part

and the eventual evolution of the research objectives.

3.2 HUO for use in Process Development

The next design that was developed included solutions to the latching and

adjustability objectives, but unlike those in the previous section this design also focused

on the third objective, i.e., designing the device to be injection molded. Figure 3.7 is a

solid model of this design. Although it appears simple, this design proved to be the best

solution to this phase of the research problem.

33

Figure 3.7: Solid Model for Injection Molded Device

The body of the device depicted in Figure 3.7 is asymmetrical. The main portion of

the device is a rectangular shaped silicone bag. The ends of the device are solid and

would not be filled with saline fluid. These ends are complementary to one another; one

end is a solid, cylindrically shaped piece while the other end is a hollow partial cylinder.

The hollow portion of the left end of Figure 3.7 would wrap around and lock into place

over top of the right end. The integrity of the latching that occurs would be determined

by the strength and stiffness of the plastic used to make the ends of the device.

Adjustability of the device is possible with the inclusion of extension pieces, one of

which is shown attached to the HUO in Figure 3.8. This portion of the device would all

be made from the same material. Unlike the main body of the device seen in Figure 3.7,

the extension piece has no silicone bag portion. Its ends, however, are identical to the

ends of the main device. As a result, the HUO can be locked together in the exact same

manner, with or without the addition of the extension piece.

34

Figure 3.8: Solid Model with Extension Link

An initial concern was that since the extension piece does not contain a saline bag

portion capable of expansion and contraction, the device would not be successful at

controlling the pressure of the urethra. After discussion with Dr. Chris Adin, the

veterinary surgeon whose idea it was to develop an improved HUO, it was determined

that this would not be an issue. Figure 3.9 is a close-up of a sutured hand-made HUO.

As seen in the figure, the likely shape of the device is a teardrop shape (from the plane

normal to the axis of the lumen area). Because of the shape of the enclosed device, the

top (tip of the teardrop) area does not induce as much pressure on the urethra as the rest

of the internal lumen area (rounded portion of the teardrop). This, however, does not

negatively affect the ability of the device to control back pressure. It was expected, then,

that as long as the extension piece remained small it would not affect the overall

effectiveness of the device.

35

Figure 3.9: Teardrop Shape of Occluder

Following Dr. Adin’s advice, it was determined that there would be a total of three

different sized occluders, each capable of including or not including the extension piece.

The extension piece would be the same for each size of occluder. The three devices

would result in a lumen diameter of 6, 8, and 10 millimeters, which corresponds to

occluder lengths of 6π mm (~18.85 mm), 8π mm (~25.13 mm), and 10π mm (~31.42

mm), respectively. The extension piece would be designed to add 1 mm to the lumen

diameter, resulting in a length of π mm (~3.14 mm). Thus, only three different devices

are needed to accommodate 6 precise urethra diameters (6, 7, 8, 9, 10, and 11 mm).

3.3 Dacron Infusion

An additional concern with the device was the desire to control not just how much

pressure the device exerted, but also in which direction the device was exerting the

pressure. Figure 3.10 displays this concern. The image on the left of the figure is the

typical pressure distribution of a donut-shaped pressure vessel. If the pressure within the

36

vessel is increased, it exerts this pressure both on the outer as well as the inner walls. If

the walls of the device are made from a non-rigid material (i.e. silicone), then one could

expect expansion not only of the inner diameter but of the outer diameter as well.

Figure 3.10: Pressure Distribution of Donut-shaped Pressure Vessel

The HUOs would ideally achieve the pressure distribution displayed on the right hand

side of Figure 3.10. In this image, the outer circumference is rigid (shown in red), so as

pressure is exerted on the outer wall, expansion will not occur. The inner wall of the

device, however, remains non-rigid. As the internal pressure of the device increases,

expansion of the device occurs, but the expansion is restricted to the inner lumen area.

Thus, all of the pressure being exerted is directed inward.

In attempts to incorporate this effect, research led to a material known as Dacron.

Dacron is a high strength flexible material made from PET fibers, used commonly for

sailcloth. The goal was to infuse the Dacron in one side of the silicone balloon, and

designate this side as the outer wall of the HUO. When saline fluid fills the HUO, the

37

inner walls made of silicone will expand but the outer walls infused with Dacron will

keep its shape.

Before designing the HUO to include the Dacron, it was important to determine its

material properties to ensure that it has a high enough strength for this application. Two

different tests were performed on the Dacron, a tensile test and a creep test.

An Instron tensile test machine was used to determine the modulus of elasticity (E) of

the Dacron. A constant velocity experiment was performed at a rate of 0.2 inches per

minute. The output of the experiment was a stress strain curve, and E was able to be

determined by measuring the slope of the stress strain plot. Equation 1 shows an example

calculation of E from the stress-strain curves. A total of ten pieces of Dacron material

were tested, resulting in an average modulus of elasticity of 15,143 psi.

(1)

To determine the effectiveness of Dacron as a backing material, it was necessary to

determine the typical stresses that would be seen on the outer walls of the device.

Roark’s Formulas for Stress and Strain by Warren C. Young has tabulated equations for

stresses for a multitude of different cases (6). In order to find typical stresses seen in the

HUOs, certain simplifying assumptions needed to be made to match up with a case seen

in the tables.

38

First, the HUO was designated as a cylindrical pressure vessel with uniform internal

pressure. The HUOs take this shape when wrapped around a urethra. The wall of the

pressure vessel was assumed to only be the silicone half with the infused Dacron. The

pressure is supplied by the saline fluid, and the inner wall is ignored. The inner geometry

can be ignored in these calculations because the important characteristics are the shape of

the outer wall (where stress is being determined) and the application of the pressure

(uniform internal pressure). Finally, the ends were assumed to be capped. Figure 3.11

and the corresponding equations (2) show the theoretical pressure vessel used to calculate

the stresses seen in the device.

Figure 3.11: Cylindrical Pressure Vessel

(2a)

(2b)

39

In the above equations, q is the internal pressure of the device, R is the radius (from

the center point of the cross-section to the inner edge of the outer wall), and t is the

thickness of the outer wall. Typical pressures seen in the HUOs are in the range of 60

mmHg to 100 mmHg. For purposes of stress calculation, the maximum pressure of 100

mmHg was used. The thickness of the wall was designated to be 1 mm, and the radius R

ranged from 2 mm to 4.5 mm (half the lumen diameter minus the wall thickness t).

Using these factors, a range of the meridional stress (σ1) and hoop stress (σ2) were found.

Equations (2a) and (2b) are considered valid when R/t is on the order ≥ 10. In the

above case, R/t ranges from only 2 to 4.5. Because of this in addition to the geometrical

assumptions made, the above stress values are not entirely accurate. However, they do

give an idea of the magnitude of stresses seen in the device. This magnitude of stress is

not even near the calculate elastic modulus (≈ 15,000 psi) of the Dacron, so it is safe to

assume that the Dacron is capable of handling the stresses that it will endure over its

lifetime.

The other test performed on the Dacron was to determine the effect of creep on the

material. Creep is defined as a permanent change of shape due to viscous deformation of

the material, induced over a long period of time (7). Although it was concluded above

that the stresses seen in the device are far lower than the modulus of the material,

40

consistent stresses over a long time (in this case, the lifetime of the implant can be over

10 years) can cause change in shape of the material.

A flexural creep test is completed by applying a constant weight to a specimen and

measuring the displacement at 1, 6, 12, and 30 minutes, then again at 1, 2, 5, 20, 50, 100,

200, 500, 700, and 1000 hours. To perform this test, a creep apparatus was designed and

built, and is shown in Figure 3.12. Each end of a strip of Dacron material is clamped to

the horizontal bars, and a calculated weight is applied in the downward direction. The

top horizontal bar is fixed, and the bottom horizontal bar is free to move in the up and

down direction. A dial indicator is used to measure the downward displacement of the

bottom horizontal bar (thus measuring the displacement of the strip of Dacron). The dial

indicator is set to 0.0” at the initial application of the downward force, and measurements

were taken at the time intervals mentioned above.

Figure 3.12: Creep Apparatus

41

The magnitude of the force applied during the creep test was determined from the

maximum hoop stress calculated above (σmax = 8.70 psi). To determine the pound-force

required for the test, σmax was multiplied by the cross-sectional area of wall of the device,

whose normal axis is parallel to the applied force. The width of the cross sectional area

was taken to be 11 mm, and the height of this area was 1 mm (this came from the

thickness of the outer wall of the theoretical pressure vessel). Multiplying σmax by the

cross sectional area, the maximum force in the direction of the hoop stress was calculated

to be Fmax = 0.15 lbs. This is a relatively small force, and since the Dacron is expected to

withstand much larger stresses, a much higher force value was used in the creep test in an

attempt to understand the materials creep behavior. The force value used in the

experiment was approximately 3 lbs.

The 3 lb force was applied to the sample of Dacron, and measurements were

tabulated at the predetermined times. After 100 hours under 3 lbs of force, the dial

indicator still read 0 (the specific dial indicator was in units of 0.001”). Even at a greatly

increased force (approximately 20 times the maximum force expected in the device), the

Dacron material showed no signs of creep. It was then concluded that the Dacron

material is strong enough to withstand the pressures seen in the device and will not be

effected by creep over the lifetime of the implant.

Once it was decided that Dacron is an appropriate material for the application, the

mold needed to be modified to allow the infusion of the Dacron in one side of the device.

To do this, an angled channel was designed into the mold. The one opening of the

channel existed at the edge of the mold cavity. This channel angled upward and

42

terminated where the two mold halves meet. The Dacron was cut to size and shape; the

center of the Dacron strip matched the shape of the device, and each end had a more

narrow extension that was fed through the channels. When these extensions were pulled

tight, the Dacron strip inside the mold cavity was suspended approximately 0.5 mm

above the bottom of the mold cavity. This allowed the liquid silicone to fill around the

Dacron sheet, infusing it approximately in the middle of the 1 mm thick silicone wall.

The channel that was designed into the mold cavity is shown at the right side of Figure

3.13, and Figure 3.14 shows an example of a device infused with the Dacron strip.

Figure 3.13: Channel for Dacron Infusion

Figure 3.14: Example of Device Infused with Dacron

43

Chapter 4: Process Design

4.1 Mold Development

The first step in the process design was to develop a prototype mold that could be

used to manufacture the test devices. This required deciding on a mold material. A

typical mold cavity material for platinum cure silicones is the platinum cure silicone

itself. The behavior of the material is such that once parts A and B are mixed and cured

(solidified), they are in a stable state and no longer chemically reactive. Thus, once a

mold cavity made from silicone cures, silicone parts can be cured in the cavity with no

chemical reaction; the mold cavity and the mold itself remain separate. The first mold,

made from the same silicone used to make the device, is shown in Figure 4.1.

Figure 4.1: Silicone Mold Cavity

44

The cavity for the mold in Figure 4.1 was designed to be just a generic rectangular

shape with length, width, and height dimensions the same as the HUOs. Although this

mold cavity served its initial intended purpose, it did not prove practical as a permanent

material for the mold cavity. The first problem was that the silicone mold cavity was

non-rigid. In addition to the flexibility of the mold, a problem existed because it was

difficult to add detailed features to the mold cavity. This method was sufficient for

making simple shapes (like rectangular cavities), but would prove impossible to add any

design details, such as the cavity for Dacron infusion.

A mold cavity material needed to be found that was not only rigid, but capable of

being designed into detailed and intricate shapes. The next approach used a rapid

prototyping method known as Fused Deposition Modeling (FDM). FDM can be used in

conjunction with modeling software to create three-dimensional parts from acrylonitrile

butadiene styrene (ABS) thermoplastic. In this project, a solid model of the desired final

product was made in the modeling software SolidWorks. After the part was modeled, a

mold cavity was modeled by subtracting the volume of the part from a solid mold cavity

shape. The negative that is left behind from this subtraction results in a mold cavity with

the same shape as the part. The image seen in Figure 3.13 was a mold cavity made from

the FDM procedure.

Cavities made from the FDM procedure proved to be very advantageous for this

application. There were three main advantages. First, the FDM machine automatically

created the blueprint necessary for 3D modeling from SolidWorks part files. All that the

user needed to do was design the part in SolidWorks, after which the software converted

45

it into the proper format for 3D FDM modeling. Second, the FDM machine is capable of

creating features on the size scale of about 0.1 mm. This allows for the addition of fine

details, such as the Dacron cavity. Third, the machine can produce a prototype mold in a

few hours. Whenever modifications to the mold cavity were required, a new cavity was

created and ready to use within a day. The FDM produced ABS plastic mold cavity was

used for a good portion of the experimental procedure. It was not until later in the design

process that the mold cavity was machined out of aluminum. This is discussed in more

detail in section 4.3

4.2 Process Development

To begin the process development, a simple rectangular mold cavity was designed in

SolidWorks and prototyped in the FDM machine. Figure 4.2 shows the solid model of

one of the mold halves. This model was a rectangular piece with filleted edges and a

material injection site.

Figure 4.2: Initial FDM Mold

46

Initially, the intent was to use a syringe pump to inject the silicone into the mold

cavity at the injection site. The liquid silicone was poured into a syringe. The syringe

was connected to one end of a tube, and the other end of the tube was inserted into the

injection site. This setup is shown in Figure 4.3.

Figure 4.3: Injection Method

The extremely high viscosity of the liquid silicone caused two problems with the

injection method. First, it was difficult to get the material to flow from the syringe,

through the tube and into the mold cavity. Even when attempting to use larger diameter

hoses, the pressure exerted on the setup from the forced flow caused many mechanical

failures to the procedure, such as leakage at the hose ends or mechanical breakdown of

the syringe pump.

The second problem caused by the high viscosity of the material was the resistance of

the material to separate inside the mold cavity. The goal was to coat only the walls of the

mold cavity with the silicone, creating a void in the center of the cavity. Using an

47

injection method, however, the material never separated by itself; instead, the material

congealed into a solid mass, filling a portion of the mold cavity.

The next approach was to develop a procedure that assisted in the development of the

desired internal void. The first attempt at this approach was to modify the exit port of a

syringe to match the desired shape and thickness of the front and back faces of the device

(width = 11 mm, thickness = 1 mm). With the modified syringe, the silicone was

manually added to each half of the mold in a consistent, uniform manner. This modified

syringe was modeled and manufactured using the same FDM procedure for making the

mold cavities. Figure 4.4 and Figure 4.5 show the modified syringe and its exit port,

respectively.

Figure 4.4: Modified Syringe

48

Figure 4.5: Exit Port of Syringe

Although this idea seemed like a viable option, the modified syringe was not

consistent at outputting a uniform single layer of silicone, 1 mm thick. Similar to using

the syringe pump, typical results were congealed masses of silicone with no uniformity or

internal void.

The next method that was tried was the simplest in concept, however, it produced the

most repeatable and successful outputs. The walls of both mold halves were coated with

liquid silicone using a simple paint brush. If the volume of material added was controlled

well enough, the silicone would stick to the walls of the mold cavity and cure without

combining with silicone on the opposite wall, leaving behind the desired void.

Using the mold cavity modeled in Figure 4.2 and the brushing procedure described

above, devices were produced with the desired internal voids. Two examples of devices

with internal voids are shown below in Figure 4.6 and Figure 4.7.

49

Figure 4.6: Successful Void A

Figure 4.7: Successful Void B

As seen in the figures, the procedure results in a sealed device with an internal void

(the device in Figure 4.7 had been cut open, so it appears empty whereas the device in

Figure 4.6 is filled with air). A common problem with both devices is that the wall

thickness is highly non-uniform. Both devices show a buildup of silicone at the bottom

50

of the device. Because the silicone resin requires up to twenty hours to cure, if the mold

is left stationary, the material will collect in the bottom of the mold cavity.

To eliminate the variation in wall thickness due to gravity, trials were done in which

the mold was manually rotated every few minutes for the first 10 hours of the cure

process. This rotation did in fact eliminate the buildup of material at the bottom face, and

two examples of these trials are shown in Figure 4.8 and Figure 4.9. In Figure 4.9, the

device is shown cut open in order to see the internal shape of the void. At this point in

the process development, the volume of material used in fabrication was not yet