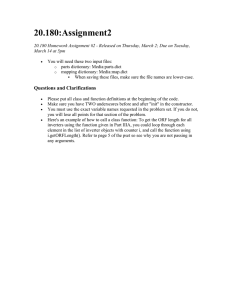

“Measurements and Analysis of a 20 kW Grid

advertisement