IX. Electrical and Instrumentation

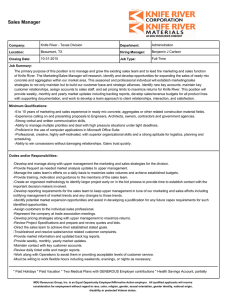

advertisement

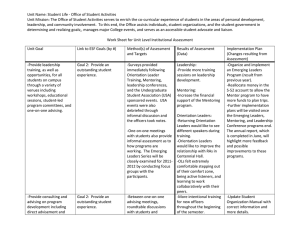

IX. Electrical and Instrumentation A. Introduction – The HRSD Engineering Department has an Electrical Shop that provides electrical and instrumentation support for all of HRSD. The Electrical Engineer in the Engineering Department is responsible for coordinating the electrical review of plans and specifications and coordinating with the Electrical Shop on design and start- up issues. Strong preferences exist for certain brands of equipment and certain criteria or features as indicated in the tables that follow. B. General – Unless otherwise agreed upon, the Engineer shall design facilities and specify equipment around the names listed in this Section. Competition is to be allowed (unless sole source is indicated). Specifications should be written around the equipment and equipment manufacturers listed to maintain quality and to exclude specific manufacturers based on past experience. In all cases NEMA vs. IEC rated components are strongly preferred. The following sections provide independent tables of standards and preferences for pump stations, interceptor system controls and treatment plants in order to accommodate the different needs and preferences of the various operating departments within HRSD. C. Pump Station and Interceptor Systems – See attached Table “Pump Station.” D. Treatment Plant – See attached Table “Treatment Plant.” Equipment Numbering Sequences shall be in accordance with the Treatment Plant Section of this document. IX- 1 04/01 Electrical and Instrumentation Standards and Preferences Index Pump Station 1. 2. 3. 4. 5. 6. 7. Treatment Plant 1. 2. 3. 4. 5. 6. 7. Switchgear MCCs Emergency Generators Energy Efficient Motors Sump Pumps Level Sensing Systems Variable Speed Drives (VSDs) 8. Switchgear and MCCs Emergency Generators Energy Efficient Motors Sump Pumps Level Sensing Systems Variable Speed Drives (VSDs) Watt Hour Meter (for MCCs or individual motors) PLCs 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. Exhaust Fans Lighting Concrete Housekeeping Pads Conduit and Conduit Systems Wire Relays Lockout/Tagout → Safety Switches/Receptacles/Plugs Electric Heaters Electrical Drawings Safety Switches (fused or unfused) Transformers Metering Vaults/Pits Pressure Sustaining/Regulating Valves Alarm Systems Flow Meters RTUs Louvers/Dampers Cathodic Protection 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. Metering Packages for Switchgear, MCCs or Individual Motors PLCs Exhaust Fans Lighting Concrete Housekeeping Pads Conduit and Conduit Systems Wire Relays Lockout/Tagout → Safety Switches/Receptacles/Plugs Heaters Electrical Drawings Safety Switches (fused or unfused) Transformers Metering Vaults/Pits Pressure Sustaining/Regulating Valves Flow Meters RTUs Louvers/Dampers Transfer Switches On-Line Vibration Monitors Panel Meters Analyzers/Monitors Miscellaneous Instrumentation Electrical Equipment Testing IX- 2 04/01 Item # 1 PUMP STATION Electrical and Instrumentation Standards and Preferences Electrical Equipment/Item Recommended/ Specific Criteria Preferred Manufacturers Switchgear and MCCs Cutler Hammer -Everything to be face-mounted, lead, lag, lagSquare D lag selectable, (any combination) with Westinghouse automatic failover Allen Bradley -Prefer bottom entry Cutler Hammer -Provide 20 amp minimum •Breakers/Solid State Breakers Westinghouse Square D Basler -Volt Meter 3 phase & off • Instrumentation Package GE -Ammeter 3 phase & off Westinghouse -kW Brown-Boveri -PF -kVA -kVAR -Utility grade CTs & PTs -Metering packages (see #8) -Provide 3 phase undervoltage & overcurrent protection Square D -Expandable contact blocks on operators •Selector Switches, Push Buttons, Cutler Hammer Lighted Push Buttons Cutler Hammer -Provide with expandable auxiliary contacts for • Contactors Square D 120 volt control circuits Buss -Must be locally available • Fuses & Fuse Holders Shawmut Square D -Copper coils/aluminum coils unacceptable • Transformers Pheonix Contact -Rail mount if possible •Terminal Strips -Industrial rated Square D -120 volt control voltage •Combination Starters (buckets) Cutler Hammer -Run light – red -Stop light – green -Power available light – white -Elapsed time meters–pump motors (Yokogawa) graduated in 1/10 hours -Externally mounted resets, operational from the front -Provide with thermo -magnetic breakers -Fused control transformer -MCC mounted lighting panels shall be provided with 25% spare breakers -Provide spare buckets (minimum 2) -Provide connections for motor leads directly fro m the motors to the starters. Do not use intermediate terminal blocks ·Rubber Mats (in front of gear) -HRSD will provide and install at substantial completion (OSHA approved electric safety rubber matting) IX- 3 04/01 Item # 2 Electrical Equipment/Item Emergency Generators •Generator PUMP STATION Electrical and Instrumentation Standards and Preferences Recommended/ Specific Criteria Preferred Manufacturers Caterpillar -Prefer diesel generators Cummins Onan -Do not prefer turbine generators Detroit Diesel, -Engines to be of domestic manufacture Series50 and 60 whenever possible only -Prime rated Kohler -4-stroke John Deere -Parts must be available in 24 hours or less -Meet EPA and VA DEQ air standards -Prefer low emission units Stamford -Generators 1Mwatt and larger require a two bearing generator -The rectifier shall be a brushless, full-wave bridge. -All stator winding leads are to be brought out to the terminal box. -Neutrals shall be sized to full rating -Temperature rise shall not exceed Class B rating with 105° C ambient rise -Alternator shall have a space heater that switches off when running. -Provide for 2/3 winding pitch -Minimum Class H insulation (epoxy) with tropicalization (anti-fungus) temperature requirements are specified by NEMA -Provide voltage regulation less than +/- 1% -Provide 150% minimum overspeed capability -Provide amortisseur winding -Provide less than 5% THD (Total Harmonic Distortion) -Provide less than 50 TIF (Telephone influence factor) -Provide Square D main breaker (American made only) -Provide elapsed time meter Yokogawa, graduated in 1/10 hours IX- 4 04/01 Item # Electrical Equipment/Item ·Diesel Engine PUMP STATION Electrical and Instrumentation Standards and Preferences Recommended/ Specific Criteria Preferred Manufacturers -Heavy-duty, direct-injected, 4-stroke diesel engine Caterpillar Prefer electronically controlled engines with an Cummins Diesel electronic control system that meets or exceeds the Detroit Diesel operation of the Woodward 2301A series governor. Kohler -State the control system John Deere -Provide system software and training to use software and operate the engine -Provide isochronous frequency regulation (no load to full load) -Provide +/- .25% steady state frequency regulation (minimum) -Provide a mechanical machine with a Woodward 2301 governor if electronically governed machines are not available. -Size air, fuel and oil filters to provide a minimum of 100 hours of operation before servicing. Provide a Racor fuel-water separator. The air filter is to be a dry type with a restriction indicator. -Provide a Nelson (or Racor) heavy duty crankcase vapor coalescer. -Provide a battery charging alternator (65 amp minimum – negative ground). -Prefer a skid-mounted radiator sized to prevent overheating in the most severe conditions (110°F ambient) -Provide residential grade super critical type exhaust system and muffler. All insulation must be blanket type (non-asbestos), removable for servicing of exhaust system -Provide 24 volt DC starting system. -Provide all diagnostic equipment for complete trouble shooting (software/technical manuals/hardware) -Provide speed sensing to protect against accidental starter engagement into a moving flywheel. (Battery charging alternator voltage will not be accepted for this purpose). -Provide an adjustable (0-15 minutes) cool down time -Provide a large red emergency stop push button. -Low oil pressure, high coolant temperature, overspeed, and over-crank shall shut down the engine and provide indicator lights. -Provide analog or digital displays for coolant temperature, oil pressure, service hours, engine RPM, system DC volts and system diagnostic code. -Provide Kim Hot-Start engine block heater (thermostatically controlled) -Provide vibration isolators between generator set base and floor -Provide lifting eyes -Provide mean effective pressure break (BMEP) calculations IX- 5 04/01 Item # Electrical Equipment/Item • Battery Chargers •Starting Batteries •Day Tanks Transfer Switches PUMP STATION Electrical and Instrumentation Standards and Preferences Recommended/ Specific Criteria Preferred Manufacturers Charles Chargers -Model #AA2410 24 volt chargers or LaMarche equal -Automatic, solid state, provide continuous taper charging -UL listed, provide with under/over voltage, current failure and loss of power acknowledgment GND -Use 80 series lead acid batteries Dynacell -Provide 2 minimum -Each battery shall provide 1200 CCA each -Provide with insulated battery rack -Provide with 3 year full replacement guarantee -Provide as a minimum 2 cranking cycles at a minimum of 30 seconds each Pryco -UL Listed – Double Wall Simplex -Provide w/Oberndorfer gear type pump. (no substitute) Pumps with rubber or nitrile impellers will not be accepted -Provide with a low level alarm -Size for 2 hour minimum running time -Provide a fuel level indicator on the day tank. -Provide a graduated stick. Cutler Hammer -Provide with an exercise cycle of 4 hours, Westinghouse field adjustable from 10 minutes to 4 hours Square D -Provide with a utility power available light ASCO normal/emergency, phase indicator lights Underground Storage Tanks (UST) Zenith Transfer switches are not acceptable Controls by MSA Tankguard Veeder Root Hersey Louvers and Dampers Greenheck IX- 6 04/01 -Provide with leak detection system -Provide in accordance with EPA and all applicable State and Local standards -Provide tank monitoring system -Provide a graduated stick for level measuring -Provide for refueling and stick access -Provide with pneumatic tank level indicating system -Provide with 48-hour fuel tank capacity -Provide for gravity damper -Provide anodized aluminum louvers and dampers with nylon bushings -Provide with bird screens readily removable without removing louvers or dampers -Designed to limit rainwater in the building -Steel is not acceptable Item # Electrical Equipment/Item Instrumentation Package Start Up and Testing •Diesel Generator Tests 3 Energy Efficient Motors 4 Sump Pumps 5 Level Sensing Systems PUMP STATION Electrical and Instrumentation Standards and Preferences Recommended/ Specific Criteria Preferred Manufacturers -Voltmeter 3 phase & off -Ammeter 3 phase & off -Frequency -Provide a voltage adjust reostat -Provide 3 phase undervoltage and over-current protection -Provide automatic and manual start and stop -Provide factory test data -Simulate and test all safety equipment. Using a reactive load bank (.8PF) run the generator: 15 minutes at idle speed 30 minutes at 25% load 30 minutes at 50% load 60 minutes at 75% load 120 minutes at 100% load 15 minutes at 25% load 15 minutes at 0% load off -Record stator, bearing, oil, ambient, and water temperatures every 15 minutes. -Record speed, voltage and amperage at 15 minute intervals as well as just prior to and after the load change -Hook up the generator and cycle the through light loading cycles as well as heavy loading cycles (3 each). Record same parameters every 15 minutes and before and after changing load. Tests to be witnessed by HRSD Automotive Supervisor and HRSD Electrical Engineer. -Create and attach to the switchgear detailed instructions. The instructions shall be laminated. The instructions shall be simple enough for anyone to pick them up and operate the diesel generator set. -See HRSD Electric Motor Specifications in Appendix F Zoeller Co -120 volt -Plug into receptacle -Float controlled IX- 7 04/01 Item # Electrical Equipment/Item • Bubbler Type •Pressure Sensing Systems •Float Balls 6 PUMP STATION Electrical and Instrumentation Standards and Preferences Recommended/ Specific Criteria Preferred Manufacturers Healy-Ruff -Complete purged air bubbler system for 612 633 7522 sensing wetwell liquid level which generates and transmits level signals to a PLC which controls pump operations -Provide with L.P. switch with N.C. dry contacts down stream of the regulator -Provide duplex air compressors mtd. on 30 gal. horizontal receiving tank (Bell & Gossett or equal) -Provide push button for manual purging of bubbler piping -Provide manual alternation of air compressors -Provide panel mounted 4 1/2 inch 0 level gauge -Provide an oil-less compressor with 120 volt 60 cycle, single phase motor with integral thermal overload protection -Provide high level alarm in wetwells. Provide with mercury switch backup. -Provide Red Valve pressure transmitters -Provide 0-100psi gauge (Ashcroft) -Provide series 40 pressure sensor -Provide a 1AP20 absolute pressure electronic transmitter -Provide Viton Boots -See Standard Detail “Pressure Reducing Station Pressure Sensor Detail” -Suction and discharge transmitters to be mounted in dry well area Fisher-Rosemont -Locate near sump pump in dry well -Alarm on high level Variable Speed Drives (VSDs) IX- 8 04/01 Item # PUMP STATION Electrical and Instrumentation Standards and Preferences Electrical Equipment/Item Recommended/ Specific Criteria Preferred Manufacturers Safetronics -Provide a programmable Ramp time •Variable Frequency Drives (VFD) Control Techniques - Provide input reactors -Pulse Width Modulated (PWM) -12 pulse drives are required, 6 pulse drives are not acceptable. -Prefer IGBTs -VFD must be able to be isolated and bypassed (manual operation) allowing the motor to operate across the line at full load speed and current. -Provide manual isolation and bypass capability -Automatic restart on power disruption -Tune out a minimum of 3 frequencies -Hands/Off/Automatic (HOA) selector switch with manual speed pot -Mount the resets and appropriate indicator lighting on the front of the drive or outside of the box -Tune drive to motor with a harmonics meter -Provide an input circuit breaker for short circuit protection -The controller electronics shall contain indicators of the following conditions: Undervoltage Overvoltage Over temperature Memory failure Emergency Stop Ground fault Instantaneous overcurrent -Provide thermostatically controlled ventilation -Provide a NEMA 12 free standing enclosure with thermostatically controlled ventilation and dust filters. -Mount the resets and the appropriate indicator lighting on the front of the drive or the outside of the box. -Do not prefer •DC Drives •Eddy Current Brake Systems 7 Watt Hour Meter (for MCCs or individual motors) -Do not prefer Power Logic IQ Plus Multilin IX- 9 04/01 -Provide cumulative hour meters on each motor (MCC). -Provide a motor on each MCC to indicate 3 phase parameters on the MCC, i.e., volts, amps, kW, PF, kVA, kWh, etc. -Provide output interface for V, I & kW Item # Electrical Equipment/Item 8 PLCs 9 Exhaust Fans 10 Lighting •Incandescent •Fluorescent Light •Metal Halide •HPS •LPS •Mercury Vapor •Emergency Lighting 11 •Exit Lighting Concrete Housekeeping Pads PUMP STATION Electrical and Instrumentation Standards and Preferences Recommended/ Specific Criteria Preferred Manufacturers Omron -Provide functional descriptions, the Siemens (TI) application program, the job-specific program Allen Bradley data and a copy of the as-built s/w Square D documentation -Include control & alarms in PLC Controls accommodate automatic purge and latch output to current state during bubbler purge. ILG -Corrosion resistant including hardware Dayton -Must be explosion proof in wet wells and Greenheck Airovent metering vaults -Provide proper levels of lighting over major Holophane equipment including switchgear, generators, Hubbell pump motors, and controls. Lighting levels Thomas should conform to the IES lighting handbook Crouse-Hinds as a minimum -Provide exterior lighting at doorways and yard lighting required by building configuration -Consider operation by photo electric cell -ALTO or equivalent lighting shall be used to limit the mercury content of the lighting -Non-fluorescent fixtures shall be metal halide Crouse Hinds -Provide explosion proof lighting in pump station wet wells -Provide 10 ft candles minimum in wet well areas Holophane -Provide w/low temp ballasts -Provide w/ lens and gaskets in chemical rooms -Do not provide fluorescent lighting and controls on the same circuit. -Provide electronic ballasts with T-8 bulbs -Provide fluorescent lighting in control cabinets (i.e. PLCs, bubbler control panels) with door switches Holophane -Suitable in high bay areas -Provide quick strike fixtures -Wall-paks are suitable inside or outside -Not acceptable for any application -Not acceptable for any application -Not acceptable for any application Dual lite MLW series -Wall-paks are provide by HRSD USI Prescolite -Highly visible 24hours/day for life -Provide a minimum of 4 inch thickness under MCCs and around conduits at floor penetrations -Chamfer all edges IX- 10 04/01 Item # 12 13 PUMP STATION Electrical and Instrumentation Standards and Preferences Electrical Equipment/Item Recommended/ Specific Criteria Preferred Manufacturers Conduit and Conduit Systems -Ream and chamfer all edges -EMT or IMC are not allowed -All flexible conduit shall be liquidtite or equal -Provide ¾ inch minimum size -Do not use plastic anchors -Seal conduits w/ a silicone product as necessary -See architectural and coatings standard for markings and coatings -Provide w/ service entrance •Spare Conduit Feeder -Add appropriate spares Robroy -Provide in wet wells, underground (not •PVC Coated Rigid Steel (inside and OCAL encased), chemical areas, outside, and damp out ) Perma -Cote areas. Provide with appropriate fittings, boxes and touch-up material -Provide with applications other than PVC •Galvanized coated above. -Underground/encased in concrete, Schedule •PVC 40 can be substituted for galvanized conduit in duct banks where EMI is not a threat -Use suitable tools w/ conduit •Tools Used -Use appropriate material to patch and repair •Patching/Repair -Use Myers hubs for wet well and outside •Flex – Liquidtite & Fittings conduit terminations Crouse Hinds •Εxplosion Proof Fittings Appleton -Use appropriate fittings and materials •Fixtures & Fittings (pull boxes) -To suit conduit materials •Struts and Straps -Use matching fasteners -In outside, wet or damp areas, use SS fasteners •Pull Boxes (wire pulled through) and -Over 6” x 6” are to be hinged Junction Boxes (Wires terminated -Gasketed inside) -Use SS or alum in outside or damp areas Wire -Provide separation of power, signal and telephone services -Use compression type lugs only -Do not splice wire -Provide conduit and wiring for telephone •Telephone •THHN, THWN -Follow NEC color coding -All wire #14 AWG and larger shall be stranded wire, rated for 600v -#12 minimum wire size for typical applications IX- 11 04/01 Item # Electrical Equipment/Item •Instrumentation 14 Relays •Industrial •Electronic 15 16 Lockout / Tagout à Safety Switches / Receptacles / Plugs 17 Electric Heaters 18 Electrical Drawings 19 Safety Switches (fused or unfused) 20 Transformers •Dry 21 PUMP STATION Electrical and Instrumentation Standards and Preferences Recommended/ Specific Criteria Preferred Manufacturers -Instrumentation control wire should be sized accordingly (#18 stranded wire recommended) -DC wire shall be color-coded blue -AC wire shall be color-coded red -Externally powered circuits (entering/leaving the cabinet) shall be color-coded yellow Note: Cabinets with multiple sources must be clearly marked as such. Wesco Cutler Hammer IDEC Potter Brumfield Agastat Pass & Seymour Hubbell Crouse Hinds Square D Cutler Hammer Westinghouse Allen Bradley Square D Cutler Hammer Westinghouse GE Metering Vaults/Pits •Dehumidifiers -Plug in ice cube type -Provided for in Division 1 of specifications -Provide for dedicated circuits for sump pumps -Provide a receptacle on each wall of the PS, Upper & lower levels. Lower levels shall be mounted at 48 inches AFF. -Provide one wp/wt receptacle on the exterior wall on a single circuit, separately switched. -Provide ground fault receptacles and breakers where required. -Provide power receptacles in control cabinets. -Not used, do not supply unless a condition requires it. -P&IDs are to conform to ISA modified standards (consulting engineer to provide) -Provide functional descriptions with the P&IDs (consulting engineer to provide) -Provide Point to Point connection drawings. Contractor shall develop. Review and approval by the Engineer shall be prior to installation. -Light duty safety switches are unacceptable -Must be pad lockable -No Aluminum Wire -Provide 220° C insulation system for 15 kVA and larger -Provide 180° C insulation system for transformers less than 15 kVA -Transformers shall handle a 15% overload without exceeding the insulation rating -Provide receptacle and location for HRSD installation IX- 12 04/01 -Fixed base Item # 22 23 24 25 26 27 Item # 1 PUMP STATION Electrical and Instrumentation Standards and Preferences Electrical Equipment/Item Recommended/ Specific Criteria Preferred Manufacturers -Provide two receptacle w/wp covers •Power Requirements -See Exhaust Fans •Exhaust Fans Pressure Sustaining/Regulating Valves KTM -No butterfly valves or pinch valves with Foxboro controls Clow -Provide 4-20 mA operated valves. Do not use pulsed control valves -Prefer Automatic Controls of Virginia or Valve Automation for actuator applications Alarm System -HRSD will provide and install the alarm system. Contractor shall provide sensors and wiring to a junction box and terminate on a terminal strip adjacent to the alarm panel location -HRSD will provide alarm points Flow Meters -Size for average flows Brooks -Use for control or billing applications •Magnetic Foxboro Yokogawa ABB Kent-Taylor Fuji -Prefer not to use for control •Ultrasonics (insertion or strap on) Polysonics -Locate inside station Panametrics -Generally, prefer not to use •Venturi RTUs HRSD to provide -Motorola – Moscad -Physical size 24”x24”x8” in a NEMA 4x enclosure •Antenna • Junction box •Sensors Louvers/Dampers Greenheck -Provide gravity dampers for all applications -See emergency generators – louvers Cathodic Protection Test Stations -Use Flush Fink Test Stations Electrical Equipment/Item Switchgear •Breakers/Solid State Breakers TREATMENT PLANT Electrical and Instrumentation Standards and Preferences Recommended/ Specific Criteria Preferred Manufacturers Cutler Hammer -Provide with push to test lights Westinghouse -Bottom entry is preferred Square D -Provide in a room strictly for switchgear Cutler Hammer -Provide appropriate spares and spaces Westinghouse Square D IX- 13 04/01 Item # 2 TREATMENT PLANT Electrical and Instrumentation Standards and Preferences Electrical Equipment/Item Recommended/ Specific Criteria Preferred Manufacturers Basler -Provide utility grade metering • Instrumentation Package GE -Volt Meter 3 phase & off Westinghouse -Ammeter 3 phase & off Brown-Boveri -Kw -PF -kVA -kVAR -Utility grade CTs & PTs -Metering packages (Reference Item #8) -Provide 3 phase undervoltage & overcurrent protection Square D -Expandable contact blocks on operators •Selector Switches, Push Buttons, Cutler Hammer Lighted Push Buttons Westinghouse Allen Bradley Cutler Hammer -Provide with expandable auxiliary contacts for • Contactors Westinghouse 120 volt control circuits Square D Allen Bradley Buss -Must be locally available • Fuses & Fuse Holders Shawmut Square D -Provide Copper coils • Switchgear Control Cutler Hammer -Aluminum coils are unacceptable Transformers Westinghouse Allen Bradley Phoenix Contact -Rail mount if possible •Terminal Strips ILSCO -Industrial rated ·Rubber Mats (in front of gear) -HRSD will provide and install at substantial completion MCCs Cutler Hammer -Do not provide in the same room with Westinghouse chemical tanks or pumps Square D -Provide with “push to test” lights Allen Bradley -Bottom entry is preferred -Provide with face mounted operators and resets Cutler Hammer •Breakers/Solid State Breakers Westinghouse Square D Westinghouse -Volt Meter 3 phase & off • Instrumentation Package -Ammeter 3 phase & off -kW -PF -kVA -kVAR -Utility grade CTs & PTs -Metering packages (Reference Item #8) -Provide 3 phase undervoltage & overcurrent protection IX- 14 04/01 Item # 3 TREATMENT PLANT Electrical and Instrumentation Standards and Preferences Electrical Equipment/Item Recommended/ Specific Criteria Preferred Manufacturers Square D -Expandable contact blocks on operators •Selector Switches, Push Buttons, Cutler Hammer Lighted Push Buttons Westinghouse Allen Bradley Cutler Hammer -Provide with expandable auxiliary contacts for • Contactors Westinghouse 120 volt control circuits Square D Allen Bradley Buss -Must be locally available • Fuses & Fuse Holders Shawmut Square D -Metering • MCC CTs and PTs Cutler Hammer -Provide Copper coils Westinghouse -Aluminum coils unacceptable Allen Bradley Pheonix Contact -Rail mount instrumentation if possible •Terminal Strips ILSCO -Industrial rated ·Combination Starters (Buckets) Square D -120 volt control voltage Cutler Hammer -Run light – red Westinghouse -Stop light – green Allen Bradley -Power available light – white -Elapsed time meters– Yokogawa -Resets operational from the front (external) -Provide with thermo -mag brkrs -Fused control transformer -25% spares and/or spaces for all sizes of buckets or expandable option -MCC mounted lighting panels shall be provided with 25% spare breakers -Provide connections for motor leads directly from the motors to the starter. Do not use intermediate terminal blocks (50 HP and smaller). ·Rubber Mats (in front of gear) -HRSD will provide and install at substantial completion Emergency Generators Caterpillar -Prefer diesel generators Cummins Onan -Do not prefer turbine generators Detroit Diesel -Engines to be of domestic manufacture Kohler whenever possible John Deere -4-stroke diesels ONLY -Parts must be available in 24 hours or less -Meet EPA and VA DEQ air standards -Prefer low emission units -All units shall be Prime Rated IX- 15 04/01 Item # Electrical Equipment/Item •Generator TREATMENT PLANT Electrical and Instrumentation Standards and Preferences Recommended/ Specific Criteria Preferred Manufacturers Stamford -Generators 1MWatt and larger require a two bearing generator -The rectifier shall be a brushless, full-wave bridge. -300 kW and below at 480 volts bring all leads out to the terminal box -400 kW and above – bring out 3 leads and a neutral (minimum) to the terminal box -Neutrals shall be sized to full rating (brought out to the terminal box) -Temperature rise on generator voltages 4160 & higher shall not exceed Class B rating with 80° C ambient rise. All others shall not exceed 105° C rating. -Alternator shall have a space heater that switches off when running. -Provide for 2/3 winding pitch -Minimum Class H insulation (operating temperature class 180° C) -Provide voltage regulation less than +/- 1% -Provide 150% minimum overspeed capability -Provide amortisseur winding -Provide less than 5% THD (Total Harmonic Distortion) -Provide less than 50 TIF (Telephone influence factor) IX- 16 04/01 Item # Electrical Equipment/Item ·Diesel Engine TREATMENT PLANT Electrical and Instrumentation Standards and Preferences Recommended/ Specific Criteria Preferred Manufacturers -Heavy-duty, direct-injected, 4-stroke diesel engine Caterpillar -Prefer electronically controlled engines Cummins Diesel -Provide electronically controlled engines with an Detroit Diesel electronic control system that meets or exceeds the Kohler operation of the Woodward 2301A series governor John Deere -Require vendor to identify the contro l system to be provided. -Provide system software and training to use software and operate the engine -Provide isochronous frequency regulation (no load to full load) -Provide +/- 0.25% steady state frequency regulation (minimum) -If electronically governed machines are not available, then provide a mechanical machine with a Woodward 2301A governor -Air, fuel and oil filters shall be sized to provide a minimum of 100 hours of operation before servicing. Provide a Racor fuel-water separator. The air filter is to be a dry type with a restriction indicator. -Provide a Nelson (or Racor) heavy duty crankcase vapor coalescer. -Prefer a skid-mounted radiator (most are site specific) sized to prevent overheating in the most severe conditions (110°F ambient) -Exhaust system and muffler shall be a hospital grade super critical type manufactured out of 304 SS material. All insulation must be blanket type (non-asbestos), removable for servicing of exhaust system -The starting system shall be 24 volt DC -Provide all diagnostic equipment for complete trouble shooting (software/technical manuals/hardware) -Speed sensing shall be provided to protect against accidental starter engagement into a moving flywheel. -Provide an adjustable (0-15 minutes) cool down time -Provide a large red emergency stop push button. -Low oil pressure, high coolant temperature, overspeed, and over-crank shall shut down the engine and provide indicator lights. -Analog or digital displays shall be provided for coolant temperature, oil pressure, service hours, engine RPM, system DC volts and system diagnostic code. -Provide Kim Hot-Start engine block heater (thermostatically controlled) set in accordance with manufacturer’s recommendation (120 ° F – 140° F degrees). -Provide vibration isolators between generator set base and floor -Provide lifting eyes -Provide brake mean effective pressure (BMEP) calculations IX- 17 04/01 Item # TREATMENT PLANT Electrical and Instrumentation Standards and Preferences Electrical Equipment/Item Recommended/ Specific Criteria Preferred Manufacturers Charles -Charles Model AA2410, 24 volt chargers or • Battery Chargers LaMarche LaMarche equal -Automatic, solid state, provide continuous taper charging -UL listed, provide with under/over voltage, current failure and loss of power acknowledgment GNB -Use 8D lead-acid batteries •Starting Batteries Dynacell -Provide a minimum of 2. The batteries shall provide 1200 CCA each. -Provide with insulated battery rack -Provide a 3 year full replacement guarantee -Provide as a minimum 2 cranking cycles at a minimum of 30 seconds each Ingersoll-Rand -Site Specific •Air Starter Pryco -UL Listed - Double Wall •Day Tanks Simplex -Provide with Oberndorfer gear type pump. (no substitute) Pumps with rubber or nitrile impellers will not be accepted -Provide with a low level alarm -Size for 2 hour minimum running time -Provide a fuel level indicator on the day tank. Controls by -Provide in accordance with EPA and all •Underground Storage Tanks (UST) MSA Tank Guard applicable State and Local standards Veeder-Root -Provide with leak detection system Hersey -Provide a graduated stick for level measuring -Provide for stick access and refueling -Provide with 48-hour fuel tank capacity Greenheck -Aluminum or PVC with hardware •Louvers and Dampers -Provide for gravity dampers -Provide anodized aluminum dampers with nylon bushings -Steel is not acceptable -Provide with bird screens readily removable without removing louvers or dampers -Designed to limit rainwater in building Basler -Volt meter 3 phase & off • Instrumentation Package Brown-Boveri -Ammeter 3 phase & off GE -kW Westinghouse -PF -kVA -kVAR -Utility grade CTs & PTs -Metering packages (Reference Item #8) -Provide 3 phase undervoltage & overcurrent protection IX- 18 04/01 Item # Electrical Equipment/Item •System Operation TREATMENT PLANT Electrical and Instrumentation Standards and Preferences Recommended/ Specific Criteria Preferred Manufacturers -Provide protection such that the two sources (utility & emergency generator) can never be closed out of phase. -Provide approvals by Virginia Power on the paralleling protection scheme. -Provide a selector switch to allow the operator to choose “curtailment” or “loss of power” (typically set to “loss of power”) -In the loss of power setting, the system shall have automatic and manual operation. The manual operation would be provided in the event the automatic functions failed. -If the operator switches to curtailment: • Depressing a single push button in the automatic mode will start the engine, parallel with the utility, ramp the plant load onto the generator and open the utility breaker. • Depressing a second push button will ramp the load back to the utility and shut down the generators. IX- 19 04/01 Item # Electrical Equipment/Item •Start Up and Testing TREATMENT PLANT Electrical and Instrumentation Standards and Preferences Recommended/ Specific Criteria Preferred Manufacturers -Provide factory test data -Simulate and test all safety equipment. Using a reactive load bank (0.8PF) run the generator: 15 minutes at idle speed 30 minutes at 25% load 30 minutes at 50% load 60 minutes at 75% load 120 minutes at 100% load 15 minutes at 25% load 15 minutes at 0% load (cool down) off -Record stator, bearing, oil, ambient, and water temperatures every 15 minutes -Record speed, voltage and amperage at 15 minute intervals as well as just prior to and after a load change -Hook up the generator to the main switchgear. Perform all automatic and manual functions a minimum of three times each. The plant will load the generators as much as possible. Particular attention should be observed to the larger starting loads. Record same parameters every 15 minutes and before and after changing load. Tests to be witnessed by HRSD Automotive Supervisor and HRSD Electrical Engineer. 4 Energy Efficient Motors 5 Sump Pumps 6 Level Sensing Systems Zoeller Co IX- 20 04/01 -Create and attach to the switchgear detailed instructions. The instructions shall be laminated. The instructions shall be simple enough for anybody to pick them up and operate the diesel generator set. -See HRSD Electric Motor Specifications in Appendix F. -Provide ammeters on motors 50 HP & larger -120 volt -Plug into receptacle -Float controlled Item # Electrical Equipment/Item •Bubbler Type •Ultrasonic •Capacitance TREATMENT PLANT Electrical and Instrumentation Standards and Preferences Recommended/ Specific Criteria Preferred Manufacturers -Complete purged air bubbler system for sensing wet well liquid level which generates and transmits level signals to control pump operations -Provide a pressure sensing device (Foxboro or equal) -Provide duplex air compressors mtd. on 30 gal. Horizontal receiving tank (Bell & Gossett or equal) -Provide push button for manual purging of bubbler piping -Provide manual alternation of air compressors -Provide lead/lag switch – no off -Provide panel mounted 4 ½” 0 level gauge -Oil-less compressor with 120 volt, 60 cycle, single phase motor with integral thermal overload protection -Provide pressure activated switches for point applications (Barksdale) Milltronics -Microprocessor -FM approved (frequency modulation) Warrick •Pressure Transmitters Foxboro •Float Balls Fisher-Rosemont •Pressure Sensing System 7 -Provide Red Valve Pressure Transmitters -Provide Ashcroft Gauges -Provide Series 40 pressure sensor -Provide 1AP20 absolute pressure electronic transmitter -Provide Viton Boots -See Standard Detail “Pressure Reducing Station Pressure Sensor Detail” Variable Speed Drives (VSDs) IX- 21 04/01 Item # TREATMENT PLANT Electrical and Instrumentation Standards and Preferences Electrical Equipment/Item Recommended/ Specific Criteria Preferred Manufacturers Safetronics -Provide a programmable ramp time •Variable Frequency Drives (VFDs) Control Techniques -Provide input reactors -Pulse Width Modulated (PWM) -12 pulse drives are required. 6 pulse drives are not acceptable. -Use IGBTs -VFD must be able to be isolated and bypassed (manual operation) allowing the motor to operate across the line at full-load speed and current. Site Specific. -Provide manual isolation and bypass capability -Automatic restart on power disruption -Tune out a minimum of 3 frequencies -Hand/Off/Automatic (HOA) selector switch -Manual speed control by potentiometer or keypad (door mounted) -Tune drive to motor with a harmonics meter -Provide an input circuit breaker for short circuit protection -The controller electronics shall contain indicators of the following conditions: Undervoltage Overvoltage Over temperature Memory failure Emergency Stop Ground fault Instantaneous overcurrent -Provide a NEMA 12 free standing enclosure with thermostatically controlled ventilation and dust filters -Mount the resets & appropriate indicator lighting on the front of the drive or the outside of the box. -Do not prefer DC VSDs •DC Drives •Eddy Current Brake Systems -Do not prefer Eddy Current clutch systems 8 Metering Packages for Switchgear, MCCs or Individual Motors IQ Plus Power Logic Multilin 9 PLCs Omron Allen Bradley Square D Siemens (TI) IX- 22 04/01 -Provide cumulative watt-hour meters on each MCC, or specific motor. -Provide a meter on each MCC to indicate 3 phase parameters on the MCC, i.e., volts, amps, kW, PF, kVA, kWh, etc. -Provide with motors 200 HP and above -Provide functional descriptions, the application program, the job-specific program data and a copy of the as-built software documentation -Include PLC fail indicator Item # Electrical Equipment/Item 10 Exhaust Fans 11 Lighting •Incandescent •Florescent Light •Metal Halide •HPS •LPS •Mercury Vapor •Emergency Lighting •Exit Lighting 12 •High-Mast Lighting Concrete Housekeeping Pads TREATMENT PLANT Electrical and Instrumentation Standards and Preferences Recommended/ Specific Criteria Preferred Manufacturers ILG -Corrosion resistant including hardware Dayton -Must be explosion proof in hazardous areas Greenheck Airovent Holophane -Provide proper levels of lighting over major Hubbell equipment including switchgear, generators, Thomas pump motors, and controls. Minimum Lighting Crouse-Hinds levels should conform to the IES lighting handbook. -ALTO or equivalent lighting shall be used to limit the mercury content of the lighting. -Non fluorescent fixtures shall be metal halide -Exterior lights shall be placed on a single photo cell (within reason). Crouse Hinds -Explosion proof in hazardous areas Holophane -Industrial areas Holophane -Provide with low temp ballasts -Provide with lens and gaskets in chemical rooms -Do not provide florescent lighting and controls on the same circuit. -Provide electronic ballasts with T-8 bulbs Holophane -Suitable in high bay areas -Provide quick strike fixtures -Wall-paks are suitable inside or Outside -Not acceptable for any application -Not acceptable for any application -Not acceptable for any application Dual Lite -Dual Lite GMM-EL-W2 in admin areas Emergency Lite -Emerg Lite PRO-2 in corrosive areas -Wall-paks are provide by HRSD Dual Lite -Highly visible 24hours/day for life (self Lithonia illuminating) -Provide lighted only if required Holophane Site Specific -Provide a minimum of 4 inch thickness under Switchgear & MCCs and around conduits at floor penetrations -Chamfer all edges IX- 23 04/01 Item # 13 Electrical Equipment/Item Conduit and Conduit Systems TREATMENT PLANT Electrical and Instrumentation Standards and Preferences Recommended/ Specific Criteria Preferred Manufacturers -Provide three separate conduit systems. One for power circuits >600 volts, one for power circuits less than 600 volts, and one for communication circuits. -Use compression type lugs only when splicing is specifically approved. -Ream and chamfer all edges -EMT or IMC are not preferred -All flexible conduit shall be liquidtite or equal -Provide ¾ inch minimum size -Do not use plastic anchors -Seal conduits with a silicone product as necessary (in the manholes to the buildings) -Administrative areas (plenum) can use EMT down to ½ inch (lighting only) -Label all conduits inside of building -Place metal tags on cables in manholes -See architectural and coatings standard for markings and coatings •Spare Conduits •PVC Coated (inside and out ) Robroy Ocal Perma -Cote •PVC •Galvanized •Tools Used •Patching/Repair •Flex – Liquidtite & Fittings •Εxplosion Proof Fittings Crouse Hinds Appleton •Fixtures & Fittings •Struts and Straps -Use appropriate fittings and materials -To suit conduit materials -Use matching fasteners -In outside, wet or damp areas use SS fasteners. -Over 6” x 6” are to be hinged -Gasketed -Use SS/aluminum in outside/wet areas -Use PVC coated reinforced fiberglass in hazardous and chemical areas -Appropriately locate above dropped ceilings -Do not splice wire -Place metal tags on cables in manholes •Pull Boxes (wire pulled through) and Junction Boxes (wires terminated inside) 14 •Wire Hangers Wire IX- 24 04/01 -Provide with service entrance -Add appropriate spares -Provide in corrosive areas, underground (not encased), chemical areas, chemical containment areas, outside and damp areas. Provide with appropriate fittings, boxes and touch-up material - Underground/encased reinforced concrete -Can replace RGS in duct banks where EMI is not a threat - Provide in all other areas not covered by PVC and PVC coated -Use suitable tools with conduit -Use appropriate material to patch and repair -Use Myers hubs where suitable Item # Electrical Equipment/Item •Telephone •THHN, THWN TREATMENT PLANT Electrical and Instrumentation Standards and Preferences Recommended/ Specific Criteria Preferred Manufacturers -Minimum wire gauge #22-24 AWG -Provide plenum rated cable in return air plenums -Follow NEC color coding -All wire #14 AWG and larger shall be stranded wire, rated for 600 volt -#12 minimum wire size for typical applications •Instrumentation •High Voltage Cable •Heat Tracing 15 Relays •Industrial •Electronic 16 17 Lockout / Tagout à Safety Switches / Receptacles / Plugs 18 Heaters •Electric •Gas Letco-Dual Controls Chromolox Wesco Allen Bradley Cutler Hammer IDEC Potter Brumfield Agastat Pass & Seymour Hubbell Crouse Hinds Qmarts Dayton Space Ray Dayton IX- 25 04/01 -Do not combine analog circuits (twisted shielded pair-TSP) with other circuits in the same conduit -Instrumentation control wires should be sized accordingly (#18 stranded wire recommended) -DC wire shall be color-coded blue -AC wire shall be color-coded red -Externally powered circuits (entering/leaving the cabinet) shall be color-coded yellow Note: Cabinets with multiple sources must be clearly marked as such. -Follow appropriate code -Provide thermostatically controlled with chemical systems -Provide self limiting with other systems -Provide with insulation -Provide with protective outer coating -Provide with indicator light -Provide with SS leads in corrosive areas -Fixed base -Plug-in/ice cube type -Provided for in Division 1 of specifications -Do not use wire binding screw type receptacles or switches -Provide for dedicated circuits for sump pumps -Provide power receptacle in control cabinets. -Provide a neutral for each circuit, multi wire circuits are not allowed without special approval and then with a two-pole breaker Item # Electrical Equipment/Item 19 Electrical Drawings 20 Safety Switches (fused or unfused) 21 Transformers •Dry •Oil Filled 22 TREATMENT PLANT Electrical and Instrumentation Standards and Preferences Recommended/ Specific Criteria Preferred Manufacturers -P&IDs are to conform to ISA modified standards (Consulting engineer to provide) -Provide functional descriptions with the P&IDs (Consulting engineer to provide) -Provide Point to Point connection drawings. Contractor shall develop. Review and approval by the engineer shall be prior to installation. -Label all conduits inside building -Place metal tags on cables in manholes -Provide final conduit & cable schedule on disk (AutoCAD). Square D -Light duty safety switches are unacceptable Cutler Hammer -Must be pad lockable Westinghouse Allen Bradley Square D -No Aluminum Wire Cutler Hammer -Provide 220° C insulation system for 15kVA Westinghouse and larger GE -Provide 180° C insulation system for transformers less than 15kVA -Transformers shall handle a 15% overload without exceeding the insulation rating Square D Cutler Hammer Westinghouse GE Metering Vaults/Pits -Provide receptacle and receptacle location per HRSD direction -Provide sump pumps as needed •Power Requirements •Exhaust Fans 23 Pressure Sustaining/Regulating Valves -Provide two receptacles with wp covers -See Exhaust Fans -Size for 12 air changes per hour (minimum) -Bring exhaust duct to within 6” AFF KTM Foxboro Clow •Butterfly Valves •V Notch Plug Valves IX- 26 04/01 -Butterfly valves are to be used in pairs -Provide 4-20 mA operated valves. Do not use pulsed control valves -Prefer Automatic Controls of Virginia or Valve Automation for actuator applications - Use EIM actuators Item # 24 Electrical Equipment/Item •V Notch Ball Valves Flow Meters •Parshall Flume •Magnetic •Ultrasonics (insertion or strap on) 25 •Venturi RTUs 26 •Antenna •Junction box •Sensors Louvers/Dampers 27 Transfer Switches 28 On-Line Vibration Monitors 29 Panel Meters •Analog •Digital •Elapsed Time •Pulse Counters •Isolators 04/01 TREATMENT PLANT Electrical and Instrumentation Standards and Preferences Recommended/ Preferred Manufacturers Brooks Foxboro Yokogawa Fuji Polysonics Panametrics Motorola HRSD to provide Greenheck Cutler Hammer Westinghouse Square D ASCO Zenith Transfer switches are not acceptable Bentley-Nevada Sole Source GR/Yokogawa Simpson Yokogawa Red Lion Simpson Yokogawa Omron Action Pack AGM IX- 27 Specific Criteria -Size for average flows -Use ultrasonic level indicator -Use for control or billing applications -Ensure vendor is clear on application -Prefer not to use for control -Generally, prefer not to use -Motorola – Moscad -Physical size 24”x24”x8” in a NEMA 4x enclosure -Provide gravity dampers for all applications -See Emergency Generators (Louvers and Dampers) -Nema 12 Enclosure unless required otherwise. -IQ Plus Monitoring Device -3300 series or latest model -Others are unacceptable Item # 30 Electrical Equipment/Item •Signal Converters Analyzers/Monitors •Combustible (LEL) •pH MSA Detronics MSA Detronics Foxboro •ORP Foxboro •O2 COSA •DO Royce •Cl2 Wallace & Tiernan Prominent Ronan LFE Yokogawa •H2S • Alarm Panel •Temperature Controllers 31 Miscellaneous Instrumentation •PID Controllers •Electric Actuators 32 TREATMENT PLANT Electrical and Instrumentation Standards and Preferences Recommended/ Preferred Manufacturers AGM Yokogawa •Valve Actuators EIM Bernards Honeywell •Louver Actuators Honeywell •Multipoint Recorders Yokogawa •Opacity Fisher/Rosemont Electrical Equipment Testing -Prefer not to use -Provide Foxboro only -Model YSI 170 -Dual-Loop Controller -HR 2400 -30-Point Recorder -Provide a RS-232 EPA Standards for the specific criteria. -Provide testing in off-peak hours or switch off an equivalent amount of load prior to testing IX- 28 04/01 Specific Criteria