SENTRY-PRO POWER SYSTEMS

By Gillette Generators, Inc.

LIQUID COOLED DIESEL ENGINE GENERATOR SET

60 HZ MODEL

SPJD-250

UL-2200 LISTED

KW POWER RATINGS RANGE FOR 60 HZ

STANDBY

Model

SPJD-250-60 HERTZ

HZ

130ºC RISE

25/27

60

STANDARD FEATURES

• All generator sets are USA prototype built and thoroughly tested. Production

models are USA factory built and 100% load tested.

• All generator sets meet NFPA-110. Level 1, when equipped with the necessary

accessories and installed per NFPA standards.

• All generators are UL-1446 and UL-2200 certified.

• Solid state, frequency compensated voltage regulation is standard on all gen-sets.

• Electronic engine governor for precise isochronous frequency regulation.

• SENTINEL “ULTIMATE” digital controller allows programming to basic engine

functions in the field. Controller has stop-manual-auto mode and engine

shutdowns, signaled by full text LCD indicators.

• Heavy Duty 100%-125% rated Circuit Breaker is standard on all gen-sets.

• All generator set control systems components and accessories provide a 1-year

limited warranty at time of initial start-up. Generators and engines are governed

by separate warranties.

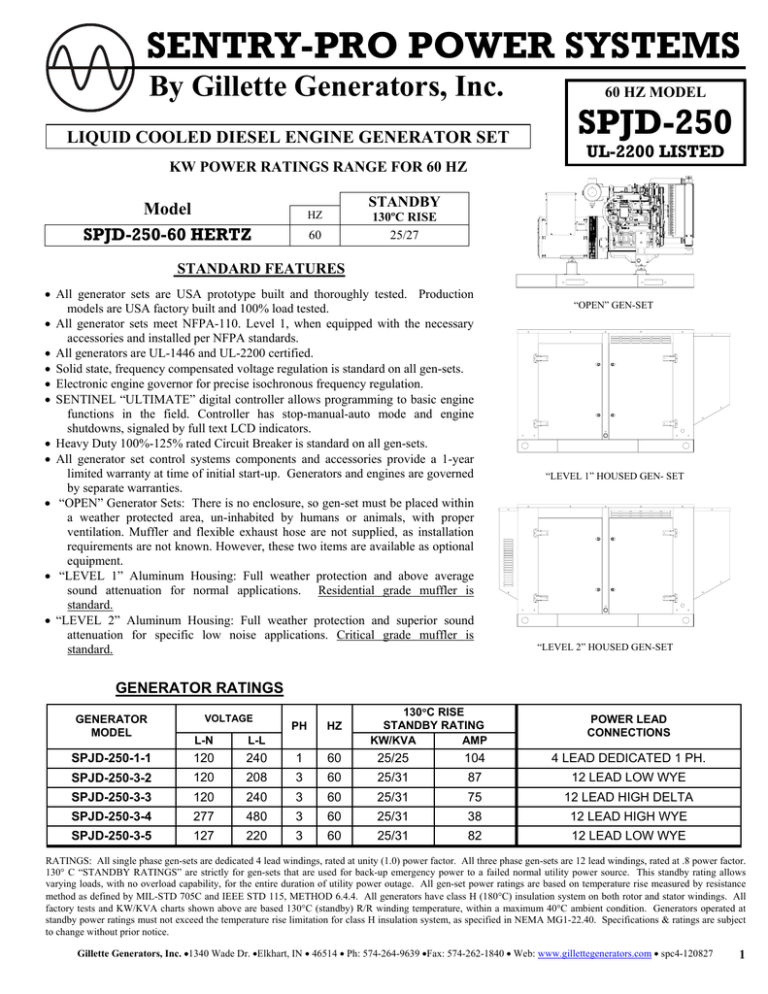

• “OPEN” Generator Sets: There is no enclosure, so gen-set must be placed within

a weather protected area, un-inhabited by humans or animals, with proper

ventilation. Muffler and flexible exhaust hose are not supplied, as installation

requirements are not known. However, these two items are available as optional

equipment.

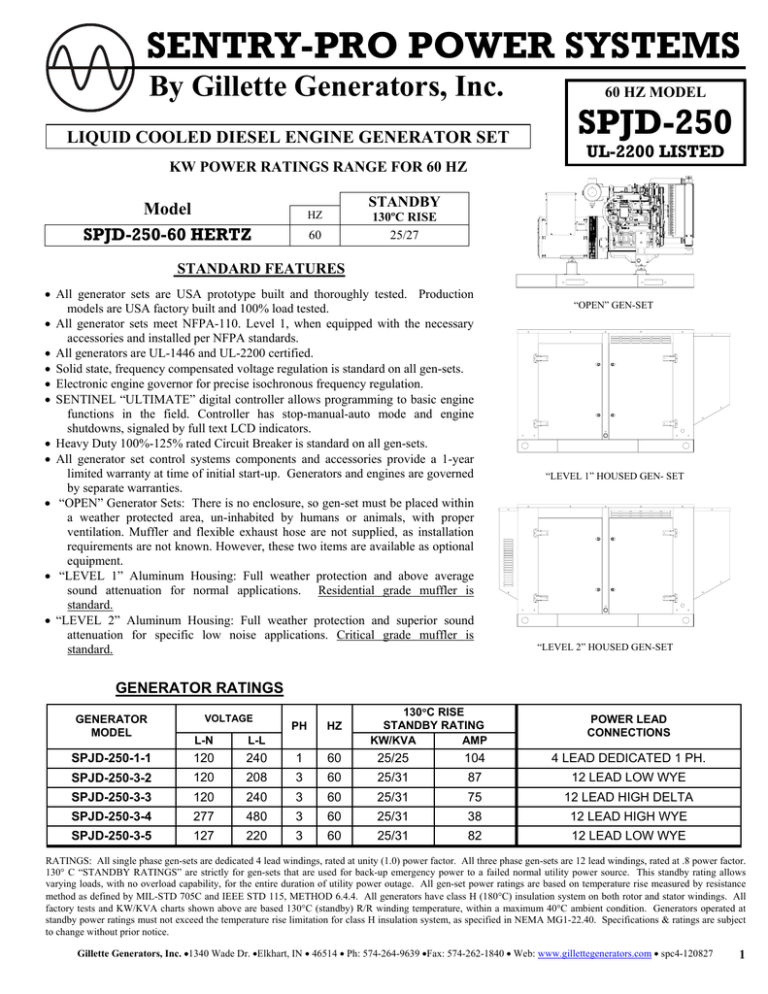

• “LEVEL 1” Aluminum Housing: Full weather protection and above average

sound attenuation for normal applications. Residential grade muffler is

standard.

• “LEVEL 2” Aluminum Housing: Full weather protection and superior sound

attenuation for specific low noise applications. Critical grade muffler is

standard.

“OPEN” GEN-SET

“LEVEL 1” HOUSED GEN- SET

“LEVEL 2” HOUSED GEN-SET

GENERATOR RATINGS

GENERATOR

MODEL

VOLTAGE

PH

HZ

130°C RISE

STANDBY RATING

KW/KVA

AMP

POWER LEAD

CONNECTIONS

L-N

L-L

SPJD-250-1-1

120

240

1

60

25/25

104

4 LEAD DEDICATED 1 PH.

SPJD-250-3-2

120

208

3

60

25/31

87

12 LEAD LOW WYE

SPJD-250-3-3

120

240

3

60

25/31

75

12 LEAD HIGH DELTA

SPJD-250-3-4

277

480

3

60

25/31

38

12 LEAD HIGH WYE

SPJD-250-3-5

127

220

3

60

25/31

82

12 LEAD LOW WYE

RATINGS: All single phase gen-sets are dedicated 4 lead windings, rated at unity (1.0) power factor. All three phase gen-sets are 12 lead windings, rated at .8 power factor.

130° C “STANDBY RATINGS” are strictly for gen-sets that are used for back-up emergency power to a failed normal utility power source. This standby rating allows

varying loads, with no overload capability, for the entire duration of utility power outage. All gen-set power ratings are based on temperature rise measured by resistance

method as defined by MIL-STD 705C and IEEE STD 115, METHOD 6.4.4. All generators have class H (180°C) insulation system on both rotor and stator windings. All

factory tests and KW/KVA charts shown above are based 130°C (standby) R/R winding temperature, within a maximum 40°C ambient condition. Generators operated at

standby power ratings must not exceed the temperature rise limitation for class H insulation system, as specified in NEMA MG1-22.40. Specifications & ratings are subject

to change without prior notice.

Gillette Generators, Inc. •1340 Wade Dr. •Elkhart, IN • 46514 • Ph: 574-264-9639 •Fax: 574-262-1840 • Web: www.gillettegenerators.com • spc4-120827

1

APPLICATION AND ENGINEERING DATA FOR MODEL SPJD-250-60 HZ

GENERATOR SPECIFICATIONS

GENERATOR FEATURES

Manufacturer.................................. Marathon Electric Generators

Model & Type............ 283PSL1517 4 Pole, 4 Lead, Single Phase

......... 283CSL1706 4 Pole, 12 Lead re-connectable, Three Phase

Exciter.....................................................Brushless, shunt excited

Voltage Regulator ....................................... Solid State, HZ/Volts

Voltage Regulation ................................½%, No load to full load

Frequency................................Field convertible, 60 HZ to 50 HZ

Frequency Regulation ......... ± ½% (½ cycle, no load to full load)

Unbalanced Load Capability..................... 100% of standby amps

Total Stator and Load Insulation...........................Class H, 180°C

Temperature Rise ......... 130°C R/R, standby rating @ 40°C amb.

1 Ø Motor Starting @ 30% Voltage Dip (240V) ..............60 kVA

3 Ø Motor Starting @ 30% Voltage Dip (208-240V).......55 kVA

3 Ø Motor Starting @ 30% Voltage Dip (480V) ..............75 kVA

Bearing..................................................... 1, Pre-lubed and sealed

Coupling.........................................................Direct flexible disc.

Total Harmonic Distortion ............... Max 3½% (MIL-STD705B)

Telephone Interference Factor ............ Max 50 (NEMA MG1-22)

Deviation Factor................................. Max 5% (MIL-STD 405B)

Ltd. Warranty Period.............. 24 Months from date of start-up or

....................................................... 1000 hours use, first to occur.

• World Renown Marathon Electric Generator having UL-1446

certification.

• Full generator protection with SENTINEL “ULTIMATE”

controller, having UL-508 certification.

• Automatic voltage regulator with over-excitation, underfrequency compensation, under-speed protection, and EMI

filtering. Entire solid-state board is encapsulated for

moisture protection.

• Generator power ratings are based on temperature rise,

measured by resistance method, as defined in MIL-STD

705C and IEEE STD 115, Method 6.4.4.

• Power ratings will not exceed temperature rise limitation for

class H insulation as per NEMA MG1-22.40.

• Insulation resistance to ground, exceeds 1.5 meg-ohm.

• Stator receives 2000 V. hi-potential test on main windings,

and rotor windings receive a 1500 V. hi-potential test, as per

MIL-STD 705B.

• Full amortisseur windings with UL-1446 certification.

• Complete engine-generator torsional acceptance, confirmed

during initial prototype testing.

• Full load testing on all engine-generator sets, before shipping.

• Self ventilating and drip-proof & revolving field design

ENGINE SPECIFICATIONS AND APPLICATIONS DATA

ENGINE___________________________________

Manufacturer............................................................... John Deere

Model and Type ............................................ 4024TF281, 4 cycle

Aspiration................................................................ Turbocharged

Cylinder Arrangement......................4 Cylinders, In-Line, 4 cycle

Displacement Cu. In. (Liters)..........................................149 (2.4)

Bore & Stroke In. (Cm.)...............................3.4 x 4.1 (8.6 x 10.5)

Compression Ratio.............................................................. 20.5:1

Main Bearings & Style............................ 4, Cu-Pb Metal, Babbitt

Cylinder Head .................................................................Cast Iron

Pistons.................................................4, Aluminum Wedge Type

Crankshaft..................................... Carbon Steel & Full Balanced

Exhaust Valve ............................................... Heat Resisting Steel

Governor .......................................................................Electronic

Frequency Regulation ................................ ±1/4% Isochronous

Air Cleaner.........................................Dry, Replaceable Cartridge

Engine Speed ................................................ ................ 1800 rpm

Max Power, bhp (kwm) Standby ................... ................. 48 (36)

BMEP: psi (kpa) Standby ............................. ................142 (981)

Ltd. Warranty Period……..24 months or 1000 hrs, first to occur

FUEL SYSTEM ____________________________

Type ......................................... Diesel Fuel Oil (ASTM No. 2-D)

Combustion System ............................................. Direct Injection

Fuel Injection Pump .................................Stanadyne Rotory Type

12 VDC Glo-Plugs........................................Standard Equipment

Fuel Filter and Water Separator……………………………...Yes

2

FUEL CONSUMPTION

GAL/HR (LITER/HR)

100% LOAD

75% LOAD

50% LOAD

STANDBY

2.2 (8.3)

1.7 (6.4)

1.1 (4.2)

OIL SYSTEM

Type ......................................................................... Full Pressure

Oil Pan Capacity qt. (L) ...................................................8.5 (8.0)

Oil Pan Cap. W/ filter qt. (L) ...........................................9.0 (8.5)

Oil Filter................................. 1, Replaceable Spin-On

ELECTRICAL SYSTEM _____________________

Ignition System .............................................................Electronic

Eng. Alternator and Starter:

Ground .....................................................................Negative

Volts DC ............................................................................ 12

Max. Amp Output of Alternator......................................... 55

Recommended Battery to -18°C (0°F):.. 12 VDC, Size BCI# 24F

Max Dimensions: ..10 3/4" lg X 6 3/4” wi X 9" hi, with standard

round posts. Min. output at 600 CCA. Battery tray (max. dim.

at 12”lg x 7”wi), hold down straps, battery cables, and battery

charger, is furnished. Installation of (1) starting battery is

required, with possible higher AMP/HR rating, as described

above, if normal environment averages -13°F (-25°C) or cooler.

CERTIFICATIONS

All engines are CARB and EPA emissions certified. All

stationary diesel engines are Interim Tier IV compliant.

Gillette Generators, Inc. •1340 Wade Dr. •Elkhart, IN • 46514 • Ph: 574-264-9639 •Fax: 574-262-1840 • Web: www.gillettegenerators.com • spc4-120827

APPLICATION AND ENGINEERING DATA FOR MODEL SPJD-250-60 HZ

COOLING SYSTEM

Type of System ................................ Pressurized, closed recovery

Coolant Pump .....................................Pre-lubricated, self-sealing

Cooling Fan Type (no. of blades) ................................. Pusher (6)

Fan Diameter inches (cm)................................................ 18" (46)

Ambient Capacity of Radiator °F (°C).............................125 (52)

Engine Jacket Coolant Capacity Qt. (L) ..........................2.7 (2.6)

Radiator Coolant Capacity Qt. (L)...............................6.46 (6.12)

Engine Heat Reject. Btu/min (kw) ……………………1412 (25)

Water Pump Capacity gpm (L/min).............. .................. 24 (91)

Heat Reject Coolant: Btu/min (kw) …. ........ ................1412 (25)

Low Radiator Coolant Level Shutdown………………...Standard

Note: Coolant temp. Shutdown switch setting at 212°F (100°C) with 50/50

(water/antifreeze) mix.

COOLING AIR REQUIREMENTS

Combustion Air cfm (m3/min) ...................... .................123 (3.5)

Max. Air Intake Restrictions :

Clean Air Cleaner, H2O (KPA).............. ................... 12 (3)

Intake Manifold Pressure, Psi (kpa) ............. .................. 11 (75)

Max. Allowable Temp. Rise, Amb:

Air to Engine Inlet, °F (°C) ................... ................... 15 (8)

Radiator Cooling Air, SCFM (m3/min) ........ ................3200 (91)

EXHAUST SYSTEM

Exhaust Outlet Size....................................................................2"

Max. Back Pressure in H2O (kpa).....................................30 (7.5)

Exhaust Flow, at rated KW, cfm (m3/min) ... .................283 (8.0)

Exhaust Temp, at rated KW,°F (ºC).............. ..............1026 (552)

SOUND LEVELS MEASURED IN dB(A)

Open

Set

Level 1 Level 2

Encl..

Encl.

Level 1, Residential Silencer....................71..........67 .........n/a

Level 2, Critical Silencer .........................68..........64 ......... 62

Level 3, Hospital Silencer........................66..........62 ......... 60

Note: Open sets (no enclosure) has (3) optional silencer system choices

due to unknown job-site applications. Level 1 enclosure has installed

residential silencer with upgrade to critical or hospital grade silencer.

Level 2 enclosure has installed critical silencer with upgrade to hospital

silencer. Sound tests are averaged from several test points and taken at

23 ft. (7 m) from source of noise at normal operation.

DERATE GENERATOR FOR ALTITUDE

3% per 1000 ft.(305m) above 3000 ft. (914m) from sea level

DERATE GENERATOR FOR TEMPERATURE

2% per 10°F (5.6°C) above 85°F (29.4°C)

DIMENSIONS AND WEIGHTS

Open

Set

Level 1

Enclosure

Level 2

Enclosure

Length in (cm)...................68 (173)....... 82 (208) .......... 89 (226)

Width in (cm)................... 36 (91) ...... 36 (91) .......... 36 (91)

Height in (cm) .................. 40 (102)...... 47 (119).......... 47 (119)

1 Ø Net Weight lbs (kg)..1244 (564)... 1599 (725) .....1779 (807)

1 Ø Ship Weight lbs (kg) 1344 (610)... 1709 (775) .....1880 (853)

3 Ø Net Weight lbs (kg)..1294 (587)... 1574 (714) .....1754 (796)

3 Ø Ship Weight lbs (kg) 1399 (635)... 1682 (763) .....1848 (838)

SENTINEL ULTIMATE DIGITAL MICROPROCESSOR CONTROLLER

SENTINEL ULTIMATE

The “Ultimate” controller

is an auto start mains

(utility) failure module for

single gen-set applications.

This controller includes a

backlit LCD display which

continuously displays the

status of the engine and

generator at all times.

The “Ultimate” controller will also monitor speed, frequency,

voltage, current, oil pressure, coolant temp., and fuel levels.

These modules have been designed to display warning and shut

down status. It also includes: (11) configurable inputs • (8)

configurable outputs • voltage monitoring • mains (utility)

failure detection • (250) event logs • configurable timers •

automatic shutdown or warning during fault detection • remote

start (on load) • engine preheat • advanced metering capability •

hour meter • text LCD displays • protected solid state outputs •

test buttons for: stop/reset • manual mode • auto mode • lamp

test • start button • power monitoring (kWh, kVAr, kVAh,

kVArh)

This controller includes the “Ultimate” in expansion features

including RS232, RS484 (using MODBUS-RTU/TCP), direct

USB connection with PC, expansion optioned using DSENet for

remote annunciation and remote relay interfacing for a distance

of up to 3300FT. The controller software is freely downloadable

from the internet and allows monitoring with direct USB cable,

LAN, or by internet via the built in web interface.

Further expansion is available by

adding the optional “WebNet“ gateway

interface module. This device will allow

comprehensive monitoring of the generator

via the cloud including identification,

location, and status. Some advantages of this

module include: reduced site visits and

maintenance costs • remote fuel management

• fault analysis • asset tracking • automatic

system alerts • maximized system up-time.

Gillette Generators, Inc. •1340 Wade Dr. •Elkhart, IN • 46514 • Ph: 574-264-9639 •Fax: 574-262-1840 • Web: www.gillettegenerators.com • spc4-120827

3

STANDARD AND OPTIONAL FEATURES FOR MODEL SPJD-250-60 HZ

STANDARD FEATURES

CONTROL PANEL:

SENTINEL “ULTIMATE” digital microprocessor with

logic allows programming in the field. Controller has:

• STOP-MANUAL-AUTO modes and automatic engine

shutdowns, signaled by full text LCD indicators:

• Low oil pressure

y Engine fail to start

• High engine temp

y Engine over speed

y Low Radiator Level

y Engine under speed

y Three auxiliary alarms

y Over & under voltage

y Battery fail alarm

Also included is tamper-proof engine hour meter

ENGINE:

Full flow oil filter • Air filter • Oil pump • Solenoid type

starter motor • Hi-temp radiator • Jacket water pump

• Thermostat • Pusher fan and guard • Exhaust manifold

• Residential Silencer • 12 VDC battery charging alternator

• Flexible exhaust connector • ”Isochronous” duty,

electronic governor • Vibration isolators • Closed coolant

recovery system with 50/50 water to anti-freeze mixture

AC GENERATOR SYSTEM:

AC generator • Shunt excited • Brushless design • Circuit

Breaker installed and wired to gen-set • Direct connection

to engine with flex disc • Class H, 180°C insulation • Self

ventilated • Drip proof construction • UL Certified

VOLTAGE REGULATOR:

½% Voltage regulation • EMI filter • Under-speed

protection • Over-excitation protection • total encapsulation

DC ELECTRICAL SYSTEM:

Battery tray • Battery cables • Battery hold down straps

• 2-stage battery float charger with maintaining &

recharging automatic charge stages.

WEATHER/SOUND

PROOF

ALUMINUM

HOUSING

CORROSION RESISTANT PROTECTION CONSISTING OF:

• 9 Heated And Agitated Wash Stages.

• Zinc Phosphate Etching-coating Stage

• Final Baked On Enamel Powder Coat

• 18/8 Stainless Steel Hardware

ACCESSORY ITEMS

F

F

F

F

F

Engine Coolant Heater with automatic 80°F on, 100°F

off, thermostat

Starting Battery Heater Blanket with automatic 60°F

on, 80°F off, thermostat

Battery Charger Upgrade, float type, 12 VDC at max.

charge, with ammeter on charger.

External Permanent Magnet Generator (PMG) for

increased induction motor starting capacity on 1∅ or

3 ∅ sets, and to meet NFPA-110 requirements.

Exhaust Silencer Critical Grade or Hospital Grade

(Replacing standard Residential Grade).

F

F

F

All brushed type 304 stainless steel weather and sound

deadening housing for coastal areas.

DSE WebNet Gateway expansion module will allow

communications with a host server via Ethernet and the

DSE cloud connection for mapping static locations, real

time instrumentation, control event log tables, and

automatic system alerts via email.

Remote Annunciator for up to (10) reporting functions.

An additional relay expansion module, plus a second

Annunciator adds another (10) reporting functions.

Design & specifications subject to change

without prior notice. Dimensions shown are

approximate. Contact Gillette for certified

drawings. DO NOT USE DIMENSIONS FOR

INSTALLATION PURPOSES.

4

Gillette Generators, Inc. •1340 Wade Dr. •Elkhart, IN • 46514 • Ph: 574-264-9639 •Fax: 574-262-1840 • Web: www.gillettegenerators.com • spc4-120827

PowerTech ETM 2.4L Engine

Model: 4024TF281

ENGINE PERFORMANCE CURVE

Rating:

Gross Power

43 hp (32 kW) Prime

49 hp (36 kW) Standby

Application: Generator

1800 RPM (60 Hz)

Nominal Engine Power @ 1800 RPM

Prime

Generator

Efficiency1

%

88

HP

kW

HP

kW

43

32

49

36

Fan Power

hp

kW

2.4

1.8

Air Intake Restriction ...................12 in.H2O (3 kPa)

Exhaust Back Pressure ........... 30 in.H2O (7.5 kPa)

Standby

Power

Factor

0.8

Prime Rating

Standby

Rating 2

kWe

kVA

kWe

kVA

27

34

30

38

4 sec Standby

Block Load

Capability3

100%

Note 1: Est. min. generator efficiency, with 5% fan power loss, to achieve Prime kVA (1500 rpm) / Standby kWe (1800 rpm).

Note 2: Based on nominal engine power.

Note 3: Results may vary by alternator and voltage regulator selection.

- PRIME

- STANDBY

Gross power guaranteed within + or - 5% at SAE J1995

and ISO 3046 conditions:

77 °F (25 °C) air inlet temperature

29.31 in.Hg (99 kPa) barometer

104 °F (40 °C) fuel inlet temperature

0.853 fuel specific gravity @ 60 °F (15.5 °C)

Conversion factors:

Power: kW = hp x 0.746

Fuel: 1 gal = 7.1 lb, 1 L = 0.85 kg

Torque: N•m = lb-ft x 1.356

All values are from currently available data and are subject

to change without notice.

Notes:

Fuel -- lb/hr (kg/hr)

All OEM Gen Set Engine Applications must be prescreened for torsional vibration compatibility with the

respective alternator end hardware.

30

(14)

OEM Engine Application Engineering will perform this

computer-based analysis work upon request.

20

(9)

10

(4.5)

Interim Tier-4 Certifications:

Certified by:

CARB; EPA

Ref: Engine Emission Label

10

(7)

Engine Performance Curves

15

(11)

25

30

35

20

(19)

(22)

(26)

(15)

Brake Power -- hp (kW)

40

(30)

45

(34)

4024 - Generator

* Revised Data

Curve 4024TF281180049 ................................ Sheet 1 of 2

November 2007

April 2008

Engine Specification Data

General Data

Lubrication System

Model ................................................................4024TF281

Number of Cylinders ......................................................... 4

Bore and Stroke--in.(mm)..................... 3.4 x 4.1 (86 x 105)

Displacement--in.3 (L) ...........................................149 (2.4)

Compression Ratio ................................................. 20.5 : 1

Valves per Cylinder--Intake/Exhaust ............................ 1 / 1

Firing Order............................................................. 1-3-4-2

Combustion System .................................... Direct Injection

Engine Type ................................................ In-line, 4-Cycle

Aspiration ......................................................Turbocharged

Engine Crankcase Vent System ................................ Open

Maximum Crankcase Pressure--in.H2O (kPa) ..........2 (0.5)

Physical Data

Cooling System

Prime

Standby

Eng. Heat Rejection--BTU/min (kW)..1303 (23) .. 1412 (25)

Coolant Flow--gal/min (L/min).................................. 24 (91)

Thermostat Start to Open--°F (°C) ......................... 192 (89)

Thermostat Fully Open--°F (°C)........................... 212 (100)

Maximum Water Pump

Inlet Restriction--in.H2O (kPa) ............................. 28 (7)

Engine Coolant Capacity--qt (L) ............................ 2.7 (2.6)

Recm’d Pressure Cap--psi (kPa) ........................... 15 (103)

Maximum Top Tank Temp--°F (°C) ...................... 221 (105)

Min. Coolant Fill Rate--gal/min (L/min) .................. 2.5 (9.5)

Min. Air-to-Boil Temperature--°F (°C) .................... 117 (47)

Electrical System

12 Volt 24 Volt

Length--in.(mm) ..................................................26.1 (662)

Width--in.(mm) ....................................................22.3 (566)

Height--in.(mm) ...................................................30.4 (772)

Weight, dry--lb (kg)...............................................553 (251)

(Includes flywheel housing, flywheel & electrics)

Center of Gravity Location

From Rear Face of Block (X-axis)--in.(mm)....7.6 (194)

Right of Crankshaft (Y-axis)--in.(mm) ...............0.6 (14)

Above Crankshaft (Z-axis)--in.(mm) ...............4.3 (108)

Max. Allow. Static Bending Moment at Rear

Face of Flywhl Hsg w/ 5-G Load--lb-ft (N•m) ....369 (500)

Thrust Bearing Load Limit (Forward)

Intermittent--lb (N)...................................... 1147 (5100)

Continuous--lb (N) .......................................629 (2800)

Exhaust Flow--ft3/min (m3/min)...........261 (7.4) .... 283(8.0)

Exhaust Temperature--°F (°C) ........963(517) .... 1026 (552)

Max. Allow. Back Press.--in.H2O (kPa)................... 30 (7.5)

Air System

Fuel System

Prime

Standby

Maximum Allowable Temp Rise--Ambient Air to

Engine Inlet--°F (°C) ............................................15 (8)

Maximum Air Intake Restriction

Dirty Air Cleaner--in.H2O (kPa).......................25 (6.25)

Clean Air Cleaner--in.H2O (kPa)..........................12 (3)

Engine Air Flow--ft3/min (m3/min) ........ 99 (2.8) ...106 (3.0)

Intake Manifold Pressure--psi (kPa)........ 9 (64) ...... 11 (75)

Rec’md. Battery Capacity (CCA)--amp............750 ...... N/A

Max. Allow. Starting Circuit Resist.--Ohm ...0.0012 ...... N/A

Starter Rolling Current

At 32 °F ( 0 °C)--amp...................................290 ...... N/A

At -22 °F (-30 °C)--amp ...............................370 ...... N/A

Maximum Voltage From Engine Crankshaft/

Generator Shaft to Ground--VAC ............0.15 ......... 0.15

Exhaust System

Prime

Prime

Prime

Standby

Oil Pressure at Rated Speed--psi (kPa) ................ 43 (296)

Oil Pressure at Low Idle--psi (kPa) ............................... N/A

Performance Data

Prime

Standby

Rated Power--hp (kW) .......................... 43 (32) ...... 49 (36)

Rated Speed--rpm ....................................1800 ......... 1800

Low Idle Speed--rpm .................................. N/A ........... N/A

BMEP--psi (kPa) ............................... 128 (883) .. 142 (981)

Friction Power @ Rated Speed--hp (kW) ................ 10(7.4)

Altitude Capability--ft (m) .............................. 10,000 (3050)

Ratio--Air : Fuel....................................... 23.9:1 ....... 22.5:1

Smoke @ Rated Speed--Bosch No. ............ 2.7 ............ 2.9

Noise--dB(A) @ 1 m .................................. 82.9 .......... 81.7

Prime

Standby

Fuel Consumption -- lb/hr (kg/h)

25 % Power ......................................4.4 (2.0) ....... 6.0 (2.7)

50 % Power ......................................8.8 (4.0) ....... 9.9 (4.5)

75 % Power ....................................13.3 (6.1) ..... 14.6 (6.6)

100 % Power ..................................17.9 (8.1) ..... 19.8 (9.0)

Standby

Standby

Fuel Injection Pump (Stanadyne)................. Unit Pump

Governor Regulation...................................................... 0%

Governor Type ......................................................Electrical

Total Fuel Flow--lb/hr (kg/hr).................................. 185 (84)

Fuel Consumption--lb/hr (kg/hr)......... 17.9(8.1) ... 19.8(9.0)

Maximum Fuel Transfer Pump Suction-ft (m) fuel........................................................... 10 (3.0)

Max. Fuel Inlet Temp.--°F (°C) ............................... 185 (85)

Fuel Filter Micron Size @ 98 % Efficiency........................ 5

All values at rated speed and power with standard options unless otherwise noted.

* Revised Data

Curve 4024TF281180049 .................................. Sheet 2 of 2

November 2007

Engine Performance Curves

4024 - Generator

November 2007

MARATHON ELECTRIC

DEDICATED SINGLE PHASE

TYPICAL SUBMITTAL DATA

Date: 03/10/05

Basic Model 283CSL1517

Kilowatt ratings at

1800 RPM

kW (kVA)

1 Phase

60 Hertz

Class B

80º C c

Continuous

P.F. Volts

0.8 120V

120/240V

1.0 120V

120/240V

4 Leads

Dripproof or Open Enclosure

Class H

Class F

90º C c

Lloyds

95º C c

ABS

105º C †

105º C c

British

Standard Continuous

130º C c

Standby

125º C †

125º C c

British

Standard Continuous

150º C c

Standby

16.5 (20.6) 17.5 (21.9) 17.5 (21.9) 19.0 (23.8)

19.0 (23.8)

21.0 (26.3) 21.0 (26.3)

21.0 (26.3)

22.0 (27.5)

26.0 (26.0) 27.0 (27.0) 27.0 (27.0) 30.0 (30.0)

30.0 (30.0)

32.0 (32.0) 32.0 (32.0)

32.0 (32.0)

35.0 (35.0)

c Rise by resistance method, Mil-Std-705, Method 680.1b.

† Rating per BS 5000.

Submittal Data: 240 Volts, 1800 RPM, 60 Hz, 1 Phase

Mil-Std-705B

Method

Description

301.1b

302.1a

Value

Insulation Resistance

High Potential Test

Main Stator

Main Rotor

Exciter Stator

Exciter Rotor

Stator Resistance, Line to Line

High Wye Connection

Rotor Resistance

Exciter Stator

Exciter Rotor

No Load Exciter Field Amps

at 240 Volts Line to Line

401.1a

410.1a

> 1.5 Meg

1500 volts

1500 volts

1500 volts

1500 volts

0.08 Ohms

1.14 Ohms

18.2 Ohms

0.14 Ohms

0.70 A DC

Mil-Std-705B

Method

505.3b

601.4a

601.4a

601.1c

-----------------------

95

30

90

% Efficiency

% Voltage Dip

40

10

0

Value

TYPICAL GENERATOR EFFICIENCY

TYPICAL MOTOR STARTING CHARACTERISTICS

20

Description

Overspeed

2250 RPM

L-L Harmonic Maximum - Total

6.3%

(Distortion Factor)

L-L Harmonic Maximum - Single

6.2%

Deviation Factor

7.0%

Type

Ext. Voltage Regulated, Brushless

Insulation

Class H

Coupling - Single Bearing

Flexible

Amortisseur Windings

Full

Cooling Air Volume

250 CFM

Exciter

Rotating

Voltage Regulator

SE350

Voltage Regulation

1%

1.0 pf

85

0.8 pf

80

75

0

10

20

30

40

50

Locked Rotor KVA

60

70

80

0

10

20

KW Output

30

40

MARATHON ELECTRIC

SYNCHRONOUS AC GENERATOR

TYPICAL SUBMITTAL DATA

Basic Model: 283PSL1706

Winding: WC1706

Date: 7/1/04

Kilowatt ratings at

1800 RPM

60 Hertz

kW (kVA)

3 Phase

0.8 Power Factor

Dripproof or Open Enclosure

Class F

Class H

125º C

105º C

British

125º C

150º C

British

105º C

130º C

Standby

Standard Continuous Standby Standard Continuous

Class B

80º C

Voltage* Continuous

90º C

Lloyds

95º C

ABS

240/480

230/460

220/440

208/416

190/380

23 (28.8)

23 (28.8)

22 (27.5)

22 (27.5)

20 (25.0)

23 (28.8)

23 (28.8)

22 (27.5)

22 (27.5)

20 (25.0)

22 (27.5)

22 (27.5)

21 (26.3)

21 (26.3)

19 (23.8)

25 (31.3)

24 (30.0)

24 (30.0)

23 (28.8)

21 (26.3)

Rise by resistance method, Mil-Std-705, Method 680.1b.

12 Leads

25 (31.3)

24 (30.0)

24 (30.0)

23 (28.8)

21 (26.3)

27 (33.8)

26 (32.5)

26 (32.5)

25 (31.3)

23 (28.8)

27 (33.8)

26 (32.5)

26 (32.5)

25 (31.3)

23 (28.8)

27 (33.8)

26 (32.5)

26 (32.5)

25 (31.3)

23 (28.8)

29 (36.3)

29 (36.3)

28 (35.0)

28 (35.0)

26 (32.5)

Rating per BS 5000.

Submittal Data: 480 Volts, 31.3 kVA, 1800 RPM, 60 Hz, 3 Phase

Mil-Std-705B

Method

Description

301.1b Insulation Resistance

302.1a High Potential Test

Main Stator

Main Rotor

Exciter Stator

Exciter Rotor

401.1a Stator Resistance, Line to Line

High Wye Connection

Rotor Resistance

Exciter Stator

Exciter Rotor

410.1a No Load Exciter Field Amps

at 480 Volts Line to Line

420.1a Short Circuit Ratio

421.1a Xd Synchronous Reactance

422.1a X2 Negative Sequence

Reactance

423.1a X0 Zero Sequence Reactance

425.1a X'd Transient Reactance

426.1a X''d Subtransient Reactance

427.1a T'd Transient Short Circuit

Time Constant

428.1a T''d Subtransient Short Circuit

Time Constant

430.1a T'do Transient Open Circuit

Time Constant

432.1a Ta Short Circuit Time

Constant of Armature Winding

Mil-Std-705B

Method

Description

Value

505.3b

Overspeed

2250 RPM

507.1c

Phase Sequence CCW-ODE

ABC

2000 Volts

601.4a

L-L Harmonic Maximum - Total

3.0%

1500 Volts

(Distortion Factor)

1500 Volts

601.4a

L-L Harmonic Maximum - Single

3.0%

1500 Volts

601.1c

Deviation Factor

<5%

--TIF (1960 Weightings)

<50

0.50 Ohms

0.41 Ohms

Additional Prototype Mil-Std Methods

17.5 Ohms

are Available on Request.

0.12 Ohms

-Generator Frame

280

0.74 A DC

-Type

Ext. Voltage Regulated, Brushless

0.76

-Insulation

Class H

2.0 pu

-Coupling - Single Bearing

Flexible

-Amortisseur Windings

Full

0.160 pu

-Cooling Air Volume

250 CFM

0.036 pu

-Exciter

Rotating

0.100 pu

-Voltage Regulator

SE350

0.092 pu

-Voltage Regulation

1%

Value

> 1.5 Meg

0.023 sec.

0.013 sec.

0.585 sec.

0.017 sec.

* Voltage refers to wye (star) connection, unless otherwise specified.

------

Heat Rejection Rate

Full Load Current

Minimum Input Hp Required

Efficiency at Rated Load

Full Load Torque

216 BTU/min

30.0 A

38.6 Hp

86.8%

113 ft*lb

MARATHON ELECTRIC

SYNCHRONOUS AC GENERATOR

TYPICAL DYNAMIC CHARACTERISTICS

Basic Model: 283PSL1706

Winding: WC1706

Date: 7/1/04

60 HERTZ

Recovery

Time (Sec.)

Recovery

Time (Sec.)

1

0

1

0

LOAD APPLICATION

LOAD REJECTION

20

20

% Voltage Rise

% Voltage Dip

240 V DELTA

208/416 V

10

240/480 V

0

240 V DELTA

208/416 V

10

240/480 V

0

0

5

10

15

20

kW at 0.8 Power Factor

25

0

5

10

15

20

kW at 0.8 Power Factor

25

TYPICAL MOTOR STARTING CHARACTERISTICS

40

240 V DELTA

208/416 V

% Voltage Dip

30

240/480 V

20

10

0

0

20

40

60

80

100

Locked Rotor kVA

TYPICAL GENERATOR EFFICIENCY

100

100

416 V

1.0 pf

90

85

0.8 pf

1.0 pf

90

85

80

80

75

75

0

480 V

95

% Efficiency

% Efficiency

95

10

20

30

40

kW Output

Voltage refers to wye (star) connection, unless otherwise specified.

0.8 pf

0

10

20

kW Output

30

40

®

DSEGenset

DSE7410/20

ENVIRONMENTAL TESTING STANDARDS

ELECTRO-MAGNETIC COMPATIBILITY

BS EN 61000-6-2

EMC Generic Immunity Standard for

the Industrial Environment

BS EN 61000-6-4

EMC Generic Emission Standard for

the Industrial Environment

AUTO START & AUTO MAINS FAILURE MODULES

FEATURES

ELECTRICAL SAFETY

BS EN 60950

Safety of Information Technology Equipment,

including Electrical Business Equipment

The DSE7410 is an Auto Start

Control Module and the DSE7420

is an Auto Mains (Utility) Failure

Control Module suitable for a wide

variety of single, diesel or gas,

gen-set applications.

A sophisticated module monitoring

an extensive number of engine

parameters, the DSE74xx will

annunciate warnings, shutdown

and engine status information on

the back-lit LCD screen, illuminated

LED, remote PC, audible alarm and

via SMS text alerts. The module

includes RS232, RS485 & Ethernet

ports as well as dedicated

terminals for system expansion.

The DSE7400 Series modules are

compatible with electronic (CAN)

and non-electronic (magnetic pickup/alternator sensing) engines and

offer a comprehensive number of

flexible inputs, outputs and

extensive engine protections so the

system can be easily adapted to

meet the most demanding industry

paralleling requirements.

TEMPERATURE

BS EN 60068-2-1

o

Ab/Ae Cold Test -30 C

BS EN 60068-2-2

Bb/Be Dry Heat +70 oC

VIBRATION

BS EN 60068-2-6

Ten sweeps in each of three

major axes

5 Hz to 8 Hz @ +/-7.5 mm,

8 Hz to 500 Hz @ 2 gn

HUMIDITY

BS EN 60068-2-30

Db Damp Heat Cyclic 20/55 oC

@ 95% RH 48 Hours

BS EN 60068-2-78

Cab Damp Heat Static 40 oC

@ 93% RH 48 Hours

The modules can be easily

configured using the DSE

Configuration Suite Software.

Selected front panel editing is also

available.

SHOCK

BS EN 60068-2-27

Three shocks in each of three major axes

15 gn in 11 mS

DEGREES OF PROTECTION

PROVIDED BY ENCLOSURES

BS EN 60529

IP65 - Front of module when installed into the

control panel with the supplied sealing gasket.

COMPREHENSIVE FEATURE LIST TO SUIT A WIDE VARIETY OF

GEN-SET APPLICATIONS

MODEM

DSE2130

DSE2131

DSE2133

DSE2152

DSE2157

DSE2548

MODBUS

PC

11

232

DSENET

EXPANSION

6

4

485

RS232 AND

RS485

USB

PORT

USB

HOST

CONFIGURABLE

INPUTS

DC OUTPUTS

ANALOGUE

SENDERS

EMERGENCY

STOP

DC POWER

SUPPLY 8-35V

ETHERNET

+

DEUTZ

ISUZU

PERKINS

CATERPILLAR

MTU

VOLVO

CUMMINS

SCANIA

DSE7410/20

7

OTHER

MAINS (UTILITY) SENSING (DSE7420)

BUS SENSING (DSE7410)

N/C VOLT FREE

OUTPUT

N/O VOLT

FREE OUTPUT

CHARGE

ALTERNATOR

GENERATOR SENSING

FUEL & CRANK

OUTPUTS

FLEXIBLE WITH CAN

VOLTS

1ph

2ph

3ph

N

CURRENT

1

1

1ph

2ph

3ph

E

N

VOLTS

D+

W/L

ELECTRONIC

ENGINES &

MAGNETIC PICK-UP

+

1ph

2ph

3ph

N

ISSUE 1

®

DSEGenset

DSE7410/20

SPECIFICATION

AUTO START & AUTO MAINS FAILURE MODULES

DC SUPPLY

CONTINUOUS VOLTAGE RATING

8 V to 35 V Continuous

CRANKING DROPOUTS

Able to survive 0 V for 50 mS, providing

supply was at least 10 V before dropout

and supply recovers to 5 V. This is achieved

without the need for internal batteries

FEATURES

DSE7420

MAXIMUM OPERATING CURRENT

260 mA at 12 V, 130 mA at 24 V

MAXIMUM STANDBY CURRENT

120 mA at 12 V, 65 mA at 24 V

CHARGE FAIL/EXCITATION RANGE

0 V to 35 V

DSE7410

OUTPUTS

OUTPUT A (FUEL)

15 A DC at supply voltage

OUTPUT B (START)

15 A DC at supply voltage

OUTPUTS C & D

8 A AC at 250 V AC (Volt free)

AUXILIARY OUTPUTS E,F,G,H,I & J

2 A DC at supply voltage

KEY FEATURES

• Configurable inputs (11)

• Configurable outputs (8)

• Voltage measurement

• Mains (utility) failure detection

• Dedicated load test button

• kW overload alarms

• Comprehensive electrical

protection

• RS232, RS485 & Ethernet

remote communications

• Modbus RTU/TCP

• PLC functionality

• Multi event exercise timer

• Back-lit LCD 4-line text display

• Multiple display languages

• Automatic start/Manual start

• Audible alarm

• Fixed and flexible LED indicators

• Event log (250)

• Engine protection

• Fault condition notification to

a designated PC

• Front panel mounting

• Protected front panel

programming

• Configurable alarms and timers

• Configurable start and stop timers

• Five key menu navigation

• Front panel editing with PIN

protection

• 3 configurable maintenance

alarms

• CAN and magnetic pick-up/Alt.

sensing

• Fuel usage monitor and low fuel

alarms

• Charge alternator failure alarm

• Manual speed control (on

compatible CAN engines)

• Manual fuel pump control

• “Protections disabled” feature

• Reverse power protection

• Power monitoring (kW h, kV Ar,

kV A h, kV Ar h)

• Load switching (load shedding

and dummy load outputs)

• Automatic load transfer (DSE7420)

• Unbalanced load protection

• Independent earth fault trip

• Fully configurable via DSE

Configuration Suite PC software

• Configurable display languages

• Remote SCADA monitoring via

DSE Configuration Suite PC

software

• Advanced SMS messaging

(additional external modem

required)

• Start & stop capability via SMS

messaging

• Additional display screens to

help with modem diagnostics

• DSENet® expansion

• Integral PLC editor

KEY BENEFITS

• RS232, RS485 & Ethernet can

be used at the same time

• DSENet® connection for

system expansion

• PLC functionality

• Five step dummy load support

• Five step load shedding support

• High number of inputs and

outputs

• Worldwide language support

• Direct USB connection to PC

• Ethernet monitoring

• USB host

• Data logging & trending

GENERATOR

VOLTAGE RANGE

15 V to 333 V AC (L-N)

FREQUENCY RANGE

3.5 Hz to 75 Hz

MAINS (UTILITY) (DSE7420)

VOLTAGE RANGE

15 V to 333 V AC (L-N)

FREQUENCY RANGE

3.5 Hz to 75 Hz

BUS (DSE7410)

VOLTAGE RANGE

15 V to 333 V AC (L-N)

FREQUENCY RANGE

3.5 Hz to 75 Hz

MAGNETIC PICK UP

VOLTAGE RANGE

+/- 0.5 V to 70 V

FREQUENCY RANGE

10,000 Hz (max)

DIMENSIONS

OVERALL

240 mm x 172 mm x 57 mm

9.4” x 6.8” x 2.2”

PANEL CUTOUT

220 mm x 160 mm

8.7” x 6.3”

MAXIMUM PANEL THICKNESS

8 mm

0.3”

STORAGE TEMPERATURE RANGE

-40 oC to +85 oC

RELATED MATERIALS

TITLE

DSE7410 Installation Instructions

DSE7420 Installation Instructions

DSE74xx Quick Start Guide

DSE74xx Operator Manual

DSE74xx PC Configuration Suite Manual

PART NO’S

053-085

053-088

057-162

057-161

057-160

DEEP SEA ELECTRONICS PLC UK

Highfield House, Hunmanby Industrial Estate, Hunmanby YO14 0PH

TELEPHONE +44 (0) 1723 890099 FACSIMILE +44 (0) 1723 893303

EMAIL sales@deepseaplc.com WEBSITE www.deepseaplc.com

DEEP SEA ELECTRONICS INC USA

3230 Williams Avenue, Rockford, IL 61101-2668 USA

TELEPHONE +1 (815) 316 8706 FACSIMILE +1 (815) 316 8708

EMAIL sales@deepseausa.com WEBSITE www.deepseausa.com

Deep Sea Electronics Plc maintains a policy of continuous development and reserves the right to change

the details shown on this data sheet without prior notice. The contents are intended for guidance only.

Registered in England & Wales No.01319649

VAT No.316923457

055-108/01/12 (1)

Tmax-Molded Case Circuit Breakers

T1 100A Frame

AC Circuit Breakers & Switches

DC Circuit Breakers & Switches

1, 3 and 4 Poles

Higher performances in less space

Field Installable Accessories

Dimensions

Compliance with Standards

UL 489

CSA C22.2 No.5.1

IEC 60947-2

Standards

EC directive:

3P Fixed Version

5.12H x 3.00W x 2.76D

The ABB Quality System complies with the international ISO

9001 - 2000 Standard (model for quality assurance in design,

development, construction, and installation and service) and

with the equivalent European EN ISO 9001 and Italian UNI EN

ISO 9001 Standards

– “Low Voltage Directives” (LVD) no. 73/23 EEC

– “Electromagnetic Compatibility Directive” (EMC) no.89/336 EEC

Interrupting ratings (RMS sym. kAmps)

Continuous Current Rating

Number of Poles

AC

240V

277V

347V

480V

600Y/347V

DC

250V

2 poles in series

500V 3 poles in series

Please Note: 15 A 1P 10Kaic @ 347Vac, 3p 14Kaic @ 480Y/277Vac, 3p 35Kaic @ 240Vac

T1

100A

1

B

100A

3-4

N

50

18

14

22

10

25

25

Company Quality Systems and Environmental Systems

The new Tmax series has a hologram on the front, obtained

using special anti-imitation techniques, which guarantees the

quality and that the circuit breaker is an original ABB product.

Attention to protection of the environment and to health and

safety in the work place is another priority commitment for ABB

and, as confirmation of this, the company environmental management system has been certified by RINA in 1997, in conformity with the international ISO 14001 Standard. This certification has been integrated in 1999 with the Management System

for Health and Safety in the workplace, according to OHSAS

18001 (British Standards), obtaining one of the first certification

of integrated management System, QES (Quality, Environment,

Safety) issued by RINA. ABB - the first industry in the electromechanical section in Italy to obtain this recognition - thanks

to a revision of the production process with an eye to ecology

has been able to reduce the consumption of raw materials

and waste from processing by 20%. ABB’s commitment to

safeguarding the environment is also shown in a concrete

way by the Life Cycle Assessments of its products carried out

directly by the ABB Research and Development in collaboration with the ABB Research Center. Selection of materials,

processes and packing materials is made optimizing the true

environmental impact of the product, also foreseeing the possibility of its being recycled.

Mounting

Trip Unit

Fixed

TMF thermo magnetic trip units, with fixed thermal and magnetic threshold (I3 = 10 x In);

Connections

Pressure-type terminals for bare copper cables

Weight (Ibs)

2.34

Auxiliary Devices for Indication and Control

•

Auxiliary contacts - AUX

•

Key lock - KLF

•

Undervoltage release - UVR

•

Early auxiliary contact - AVE

•

Shunt trip - SOR

•

Front terminal for copper cable - FC CU

•

Terminal covers

•

Front extended terminal - EF

•

Flange handle mechanism

•

Phase separators

•

Direct rotary handle - RHD

•

Residual current release (IEC Only)

•

Through the door rotary handle

•

Mechanical interlock

•

Solenoid operator

Publication LV035

No. 1SXU 210 035 D0201

Printed in USA, November, 2005

ABB Inc.

1206 Hatton Road

Wichita Falls, TX 76302

For more information and

the location of your local

field office please go to

www.abb-control.com

Powerpact® Q-Frame Molded Case Circuit Breakers and Switches

Catalog

DESCRIPTION

The Square D® Powerpact® Q-Frame line of circuit breakers includes QB, QD, QG and QJ molded case

circuit breakers and QB automatic switches. They are rated 240 Vac, 250 A max. and are available in

lug/lug or bus-connected unit-mount construction, or I-Line® group-mounted construction.

Applications

The Powerpact Q-Frame circuit breakers are used for overcurrent protection and switching on ac

systems. Powerpact Q-Frame circuit breakers are rated for 240 Vac (208Y/120 for 3-pole 100 kA) and

are available with UL® Listed interrupting ratings from 10,000 to 100,000 A rms symmetrical. Unit-mount

circuit breakers are available with lugs on both ends for cabled applications or with mounting studs for

bus-mounted applications. These circuit breakers may be mounted in individual enclosures, metering

devices, panelboards or switchboards. The I-Line circuit breakers are specifically designed for use in

I-Line panelboards and switchboards.

NOTE: The Powerpact Q-Frame Circuit Breaker is a direct replacement for the Q2 Series device.

Figure 1: Powerpact Q-Frame Unit-Mount Circuit Breakers

Powerpact Q-Frame Two-Pole

Unit-Mount Molded Case Circuit Breaker

Powerpact Q-Frame Three-Pole

Unit-Mount Molded Case Circuit Breaker

Figure 2: Powerpact Q-Frame I-Line Group-Mounted Circuit Breakers

Powerpact Q-Frame Two-Pole

I-Line Molded Case Circuit Breaker

Powerpact Q-Frame Three-Pole

I-Line Molded Case Circuit Breaker

3

10/03

© 2002–2003 Schneider Electric All Rights Reserved

Powerpact® Q-Frame Molded Case Circuit Breakers and Switches

Catalog

SUMMARY OF

SPECIFICATIONS

Table 8 (below) contains a summarization of specifications for UL and CSA rated Powerpact Q-frame

molded case circuit breakers and automatic switches.

Table 8: Specifications for UL and CSA Rated Molded Case Circuit Breakers and Switches

Specifications:

For Molded Case Circuit Breakers:

For Automatic Switches:

Number of Poles

2- and 3-pole

2- and 3-pole

Operating Voltage

240 Vac (208Y/120 for 3-pole at 100 kA)

240 Vac

Unit-mount 70–250 A

Unit-mount 70–250 A

Current Rating

Rated Frequency

I-Line 70–225 A

I-Line 70–225 A

50–60 Hz

50–60 Hz

10 kA (QB)

10 kA (QB)

25 kA (QD)

—

65 kA (QG)

—

100 kA (QJ)

—

Interrupting Rating (AIR)

UL489 (File E84905)

UL489 (File 33117)

Certification Standards

NEMA AB-1-1999

CSA C22.2 No. 5-02 (File 33117)

ANCE NMX-J-266-ANCE-2002

—

Mounting

Unit-mount and I-Line Mounting

Unit-mount and I-Line Mounting

Lugs: #4–300 kcmil (25–150 mm²)

Lugs: #4–300 kcmil (25–150 mm²)

Studs: 1/4-20

Studs: 1/4-20

Connectors

I-Line Plug-on and Bolt-on

I-Line Plug-on and Bolt-on

Forward or Reverse Feed

Forward or Reverse Feed

Temperature

40° C (104° F)

40° C (104° F)

Endurance Rating (C/O Cycles)

1,000 load; 5,000 no load (6,000 total)

1,000 load; 5,000 no load (6,000 total)

Connection

Table 9 (below) contains a summarization of specifications for UL and CSA rated Powerpact Q-Frame

molded case circuit breakers and automatic switches.

Table 9: IEC Declared Ratings

Standards:

For Molded Case Circuit Breakers:

Certification Standard

IEC 60947-2—1995 + A1:1997 + A2:2001 IEC 60947-2, Appendix L

For Automatic Switches:

Number of Poles

2- and 3-pole

2- and 3-pole

Rated Current In

225 A

225 A

Rated Operational Voltage Ue

IEC 415Y/240~

IEC 415Y/240~

Rated Insulation Voltage Ui

750 V

750 V

Overcurrent Protection Device

—

Requires equivalent 225 A circuit breaker

Rated Conditional Short-circuit Current Icc

—

10 kA

Instantaneous Tripping Current Ii

—

2.5 kA

Rated Frequency

50–60 Hz

50–60 Hz

Rated Ultimate Short-circuit Breaking

Capacity, Icu

Icu = 10 kA

—

Rated Service Short-circuit Breaking

Capacity Ics

50% of Icu

—

Classification

—

X

Connection Method

Forward or reverse

Forward or reverse

Suitable for Isolation

Yes (without padlock attachment)

Yes (without padlock attachment)

Impulse Voltage

6k V

6k V

8

© 2002–2003 Schneider Electric All Rights Reserved

10/03

Genset Chargers

2610A

2608A-B-01

2602A-12

Guest chargers are proven performers in genset applications.

For specific application information, or if you are developing a new

product, be sure to consult with the Guest applications engineering

team to ensure the correct charger is specified.

Genset Chargers

MODEL

TOTAL

AMPS

OUTPUTS

AMPS PER

OUTPUT

BATTERY

SYSTEM

INPUT

VOLTAGE

AC

DC

DIMENSIONS

WT.

(LBS)

AGENCY

LISTING

2

1

2

12V

100 - 130

50/60Hz

6' w/

ConnectCharge plug

4' w/ ring

terminals

2.9" x 5.1" x 1.5"

2

UL

5

1

5

24V

100 - 130

50/60Hz

6' SJT 18-3

w/ ConnectCharge plug

6' SJT 18-3

w/ ring

terminals

7.4" x 6.3" x 2.4"

4.5

UL

6

1

6

12V

100 - 130

50/60Hz

6' cable w/

molded plug

4' w/ ring

terminals

3.5" x 6.4" x 2.3"

4

UL

rated -40 to 105C

rated -40 to 105C

100 - 130

50/60Hz

Studs

Studs

5.5" x 7.8" x 2.4"

5.6

2602A-12

2602A-12-B (bulk)

2605A-1-24RT-01

(bulk pack only) (1)

2608A-B-01

(bulk pack only) (1)

2610A

10

2610A-B (bulk)

2

5/5

12V+12V

–

UL

(bulk only)

(1) 2-stage charging

Individual agency listings as shown in product chart.

12

Phone: 800-767-8541 • Fax: 707-226-9670 • www.guestindustrial.com

14

®

Features

• Compact Spiral Chamber Design

• Premium Silencing

• Low Back Pressure

• Low Weight

• Aluminized Steel Construction

Maximum Temp: 1200 °F (650 °C)

• Standard High-Temperature Finish

• All MIG Welded Construction

• Steel Wool and Mesh Liner

• Slip-fit Connections Standard

TS Residential Grade - TR Model

Typical Insertion Loss 22-28 dbA*

K

K

C

H

D

B

Options

• Factory Customization Available

• 316L Stainless Steel Construction

• Reverse Flow

• Inlet/Outlet Configurations

• 125/150# A.N.S.I. Flange Connections

• Male/Female N.P.T. Connections

• Exterior Finishes

• Complete line of Accessories and

Mounting Brackets

G

A

F

E

*Actual insertion loss value may vary by application.

All measurements in inches unless otherwise noted.

COWL

Model No.

TS15TR

TS20TR

TS25TR

TS30TR

TS35TR

TS40TR

TS45TR

TS50TR

TS60TR

TS70TR

TS80TR

TS100TR

TS120TR

COWL

Part No.

TS15TRS000

TS20TRS000

TS25TRS000

TS30TRS000

TS35TRS000

TS40TRS000

TS45TRS000

TS50TRS000

TS60TRS000

TS70TRS000

TS80TRS000

TS100TRS000

TS120TRS000

Inlet Outlet

A dia. B dia.

(I.D.) (O.D.)

1.50

2.00

2.50

3.00

3.50

4.00

4.50

5.00

6.00

8.00

8.00

10.00

12.00

1.50

2.00

2.50

3.00

3.50

4.00

4.50

5.00

6.00

8.00

8.00

10.00

12.00

C

D

E

F

G

H

K

Approximate

Weight

5.24

7.24

8.24

9.24

11.49

15.49

12.49

16.49

22.49

15.35

24.27

30.08

36.08

2.50

3.50

3.50

5.25

5.25

5.25

5.00

5.00

5.00

6.55

6.55

6.25

5.75

4.34

4.59

5.66

7.41

7.66

7.91

10.28

10.53

11.03

15.00

15.00

19.00

22.50

2.07

2.07

2.07

2.07

2.26

2.35

2.57

2.57

2.57

3.97

3.97

2.62

3.71

7.18

7.18

8.81

11.81

11.81

11.81

16.06

16.06

16.06

22.00

22.00

28.00

33.00

8.68

9.18

11.31

14.81

15.31

15.81

20.56

21.06

22.06

30.00

30.00

38.00

45.00

0.50

0.50

0.50

0.75

0.75

0.75

1.00

1.00

1.00

1.45

1.45

1.75

2.25

11 lbs

15 lbs

20 lbs

32 lbs

38 lbs

47 lbs

66 lbs

74 lbs

94 lbs

105 lbs

162 lbs

268 lbs

380 lbs

Engine Exhaust Silencer & Accessories

Representative Cowl Insertion Loss - TS Series dB(A)

35

Insertion Loss, dB(A)

30

Silencer

Flange/Gasket

Rain Cap

25

Elbows

20

15

10

Mounting Bracket

5

62.5

125

500

2000

250

1000

Octave Band Center Frequency (Hz)

4000

8000

Flex Connector

Mitered Exhaust

Not pictured: Insulation Blanket

Phillips & Temro Industries • Winnipeg, MB Canada • (204) 667-2260 • Fax (204) 661-2639

Prior Lake, MN U.S.A. • (612) 440-9200 • Fax (612) 440-3400

Rev 11/99

Page 23

TS-TR

Exhaust Silencer Specifications

®

Exhaust Silencer Specifications

Features

• Compact Spiral Chamber Design

• Premium Silencing

• Low Back Pressure

• Low Weight

• Aluminized Steel Construction

Maximum Temp: 1200 °F (650 °C)

• Standard High-Temperature Finish

• All MIG Welded Construction

• Steel Wool and Mesh Liner

• Slip-fit Connections Standard

TXS Critical Grade - TR Model

Typical Insertion Loss 28-33 dbA*

K

C

H

D

B

Options

• Factory Customization Available

• 316L Stainless Steel Construction

• Reverse Flow

• Inlet/Outlet Configurations

• 125/150# A.N.S.I. Flange Connections

• Male/Female N.P.T. Connections

• Exterior Finishes

• Complete line of Accessories and

Mounting Brackets

G

A

F

E

*Actual insertion loss value may vary by application.

All measurements in inches unless otherwise noted.

COWL

Model No.

TXS15TR

TXS20TR

TXS25TR

TXS30TR

TXS35TR

TXS40TR

TXS45TR

TXS50TR

TXS60TR

TXS70TR

TXS80TR

TXS100TR

TXS120TR

COWL

Part No.

TXS15TRS000

TXS20TRS000

TXS25TRS000

TXS30TRS000

TXS35TRS000

TXS40TRS000

TXS45TRS000

TXS50TRS000

TXS60TRS000

TXS70TRS000

TXS80TRS000

TXS100TRS000

TXS120TRS000

Inlet Outlet

A dia. B dia.

(I.D.) (O.D.)

1.50

2.00

2.50

3.00

3.50

4.00

4.50

5.00

6.00

8.00

8.00

10.00

12.00

1.50

2.00

2.50

3.00

3.50

4.00

4.50

5.00

6.00

8.00

8.00

10.00

12.00

C

D

E

F

G

H

K

Approximate

Weight

5.24

7.24

8.24

9.24

11.49

15.49

12.49

16.49

22.49

15.41

24.33

30.08

36.08

2.50

3.50

3.25

5.00

5.00

5.00

4.55

4.55

4.55

6.55

6.55

6.25

5.75

5.19

5.41

7.16

9.53

9.78

10.03

11.94

12.19

12.69

17.25

17.25

22.00

26.00

2.07

2.07

1.82

2.07

2.07

2.07

1.46

2.12

2.05

3.97

3.97

2.62

3.71

8.81

8.81

11.81

16.06

16.06

16.06

19.38

19.38

19.38

26.50

26.50

34.00

40.00

10.38

10.81

14.31

19.06

19.56

20.06

23.88

24.38

25.38

34.50

34.50

44.00

52.00

0.50

0.50

0.75

1.00

1.00

1.00

1.45

1.45

1.45

1.45

1.45

1.75

2.25

14 lbs

19 lbs

32 lbs

52 lbs

63 lbs

77 lbs

81 lbs

98 lbs

137 lbs

147 lbs

227 lbs

375 lbs

532 lbs

Engine Exhaust Silencer & Accessories

Representative Cowl Insertion Loss - TXS Series dB(A)

35

Silencer

Insertion Loss, dB(A)

30

Flange/Gasket

Rain Cap

Elbows

25

20

15

10

Mounting Bracket

5

62.5

125

500

2000

250

1000

Octave Band Center Frequency (Hz)

4000

8000

Flex Connector

Phillips & Temro Industries • Winnipeg, MB Canada • (204) 667-2260 • Fax (204) 661-2639

Prior Lake, MN U.S.A. • (612) 440-9200 • Fax (612) 440-3400

Mitered Exhaust

Not pictured: Insulation Blanket

Rev 11/99

Page 33

TXS-TR

K