RACO SolutionsII Catalog

advertisement

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

SolutionsII

© RACO Interior Products, Inc. 2001

1

RACO Interior OfficeFronts™

™™

SolutionsII

SolutionsII

Product

TypicalOverview

Details

I. GENERAL DESCRIPTION

Work Included: Furnish all necessary materials, labor and equipment for the complete

installation of interior aluminum framing as shown on the drawings and specified herein.

(Specifier Note: It is suggested that related items such as aluminum & wood entrance doors,

glass, be included whenever possible.)

Work Not Included: Structural support of the framing system, interior closures, trim.

(Specifier list other exclusions).

Related Work Specified Elsewhere: (Specifier list).

QUALITY ASSURANCE

Drawings and specifications are based on the Solutions II Interior Officefronts(TM) System

as manufactured by RACO Interior Products, Inc. Whenever substitute products are to be

considered, supporting technical literature, samples, drawings and performance data must be

submitted ten (10) days prior to bid in order to make a valid comparison of the products

involved. Test reports certified by an independent test laboratory must be made available

upon request.

II. PRODUCTS MATERIALS

Extrusions shall be 6063-T5 alloy and temper (A.S.T.M. B221 alloy T5 temper). Fasteners,

shall be aluminum, stainless steel or zinc plated steel in accordance with A.S.T.M. A 164.

Glazing gaskets shall be E.P.D.M. elastomeric extrusions.

FINISH

All exposed framing surfaces shall be free of scratches and other serious blemishes. Aluminum

extrusions shall be given a caustic etch followed by an anodic oxide treatment to obtain...

(Specify one of the following):

_____#14 Clear anodic coating

_____#63 Bronze Paint

_____#65 Black Paint

_____#61 White Paint

_____#62 Grey Paint

_____#88 Custom Match Paint

© RACO Interior Products, Inc. 2001

2

RACO Interior OfficeFronts™

™™

SolutionsII

SolutionsII

Product

TypicalOverview

Details

FABRICATION

The framing system shall provide for flush glazing on all sides with no projecting stops. Vertical

and horizontal framing members shall have a nominal face dimension of (Specify).

III. EXECUTION

INSTALLATION

All glass and door framing shall be set in correct locations as shown in the details and shall be

level, square, plumb and in alignment with other work in accordance with the manufacturers’

installation instructions and approved shop drawings. All work shall start from bench marks and

/ or column lines as established by the architectural drawings and the general contractor with

guaranteed accuracy.

PROTECTION AND CLEANING

After installation the General Contractor shall adequately protect exposed portions of aluminum

surfaces from damage by grinding and polishing compounds, plaster, lime, acid, cement, or

other contaminants. The General Contractor shall be responsible for final cleaning in

accordance with A.A.M.A. specifications 609.1 for anodize

© RACO Interior Products, Inc. 2001

3

RACO Interior OfficeFronts™

™™

SolutionsII

SolutionsII

Product

TypicalOverview

Details

RACO Interior OfficeFronts™ door frames,

sidelights and borrowed light frames can be

shipped to the job site K.D., as open assembled

panels, or as shop glazed panels ready for

installation into finished drywall openings as shown

on the approved shop drawings. Solutions II

framing features screw race joinery. Horizontal and

vertical mullions are joined together with screws

driven through the back of the two piece (split)

vertical members into the extruded screw splines in

the horizontals.

Solutions II offers the architect/designer unlimited

design possibilities with standard 1½", 2", 3", 4" and

5" trim profiles that can be mixed and matched on

door frames and borrowed light

Top load,

push-in gaskets

© RACO Interior Products, Inc. 2001

Borrowed and sidelight openings provide for flush

glazing on all four sides with no projecting glass

stops or exposed fasteners. Top load glazing

gaskets are used on both sides of the glass to

secure it into the aluminum glazing pockets and

eliminate visible raw glass edges.

4

RACO Interior OfficeFronts™

™ Reference

™ Typical Details

SolutionsII

SolutionsII

Drawings

Door Frame

1

3

2

Door Frame with Sidelight

5

1

4

7

6

2

8

See reference matrix pages for typical details information.

© RACO Interior Products, Inc. 2001

5

RACO Interior OfficeFronts™

™ Reference

™ Typical Details

SolutionsII

SolutionsII

Drawings

Door Frame with Partial Height Sidelight

5

1

4

2

8

6

3

Door Frame with Transom

5

6

9

3

2

See reference matrix pages for typical details information.

© RACO Interior Products, Inc. 2001

6

RACO Interior OfficeFronts™

™ Reference

™ Typical Details

SolutionsII

SolutionsII

Drawings

Door Frame with Sidelight and Transom

5

5

10

6

9

4

2

6

8

Borrowed Light

5

10

7

6

8

6

See reference matrix pages for typical details information.

© RACO Interior Products, Inc. 2001

7

RACO Interior OfficeFronts™

™ Reference

™ Typical Details

SolutionsII

SolutionsII

Drawings

Partial Height Borrowed Light

5

10

7

6

8

Cased Opening

11

11

11

11

11

See reference matrix pages for typical details information.

© RACO Interior Products, Inc. 2001

8

RACO Interior OfficeFronts™

™ Reference

™ Typical Details

SolutionsII

SolutionsII

Drawings

Corners

RN425

RN425

RN255

RN425

RN425

RN425

RN252

RN255

RN425

RN425

RN425

RN252

RN425

RN252

RN252

RN425

RN425

RN425

RN252

RN252

RC306

RC306

RN425

RN425

12

RN425

13

RN425

14

15

RR238

JR454

JD454

RR212

RR519

RR517

NS700

4

1/2"

4

1/2"

RR213

JP454

JP454

16

17

18

JD454

JD454

4

1/2"

4

1/2"

JD454

JR454

20

21

See reference matrix pages for typical details information.

© RACO Interior Products, Inc. 2001

9

19

RACO Interior OfficeFronts™

SolutionsII

SolutionsII™™Reference

Typical Details

Matrix

Elevation Number

375 Series

1 ½” Profile

2” Profile

3” Profile

4” Profile

5” Profile

1

2

N2-1, N2-2

N2-15

N2-29

N2-43

N2-57

N2-3

N2-17

N2-31

N2-45

N2-59

3

4

5

6

N2-4

N2-18

N2-32

N2-46

N2-60

N2-5, N2-6

N2-19, N2-20

N2-33, N2-34

N2-47, N2-48

N2-61, N2-62

N2-7, N2-8

N2-21

N2-35

N2-49

N2-63

N2-7

N2-21

N2-35

N2-49

N2-63

7

N2-9

N2-23

N2-37

N2-51

N2-65

8

N2-10, N2-11

N2-16, N2-22

N2-24, N2-25

N2-30, N2-36

N2-38, N2-39,

N2-44, N2-50

N2-52, N2-53

N2-58, N2-64

N2-66, N2-67

N2-71, N2-72

9

N2-12

N2-26

N2-40

N2-54

N2-68

10

N2-13

N2-27

N2-41

N2-55

N2-69

11

12

N2-14

N2-28

N2-42

N2-56

N2-70

N2-73

N2-83

N2-84

N2-85

N2-86

N2-74

N2-87

N2-88

N2-89

N2-90

N2-75

N2-91

N2-92

N2-93

N2-94

N2-76

N2-95

N2-96

N2-97

N2-98

13

14

15

16

17

18

N2-77

N2-78

N2-79

19

20

N2-80

21

N2-82

N2-81

See reference elevation pages for typical details information.

© RACO Interior Products, Inc. 2001

10

RACO Interior OfficeFronts™

SolutionsII

SolutionsII™™Reference

Typical Details

Matrix

Elevation Number

487 Series

1 ½” Profile

2” Profile

3” Profile

4” Profile

5” Profile

1

2

N3-1, N3-2

N3-15

N3-29

N3-43

N3-57

N3-3

N3-17

N3-31

N3-45

N3-59

3

4

5

6

N3-4

N3-18

N3-32

N3-46

N3-60

N3-5, N3-6

N3-19, N3-20

N3-33, N3-34

N3-47, N3-48

N3-61, N3-62

N3-7, N3-8

N3-21

N3-35

N3-49

N3-63

N3-7

N3-21

N3-35

N3-49

N3-63

7

N3-9

N3-23

N3-37

N3-51

N3-65

8

N3-10, N3-11

N3-16, N3-22

N3-24, N3-25

N3-30, N3-36

N3-38, N3-39,

N3-44, N3-50

N3-52, N3-53

N3-58, N3-64

N3-66, N3-67

N3-71, N3-72

9

N3-12

N3-26

N3-40

N3-54

N3-68

10

N3-13

N3-27

N3-41

N3-55

N3-69

11

12

N3-14

N3-28

N3-42

N3-56

N3-70

N3-73

N3-83

N3-84

N3-85

N3-86

N3-74

N3-87

N3-88

N3-89

N3-90

N3-75

N3-91

N3-92

N3-93

N3-94

N3-76

N3-95

N3-96

N3-97

N3-98

13

14

15

16

17

18

N3-77

N3-78

N3-79

19

20

N3-80

21

N3-82

N3-81

See reference elevation pages for typical details information.

© RACO Interior Products, Inc. 2001

11

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN218

1-1/2"

RN425

1-1/2"

RN255

N2-001_375_1.5-inch_door-head_at-drywall.dxf

See also N2-002

RN255

N2-002_375_1.5-inch_door-head.dxf

See also N2-001

RN255

RN255

1-1/2"

1-1/2"

RN425

RN425

N2-003_375_1.5-inch_hinge-jamb.dxf

© RACO Interior Products, Inc. 2001

N2-004_375_1.5-inch_strike-jamb.dxf

12

RN425

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN254

RN255

RN254

RN255

1-1/2"

1-1/2"

RN425

RN425

N2-006_375_1.5-inch_hinge-jamb_at-glass.dxf

See also N2-005

N2-005_375_1.5-inch_strike-jamb_at-glass.dxf

See also N2-006

RN218

RN425

RN425

1-1/2"

1-1/2"

RN252

RN252

N2-007_375_1.5-inch_head_and_jamb.dxf

See also N2-008

N2-008_375_1.5-inch_head.dxf

See also N2-007

RN250

RN251

RN251

RN251

RN425

1-1/2"

1-1/2"

RN425

RN261

N2-009_375_1.5-inch_horizontal-mullion.dxf

© RACO Interior Products, Inc. 2001

N2-010_375_1.5-inch_sill_at-drywall_one-snap.dxf

See also N2-011, N2-016, N2-022

13

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN258

RN250

RN258

RN425

RN425

1-1/2"

RN214

RN251

1-1/2"

RN256

N2-011_375_1.5-inch_sill_at-drywall_two-snap.dxf

See also N2-010, N2-016, N2-022

N2-012_375_1.5-inch_transom-bar.dxf

RN203

RN425

RN252

1-1/2"

RN254

1-1/2"

RN425

N2-014_375_1.5-inch_cased-head_and_jamb_and_sill.dxf

N2-013_375_1.5-inch_vertical-mullion.dxf

3 3/4"

RN250

RN251

RN417

1-15/16"

RN425

RN220

RN255

N2-015_375_2-inch_door-head.dxf

© RACO Interior Products, Inc. 2001

1-1/2"

N2-016_375_1.5-inch_sill_one-snap.dxf

See also N2-010, N2-011, N2-022

14

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN417

RN417

3 3/4"

3 3/4"

RN255

RN255

1-15/16"

1-15/16"

N2-017_375_2-inch_hinge-jamb.dxf

N2-018_375_2-inch_strike-jamb.dxf

RN417

RN417

RN253

RN255

1-15/16"

N2-019_375_2-inch_strike-jamb_at-glass.dxf

See also N2-020

© RACO Interior Products, Inc. 2001

RN253

RN255

1-15/16"

N2-020_375_2-inch_hinge-jamb_at-glass.dxf

See also N2-019

15

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

3 3/4"

RN258

RN425

RN258

1-1/2"

RN214

RN417

1-15/16"

RN221

RN252

N2-021_375_2-inch_head_and_jamb.dxf

RN250

N2-022_375_1.5-inch_sill_two-snap.dxf

See also N2-010, N2-011, N2-016

RN250

RN251

RN251

RN417

1-15/16"

RN417

1-15/16"

RN254

N2-024_375_2-inch_sill_at-drywall_one-snap.dxf

See also N2-025, N2-030, N2-036

N2-023_375_2-inch_horizontal-mullion.dxf

RN250

RN258

RN258

RN214

RN417

RN417

1-15/16"

1-15/16"

N2-025_375_2-inch_sill_at-drywall_two-snap.dxf

See also N2-024, N2-030, N2-036

© RACO Interior Products, Inc. 2001

RN251

RN260

N2-026_375_2-inch_transom-bar.dxf

16

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN417

RN203

RN417

RN252

1-15/16"

3 3/4"

RN253

1-15/16"

N2-028_375_2-inch_cased-head_and_jamb_and_sill.dxf

N2-027_375_2-inch_vertical-mullion.dxf

RN250

RN427

3"

RN443

RN251

RN417

1-15/16"

RN221

RN255

N2-029_375_3-inch_door-head.dxf

© RACO Interior Products, Inc. 2001

N2-030_375_2-inch_sill_one-snap.dxf

See also N2-024, N2-025,N2-036

17

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN443

RN443

RN255

RN255

RN427

RN427

3"

3"

N2-031_375_3-inch_hinge-jamb.dxf

N2-032_375_3-inch_strike-jamb.dxf

RN443

RN443

RN255

RN252

RN252

3"

3"

N2-033_375_3-inch_strike-jamb_at-glass.dxf

See also N2-034

© RACO Interior Products, Inc. 2001

RN255

N2-034_375_3-inch_hinge-jamb_at-glass.dxf

See also N2-033

18

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN258

RN258

RN427

RN417

RN214

1-15/16"

3"

RN443

RN221

RN252

N2-036_375_2-inch_sill_two-snap.dxf

See also N2-024, N2-025, N2-030

N2-035_375_3-inch_head_and_jamb.dxf

RN250

RN250

RN251

RN251

RN443

3"

3"

RN443

RN427

N2-038_375_3-inch_sill_at-drywall_one-snap.dxf

See also N2-39, N2-044, N2-050

RN252

N2-037_375_3-inch_horizontal-mullion.dxf

RN250

RN258

RN251

RN258

RN443

3"

RN214

RN443

3"

RN255

RN427

N2-039_375_3-inch_sill_at-drywall_two-snap.dxf

See also N2-038, N2-044, N2-050

© RACO Interior Products, Inc. 2001

N2-040_375_3-inch_transom-bar.dxf

19

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN443

RN203

RN443

RN427

R

N252

RN252

3"

3"

N2-042_375_3-inch_cased-head_and_jamb_and_sill.dxf

N2-041_375_3-inch_vertical-mullion.dxf

RN250

RN251

RN427

RN443

RN443

3"

RN427

4"

RN222

RN255

N2-044_375_3-inch_sill_one-snap.dxf

See also N2-038, N2-039, N2-050

N2-043_375_4-inch_door-head.dxf

© RACO Interior Products, Inc. 2001

20

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN419

RN419

RN255

RN255

RN427

RN427

4"

4"

N2-045_375_4-inch_hinge-jamb.dxf

N2-046_375_4-inch_strike-jamb.dxf

RN419

RN255

RN419

RN252

4"

N2-047_375_4-inch_strike-jamb_at-glass.dxf

See also N2-048

© RACO Interior Products, Inc. 2001

RN255

RN252

4"

N2-048_375_4-inch_hinge-jamb_at-glass.dxf

See also N2-047

21

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN258

RN258

RN427

4"

RN419

RN214

3"

RN443

RN427

RN222

RN252

N2-050_375_3-inch_sill_two-snap.dxf

See also N2-038, N2-039, N2-044

N2-049_375_4-inch_head_and_jamb.dxf

RN250

RN250

RN251

RN251

RN419

4"

4"

RN419

RN427

RN252

N2-051_375_4-inch_horizontal-mullion.dxf

© RACO Interior Products, Inc. 2001

N2-052_375_4-inch_sill_at-drywall_one-snap.dxf

See also N2-053, N2-058, N2-064

22

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN250

RN258

RN251

RN258

RN214

RN419

4"

RN419

4"

RN427

RN255

N2-053_375_4-inch_sill_at-drywall_two-snap.dxf

See also N2-052, N2-058, N2-064

N2-054_375_4-inch_transom-bar.dxf

RN419

RN203

4"

RN419

R

N252

RN252

RN427

4"

N2-055_375_4-inch_vertical-mullion.dxf

© RACO Interior Products, Inc. 2001

N2-056_375_4-inch_cased-head_and_jamb_and_sill.dxf

23

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN250

RN251

RN427

RN419

RN445

4"

5"

RN427

RN223

N2-058_375_4-inch_sill_one-snap.dxf

See also N2-052, N2-053, N2-064

RN255

RN445

N2-057_375_5-inch_door-head.dxf

RN445

RN255

RN427

5"

N2-060_375_5-inch_strike-jamb.dxf

RN255

RN427

5"

N2-059_375_5-inch_hinge-jamb.dxf

© RACO Interior Products, Inc. 2001

24

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN445

RN252

RN255

RN445

5"

N2-061_375_5-inch_strike-jamb_at-glass.dxf

See also N2-062

RN252

RN255

5"

N2-062_375_5-inch_hinge-jamb_at-glass.dxf

See also N2-061

RN427

RN258

RN258

5"

RN445

RN214

RN419

4"

RN427

RN252

RN223

N2-063_375_5-inch_head_and_jamb.dxf

© RACO Interior Products, Inc. 2001

N2-064_375_4-inch_sill_two-snap.dxf

See also N2-052, N2-053, N2-058

25

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN250

RN250

RN251

RN251

RN445

5"

5"

RN445

RN427

RN252

N2-065_375_5-inch_horizontal-mullion.dxf

N2-066_375_5-inch_sill_one-snap.dxf

See also N2-067, N2-071, N2-072

RN250

RN258

RN251

RN258

RN214

RN445

5"

5"

RN445

RN427

RN255

N2-067_375_5-inch_sill_two-snap.dxf

See also N2-066, N2-071, N2-072

© RACO Interior Products, Inc. 2001

N2-068_375_5-inch_transom-bar.dxf

26

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN203

RN445

RN445

5"

R

N252

RN252

RN427

5"

N2-070_375_5-inch_cased-head_and_jamb_and_sill.dxf

N2-069_375_5-inch_vertical-mullion.dxf

RN250

RN258

RN251

RN258

RN214

RN445

5"

5"

RN445

RN427

RN427

RN224

RN224

N2-071_375_5-inch_sill_one-snap.dxf

See also N2-066, N2-067, N2-072

© RACO Interior Products, Inc. 2001

N2-072_375_5-inch_sill_two-snap.dxf

See also N2-066, N2-067, N2-071

27

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN425

RN255

RN425

RN425

RN252

RN425

N2-073_375_1.5-inch_door-and-glass_corner_at-drywall.dxf

RN425

RN425

RN252

RN425

RN252

RN425

N2-074_375_1.5-inch_glass-and-glass_corner_at-drywall.dxf

© RACO Interior Products, Inc. 2001

28

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN425

RN255

RN425

RN425

RN252

N2-075_375_1.5-inch_door-and-glass_corner.dxf

RC306

RN425

RN425

RN252

RN425

RN425

RN252

N2-076_375_1.5-inch_glass-and-glass_corner.dxf

RC306

RN425

© RACO Interior Products, Inc. 2001

29

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

JR454

4 -1/2"

JP454

N2-077_375_1-way_corner.dxf

JD454

4 -1/2"

JP454

N2-078_375_2-way_corner.dxf

© RACO Interior Products, Inc. 2001

30

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RR238

RR212

RR519

RR517

NS700

RR213

N2-080_375_adjustable_corner.dxf

N2-079_375_radius_corner.dxf

JD454

JD454

4 - 1/2”

4 - 1/2"

JR454

JD454

N2-081_375_3-way_corner.dxf

© RACO Interior Products, Inc. 2001

N2-082_375_4-way_corner.dxf

31

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN417

RN255

RN425

RN425

RN252

RN417

RN443

N2-083_375_2-inch_door-and-glass_corner_at-drywall.dxf

RN443

RN255

RN425

RN425

RN427

CLIP

RN252

RN427

CLIP

RN443

N2-084_375_3-inch_door-and-glass_corner_at-drywall.dxf

© RACO Interior Products, Inc. 2001

32

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN419

RN255

RN425

RN425

RN427

CLIP

RN252

RN427

CLIP

RN419

N2-085_375_4-inch_door-and-glass_corner_at-drywall.dxf

RN445

RN255

RN425

RN425

RN252

RN427

CLIP

RN427

CLIP

RN445

N2-086_375_5-inch_door-and-glass_corner_at-drywall.dxf

© RACO Interior Products, Inc. 2001

33

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN417

RN425

RN252

RN425

RN252

RN417

N2-087_375_2-inch_glass-and-glass_corner_at-drywall.dxf

RN443

RN425

RN252

RN425

RN427

CLIP

RN252

RN427

CLIP

RN443

N2-088_375_3-inch_glass-and-glass_corner_at-drywall.dxf

© RACO Interior Products, Inc. 2001

34

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN419

RN425

RN252

RN425

RN427

CLIP

RN252

RN427

CLIP

RN419

N2-089_375_4-inch_glass-and-glass_corner_at-drywall.dxf

RN445

RN425

RN252

RN425

RN252

RN427

CLIP

RN427

CLIP

RN445

N2-090_375_5-inch_glass-and-glass_corner_at-drywall.dxf

© RACO Interior Products, Inc. 2001

35

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN417

RN255

RN425

RN425

RN252

RC306

RN417

N2-091_375_2-inch_door-and-glass_corner.dxf

RN443

RN255

RN425

RN425

RN427

CLIP

RN252

RC306

RN427

CLIP

RN443

N2-092_375_3-inch_door-and-glass_corner.dxf

© RACO Interior Products, Inc. 2001

36

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN419

RN255

RN425

RN425

RN427

CLIP

RN252

RC306

RN427

CLIP

RN419

N2-093_375_4-inch_door-and-glass_corner.dxf

RN445

RN255

RN425

RN425

RN252

RN427

CLIP

RC306

RN427

CLIP

RN445

N2-094_375_5-inch_door-and-glass_corner.dxf

© RACO Interior Products, Inc. 2001

37

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN417

RN252

RN425

RN425

RN252

RC306

RN417

N2-095_375_2-inch_glass-and-glass_corner.dxf

RN443

RN252

RN425

RN425

RN427

CLIP

RN252

RC306

RN427

CLIP

RN443

N2-096_375_3-inch_glass-and-glass_corner.dxf

© RACO Interior Products, Inc. 2001

38

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN419

RN252

RN425

RN425

RN427

CLIP

RN252

RC306

RN427

CLIP

RN419

N2-097_375_4-inch_glass-and-glass_corner.dxf

RN445

RN252

RN425

RN425

RN252

RN427

CLIP

RC306

RN427

CLIP

R

N445

N2-098_375_5-inch_glass-and-glass_corner.dxf

© RACO Interior Products, Inc. 2001

39

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN318

RN425

RN425

1-1/2"

1-1/2"

RN355

RN355

N3-001_487_1.5-inch_door-head_at-drywall.dxf

See also N3-002

N3-002_487_1.5-inch_door-head.dxf

See also N3-001

RN355

RN355

1-1/2"

1-1/2"

RN425

RN425

N3-003_487_1.5-inch_hinge-jamb.dxf

© RACO Interior Products, Inc. 2001

N3-004_487_1.5-inch_strike-jamb.dxf

40

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN355

RN354

RN354

RN355

RN425

RN425

1-1/2"

1-1/2"

N3-005_487_1.5-inch_strike-jamb_at-glass.dxf

See also N3-006

N3-006_487_1.5-inch_hinge-jamb_at-glass.dxf

See also N3-005

RN318

RN425

1-1/2"

1-1/2"

RN352

RN352

RN425

N3-007_487_1.5-inch_head_and_jamb.dxf

See also N3-008

N3-008_487_1.5-inch_head.dxf

See also N3-007

RN350

RN351

RN351

RN351

RN425

1-1/2"

1-1/2"

RN425

RN361

N3-009_487_1.5-inch_horizontal-mullion.dxf

© RACO Interior Products, Inc. 2001

N3-010_487_1.5-inch_sill_at-drywall_one-snap.dxf

See also N3-011, N3-016, N3-022

41

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN425

RN358

RN358

RN350

RN425

RN351

1-1/2"

RN314

1-1/2"

RN356

N3-011_487_1.5-inch_sill_at-drywall_two-snap.dxf

See also N3-010, N3-016, N3-022

N3-012_487_1.5-inch_transom-bar.dxf

RN303

1-1/2"

RN352

RN354

Rn425

RN425

N3-014_487_1.5-inch_cased-head_and_jamb_and_sill.dxf

1-1/2"

N3-013_487_1.5-inch_vertical-mullion.dxf

RN417

RN350

Rn425

RN351

1-15/16"

1-1/2"

RN355

N3-015_487_2-inch_door-head.dxf

© RACO Interior Products, Inc. 2001

RN320

N3-016_487_1.5-inch_sill_one-snap.dxf

See also N3-010, N3-011, N3-022

42

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN417

RN417

RN355

RN355

1-15/16"

1-15/16"

N3-017_487_2-inch_hinge-jamb.dxf

N3-018_487_2-inch_strike-jamb.dxf

RN417

RN417

RN353

RN355

RN355

RN353

1-15/16"

N3-019_487_2-inch_strike-jamb_at-glass.dxf

See also N3-020

© RACO Interior Products, Inc. 2001

1-15/16"

N3-020_487_2-inch_hinge-jamb_at-glass.dxf

See also N3-019

43

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN425

RN358

RN358

1-1/2"

RN314

1-15/16"

RN321

RN352

RN417

N3-021_487_2-inch_head_and_jamb.dxf

RN417

RN350

N3-022_487_1.5-inch_sill_two-snap.dxf

Rn417

RN351

RN350

RN351

1-15/16"

1-15/16"

RN354

N3-024_487_2-inch_sill_at-drywall_one-snap.dxf

See also N3-025, N3-030, N3-036

N3-023_487_2-inch_horizontal-mullion.dxf

Rn417

RN417

RN358

RN350

RN351

1-15/16"

RN358

RN314

N3-025_487_2-inch_sill_at-drywall_two-snap.dxf

See also N3-024, N3-030, N3-036

© RACO Interior Products, Inc. 2001

1-15/16"

RN360

RN260

N3-026_487_2-inch_transom-bar.dxf

44

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN417

RN417

RN352

RN303

RN353

1-15/16"

1-15/16"

N3-028_487_2-inch_cased-head_and_jamb_and_sill.dxf

N3-027_487_2-inch_vertical-mullion.dxf

RN443

RN427

RN417

3"

RN350

RN351

1-15/16"

RN355

RN321

N3-029_487_3-inch_door-head.dxf

N3-030_487_2-inch_sill_one-snap.dxf

See also N3-024, N3-025, N3-036

© RACO Interior Products, Inc. 2001

45

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN443

RN443

RN355

RN355

RN427

RN427

3"

3"

N3-031_487_3-inch_hinge-jamb.dxf

N3-032_487_3-inch_strike-jamb.dxf

RN443

RN443

RN355

RN352

RN355

RN352

3"

N3-033_487_3-inch_strike-jamb_at-glass.dxf

See also N3-034

© RACO Interior Products, Inc. 2001

3"

N3-034_487_3-inch_hinge-jamb_at-glass.dxf

See also N3-033

46

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN417

RN358

RN427

RN314

3"

RN321

N3-035_487_3-inch_head_and_jamb.dxf

RN350

1-15/16"

N3-036_487_2-inch_sill_two-snap.dxf

See also N3-024, N3-025, N3-030

RN352

RN443

RN443

RN358

RN350

RN443

RN351

RN351

3"

RN427

3"

N3-038_487_3-inch_sill_at-drywall_one-snap.dxf

See also N3-039, N3-044, N3-050

RN352

N3-037_487_3-inch_horizontal-mullion.dxf

RN443

RN358

RN443

RN350

RN351

RN358

3"

RN314

3"

RN355

RN427

N3-039_487_3-inch_sill_at-drywall_two-snap.dxf

See also N3-038, N3-044, N3-050

© RACO Interior Products, Inc. 2001

N3-040_487_3-inch_transom-bar.dxf

47

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN443

RN303

RN352

RN352

RN443

3"

RN427

3"

N3-042_487_3-inch_cased-head_and_jamb_and_sill.dxf

N3-041_487_3-inch_vertical-mullion.dxf

RN443

RN427

4"

RN443

RN350

RN351

3"

RN355

RN427

RN322

N3-043_487_4-inch_door-head.dxf

© RACO Interior Products, Inc. 2001

N3-044_487_3-inch_sill_one-snap.dxf

See also N3-038, N3-039, N3-050

48

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN419

RN419

RN355

RN355

RN427

RN427

4"

4"

N3-046_487_4-inch_strike-jamb.dxf

N3-045_487_4-inch_hinge-jamb.dxf

RN419

RN355

RN419

RN352

RN352

RN355

4"

N3-047_487_4-inch_strike-jamb_at-glass.dxf

See also N3-048

© RACO Interior Products, Inc. 2001

4"

N3-048_487_4-inch_hinge-jamb_at-glass.dxf

See also N3-047

49

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN419

RN358

RN443

RN358

RN427

4"

RN314

3"

RN427

RN322

RN352

N3-050_487_3-inch_sill_two-snap.dxf

See also N3-038, N3-039, N3-044

N3-049_487_4-inch_head_and_jamb.dxf

RN419

RN350

RN351

RN350

RN419

RN351

4"

4"

RN427

RN352

N3-051_487_4-inch_horizontal-mullion.dxf

© RACO Interior Products, Inc. 2001

N3-052_487_4-inch_sill_at-drywall_one-snap.dxf

See also N3-053, N3-058, N3-064

50

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN419

RN419

RN358

RN350

RN351

RN358

4"

RN314

4"

RN355

RN427

N3-053_487_4-inch_sill_at-drywall_two-snap.dxf

See also N3-052, N3-058, N3-064

N3-054_487_4-inch_transom-bar.dxf

RN419

RN419

RN352

RN303

4"

RN352

RN427

4"

N3-055_487_4-inch_vertical-mullion.dxf

© RACO Interior Products, Inc. 2001

N3-056_487_4-inch_cased-head_and_jamb_and_sill.dxf

51

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN427

RN445

5"

RN355

N3-057_487_5-inch_door-head.dxf

RN350

RN351

RN419

4"

RN427

RN323

N3-058_487_4-inch_sill_one-snap.dxf

See also N3-052, N3-053, N3-064

© RACO Interior Products, Inc. 2001

52

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN445

RN355

RN427

5"

N3-059_487_5-inch_hinge-jamb.dxf

RN445

RN355

RN427

5"

N3-060_487_5-inch_strike-jamb.dxf

© RACO Interior Products, Inc. 2001

53

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN445

RN355

RN352

5"

N3-061_487_5-inch_strike-jamb_at-glass.dxf

See also N3-062

RN445

RN352

RN355

5"

N3-062_487_5-inch_hinge-jamb_at-glass.dxf

See also N3-061

© RACO Interior Products, Inc. 2001

54

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN445

RN427

RN419

RN358

RN358

RN314

5"

4"

RN427

RN352

RN323

N3-064_487_4-inch_sill_two-snap.dxf

See also N3-052, N3-053, N3-058

N3-063_487_5-inch_head_and_jamb.dxf

RN445

RN350

RN350

RN445

RN351

RN351

5"

5"

RN427

RN352

N3-065_487_5-inch_horizontal-mullion.dxf

© RACO Interior Products, Inc. 2001

N3-066_487_5-inch_sill_one-snap.dxf

See also N3-067, N3-071, N3-072

55

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN350

RN445

RN358

RN445

RN351

RN358

RN314

5"

5"

RN355

RN427

N3-067_487_5-inch_sill_two-snap.dxf

See also N3-066, N3-071, N3-072

N3-068_487_5-inch_transom-bar.dxf

RN445

RN303

Rn445

5"

RN352

RN352

RN427

5"

N3-069_487_5-inch_vertical-mullion.dxf

© RACO Interior Products, Inc. 2001

N3-070_487_5-inch_cased-head_and_jamb_and_sill.dxf

56

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN350

RN351

RN445

5"

RN427

RN324

N3-071_487_5-inch_sill_one-snap.dxf

See also N3-066, N3-067,N3-072

RN358

RN358

RN314

5"

RN445

RN427

RN324

N3-072_487_5-inch_sill_two-snap.dxf

See also N3-066, N3-067, N3-071

© RACO Interior Products, Inc. 2001

57

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN425

RN355

RN425

RN425

RN352

RN425

N3-073_487_1.5-inch_door-and-glass_corner_at-drywall.dxf

© RACO Interior Products, Inc. 2001

58

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN425

RN425

RN352

RN425

RN352

RN425

N3-074_487_1.5-inch_glass-and-glass_corner_at-drywall.dxf

© RACO Interior Products, Inc. 2001

59

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN425

RN355

RN425

RN425

RN352

RN425

N3-075_487_1.5-inch_door-and-glass_corner.dxf

© RACO Interior Products, Inc. 2001

60

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN425

RN352

RN425

RN425

RN352

RN425

N3-076_487_1.5-inch_glass-and-glass_corner.dxf

© RACO Interior Products, Inc. 2001

61

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RR444

5 5/8"

N3-077_487_1-way_corner.dxf

RR443

5 5/8"

N3-078_487_2-way_corner.dxf

© RACO Interior Products, Inc. 2001

62

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RR438

RR519

RR517

NS700

N3-079_487_radius_corner.dxf

RR313

RR313

N3-080_487_adjustable_corner.dxf

© RACO Interior Products, Inc. 2001

63

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RR443

5 5/8"

RR444

N3-081_487_3-way_corner.dxf

RR443

5 5/8"

RR443

N3-082_487_4-way_corner.dxf

© RACO Interior Products, Inc. 2001

64

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN417

RN355

RN425

RN425

RN352

RN417

N3-083_487_2-inch_door-and-glass_corner_at-drywall.dxf

© RACO Interior Products, Inc. 2001

65

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN443

RN355

RN425

RN425

RN427

CLIP

RN352

RN427

CLIP

N3-084_487_3-inch_door-and-glass_corner_at-drywall.dxf

© RACO Interior Products, Inc. 2001

66

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN419

RN355

RN425

RN425

RN427

CLIP

RN352

RN427

CLIP

RN419

N3-085_487_4-inch_door-and-glass_corner_at-drywall.dxf

© RACO Interior Products, Inc. 2001

67

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN445

RN355

RN425

RN425

RN352

RN427

CLIP

RN427

CLIP

RN445

N3-086_487_5-inch_door-and-glass_corner_at-drywall.dxf

© RACO Interior Products, Inc. 2001

68

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN417

RN425

RN352

RN425

RN352

RN417

N3-087_487_2-inch_glass-and-glass_corner_at-drywall.dxf

© RACO Interior Products, Inc. 2001

69

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN443

RN425

RN352

RN425

RN427

CLIP

RN352

RN427

CLIP

RN443

N3-088_487_3-inch_glass-and-glass_corner_at-drywall.dxf

© RACO Interior Products, Inc. 2001

70

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN419

RN425

RN352

RN425

RN427

CLIP

RN352

RN427

CLIP

N3-089_487_4-inch_glass-and-glass_corner_at-drywall.dxf

© RACO Interior Products, Inc. 2001

71

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN445

RN425

RN352

RN425

RN352

RN427

CLIP

RN427

CLIP

RN445

N3-090_487_5-inch_glass-and-glass_corner_at-drywall.dxf

© RACO Interior Products, Inc. 2001

72

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN417

RN355

RN425

RN425

RN352

RN417

N3-091_487_2-inch_door-and-glass_corner.dxf

© RACO Interior Products, Inc. 2001

73

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN443

RN355

RN425

RN425

RN427

CLIP

RN352

RN427

CLIP

RN443

N3-092_487_3-inch_door-and-glass_corner.dxf

© RACO Interior Products, Inc. 2001

74

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN419

RN355

RN425

RN425

RN427

CLIP

RN352

RN427

CLIP

RN419

N3-093_487_4-inch_door-and-glass_corner.dxf

© RACO Interior Products, Inc. 2001

75

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN445

RN355

RN425

RN425

RN352

RN427

CLIP

RN427

CLIP

RN445

N3-094_487_5-inch_door-and-glass_corner.dxf

© RACO Interior Products, Inc. 2001

76

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN417

RN352

RN425

RN425

RN352

RN417

N3-095_487_2-inch_glass-and-glass_corner.dxf

© RACO Interior Products, Inc. 2001

77

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN443

RN352

RN425

RN425

RN427

CLIP

RN352

RN427

CLIP

RN443

N3-096_487_3-inch_glass-and-glass_corner.dxf

© RACO Interior Products, Inc. 2001

78

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN419

RN352

RN425

RN425

RN427

CLIP

RN352

RN427

CLIP

RN419

N3-097_487_4-inch_glass-and-glass_corner.dxf

© RACO Interior Products, Inc. 2001

79

RACO Interior OfficeFronts™

SolutionsII ™ Typical Details

RN445

RN352

RN425

RN425

RN352

RN427

CLIP

RN427

CLIP

RN445

N3-098_487_5-inch_glass-and-glass_corner.dxf

© RACO Interior Products, Inc. 2001

80

RACO Interior OfficeFronts™

™ Guide

™ Typical

SolutionsII

SolutionsII

Specifications

Details

GUIDE

SPECIFICATION

Manufacturer:

Raco Interior Products, Inc.

2000 Silber Road

Houston, Texas 77055

713 682 6100 voice

800 272 7226 toll free voice

713 682 2079 fax

www.RacoInteriors.com

SECTION 08120

INTERIOR ALUMINUM DOORS, DOOR FRAMES, AND STOREFRONT FRAMING

(SOLUTIONS II SYSTEM)

************************************************************************************************************************

This guide specification has been prepared by RACO Interior Products, Inc. in printed and electronic media, as an aid to

specifiers in preparing written construction documents for interior applications for aluminum door frames, sidelight framing,

storefront framing, and aluminum and glass doors.

Edit entire master to suit project requirements. Modify or add items as necessary. Delete items that are not applicable.

Words and sentences within brackets [_____] reflect a choice to be made regarding inclusion or exclusion of a particular item

or statement. This section may include performance, proprietary, and descriptive type specifications. Edit to avoid conflicting

requirements. Editor notes to guide the specifier are included between lines of asterisks to assist in choices to be made.

Remove these notes before final printing of specification.

This guide specification is written around the Construction Specifications Institute (CSI), Section Format standards references

to section names and numbers are based on MasterFormat 95.

For specification assistance on specific product applications, please contact our offices above or any of our local product

representatives throughout the country.

RACO reserves the right to modify these guide specifications at any time. Updates to this guide specification will be posted to

the manufacturer’s web site and/or in printed matter as they occur. Raco makes no expressed or implied warranties regarding

content, errors, or omissions in the information presented.

************************************************************************************************************************

PART 1

GENERAL

1.1

SUMMARY

A.

Related Documents:

1.

Provisions established within the General and Supplementary Conditions of the Contract, Division 1 _

General Requirements, and the Drawings are collectively applicable to this Section.

*************************************************************************************************************************

Edit the "Section Includes" paragraph to briefly describe the content of the section. After editing section, refer back to this

paragraph to verify no conflicts occur.

************************************************************************************************************************

© RACO Interior Products, Inc. 2001

81

RACO Interior OfficeFronts™

™ Guide

™ Typical

SolutionsII

SolutionsII

Specifications

Details

B.

C.

Section Includes:

1.

Aluminum door frames for interior use.

2.

[Aluminum door frames with sidelight frame components for interior use.]

3.

[Aluminum OfficeFronts framing system for interior use.]

4.

[Aluminum and glass doors for interior use.]

Related Sections:

1.

[Section 08210 - Wood Doors.]

2.

[Section 08220 - Plastic Doors.]

3.

[Section 08710 - Door Hardware.]

4.

[Section 08800 - Glazing.]

1.2

SUBMITTALS

************************************************************************************************************************

Include submittal requirements below which are consistent with the scope of the project and extent of work of this section.

Only request submittals which are necessary for review of design intent.

Do not request submittals if drawings sufficiently describe the products of this section or if proprietary specifying techniques

are used. The review of submittals increases the possibility of unintended variations to drawings.

************************************************************************************************************************

A.

Submit under provisions of Section 01300.

B.

Product Data: Submit for door, sidelight and OfficeFronts frames.

1.

Include information for factory finish, glazing gaskets, accessories and other required

components.

2.

Include color charts for finish indicating manufacturer's standard colors available for selection.

C.

Shop Drawings: Submit schedule indicating opening identification number, frame types, dimensions,

swing, label, and hardware requirements. Use same reference numbers for openings as Contract

Drawings.

D.

Include elevations and details indicating frame types, profiles, conditions at openings, methods and

locations of anchoring, glazing requirements, hardware locations, and reinforcements for hardware,

details of connections to special construction and other custom features.

E.

Samples: Submit following:

1.

Samples indicating quality of finish in selected colors on alloys used for Work.

2.

Where normal color and texture variations are expected, include additional samples to show

range of such variation.

F.

Informational Submittals: Submit manufacturer's instructions.

1.4

QUALITY ASSURANCE

************************************************************************************************************************

Include quality assurance requirements below which are consistent with the size and scope of the project and extent of work of

this section. Only request qualification statements you intend to review, and which are necessary to establish qualifications of

the product, manufacturer, or installer.

************************************************************************************************************************

A.

Single Source Responsibility: Provide aluminum frames, aluminum and glass doors, and

accessories produced by a single manufacturer for each type of product indicated.

B.

Manufacturer’s Qualifications: Manufacturer shall demonstrate previous experience in manufacturing

of interior aluminum door and OfficeFronts framing for a period of not less than 10 years on

comparable sized project.

C.

[Fire and Smoke Rated Assemblies:

1.

Where fire-rated openings are scheduled or required by authorities having jurisdiction, provide

fire-rated aluminum frames that have been tested and certified to meet the requirements of

UBC 7.2 Fire Test of Door Assemblies for specified exposure by an agency acceptable to

governing authorities.

2.

Provide labels permanently fastened on each fire rated frame and door that are within size

limits established by NFPA and the testing authority.]

© RACO Interior Products, Inc. 2001

82

RACO Interior OfficeFronts™

™ Guide

™ Typical

SolutionsII

SolutionsII

Specifications

Details

1.5

DELIVERY, STORAGE, AND HANDLING

A.

Deliver frames and doors in cartons to provide protection during transit and storage at project site.

B.

Inspect frames and doors upon delivery for damage.

1.

Repair minor damage to pre-finished products by means as recommended by manufacturer

2.

Replace frames and doors that cannot be satisfactorily repaired.

C.

Store frames and doors at project site under cover and as near as possible to final installation

location. Do not use covering material that will cause discoloration of aluminum finish.

1.6

ENVIRONMENTAL REQUIREMENTS

A.

Do not begin installation of frames or doors until area of work has been completely enclosed and

interior is protected from the elements.

B.

Maintain temperature and humidity in areas of installation within reasonable limits, as close as

possible to final occupancy. If necessary, provide temperature control and ventilation to maintain

required environmental conditions.

1.7

WARRANTY

A.

Warrant against defects in manufacturing of materials for a period of 2 years from date of substantial

completion.

B.

Warrant framing finish against defects, including cracking, flaking, blistering, peeling, and excessive

fading, chalking and non-uniformity in color for a period of 5 years.

C.

[Warrant aluminum and glass doors for life of door against corner construction failure, causing

wracking of door beyond acceptable tolerances.]

PART 2

PRODUCTS

2.1

ACCEPTABLE MANUFACTURERS AND PRODUCTS

A.

Manufacturers:

1.

Meet of exceed standards of manufacture, appearance, performance, function, and design, of

Raco Interior OfficeFronts by RACO Interior Products, Inc.

2.

Substitutions: Comply with provisions of Section 01600.

B.

Acceptable Products:

************************************************************************************************************************

Select from product list below for particular project needs.

Include item 1 below if only door frames are required. Delete items a, b, and c if fire rated doors are not required.

Include item 2 below if sidelights and storefront framing is required

Include item 3 below if aluminum and glass swinging doors are required

Include item 4 below if sliding aluminum and glass doors are required.

************************************************************************************************************************

1.

[Interior Door Frames: RACO Solutions II [fixed] [adjustable] throat frames to accommodate

wall thicknesses indicated on Drawings; [ceiling height] [____] height system; with applied full

face trim of [1-1/2] [2] [3] [4] [5] inch width.

a.

[Provide fire rated frames to [20] [90] minute rating complying with UL 10B, ASTM

E152, and NFPA 252.]]

2.

[Interior OfficeFronts Framing: RACO Solutions II OfficeFronts, fixed throat frames to

accommodate wall thicknesses indicated on Drawings; [ceiling height] [____] height system,

with applied full face trim of [1-1/2] [2] [3] [4] [5] inch width.]

3.

[Swinging Aluminum and Glass Doors: RACO Series 550, wide stile doors , having [square]

[beveled] glazing stops, and EPDM glazing gaskets, [and having ADA compliant bottom rail].

************************************************************************************************************************

Select item a. below for non-fire rated doors and item b. for fire rated doors. In item c., custom mullion configurations can be

specified and should be indicated on the Drawings as to type and locations. Hardware for swinging doors can be specified in

e. below, or this sections can be reference to Section 08710 for all hardware requirements.

************************************************************************************************************************

© RACO Interior Products, Inc. 2001

83

RACO Interior OfficeFronts™

™ Guide

™ Typical

SolutionsII

SolutionsII

Specifications

Details

a.

b.

[Provide non-fire rated with adjustable bottom rails for field adjustment.]

[Provide with 20 minute (without hose stream test) fire rated label, factory glazed with

approved clear (wireless) or approved wire glass.

c.

[Provide with custom horizontal and vertical mullion pattern as indicated on Drawings]

d.

[Provide complete with the following hardware in [________] finish:

(1)

[1-1/2] [2] pair of 4-1/2 x 4-1/2 inch [standard] [ball bearing] butts.

(2)

Exposed overhead closer, [standard] [slim line] profile.

(3)

[Latch] [Lock] set to match other devices in project.

(4)

Flush bolts for inactive leaf of pairs of doors.

(5)

Balance of hardware as indicated in Section 08710.]

4. [Sliding Aluminum and Glass Doors: Series 2000, Sliding Doors, complete with 2-1/16 inch stiles,

2-1/8 inch top rail, and 3-3/16 inch bottom rail.]

2.2

MATERIALS

A.

Aluminum: Meeting requirements of ASTM B221, 6063T5 alloy, and as otherwise required to assure

compliance with dimensional tolerances and maintain color uniformity. Billets shall be composed of

at least 33% recycled aluminum.

B.

Anchorage Devices, Clips and Fasteners: Manufacturer's standard type, compatible with materials

being secured.

C.

Accessories: As necessary for complete system.

2.3

EXTRUDED ALUMINUM FRAME AND DOOR FABRICATION

A.

[Utilize adjustable angle vertical mullion for segmented curved OfficeFronts.

B.

[Utilize reduced profile corner section for 90 degree corners.]

C.

Assemble all door frames, sidelights, and window units with screws utilizing internal screw spline

system, insert into the drywall rough opening, and then attach perimeter flanges.

D.

Assemble all sidelights and windows without the use of clips.

E.

Do not exceed maximum size of window or door to meet applicable code requirements.

F.

Factory pre-machine door frame jambs [and doors] and prepare for hardware, with concealed

reinforcement plates, drilled and tapped as required, and fastened within frame with concealed

screws.

2.4

FINISHES

A.

Factory finish extruded frame and door components so that all parts exposed to view upon

completion of installation are uniform in finish and color. Exposed surfaces shall be free of scratches

and other serious blemishes.

B.

[Factory Applied Paint Finish: Comply with AAMA(2603)603.8 and AA-DAF-45, factory applied

backed enamel coating.

1.

Color: [As selected from manufacturer’s standard colors] [Custom color to match Architect’s

sample].]

C.

Clear Anodized: AA-M12C22A21, etched, medium matte, clear anodic coating.

D.

[Clean all aluminum surfaces of contaminants and leave ready for field painting per Section 09900.]

PART 3

3.1

EXECUTION

EXAMINATION

A.

Examine project conditions and verify that project is ready for work of this section to proceed. Do not

proceed with installation until unsatisfactory conditions have been corrected.

B.

Verify wall thickness does not exceed manufacturer’s recommended tolerances of specified throat

size.

© RACO Interior Products, Inc. 2001

84

RACO Interior OfficeFronts™

™ Guide

™ Typical

SolutionsII

SolutionsII

Specifications

Details

3.2

INSTALLATION

A.

Comply with frame and door manufacturer's printed installation instructions and approved shop

drawings. Do not attempt installation in areas where wall thickness exceeds tolerances of specified

throat size.

B.

Install frames plumb and square, free from warp or twist, securely anchored to substrates with

fasteners recommended by frame manufacturer. Maintain dimensional tolerances and alignment

with adjacent work. Ensure joints are hairline tight and surfaces flush with adjacent components.

C.

Set all doors in correct locations as shown on the drawings, level, square, plumb and in alignment

with other work in accordance with the manufacturer's installation instructions and approved shop

drawings.

D.

[Install glass in accordance with Section 08800.]

3.3

ADJUSTING AND CLEANING

A.

Protect exposed portions of aluminum surfaces from damage by plaster, lime, acid, cement, and

other contaminants.

B.

Touch up marred areas so that touch-up is not visible from a distance of 4 feet. Remove and replace

frames that cannot be satisfactorily adjusted.

3.4

PROTECTION

A.

Protect as required to assure that frames and doors will be without damage until Substantial

Completion.

END OF SECTION

© RACO Interior Products, Inc. 2001

85

SolutionsII

RACO Interior OfficeFronts™

Installation Instructions

RACO

Interior Products, Inc.

3OLUTIONS))

­

- / / "

] Ê -/" , Ê Ê *," /

/"

Ê

-/,1

/"

,Ê

Ê " Ê 1

-

"/-

1

The following precautions are recommended to protect the material against damage. Following these precautions will

help ensure early acceptance of your products and workmanship.

!

(ANDLE#AREFULLY All aluminum materials at job site must be stored in a safe place well removed form possible damage by

other trades. Cardboard wrapped or paper interleaved materials must be kept dry. Check arriving materials for quantity and

keep record of where various materials are stored.

"

+EEPMATERIALAWAYFROMWATERMUDANDSPRAY Prevent cement, plaster or other materials form damaging the finish.

# 0ROTECTTHEMATERIALSAFTERERECTION Protect erected frame with polyethylene or canvas splatter screen. Cement, plaster,

terrazzo, other alkaline solutions and acid based materials used to clean masonry are harmful to the finish. If any of these

materials come in contact with the aluminum, Immediately remove with water and mild soap. Care must be taken when

laying carpet to prevent the backing from scraping against the finished metal.

, " Ê 1 ,Ê

-Ê " ,Ê Ê -//"

- / / "

Ê

-/,1

/"

-

-\

2EVIEW#ONTRACT$OCUMENTS Check shop drawing, installation instructions, architectural drawings and shipping lists to

become thoroughly familiar with the project. The shop drawings take precedence and include specific details for the project.

Note any field verify notes on the shop drawings prior to installing. The installation instructions are of a general nature and

cover most common conditions.

)NSTALLATION All materials are to be installed plumb, level and true.

"ENCH-ARKS All work should start from bench marks and/or column lines as established by the architectural drawings

and the general contractor with guaranteed accuracy. Working from these datum points and lines, determine:

A The plane of the wall in reference to offset lines provided on each floor.

B The finish floor lines in reference to bench marks on the building columns.

C The finished ceiling in reference to bench marks on building columns.

&IELD7ELDING All field welding must be adequately shielded to avoid any splatter on glass or aluminum. Results will be

unsightly and/or structurally unsound. Advise general contractor and other trades accordingly.

3URROUNDINGCONDITIONS Make certain that construction which will receive your materials is in accordance with the

contract documents. If not, notify the general contractor in writing and resolve differences before proceeding with work.

#HECKQUANTITYOFMATERIALSONARRIVAL Be sure you have everything required to begin installation.

3EALANTS Sealants must be compatible with all materials with which they have contact, including other sealant surfaces.

Consult with sealant manufacturer for recommendation relative to joint size, shelf life, compatibility, priming, tooling,

adhesion, etc. Due to varying job conditions, all sealants used should be approved by sealant manufacturer to insure that

they will function for conditions shown on instructions and shop drawings.

&ASTENING Within this body of instructions ‘fastening’ means any method of securing one part to another or to adjacent

materials. Only those fasteners used within the system and for attaching aluminum frames to the drywall are shown

in these instructions. Consult the fastener supplier for proper size and type fasteners used to secure frame (anchors)

into concrete.

"UILDING#ODES Due to the diversity in state/provincial, local and federal laws and codes that govern the design and

application of architectural products, it is the responsibility of the individual architect, owner and installer to assure that

products selected for use on projects comply with all applicable building codes and laws. Raco Interior Products exercises no

control over the use or application of its products, glazing materials and operating hardware and assumes no responsibility

thereof.

&INAL#LEANING Final cleaning of exposed aluminum surfaces should be done in accordance with AAMA specifications

609.1 for anodized aluminum and 610.1 for painted aluminum.

The rapidly changing technology within the architectural aluminum products industry demands that Raco Interior Products reserve the right to revise,

discontinue or change any product line, specification or electronic media without prior written notice.

Note: Dimensions in parentheses ( ) are millimeters unless otherwise noted. Other metric units shown in this manual are:

M = meter

,

"Ê

+G = kilogram

/ , ",Ê *," 1 /-] Ê °

0A = pascal

+0A = kilopascal

-0A = megapascal

3OLUTIONS))

­

- / / "

Ê

-/,1

/"

/Ê"Ê

"

/

-

/-

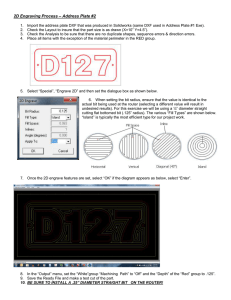

GENERAL NOTES ....................................................................................................................... 2

Solutions II COMPONENTS ......................................................................................................... 4

DRYWALL FRAMING CONSTRUCTION ................................................................................... 10

Solutions II DESCRIPTION AND ROUGH OPENING SIZES .................................................... 11

DOOR FRAME INSTALLATION ................................................................................................. 12

TRANSOM DOOR FRAME INSTALLATION .............................................................................. 15

SIDELIGHT, BORROWED LIGHT & CLERESTORY CUTTING

FORMULAS, ASSEMBLY PROCEDURES, AND INSTALLATION .......................................... 16

ADJUSTABLE MULLION ASSEMBLY AND INSTALLATION ..................................................... 24

CORNER MULLION ASSEMBLY AND INSTALLATION............................................................. 27

BUTT GLAZE SPACER INSTALLATION .................................................................................... 30

GLAZING NOTES & GLASS SIZES........................................................................................... 31

HARDWARE INSTALLATION..................................................................................................... 34

COLUMN CONSTRUCTION ...................................................................................................... 39

,

" Ê / , " ,Ê * ," 1 /- ]Ê

°

3OLUTIONS))

­

"*" /

- / / "

Ê

-/,1

/"

-

,*/"

-,-ÊÎÇx

-,-Ê{nÇ

C Beam

RN201

RN301

Cased Jamb/Head

RN203

RN303

Flat Insert

RN207

RN307

Floor Track (FS 5S)

RN208

RN308

Sill Double Snap Base

RN214

RN314

Head & Floor Track

(FS5)

RN218

RN318

Floor Track

(FS5 Extended Leg)

RN219

N/A

RN 7DL Glazing Base

RN250

RN350

RN251

RN351

RN 5M Wall Jamb/Head

RN252

RN352

RN 5D 2" Glazing Insert

RN253

RN353

RN5DS 11/2"

Glazing Insert

RN254

RN354

RN Door Frame

RN255

RN355

RN 4S Transom

Door Frame Header

Insert 11/2"

RN256

RN356

RN 7SS Shallow Snap

RN258

RN358

RN 7DL Glazing Snap

(use With RN 7DL Base

and RN 7M Base)

,

"Ê

/ , ",Ê *," 1 /-] Ê °

-

3OLUTIONS))

­

"*" /

- / / "

Ê

-/,1

/"

-

-,-ÊÎÇx

-,-Ê{nÇ

RN DF Header with

Removable Stop

RN259

N/A

RN 4DS Transom Door

Frame Header Insert 2"

RN260

RN360

RN 7M Horizontal

Mull Base

RN261

RN361

Adjustable Mullion

RR212

RR412

Mullion Axle

RR213

RR413

11/2" Sill Channel

RR220

RR420

2" Sill Channel

RR221

RR421

3" Sill Channel

RR222

RR422

4" Sill Channel

RR223

RR423

5" Sill Channel

RR224

RR424

-

,*/"

,

" Ê / , " ,Ê * ," 1 /- ]Ê

°

3OLUTIONS))

­

"*" /

- / / "

Ê

-/,1

/"

-

,*/"

Corner Mullion

Back Cover

Corner Mullion

Face Trim

,

"Ê

/ , ",Ê *," 1 /-] Ê °

-

-,-ÊÎÇx

-,-Ê{nÇ

RR238

RR438

RR517

RR517

Used For All Series

Used For All Series

Two Pocket Corner

Member

JD454

RR443

One Pocket Corner

Member

JR454

RR444

Flat Corner

Member

JP454

RR445

3OLUTIONS))

­

"*" /

,

- / / "

Ê

-/,1

/"

-

,*/"

{ää

"*" /

,

{£{

Trim #700

3 " x 1 "

/8 1 /2

,

{ÓÈ

Trim #716

/16" x 11/2"

Trim Radius

11/2"

,

{£Ç

7

,

{ÓÇ

Trim #201

/8" x 115/16"

Trim Clip #21C

3

,

{£

,

{{Î

Trim 3"

/8" x 3"

Trim #401

3 " x "

/8 4

,

{Óä

3

,

{{x

Trim #4TM

Scribe Trim 4"

,

{Ó£

Trim 5"

/8" x 5"

3

-Ó{Ó

Trim #500

5 " x 1 "

/8 1 /2

,

-

,*/"

{Óx

RN Stop

used with

RN 259

,

-

Flat Bar Strap

1

/16" x 2"

{ÓÓ

Trim #5TM

Scribe Trim 5"

,

" Ê / , " ,Ê * ," 1 /- ]Ê

°

3OLUTIONS))

­

"*" /

- / / "

-

,*/"

Ê

-/,1

/"

"*" /

/4" Top Load

Gasket

Vinyl

1

6,ÓÎn

Clip for Mitered

Corner

Çää

/8" Top Load

Gasket

Vinyl

3

6,xÈÎ

Face Clip for

Radius Corner

änä

/16" Top Load

Gasket

Vinyl

9

-x£Î

Drill Jig for

Solutions II

/x£È

Setting Blocks for

1 " to 3 "

/4

/8

Glass

-x£{

Magnetic Socket

for ST351 Screw

-/£ÎÇ

Setting Blocks for

1 " to 9

/2

/16"

Glass

7{xÓ

#6 x 9/16"

Tek Screw

-/Îx£

#10 x 1"

H.H. Assembly

Screw

Edge Block for

Deep Pocket

-/äÈÈ

,*ÓÎÎ q ÎÇx

,*{ÎÎ q {nÇ

Anchor Clip for

Radius Corner

with Screws

,£Î{

Clip for Mitered

Corner

/ , ",Ê *," 1 /-] Ê -

,*/"

,£Îx

6,ÓÓx

,

"Ê

-

°

R4 LongPoint

Tek Screw

3OLUTIONS))

­

"*" /

- / / "

-

,*/"

,{Óx

Ê

-/,1

/"

"*" /

-

-

,*/"

,ÈäÓ

Butt Glaze

Support

1 "

/4 Glass

,ÎÓx

RN Clip "T"

.400" x 2" x 31/2"

*£ÈÎ

Butt Glaze

Support

90° Corner

1 "

/4 Glass

,{În

Reinforcement

Plate for Parallel

Arm Closer or

Coordinator

Çxn

Reinforcement for

Surface Mounted

Regular Arm Closer

Butt Glaze

Support

3 "

/8 Glass

,ÎÎn

£xx

Butt Glaze

Support

90° Corner

3 "

/8 Glass

Spacer Bar for

Surface Mounted

Parallel Arm Closer

and Spacer Bar for

Surface mounted

Coordinator

Comes in Various Lengths

,£ä£

6-Óää

Adjustable

Mullion

Gasket

RN Clip #1

.830" x 21/2"

,£äÈ

6,Èää

RN Clip #6

.500" x 3"

Door Frame

Gasket

,£äÇ

RN Clip #7

.500" x 21/2"

,£än

RN Clip #8

.400" x 2" x 2"

,

" Ê / , " ,Ê * ," 1 /- ]Ê

°

3OLUTIONS))

­

- / / "

,97Ê,

Ê

-/,1

/"

Ê

"

-

-/,1

/"

Solutions II is a interior door frame and glazing system designed to fit over conventional drywall construction. The system is assembled into rough openings left in the drywall and attached to the wall. Solutions II

fits over two common drywall throat sizes. They are 3-3/4” and 4-7/8” wall thicknesses.

Care should be taken by the drywall installer to keep the wall thickness as close to nominal as possible and

never more than 1/8” thicker than nominal. Walls constructed greater than nominal may cause the trim not

to sit flat against the drywall.

Note the C stud nearest the edge of the rough opening should be reversed so that the open end of the stud

is towards the rough opening. This includes the head and sill if they cover drywall.

Before installing the frame, confirm the drywall is within tolerance in thickness and that the rough opening

is the proper size and plumb.

,97Ê

"

-/,1

/"

Ê,

"

Head

Head

Jamb

Jamb

Sill

Jamb

Shown with 6" Compressions Channel Segments. Use segments

at areas where wall is wider than nominal drywall thickness

dimensions. Wall will compress up to 1/4"

,

"Ê

/ , ",Ê *," 1 /-] Ê °

3OLUTIONS))

­

NÊ-

- / / "

Ê

-/,1

/"

-

"7Ê/"Ê1,Ê,"1Ê"*

-

Ê" , Ê " 1 Ê " " , Ê , Ê 7 / " 1 / Ê - /

• Rough Opening Width is equal to Door Opening Width plus 1-1/2”

• Rough Opening Height (less than Ceiling Height) is equal to Door Opening Height plus 3/4”

NÊ-

Ê" , Ê " 1 Ê " " , Ê , Ê 7 / Ê - / Ê "

Ê - • Rough Opening Width is equal to Door Opening Width plus Day Light Opening Width of window(s) plus the width of the

vertical intermediate(s) plus 1-1/2”

• Rough Opening Height (less than Ceiling Height) is equal to Door Opening Height plus 3/4” if sidelight is to the finished floor.

If sidelight is over drywall at the sill, rough opening is DLO plus 1-1/2”.

NÊ-

Ê" , Ê " 1 Ê " " , Ê , Ê 7 / Ê - / Ê "

Ê " / Ê - -

• Rough Opening Width is equal to Door Opening Width plus Day Light Opening Width of the windows plus the width of the

vertical intermediates plus 1-1/2”

• Rough Opening Height (less than Ceiling Height) is equal to Door Opening Height plus 3/4”

NÊ-

Ê" , Ê " 1 Ê " " , Ê , Ê 7 / Ê / , - " Ê /

• Rough Opening Width is equal to Door Opening Width plus 1-1/2”

• Rough Opening Height (less than Ceiling Height) is equal to Door Opening Height plus Day Light Opening Height of Transom

plus Door Frame Header Width plus 3/4”

NÊ",,"7 Ê /

• Rough Opening Width is equal to Day Light Opening Width plus 1- 1/2”

• Rough Opening Height (less than Ceiling Height) is equal to Day Light Opening Height plus 1-1/2”

Rough opening tolerances are plus or minus 1/4”

All C studs nearest the edges of the rough opening

should be reversed so that the open end of the stud is

towards the rough opening.

The edge of the C studs should be flush with the edge

of the drywall and care should be taken that the drywall

edge is square and plumb.

All attachment screws should be embedded into the

drywall. All screws attaching C studs and stud track

should not cause the drywall to flare.

The drywall thickness should not exceed the nominal

wall thickness. This includes head and sill conditions if

covering drywall.

Cross Section Of Door Frame Jamb Showing Reversed C Stud

And Coverage Of Frame Over Drywall

,

" Ê / , " ,Ê * ," 1 /- ]Ê

°

3OLUTIONS))

­

"7Ê/"Ê

- / / "

-/ÊÊ-

Ê

-/,1

/"

-

Ê",Ê"1Ê"",Ê,

(Drywall at the head) (Extra length on the bottom of the jambs for field cutting to fit floor variance)

#HECKWALLTHICKNESSANDROUGHOPENINGDIMENSIONS

Do not proceed unless the drywall is within tolerance

and plumb.

#HECKTHEDOORFRAMEFORDAMAGEORMISSINGPARTS

Parts list for single door frame: (double frame similar)

• Door frame header

Trim for both sides

• Door frame hinge jamb (two if double frame)

Trim for both sides, one side is factory notched to

clear the hinges

• Door frame strike jamb (none if double frame)

Trim for both sides, one side is factory notched to

clear the strike

• Door stop gasket for header and both jambs

• Corner clips (4-RA108) to connect the header with the

jambs

0LACEDOORFRAMEHEADEROVERDRYWALL

• Do not attach header at this time

• Make sure door stop is facing the right direction

• Adjust the header to its proper height and confirm the

door opening height (use temporary screws to hold if

necessary)

• Measure from the rabbet line to the finished floor on

each side to determine the exact lengths of the two

jambs to accommodate variance in the floor

• Cut the excess “extra length” off the bottom of the

jambs to fit

)NSERTTHETABSATTHETOPOFTHEHINGEJAMBINTO

THESLOTSINTHEHEADERANDTHENPLACETHEJAMB

OVERTHEDRYWALL

)NSERTTHETABSATTHETOPOFTHESTRIKEJAMBINTO

THESLOTSINTHEHEADERANDTHENPLACETHEJAMB

OVERTHEDRYWALL

&INALADJUSTMENTANDATTACHMENT

3TARTWITHTHEHINGEJAMB

• Plumb vertically

• Make sure jamb is not rotated in or out

• Secure to the wall with 1-1/4” drywall screws on

both sides of the jamb (screws supplied by others)

• Top screw within one inch of the top of the jamb

• Bottom screw within one inch of the bottom of

the jamb

• Intermediate screws every 9 to 12 inches

0ULLHEADERTIGHTTOTHETOPOFTHEJAMB

• Level the header

• Make sure header is not rotated in or out

• Secure header to the jambs using the corner clips

(all four corners)

• Secure the header to the wall using 1-1/4" drywall

screws on both sides (screws supplied by others)

– First screws within one inch of each end

– Intermediate screws every 9 to 12 inches

3TRIKEJAMB