Textile Research Journal

http://trj.sagepub.com

Recent Advances in Antimicrobial Treatments of Textiles

Yuan Gao and Robin Cranston

Textile Research Journal 2008; 78; 60

DOI: 10.1177/0040517507082332

The online version of this article can be found at:

http://trj.sagepub.com/cgi/content/abstract/78/1/60

Published by:

http://www.sagepublications.com

Additional services and information for Textile Research Journal can be found at:

Email Alerts: http://trj.sagepub.com/cgi/alerts

Subscriptions: http://trj.sagepub.com/subscriptions

Reprints: http://www.sagepub.com/journalsReprints.nav

Permissions: http://www.sagepub.com/journalsPermissions.nav

Downloaded from http://trj.sagepub.com at MICHIGAN STATE UNIV LIBRARIES on March 6, 2008

© 2008 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

Textile Research Journal

Article

Recent Advances in Antimicrobial Treatments of Textiles

Yuan Gao1 and Robin Cranston

Abstract

The growth of microbes on textiles

during use and storage negatively affects the

wearer as well as the textile itself. The detrimental

effects can be controlled by durable antimicrobial

finishing of the textile using broad-spectrum biocides or by incorporating the biocide into synthetic fibers during extrusion. Consumers’ attitude

towards hygiene and active lifestyle has created a

rapidly increasing market for antimicrobial textiles,

which in turn has stimulated intensive research

and development. This article reviews the requirements for antimicrobial finishing, qualitative and

quantitative evaluations of antimicrobial efficacy,

the application methods of antimicrobial agents

and some of the most recent developments in antimicrobial treatments of textiles using various active

agents such as silver, quaternary ammonium salts,

polyhexamethylene biguanide, triclosan, chitosan,

dyes and regenerable N-halamine compounds and

peroxyacids. Examples of commercial antimicrobial products are presented to illustrate the active

agents used and their finishing methods.

Division of Textile and Fibre Technology,

Commonwealth Scientific and Industrial Research

Organization (CSIRO), Bayview Ave, Clayton 3168,

Australia

Key words

textile, fiber, fabric, antimicrobial,

antibacterial, biocide

Textiles have long been recognized as media to support the

growth of microorganisms such as bacteria and fungi. These

microorganisms are found almost everywhere in the environment and can multiply quickly when basic requirements,

such as moisture, nutrients and temperature are met. Most

synthetic fibers, due to their high hydrophobicity, are more

resistant to attacks by microorganisms than natural fibers

[1]. Proteins in keratinous fibers and carbohydrates in

cotton can act as nutrients and energy sources under certain conditions. Soil, dust, solutes from sweat and some

textile finishes can also be nutrient sources for microorganisms [1].

The growth of microorganisms on textiles inflicts a

range of unwanted effects not only on the textile itself but

also on the wearer. These effects include the generation of

unpleasant odor, stains and discoloration in the fabric, a

reduction in fabric mechanical strength and an increased

Textile Research Journal Vol 78(1): 60–72 DOI: 10.1177/0040517507082332

likelihood of contamination [1]. For these reasons, it is

highly desirable that the growth of microbes on textiles be

minimized during their use and storage.1

Consumers’ demand for hygienic clothing and activewear

has created a substantial market for antimicrobial textile

products. Estimations have shown that the production of

antimicrobial textiles was in the magnitude of 30,000 tones

in Western Europe and 100,000 tones worldwide in 2000

[2, 3]. Furthermore, it was estimated that the production

increased by more than 15% a year in Western Europe

between 2001 and 2005, making it one of the fastest growing sectors of the textile market [4]. Sportswear, socks,

shoe linings and lingerie accounted for 85% of the total

1

Corresponding author: tel: +61-3-9545 2104; fax: +61-3-9545

2363; e-mail: yuan.gao@csiro.au

www.trj.sagepub.com © 2008 SAGE Publications

Los Angeles, London, New Delhi and Singapore

Downloaded from http://trj.sagepub.com at MICHIGAN STATE UNIV LIBRARIES on March 6, 2008

© 2008 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

Recent Advances in Antimicrobial Treatments of Textiles Y. Gao and R. Cranston

production [2, 3]. There is also a broader market for antimicrobial fibers, for instance, in outdoor textiles, air filters,

automotive textiles, domestic home furnishings and medical textiles. This high demand, in turn, has stimulated

intensive research and development. Some earlier work in

antimicrobial textiles has been briefly reviewed by Purwar

and Joshi [1] and Williams et al. [5]. Since then a large

number of papers and patents have been published. In this

article, we summarize some of the most recent development in antimicrobial treatments of synthetic, cotton and

wool fabrics or fibers using various active agents, and the

methods for the evaluation of antimicrobial efficacy. Numerous antimicrobial textile products have been launched on

the market by leading manufacturers. Examples are presented to illustrate the active agents used in these products

and their application methods.

Requirements for Antimicrobial

Finishing

In order to obtain the greatest benefit, an ideal antimicrobial treatment of textiles should satisfy a number of requirements [1, 5]. Firstly, it should be effective against a broad

spectrum of bacterial and fungal species, but at the same

time exhibit low toxicity to consumers, e.g. not cause toxicity, allergy or irritation to the user. Antimicrobial-treated

textiles have to meet standards in compatibility tests (cytotoxicity, irritation and sensitization) before marketing. Secondly, the finishing should be durable to laundering, dry

cleaning and hot pressing. This is the greatest challenge as

textile products are subjected to repeated washing during

their life. Thirdly, the finishing should not negatively affect

the quality (e.g. physical strength and handle) or appearance of the textile. Finally, the finishing should preferably

be compatible with textile chemical processes such as dyeing, be cost effective and not produce harmful substances to

the manufacturer and the environment.

One further consideration is that the antimicrobial finishing of textiles should not kill the resident flora of nonpathogenic bacteria on the skin of the wearer. The skin

resident flora consists of several bacterial genera, which

are important to the health of the skin as they lower skin

surface pH and produce antibiotics to create an unfavorable environment for the growth of pathogenic bacteria [6].

Fortunately, antimicrobial agents on textiles may only

reduce the density of the skin resident flora but do not

completely eliminate them. To date, no evidence exists that

the use of antimicrobial textiles changes the ecology of

skin resident flora leading to the outgrowth of pathogenic

bacteria [6].

61

Modes of Antimicrobial Action

A living microbe (e.g. bacterium, fungus) typically has an

outermost cell wall which is mainly composed of polysaccharides. This cell wall maintains the integrity of cellular

components and shields the cell from the extracellular

environment. Immediately beneath the cell wall is a semipermeable membrane which encloses intracellular organelles

and a myriad of enzymes and nucleic acids. The enzymes

are responsible for the chemical reactions that take place

within the cell, and the nucleic acids store all of the genetic

information of the organism. The survival or growth of

microorganisms depends on the integrity of the cell and

the concerted action and proper state of all of these components. Antimicrobial agents either inhibit the growth

(-static) or kill (-cidal) the microorganisms. Almost all antimicrobial agents used in commercial textiles, e.g. silver,

triclosan, polyhexamethylene biguanide (PHMB) and

quaternary ammonium compounds, are biocides. They damage the cell wall or alter cell membrane permeability, denature proteins, inhibit enzyme activity or inhibit lipid synthesis,

all of which are essential for cell survival. The mechanisms

of biocides used on commercial textiles are discussed in the

following sections.

Application of Antimicrobial Agents

Various methods, depending on the particular active agent

and fiber type, have been developed or are under development to confer antimicrobial activity to textiles. For synthetic

fibers, the antimicrobial active agents can be incorporated

into the polymer prior to extrusion or blended into the fibers during their formation. Such processing provides the

best durability as the active agent is physically embedded in

the structure of the fiber and released slowly during use.

This method of fabrication has been adopted by some manufacturers, such as the silver-containing Bioactive® polyester fibers developed by Trevira and the triclosan-containing

Silfresh® cellulose acetate fibers manufactured by Novaceta. The conventional exhaust and pad–dry–cure processes

have been used for antimicrobial finishing on natural as

well as synthetic fibers for the biocides such as triclosan [7]

and PHMB [8, 9]. Padding, spraying and foam finishing

have been used for the silicone-based quaternary agent

AEM 5700 [10]. Many other methods have been reported,

such as the use of nanosized colloidal solutions [11], nanoscale shell–core particles [12, 13], chemical modification of

the biocide for covalent bond formation with the fiber [14,

15], crosslinking of the active agent onto the fiber using a

crosslinker [16, 17] and polymerization grafting [18]. These

methods are further illustrated in the following sections.

An emerging method for antimicrobial finishing is to use

the sol-gel process which allows the fabrication of materi-

Downloaded from http://trj.sagepub.com at MICHIGAN STATE UNIV LIBRARIES on March 6, 2008

© 2008 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

TRJ

TRJ

62

Textile Research Journal 78(1)

als with a large variety of properties: ultra-fine powders,

monolithic ceramics and glasses, ceramic fibers, inorganic

membranes, thin film coatings and aerogels. Sol-gel has

been extensively explored for applications such as coating

[19]. It is claimed that sol-gel technology can enable the

coating of textiles with almost unlimited functionality by

incorporating functional agents into the sol-gel nanoparticles [20, 21]. With regards to antimicrobial ability, several

biocides have been encapsulated in sol-gel particles which

are then coated onto textile products to provide the

desired functionality [20, 22].

Evaluation of Antimicrobial Efficacy

A number of test methods have been developed to determine the efficacy of antimicrobial textiles [23, 24, 25]. These

methods generally fall into two categories: the agar diffusion test and suspension test. The bacterial species Staphylococcus aureus (Gram positive) and Klebsiella pneumoniae

(Gram negative) are recommended in most test methods.

These two species are potentially pathogenic and therefore

require proper physical containment facilities for handling

(e.g. a biosafety cabinet). Many studies have used the innocuous Escherichia coli (Gram negative) as a test microorganism which can be cultured and handled in a standard

laboratory with minimal health risk.

Agar Diffusion Test

The agar diffusion tests include AATCC 147-2004 (American Association of Textile Chemists and Colorists), JIS L

1902-2002 (Japanese Industrial Standards) and SN 1959201992 (Swiss Norm). They are only qualitative, but are simple to perform and are most suitable when a large number

of samples are to be screened for the presence of antimicrobial activity. In these tests, bacterial cells are inoculated on

nutrient agar plates over which textile samples are laid for

intimate contact. The plates are then incubated at 37°C for

18–24 h and examined for growth of bacteria directly underneath the fabrics and immediately around the edges of the

fabrics (zone of inhibition). No bacterial growth directly

underneath the fabric sample indicates the presence of

antimicrobial activity. The zone of inhibition should not be

expected if the antimicrobial agent is firmly attached to the

textile (e.g. covalently) which prevents its diffusion into the

agar. If the antimicrobial agent can diffuse into the agar, a

zone of inhibition becomes apparent and its size provides

some indication of the potency of the antimicrobial activity

or the release rate of the active agent.

Suspension Test

This type of test is exemplified by AATCC 100-2004, JIS L

1902-2002 and SN 195924-1992. These methods provide

quantitative values on the antimicrobial finishing, but are

more time-consuming than agar diffusion tests. Typically, a

small volume (e.g. 1 ml) of bacterial inoculum in a growth

media is fully absorbed into fabric samples of appropriate

size without leaving any free liquid. This ensures intimate

contact between the fabric and the bacteria. After incubating the inoculated fabrics in sealed jars at 37°C or 27°C for

up to 24 h, the bacteria in the fabric are eluted and the

total number is determined by serial dilution and plating

on nutrient agar plates. Antimicrobial activity, expressed as

percentage of reduction, is calculated by comparing the

size of the initial population with that following the incubation. Appropriate controls, e.g. samples that have gone

through the same processing except the antimicrobial finishing, should be included in each experiment to ascertain

that the observed decrease in bacterial number is truly due

to the antimicrobial finishing. Choosing a calculation equation may be important. It has been observed that two different equations can produce very different results for the

same set of data [9].

It should be noted that suspension tests are often performed under artificial conditions that promote bacterial

growth (e.g. rich nutrients in the inoculum and saturating

moisture in the testing fabrics). The moisture in the tests is

also essential for the action of the biocide. As a result, dramatic results are often produced (e.g. >99% bacterial cells

are killed during the assays), leading to an overwhelming

impression of the efficacy of the antimicrobial ability. However, such conditions are rarely found during the normal

use of a textile product. To date, very few studies have examined the antimicrobial effects under normal wearing conditions. To more closely mimic the real-life situation, the JIS

L 1902-2002 method recommends the use of bacterial cells

suspended in heavily diluted nutrient media to limit nutrient levels. The ISO (International Organization for Standardization) has developed a test method (ISO 20743) in

which bacteria are “printed” onto the surface of textiles

without them being in an aqueous suspension [25, 26]. The

printed samples are then incubated under humid conditions at 20°C for a specified time (18–24 h) following which

the surviving cells are counted.

Antimicrobial tests only assess the antimicrobial effectiveness of the treated textiles. Before marketing, the textile products have to pass biocompatibility tests which

involve three separate assays: cytotoxicity, sensitization

and irritation. These assays are outside the scope of this

review but are discussed elsewhere [23, 24].

Antimicrobial Agents for Textiles

Several major classes of antimicrobial agents are used in

the textile industry. They are generally not new per se and

have been in use in other industries, e.g. as food preserva-

Downloaded from http://trj.sagepub.com at MICHIGAN STATE UNIV LIBRARIES on March 6, 2008

© 2008 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

Recent Advances in Antimicrobial Treatments of Textiles Y. Gao and R. Cranston

tives, disinfectants, swimming pool sanitizers or in wound

dressings. These agents are potent in their bactericidal

activity, as indicated by their Minimal Inhibitory Concentration (MIC) values. However, their attachment to a textile surface or incorporation within the fiber substantially

reduces their activity and limits their availability. Furthermore, the biocide can be gradually lost during the use and

washing of the textile. For these reasons, large amounts of

these biocides need to be applied to textiles to effectively

control bacterial growth and to sustain durability.

Metals and Metal Salts

Many heavy metals are toxic to microbes at very low concentrations either in the free state or in compounds. They

kill microbes by binding to intracellular proteins and inactivating them [27]. Although some other metals, such as

copper [28], zinc [29, 30] and cobalt [31], have attracted

attention as effective antimicrobial agents for textiles, silver is by far the most widely used in general textiles [1, 5] as

well as in wound dressings [32]. It has a MIC value of 0.05–

0.1 mg/l against E. coli [33]. Some concerns have been

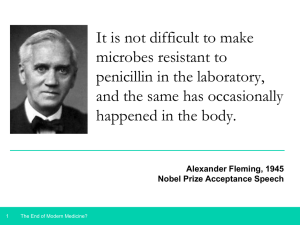

expressed about the development of bacterial resistance to

silver [34, 35].

For synthetic fibers, silver particles can be incorporated

into the polymer before extrusion [36] or before nanofiber

formation using electrospinning [37, 38]. During use, silver

diffuses onto the surface of the fiber and forms silver ions

in the presence of moisture. The rate of silver release can

be influenced by the chemistry and physical characteristics

of the fiber and the amount of silver in the fiber. Gradual

release can lead to an extended period of biocidal activity

[5]. Apart from direct incorporation, nanosized silver in

colloidal solution has been padded onto synthetic and cellulosic fabrics to achieve a durable finishing [11]. Silver has

also been directly absorbed into pre-formed SeaCell®

Active, a fiber made of cellulose from certain seaweeds

with a large capacity for absorbing minerals [39].

The treatment of natural fibers with metals can only be

undertaken at the finishing stage and various strategies

have been devised to enhance the uptake and durability.

Cotton has been pretreated with succinic acid anhydride,

which acted as ligand for metal ions to enhance the subsequent adsorption of metallic salts (Ag+ and Cu2+) and to

provide very effective antibacterial activity [40]. In protein fibers (e.g. wool), the free carboxyl groups of aspartyl

and glutamyl residues are considered the most likely

binding sites for metal ions. The binding capacity can be

further enhanced by pre-treatment with tannic acid which

increases the number of binding sites, or with EDTA dianhydride which has chelating ability towards metal ions [41,

42, 43]. However, such treatments of textiles with metal

ions have serious limits due to technical and environmental

problems and therefore have not been adopted in commercial production.

63

Recent breakthroughs in technology have overcome

cost, environmental and technical challenges associated

with producing some metal treated textiles on a commercial scale. As a result, silver is now used in a large number of

commercial antimicrobial synthetic fibers and yarns. For

example, Thomson Research Associates manufactures UltraFresh® and Silpure® products. The silver is in the form of

ultra-fine metallic particles and is primarily applied to polyester fabrics at the finishing stage. Milliken has developed

a silver-based antimicrobial agent, AlphaSan®, which is a zirconium phosphate-based ceramic ion-exchange resin containing silver and is added during the extrusion process of

synthetic fibers. AlphaSan® is being used by a number of

companies to produce antimicrobial textiles, for examples,

the polyester and nylon yarn by O’Mara (MicroFresh® and

SoleFresh®) and the polyester yarn by Sinterama (GuardYarn®). AgION Technologies produces silver-based antimicrobial textiles using an ion-exchange mechanism. In this

procedure, silver ions are manufactured into multi-faceted

zeolite carriers which are then incorporated into a polymer

or coating. Under conditions that support bacterial growth,

silver ions in the zeolite are exchanged with sodium ions

present in ambient moisture to control bacterial growth

[44]. In addition, The Bioactive® polyester fibers produced

by Trevira also have silver incorporated into the fibers. Very

recently, silver finishing was extended to wool on a commercial scale by Nanohorizon Inc. [45]. In this treatment,

silver nanoparticles (SmartSilver®) are applied to wool

using typical fabric and garment dye systems. The original

properties of the wool, including handle and dyeability,

remain unchanged after the treatment.

Quaternary ammonium compounds

Quaternary ammonium compounds (QACs), particularly

those containing chains of 12–18 carbon atoms, have been

widely used as disinfectants [27]. These compounds carry a

positive charge at the N atom in solution and inflict a variety of detrimental effects on microbes, including damage

to cell membranes, denaturation of proteins and disruption

of the cell structure [27]. During inactivation of bacterial

cells, the quaternary ammonium group remains intact and

retains its antimicrobial ability as long as the compound is

attached to textiles [46].

The attachment of QAC to a textile substrate is believed

to be predominantly by ionic interaction between the cationic QAC and anionic fiber surface [47, 48]. Therefore,

for polyester fibers such as Acrilan® (from Acrilan) and

Orlon® (from Dupont) which contain carboxylic or sulfonate groups, QAC can be directly exhausted under near

boiling conditions [49, 50, 51]. Similarly, the glutamyl and

aspartyl residues in wool provide carboxylic groups.

Exhaustion of QACs, particularly cetylpyridinium chloride,

onto untreated wool at a level of around 5% oww can

render it antimicrobial with durability to 10 launderings [52,

Downloaded from http://trj.sagepub.com at MICHIGAN STATE UNIV LIBRARIES on March 6, 2008

© 2008 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

TRJ

TRJ

64

Textile Research Journal 78(1)

53]. Cotton fabrics have been treated with a 4-aminobenzenesulfonic acid-chloro-triazine adduct which increased the

anionic sites on the fabric surface and facilitated the

exhaustion of QACs [54]. In general, the exhaustion in

these studies was affected by pH, the concentration of the

QAC, temperature and exhaustion time.

Other synthetic fibers, such as Nylon 66, contain fewer

reactive sites and are quite resistant to chemical modification procedures, including antimicrobial finishing. Sun and

colleagues have hypothesized that dye molecules may act

as bridges to bind functional molecules to the fiber surface

[46]. In their studies, the fabrics were first dyed with acid

dyes before QACs were applied under alkaline conditions.

The ionic interaction between the dye molecules and the

QAC was sufficiently strong to provide a semi-durable

antimicrobial finishing [46, 47, 48].

Attempts have been made to covalently attach QAC onto

wool. Diz et al. synthesized a new QAC, N-dodecyl-aminobetaine-2-mercaptoethylamine hydrochloride (DABM) [15,

55]. DABM can react with wool by means of its thiol group,

either with cysteine-S-sulphonate residues (Bunte salts) of

sodium bisulphite pretreated wool or with the disulfide

bond of cystine wool, forming an asymmetrical disulfide

bond. Such covalent attachment of the quaternary ammonium surfactant provides antimicrobial activity [15, 55].

One commercial antimicrobial textile product using

QAC as the active agent is the BIOGUARD® produced by

AEGIS Environments. The active substance, 3-trimethoxysilylpropyldimethyloctadecyl ammonium chloride (AEM

5700, formerly known as the Dow Corning 5700 Antimicrobial Agent; see Figure 1), has a MIC of 10–100 mg/l

against Gram-positive and Gram-negative bacteria [59].

AEM 5700 is made into an aqueous solution and applied

by padding, spraying and foam finishing. Upon drying, the

non-volatile silane forms covalent bonds with the textile,

resulting in excellent durability [57]. So far, this chemical

has been commercially used on cotton, polyester and nylon

fabrics. Although little information is available on bacterial

resistance to this particular QAC, bacterial resistance to

other QACs have been widely observed [58, 59].

Figure 1 Structure of 3-(trihydroxysilyl) propyldimethyloctadecyl ammonium chloride (AEM 5700).

PHMB

PHMB (Figure 2, trade name Vantocil) is a heterodisperse

mixture of polyhexamethylene biguanides with an average

molecular weight of approximately 2500 Da. Being a

potent and broad spectrum bactericidal agent with low toxicity (MIC = 0.5–10 ppm, Arch technical information), it

has been successfully used as a disinfectant in the food

industry and in the sanitization of swimming pools [27] and

is being explored as a biocide in mouthwashes [60] and

wound dressings [61]. PHMB impairs the integrity of the

cell membrane in its action, and its activity increases on a

weight basis with increasing levels of polymerization [27].

To date, bacterial resistance to PHMB has rarely been

observed although resistance to the bisbiguanide chlorhexidine is well known [58, 59].

In 1997, Payne patented a treatment of cellulosic fibers

with PHMB in which an after-treatment with a strong

organic acid was used to increase durability as well as to

overcome fabric yellowing [62]. Payne and Yates later

extended PHMB treatment to synthetic fibers using a selfcrosslinkable resin and a catalyst [63]. PHMB can also be

directly exhausted onto cotton at room temperature and

neutral pH [8, 9], or applied in a pad–dry–cure process

[64]. Owing to its cationic nature, PHMB attachment to

cotton is believed to be through ionic as well as hydrogen

bonding [65]. The carboxyl groups on cotton fabrics that

have originated from chemical finishing are involved in

some of these interactions [66, 67]. Dyeing of cotton fabrics with reactive dyes, which introduces additional anionic

sulphonic groups in the fabric, further increases the uptake

of PHMB [66, 67], but the strong ionic bonding may

decrease the release of free PHMB and antimicrobial efficiency [68]. PHMB needs to be applied at a level of 2–4%

owf for durable finishing and 0.25–1% owf for disposable

items (Arch technical information).

Arch Chemicals has developed a special grade of PHMB,

Reputex 20®, for textile treatments [69]. Reputex® has a

higher molecular weight than Vantocil, containing an average

of 16 biguanide units in the polymer (Arch technical information). This longer polymer length not only results in

higher biocidal activity but also provides more cationic sites

per molecule for possibly stronger binding to the textile surface. Reputex® is initially applied to cotton or its blends

using exhaust or pad–dry–cure processes, and more recently

to polyester and nylon [70], under the trade name Purista®.

Figure 2 Structure of polyhexamethylene biguanide

(PHMB).

Downloaded from http://trj.sagepub.com at MICHIGAN STATE UNIV LIBRARIES on March 6, 2008

© 2008 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

Recent Advances in Antimicrobial Treatments of Textiles Y. Gao and R. Cranston

Triclosan

Triclosan (2,4,4’-trichloro-2’-hydroxydiphenyl ether, Figure 3)

is a broad-spectrum antimicrobial agent with a MIC of less

than 10 ppm against many common bacterial species [71].

Unlike most other cationic biocides used on textiles, triclosan

is not ionized in a solution. It has been in use since the 1960s

in a wide array of professional and consumer products

including hand soaps, surgical scrubs, shower gels, deodorants, healthcare handwashes, toothpastes and mouthwashes

[71, 72]. It inhibits microbial growth by blocking lipid biosynthesis [73].

In 2004, Payne patented the treatment of cotton or cotton blends with triclosan mixed with a polyurethane resin

and a plasticizer [74]. Being a relatively small molecule, triclosan can also act like a disperse dye and can be used by

exhaustion prior to dyeing, together with dyeing or after

dyeing of polyester and nylon fibers at 5% owf (see [7]).

During fabric use, the agent migrates to the surfaces of the

treated textiles at a slow yet sustained rate to provide antimicrobial efficacy [7]. To achieve a more durable finishing,

triclosan has been inserted into the hydrophobic cavity of

β-cyclodextrins to form an inclusion complex which was

then embedded in a polymer film or fiber [75], or encapsulated in microspheres which were subsequently attached to

viscose [76]. Triclosan can also be directly incorporated

into synthetic polymers through melt-mixing or suspension

polymerization [77, 78].

A number of companies manufacture and market triclosan-based fibers, yarns or fabrics. For instance, the nylon

and polyester products Tinosan AM 100® and CEL® (Ciba

Speciality Chemicals), the Silfresh® cellulose acetate yarn

(Novaceta) and Microban® textile products (Microban

International) all contain triclosan as the active antimicrobial agent which is applied at the finishing stage or incorporated into the fiber during extrusion [7, 10].

However, bacterial resistance to triclosan has been well

documented and is of great concern [59, 79]. Furthermore,

when exposed to sunlight in the environment, triclosan

breaks down into 2,8-dichlorodibenzo-p-dioxin [80, 81] which

is chemically related other toxic polychlorinated dioxins

[82]. Owing to such health and environmental issues, a

number of leading retailers as well as governments in

Europe are concerned about or have banned the “unneces-

Figure 3 Structure of triclosan.

65

sary use” of triclosan in textiles and some other products

[83, 84].

Chitosan

Chitosan (Figure 4) is the deacetylated derivative of chitin,

which is the main component of the shells of crustaceans

such as shrimps, crabs and lobsters [85]. Large quantities of

chitin are produced as a byproduct of the seafood industry.

Chitosan has been found to inhibit the growth of microbes

in a large body of work that has been extensively reviewed

by Lim and Hudson [86]. It has a MIC of 0.05–0.1% (w/v)

against many common bacterial species, although the activity can be affected by its molecular weight and degree of

deacetylation [86, 87, 88]. The antimicrobial mechanism is

not clear but is generally accepted that the primary amine

groups provide positive charges which interact with negatively charged residues on the surface of microbes. Such

interaction causes extensive changes in the cell surface

and cell permeability, leading to leakage of intracellular

substances [86]. This antimicrobial ability, coupled with

its non-toxicity, biodegradability and biocompatibility, is

facilitating chitosan’s emerging applications in food science, agriculture, medicine, pharmaceuticals and textiles

[85, 86].

Figure 4 Deacetylation of chitin to chitosan.

Downloaded from http://trj.sagepub.com at MICHIGAN STATE UNIV LIBRARIES on March 6, 2008

© 2008 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

TRJ

TRJ

66

Textile Research Journal 78(1)

The prime focus for chitosan as an antimicrobial treatment has been on cotton. Early work indicated that the antimicrobial effect was potent against a range of microbes, but

the finishing was not durable [86]. To improve durability,

chitosan has been crosslinked to cotton using chemicals

such as dimethyloldihydroxyethyleneurea (DMDHEU),

citric acid, 1,2,3,4-butanetetracarboxylic acid (BTCA) or

glutaric dialdehyde [16, 17, 89, 90]. These chemicals, some

of which are used in cotton durable press, crosslink chitosan

to cotton through hydroxyl groups. Antimicrobial activity

with a durability of up to 50 washes has been reported in

some of these studies. Ye et al. [12, 13] synthesized nanoscale core–shell particles of poly(n-butyl acrylate) cores and

chitosan shells and applied them to cotton fabrics in a pad–

dry–cure process. The antibacterial activity was maintained

at over 90% reduction levels after 50 washes.

Chitosan has been applied to wool as a shrink-proofing

polymer, although antimicrobial activity of the treated

wool was not examined in these studies [91, 92, 93, 94, 95,

96]. Given the intrinsic antimicrobial activity of chitosan, it

is envisaged that the shrink-proofing treatment will dually

lead to antimicrobial function. Owing to the hydrophobic

and non-reactive nature of the wool fiber surface, treatment with chitosan requires pre-treatments so that the polymer can adhere to the surface. Pre-treatments include

oxidation with peroxide [91, 92, 93], protease digestion [94,

95] and plasma treatment [96]. Hsieh et al. reported oxidizing wool with potassium permanganate and crosslinking

chitosan onto it using citric acid in a pad–dry–cure treatment [97]. Although chitosan conferred durable antimicrobial ability and shrink resistance, the disadvantage was that

the handle of the fabric, together with some other physical

properties, was adversely affected [93, 97, 98].

In addition to native chitosan, a number of chitosan

derivatives have been synthesized and used as antimicrobial

agents on textiles. These include chito-oligosaccharide [99,

100], N-(2-hydroxy)propyl-3-trimethylammonium chitosan

chloride [101, 102, 103] and N-p-(N-methylpyridinio)methylated chitosan chloride and N-4-[3-(trimethyl-ammonio)

propoxy]benzylated chitosan chloride [104]. Many of these

derivatives contain a quaternary ammonium group to enhance

the antimicrobial activity. Another derivative is O-acrylamidomethyl-N-[(2-hydroxyl-3-trimethylammonium)propyl] chitosan chloride [14]. The acrylamidomethyl group is fiber

reactive and can form a covalent bond with cellulose in cotton, resulting in excellent durability. Kenawy et al. attached

several compounds to the reactive amino group of chitosan

[105]. These modified chitosans were highly active against

microbes, in particular fungi species.

Despite such active research and recent patents covering the use of chitosan on cotton [106] and polyester [107],

chitosan has yet to be used as a finishing agent on any commercial textiles. The poor handle, among other factors,

may be limiting its application on textiles. Nevertheless,

the Swiss company Swicofil manufactures a composite

fiber of chitosan and viscose, Crabyon®, that has durable

antimicrobial efficacy and is suitable for a range of textile

products [108]. Furthermore, chitosan can be spun into fibers but their applications seem to be limited to medical

uses (e.g. medical gauzes, sutures and wound dressings)

[109, 110].

Regenerable N-halamine and Peroxyacid

One route that has been explored for durable antimicrobial finishing is to make the finishing regenerable by using

chlorine-containing N-halamine compounds. N-halamine

compounds are broad-spectrum disinfectants that have

been used in water treatment [111], and their antimicrobial

ability is attributed to the oxidative properties of the halamine bond (N–Cl). In deactivating a microorganism, the

N-halamine bond is reversibly reacted to N–H. However,

the inactive substance can be recharged with chlorine in a

bleaching solution during laundering, as depicted in Figure 5

(see also 112). This regenerable approach was first proposed and demonstrated for the treatment of cotton by

Sun and Xu in 1998 [113]. Different heterocyclic N-halamine compounds have since been covalently attached to

nylon [114], polyester fibers [115, 116], cotton [116] and

keratinous fibers [117], or grafted onto cellulosic fabrics

[18, 118, 119, 120] and synthetic fabrics [121, 122]. In most

cases strong and regenerable antimicrobial activity was

achieved by washing and recharging the substrates in aqueous solution containing chlorine.

However, as pointed out by Li [123], N-halamine treatment also results in a substantial amount of adsorbed chlorine (or other halogens) remaining on the surface of the

fabric in addition to the covalently bonded N-halamines.

Such residual adsorbed halogen (e.g. chlorine) produces

an unpleasant odor and discolors fabrics, which has proven

problematic for such a promising antimicrobial system in

the textile industry. A reduction step (i.e. with sodium

sulfite) has been used to remove the unbonded residual

Figure 5 Regenerable antimicrobial treatments using Nhalamine compounds (A) and peroxyacids (B).

Downloaded from http://trj.sagepub.com at MICHIGAN STATE UNIV LIBRARIES on March 6, 2008

© 2008 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

Recent Advances in Antimicrobial Treatments of Textiles Y. Gao and R. Cranston

67

Table 1 Some commercially used biocides and those under development for the treatment of various fibers. In the

application method column, “F” denotes that biocide is used as finishing agent and “I” denotes that biocide is incorporated

into the fiber during extrusion.

Application

method

Commercial

products?

Polyester

Nylon

Wool

Regenerated cellulose

F/I

I

F

F

Yes

Yes

Yes

Yes?

Slow release, durable but Ag can be depleted

QACs

(e.g. AEM

5700)

Cotton

Polyester

Nylon

Wool

F

F

F

F

Yes

Yes

Yes

No

Covalent bonding, very durable, Possible bacterial resistance

PHMB

Cotton

Polyester

Nylon

F

F

F

Yes

Yes

Yes

Large amount needed, Potential bacterial resistance

Triclosan

Polyester

Nylon

Polypropylene

Cellulose acetate

Acrylic fiber

F/I

F/I

I

I

I

Yes

Yes

Yes

Yes

Yes

Large amt needed, Bacterial resistance, breaks

down into toxic dioxin, banned in some European countries

Chitosan

Cotton

Polyester

Wool

F

F

F

No

No

No

Adverse effect on handle, low durability

N-halamine Cotton

Polyester

Nylon

Wool

F

F

F

F

No

No

No

No

Needs regeneration, odor from residual chlorine

Peroxyacids Cotton

Polyester

F

F

No

No

Needs regeneration, poor durability

Biocide

Fiber

Silver

chlorine (or other halogen) from the target fabric surface

to overcome this problem [123].

An alternative regenerable antimicrobial finishing uses

peroxyacids, such as peroxyacetic acid which is a well

known and powerful disinfectant used in hospitals [124].

Peroxyacids are converted to carboxylic acid in deactivating microbes but can be regenerated through the reaction

with an oxidant (e.g. hydrogen peroxide) [125, Figure 5].

Huang and Sun demonstrated the feasibility by grafting

BTCA or citric acid onto cotton fabrics in a pad–dry–cure

process similar to cotton durable press [125, 126]. The

grafted polycarboxylic acid provided the necessary carboxylic groups which were then converted to peroxyacids in an

oxygen bleach bath [125] or with the strong oxidant sodium

perborate [126]. Such finishing can also be applied to polyester fabrics [127]. While the peroxyacids on the fabrics

was stable over extended periods during fabric storage, the

antimicrobial activity appeared to be diminished after several washing and recharging cycles [125, 126].

Comments

Dyes

Some synthetic dyes used in the textile industry, e.g. metallic dyestuff, exhibit antimicrobial activities [128]. Therefore,

dyeing and antimicrobial finishing can be simultaneously

achieved by choosing specific dyes. Some synthetic dyes

have been specifically made with antimicrobial activity. For

examples, a new series of azo disperse dyestuffs, prepared

by the reaction of sulphanilamidodiazonium chloride

derivatives with indan-1,3-dione, gave excellent dyeing and

antimicrobial results on wool and nylon [129]. Another

approach to achieve simultaneous dyeing and antimicrobial finishing is to covalently attach a biocide to a dye via a

linker. For example, novel cationic dyes were synthesized

by linking quaternary ammonium group to the aminoanthraquinioid chromophore [130, 131]. These dyes showed

varying levels of antimicrobial activities, depending on

their structures, but when applied to acrylic fabrics the

antimicrobial durability generally did not last for more

than five washes [132]. Some natural dyes have also been

examined for antimicrobial ability. Curcumin, a common

Downloaded from http://trj.sagepub.com at MICHIGAN STATE UNIV LIBRARIES on March 6, 2008

© 2008 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

TRJ

TRJ

68

Textile Research Journal 78(1)

dye used for fabric and food colorations [133], a dye isolated from Quercus infectoria [134] and the colorant Berberine, which contains the quaternary ammonium group,

all exhibit durable antimicrobial efficacy when attached to

textiles []135.

Summary

The biocides discussed above are summarized in Table 1.

Silver, PHMB, quaternary ammonium compounds and triclosan are currently used in commercial antimicrobial textiles of synthetic fibers (e.g. nylon, polyester, cellulose

acetate or polypropylene) and natural fibers (cotton and

wool), while chitosan and a number of regenerable biocides

are in the development stage. These biocides, depending on

the particular fiber, can be used either as finishing agents or

incorporated into the fiber during extrusion.

microbial textiles should be considered and monitored

closely.

Acknowledgment

The authors would like to offer their sincere thanks to Dr

David J. Evans and Dr Ron J. Denning, Division of Textile

and Fibre Technology, CSIRO, for critically reading the

manuscript during its preparation.

Literature Cited

1.

2.

3.

Conclusion

Customer desire for comfort, hygiene and well-being has

created a large and rapidly increasing market for antimicrobial textiles. Numerous manufacturers in the textile industry have responded to this demand by launching their brands

of antimicrobial products. These products use broad-spectrum biocides such as silver, polyhexamethylene biguanide,

quaternary ammonium compounds and triclosan as the

active agents. Some treatments are applied at the finishing

stage while in other cases the biocide can be incorporated

into synthetic fibers during extrusion. Collectively, commercial antimicrobial textiles cover most of the major fiber

types in the textile industry. On the other hand, the use of

several other biocides, such as chitosan and its derivatives,

specific dyes and regenerable active N-halamine compounds

and peroxyacids, is in the development stage. These products vary in their effectiveness and durability depending on

the type of fabric, the biocide and the finishing method used

in the system. In some cases the antimicrobial efficacy is lost

or severely depleted after 10 or fewer washing cycles.

While antimicrobial textiles provide the benefits in

hygiene, odor control and protection of the fabric from

microbial attack, bacterial resistance to the biocides used

and their toxic breakdown products in the household and

environment have been concerns. Most biocides used on

commercial textiles can induce bacterial resistance to these

substances, which can lead to increased resistance to certain antibiotics in clinical use [136]. Bacterial resistance

may be a particular concern because large quantities of

biocides are needed on the textiles to achieve adequate

activity and durability. Such concerns have resulted in the

banning of the use of triclosan on textiles by a number

leading retailers and governments in Europe. The longterm benefits and potential problems associated with anti-

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

Purwar, R., and Joshi, M., Recent Developments in Antimicrobial Finishing of Textiles—A Review, AATCC Review, 4,

22–26 (2004).

The 2nd European Conference on Textiles and the Skin, Bönnigheim, Germany 2004, http://www.hohenstein.com.tr/ximages/15676_hohtextile.pdf (accessed June 2007).

Pavlidou, V., New Multifunctional Textiles: Antimicrobial

Treatments, in “Proceedings of the Intelligent Textile Structures—Application, Production and Testing International

Workshop”, Thessaloniki, Greece 2005, http://centrum.vslib.

cz/centrum/itsapt/greece2005.html (accessed June 2007).

Antimicrobial Fabrics Help Fight War Against Germs, http://

www.textilesintelligence.com/til/press.cfm?prid=325

(accessed June 2007).

Williams, J. F., HaloSource, V., and Cho, U., Antimicrobial

Functions for Synthetic Fibers: Recent Developments,

AATCC Review, 5, 17–21 (2005).

Elsner, P., Antimicrobials and the Skin Physiological and

Pathological Flora, in “Biofunctional Textiles and the Skin,”

Hipler, U. C., and Elsner, P. (eds), Karger, Basel, 2006, pp. 3541.

Mao, J. W., and Murphy, L., Durable Freshness for Textiles,

AATCC Review, 1, 28–31 (2001).

Payne, J. D., and Kudner, D. W., A Durable Antiodor Finish

for Cotton Textiles, Textile Chemist and Colorist 28, 28–30

(1996).

Wallace, M. L., Testing the Efficacy of Polyhexamethylene

Biguanide as an Antimicrobial Treatment for Cotton Fabric,

AATCC Review, 1, 18–20 (2001).

Mansfield, R. G., Keeping it Fresh, Textile World, 152, 42–45

(2002).

Lee, H. J., Yeo, S. Y, and Jeong, S. H., Antibacterial Effect of

Nanosized Silver Colloidal Solution on Textile Fabrics, J.

Mater. Sci., 38, 2199–2204 (2003).

Ye, W. J. et al., Novel Core–Shell Particles with Poly(n-butyl

acrylate) Cores and Chitosan Shells as an Antibacterial Coating for Textiles, Polymer, 46, 10538–10543 (2005).

Ye, W. J. et al., Durable Antibacterial Finish on Cotton Fabric

by using Chitosan-based Polymeric Core–Shell Particles, J.

Appl. Polymer Sci., 102, 1787–1793 (2006).

Lim, S. H., and Hudson, S. M., Application of a Fiber-reactive

Chitosan Derivative to Cotton Fabric as an Antimicrobial Textile Finish, Carbohydr. Polymer, 56, 227–234 (2004).

Diz, M., Jocic, D., Infante, M. R., and Erra, P., Reaction of a

New Thiol Cationic Surfactant with Bunte Salt in Wool Fibers, Textil. Res. J., 67, 486–493 (1997).

Downloaded from http://trj.sagepub.com at MICHIGAN STATE UNIV LIBRARIES on March 6, 2008

© 2008 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

Recent Advances in Antimicrobial Treatments of Textiles Y. Gao and R. Cranston

16. El-Tahlawy, K. F., El-Bendary, M. A., Elhendawy, A. G., and

Hudson, S. M., The Antimicrobial Activity of Cotton Fabrics

Treated with Different Crosslinking Agents and Chitosan,

Carbohydr. Polymer, 60, 421–430 (2005).

17. Zhang, Z. T., Chen, L., Ji, J. M., Huang, Y. L., and Chen, D.

H., Antibacterial Properties of Cotton Fabrics Treated with

Chitosan, Textil. Res. J., 73, 1103–1106 (2003).

18. Sun, Y., and Sun, G., Durable and Regenerable Antimicrobial

Textile Materials Prepared by a Continuous Grafting Process,

J. Appl. Polymer Sci., 84, 1592–1599 (2002).

19. Attia, S. M. et al., Review on Sol-gel Derived Coatings: Process, Techniques and Optical Applications, J. Mater. Sci. Technol., 18, 211–218 (2002).

20. Mahltig, B., Haufe, H., and Bottcher, H., Functionalisation of

Textiles by Inorganic Sol-gel Coatings, J. Mater. Chem., 15,

4385–4398 (2005).

21. Cunko, R., and Varga, K., Application of Ceramics for the

Production of High-performance Textiles, TEKSTIL, 55, 267–

278 (2006).

22. Mahltig, B., Fiedler, D., and Bottcher, H., Antimicrobial Solgel Coatings, J. Sol-Gel Sci. Technol., 32, 219–222 (2004).

23. Joiner, B. G., Determining Antimicrobial Efficacy and Biocompatibility of Treated Articles using Standard Test Methods, in “Bioactive Fibres and Polymers”, Edwards, J. V., and

Vigo, T. L. (eds), American Chemical Society, Washington

DC, 2001, Ch. 12, pp. 201–217.

24. Hofer, D., Antimicrobial Textiles—Evaluation of their Effectiveness and Safety, in “Biofunctional Textiles and the Skin”,

Hipler, U. C., and Elsner, P. (eds), Karger, Basel, 2006,

pp. 42–50.

25. Analysis and Assessment of Current Protocols to Develop Harmonised Test Methods and Relevant Performance Standards for

the Efficacy Testing of Treated Articles/Treated Materials, http://

www.olis.oecd.org/olis/2007doc.nsf/43bb6130e5e86e5fc12569

fa005d004c/0b18528d8e9cec03c1257288005b024c/$FILE/

JT03222464.PDF (accessed June 2007).

26. Determination of Antibacterial Activity of Antibacterial

Finished Products, http://www.iso.org/iso/en/CatalogueDetailPage.CatalogueDetail?CSNUMBER=34261&scopelist=

PROGRAMME (accessed June 2007).

27. McDonnell, G., and Russell, A. D., Antiseptics and Disinfectants: Activity, Action, and Resistance, Clin. Microbiol. Rev.,

12, 147–179 (1999).

28. http://www.cupron.com/Cupron-News-Antimicrobial/.

29. Yadav, A. et al., Functional Finishing in Cotton Fabrics using

Zinc Oxide Nanoparticles, Bull. Mater. Sci., 29, 641–645 (2006).

30. Charbonneaux, T., and Rochat, S., “Articles with Antibacterial

and Antifungal Activity”, United States Patent Application

20060208390 (2006).

31. Antelman, M. S., “High Performance Cobalt (II,III) Oxide

Antimicrobial Textile Articles”, United States Patent no

6,228,491 (2001).

32. Hermans, M. H., Silver-containing Dressings and the Need

for Evidence, Am. J. Nurs., 106, 60–68 (2006).

33. Butkus, M. A., Edling, L., and Labare, M. P., The Efficacy of

Silver as a Bactericidal Agent: Advantages, Limitations and

Considerations for Future Use, J. Water Sup. Res. Tech.-Aqua,

52, 407–416 (2003).

34. Percival, S. L., Bowler, P. G., and Russell, D., Bacterial Resistance to Silver in Wound Care, J. Hosp. Infect., 60, 1–7 (2005).

69

35. Silver, S., and Phung le, T., Silver, G., Silver as biocides in

burn and wound dressings and bacterial resistance to silver

compounds, J. Ind. Microbiol. Biotechnol. 33, 627-634. (2006).

36. Yeo, S. Y., Lee, H. J., and Jeong, S. H., Preparation of Nanocomposite Fibers for Permanent Antibacterial Effect, J. Mater.

Sci., 38, 2143–2147 (2003).

37. Son, W. K., Youk, J. H., and Park, W. H., Antimicrobial Cellulose Acetate Nanofibers Containing Silver Nanoparticles,

Carbohydr. Polymer, 65, 430–434 (2006).

38. Hong, K. H., Park, J. L., Sul, I. H., Youk, J. H., and Kang, T. J.,

Preparation of Antimicrobial Poly(vinyl alcohol) Nanofibers

Containing Silver Nanoparticles, J. Polymer Sci. B Polymer

Phys., 44, 2468–2474 (2006).

39. Hipler, U.C., Elsner, P., and Fluhr, J.W., Antifungal and Antibacterial Properties of a Silver-loaded Cellulosic Fiber, J.

Biomed. Mater. Res. B Appl. Biomater., 77, 156–163 (2006).

40. Nakashima, T., Sakagami, Y., Ito, H., and Matsuo, M., Antibacterial Activity of Cellulose Fabrics Modified with Metallic

Salts, Textil. Res. J., 71, 688–694 (2001).

41. Freddi, G., Arai, T., Colonna, G. M., Boschi, A., and Tsukada,

M., Binding of Metal Cations to Chemically Modified Wool

and Antimicrobial Properties of the Wool–Metal Complexes,

J. Appl. Polymer Sci., 82, 3513–3519 (2001).

42. Arai, T., Freddi, G., Colonna, G. M., Scotti, E., Boschi, A.,

Murakami, R., and Tsukada, M., Absorption of Metal Cations

by Modified B-mori Silk and Preparation of Fabrics with an

Antimicrobial Activity, J. Appl. Polymer Sci., 80, 297–303 (2001).

43. Tsukada, M., Arai, T., Colonna, G. M., Boschi, A., and Freddi,

G., Preparation of Metal-containing Protein Fibers and their

Antimicrobial Properties, J. Appl. Polymer Sci., 89, 638–644

(2003).

44. The AgION® Technology Behind the Performance, http://

www.bioshieldtech.com/tech.html (accessed June 2007).

45. NanoHorizons Announces SmartSilver Anti-Odor Nanotechnology for Wool, http://www.azonano.com/news.asp?newsID=

3609 (accessed June 2007).

46. Kim, Y. H., and Sun, G., Dye Molecules as Bridges for Functional Modifications of Nylon: Antimicrobial Functions, Textil.

Res. J., 70, 728–733 (2000).

47. Kim, Y. H., and Sun, G., Durable Antimicrobial Finishing of

Nylon Fabrics with Acid Dyes and a Quaternary Ammonium

Salt, Textil. Res. J., 71, 318–323 (2001).

48. Son, Y. A., and Sun, G., Durable Antimicrobial Nylon 66 Fabrics: Ionic Interactions with Quaternary Ammonium Salts, J.

Appl. Polymer Sci., 90, 2194–2199 (2003).

49. Kim, Y. H., and Sun, G., Functional Finishing of Acrylic and

Cationic Dyeable Fabrics: Intermolecular Interactions, Textil.

Res. J., 72, 1052–1056 (2002).

50. Cai, Z. S., and Sun, G., Antimicrobial Finishing of Acrilan

Fabrics with Cetylpyridinium Chloride, J. Appl. Polymer Sci.,

94, 243–247 (2004).

51. Cai, Z. S., and Sun, G., Antimicrobial Finishing of Acrilan

Fabrics with Cetylpyridinium Chloride: Affected Properties

and Structures, J. Appl. Polymer Sci., 97, 1227–1236 (2005).

52. Zhu, P., and Sun, G., Antimicrobial Finishing of Wool Fabrics

using Quaternary Ammonium Salts, J. Appl. Polymer Sci., 93,

1037–1041 (2004).

53. Zhao, T., and Sun, G., Antimicrobial Finishing of Wool Fabrics with Quaternary Aminopyridinium Salts, J. Appl. Polymer

Sci., 103, 482–486 (2006).

Downloaded from http://trj.sagepub.com at MICHIGAN STATE UNIV LIBRARIES on March 6, 2008

© 2008 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

TRJ

TRJ

70

Textile Research Journal 78(1)

54. Son, Y. A., Kim, B. S., Ravikumar, K., and Lee, S. G., Imparting Durable Antimicrobial Properties to Cotton Fabrics using

Quaternary Ammonium Salts through 4-Aminobenzenesulfonic Acid-chloro-triazine Adduct, Eur. Polymer J., 42, 3059–

3067 (2006).

55. Diz, M., Infante, M. R., Erra, P., and Manresa, A., Antimicrobial Activity of Wool Treated with a New Thiol Cationic Surfactant, Textil. Res. J., 71, 695–700 (2001).

56. Hayes, S. F., and White, W. C., How Antimicrobial Treatment

can Improve Nonwovens, http://www.aegisasia.com/How_Antimicrobial_Treatment_Can_Improve.pdf (accessed June 2007).

57. A New, Durable Antimicrobial Finish for Textiles, http://

microbeshield.com/techdocs/

New_Durable_Antimicrobial_Finish_for_Textiles_4A1-F.pdf

(accessed June 2007).

58. Russell, A. D., Introduction of Biocides into Clinical Practice

and the Impact on Antibiotic Resistance, J. Appl. Microbiol.

92, 121S–135S (2002).

59. Russell, A. D., Bacterial Adaptation and Resistance to Antiseptics, Disinfectants and Preservatives is Not a New Phenomenon, J. Hosp. Infect., 57, 97–104 (2004).

60. Rosin, M., Welk, A., Bernhardt, O., Ruhnau, M., Pitten, F. A.,

Kocher, T., and Kramer, A., Effect of a Polyhexamethylene

Biguanide Mouthrinse on Bacterial Counts and Plaque, J.

Clin. Periodontol., 28, 1121–1126 (2001).

61. Cazzaniga, A., Serralta, V., Davis, S., Orr, R., Eaglstein, W.,

and Mertz, P. M., The Effect of an Antimicrobial Gauze

Dressing Impregnated with 0.2-percent Polyhexamethylene

Biguanide as a Barrier to Prevent Pseudomonas aeruginosa

Wound Invasion, Wound-compend. Clin. Res. Prac., 14, 169–

176 (2002).

62. Payne, J. D., “Antimicrobial Treatment of Textile Materials”,

United States Patent no 5,700,742, (1997).

63. Payne, J. D., and Yates, J. E., “Fibres Treated with Antimicrobial Agents”, European Patent Office Publication no

EP1697577(A1) (2006).

64. Yang, Y. Q., Corcoran, L., Vorlicek, K., and Li, S., Durability

of Some Antibacterial Treatments to Repeated Home Launderings, Textile Chemist and Colorist Am. Dyestuff Rep., 32, 44–

49 (2000).

65. Blackburn, R. S. et al., Sorption of Poly(hexamethylenebiguanide) on Cellulose: Mechanism of Binding and Molecular

Recognition, Langmuir, 22, 5636–5644 (2006).

66. Kawabata, A., and Taylor, J. A., Effect of Reactive Dyes upon

the Uptake and Antibacterial Action of Poly(hexamethylene

biguanide) on Cotton. Part 1: Effect of Bis(monochlorotriazinyl) Dyes, Color. Technol., 120, 213–219 (2004).

67. Kawabata, A., and Taylor, J. A., The Effect of Reactive Dyes

upon the Uptake and Antibacterial Action of Poly(hexamethylene biguanide) on Cotton. Part 2: Uptake of Poly(hexamethylene

biguanide) on Cotton Dyed with Beta-sulphatoethylsulphonyl

Reactive Dyes, Dyes Pigments, 68, 197–204 (2006).

68. Kawabata, A., and Taylor, J. A., The Effect of Reactive Dyes

upon the Uptake and Antibacterial Action of Poly(hexamethylene biguanide) on Cotton. Part 3: Reduction in the Antibacterial Efficacy of Poly(hexamethylene biguanide) on Cotton,

Dyed with Bis(monochlorotriazinyl) Reactive Dyes, Carbohydr. Res., 67, 375–389 (2007).

69. http://www.archchemicals.com/Fed/BIO/Products/Brand/reputex. htm (accessed June 2007).

70. Purista to Develop Freshness Treatment for Synthetic Fibres,

http://www.fibre2fashion.com/news/company-news/purista/

newsdetails.aspx?news_id=22045 (accessed June 2007).

71. Jones, R. D., Jampani, H. B., Newman, J. L., and Lee, A. S.,

Triclosan: A Review of Effectiveness and Safety in Health

Care Settings, Am. J. Infect. Contr., 28, 184–196 (2000).

72. Bhargava, H. N., and Leonard, P. A., Triclosan: Applications

and Safety, Am. J. Infect. Contr., 24, 209-218 (1996).

73. Levy, C. W., Roujeinikova, A., Sedelnikova, S., Baker, P. J.,

Stuitje, A. R., Slabas, A. R., Rice, D. W., and Rafferty, J. B.,

Molecular Basis of Triclosan Activity, Nature, 398, 383–384

(1999).

74. Payne, S. A., “Antimicrobial Superfinish and Method of Making”, United States Patent Application no 20040077747 (2004).

75. Lu, J., Hill, M. A., Hood, M., Greeson, D. F., Horton, J. R.,

Orndorff, P. E., Herndon, A. S., and Tonelli, A.E., Formation

of Antibiotic, Biodegradable Polymers by Processing with

Irgasan DP300R (Triclosan) and its Inclusion Compound with

Beta-cyclodextrin, J. Appl. Polymer Sci., 82, 300–309 (2001).

76. Goetzendorf-Grabowska, B., Krolikowska, H., and Gadzinowski, M., Polymer Microspheres as Carriers of Antibacterial Properties of Textiles: A Preliminary Study, Fibres and

Textiles in Eastern Europe, 12, 62–64 (2004).

77. Kalyon, B. D., and Olgun, U., Antibacterial Efficacy of Triclosan-incorporated Polymers, Am. J. Infect. Contr., 29, 124–

125 (2001).

78. Iconomopoulou, S. M., Andreopoulou, A. K., Soto, A., Kallitsis, J. K., and Voyiatzis, G. A., Incorporation of Low Molecular Weight Biocides into Polystyrene-divinyl Benzene Beads

with Controlled Release Characteristics, J. Contr. Release, 102,

223–233 (2005).

79. Yazdankhah, S. P. et al., Triclosan and Antimicrobial Resistance in Bacteria: An Overview, Microb. Drug Resist.-Mech.

Epidemiol. Dis., 12, 83–90 (2006).

80. Latch, D. E. et al., Photochemical Conversion of Triclosan to

2,8-Dichlorodibenzo-p-dioxin in Aqueous Solution, J. Photchem. Photobiol. Chem., 158, 63–66 (2003).

81. Sanchez-Prado, L. et al., Further Research on the PhotoSPME of Triclosan, Anal. Bioanal. Chem., 384, 1548–1557

(2006).

82. Larsen, J. C., Risk Assessments of Polychlorinated Dibenzop-dioxins, Polychlorinated Dibenzofurans, and Dioxin-like

Polychlorinated Biphenyls in Food, Mol. Nutr. Food Res., 50,

885–896 (2006).

83. Why We Do Not Use Microban®, http://www.cleanshopper.com/microban.php (accessed June 2007).

84. Triclosan, Banned from UK supermarkets, http://www.annieappleseedproject.org/tricbanfromu.html (accessed June 2007).

85. Rinaudo, M., Chitin and Chitosan: Properties and Applications, Progr. Polymer Sci., 31, 603–632 (2006).

86. Lim, S. H., and Hudson, S. M., Review of Chitosan and its

Derivatives as Antimicrobial Agents and Their uses as Textile

Chemicals, J. Macromol. Sci. Polymer Rev., 43, 223–269 (2003).

87. No, H. K., Park, N. Y., Lee, S. H., and Meyers, S. P., Antibacterial Activity of Chitosans and Chitosan Oligomers with Different Molecular Weights, Int. J. Food Microbiol., 74, 65–72

(2002).

88. Shin, Y., Yoo, D. I., and Jang, J., Molecular Weight Effect on

Antimicrobial Activity of Chitosan Treated Cotton Fabrics, J.

Appl. Polymer Sci., 80, 2495–2501 (2001).

Downloaded from http://trj.sagepub.com at MICHIGAN STATE UNIV LIBRARIES on March 6, 2008

© 2008 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

Recent Advances in Antimicrobial Treatments of Textiles Y. Gao and R. Cranston

89. Lee, S., Cho, J. S., and Cho, G. S., Antimicrobial and Blood

Repellent Finishes for Cotton and Nonwoven Fabrics based

on Chitosan and Fluoropolymers, Textil. Res. J., 69, 104–112

(1999).

90. Chung, Y. S., Lee, K. K., and Kim, J. W., Durable Press and

Antimicrobial Finishing of Cotton Fabrics with a Citric Acid

and Chitosan Treatment, Textil. Res. J., 68, 772–775 (1998).

91. Julia, M. R., Cot, M., Erra, P., Jocic, D., and Canal, J. M., The

Use of Chitosan on Hydrogen Peroxide Pretreated Wool, Textile Chemist and Colorist, 30, 78–83 (1998).

92. Pascual, E., and Julia, M. R., The Role of Chitosan in Wool

Finishing, J. Biotechnol., 89, 289–296 (2001).

93. Roberts, G. A. F., and Wood, F. A., A Study of the Influence

of Structure on the Effectiveness of Chitosan as an Anti-felting Treatment for Wool, J. Biotechnol., 89, 297–304 (2001).

94. Rybicki, E., Filipowska, B., and Walawska, A., Application of

Natural Biopolymers in Shrink-proofing of Wool, Fibres and

Textiles in Eastern Europe, 8, 62–65 (2000).

95. Onar, N., and Sariisik, M., Application of Enzymes and Chitosan Biopolymer to the Antifelting Finishing Process, J. Appl.

Polymer Sci., 93, 2903–2908 (2004).

96. Erra, P., Molina, R., Jocic, D., Julia, M. R., Cuesta, A., and

Tascon, J. M. D., Shrinkage Properties of Wool Treated with

Low Temperature Plasma and Chitosan Biopolymer, Textil.

Res. J., 69, 811–815 (1999).

97. Hsieh, S. H., Huang, Z. K., Huang, Z. Z., and Tseng, Z. S.,

Antimicrobial and Physical Properties of Woolen Fabrics

Cured with Citric Acid and Chitosan, J. Appl. Polymer Sci., 94,

1999–2007 (2004).

98. Jeong, Y. J. et al., Changes in the Mechanical Properties of

Chitosan-treated Wool Fabric, Textil. Res. J., 72, 70–76 (2002).

99. Seong, H. S., Whang, H. S., and Ko, S. W., Synthesis of a Quaternary Ammonium Derivative of Chito-oligosaccharide as

Antimicrobial Agent for Cellulosic Fibers, J. Appl. Polymer

Sci., 76, 2009–2015 (2000).

100.Kim, J. Y., Lee, J. K., Lee, T. S., and Park, W. H., Synthesis of

Chitooligosaccharide Derivative with Quaternary Ammonium

Group and its Antimicrobial Activity against Streptococcus

mutans, Int. J. Biol. Macromol., 32, 23–27 (2003).

101.Kim, Y. H., Choi, H. M., and Yoon, J. H., Synthesis of a Quaternary Ammonium Derivative of Chitosan and its Application to a Cotton Antimicrobial Finish, Textil. Res. J., 68, 428–

434 (1998).

102.Kim, Y. H., Nam, C. W., Choi, J. W., and Jang, J. H., Durable

Antimicrobial Treatment of Cotton Fabrics using N-(2hydroxy)propyl-3-trimethylammonium Chitosan Chloride and

Polycarboxylic Acids, J. Appl. Polymer Sci., 88, 1567–1572 (2003).

103.Montazer, M., and Afjeh, M. G., Simultaneous X-linking and

Antimicrobial Finishing of Cotton Fabric, J. Appl. Polymer

Sci., 103, 178–185 (2007).

104.Suzuki, K., Oda, D., Shinobu, T., Saimoto, H., and Shigemasa,

Y., New Selectively N-substituted Quaternary Ammonium

Chitosan Derivatives, Polymer J., 32, 334–338 (2000).

105.Kenawy, E. R., Abdel-Hay, F. I., Abou El-Magd, A., and Mahmoud, Y., Biologically Active Polymers: Modification and

Anti-microbial Activity of Chitosan Derivatives, J. Bioact.

Comp. Poly. 20, 95–111 (2005).

106.Liang, C., “Anti-microbial Chitosan Composition for Textile

Products”, United States Patent Application no 20060008515

(2005).

71

107.Joerger, M. C., Koniz, R. F., Sabesan, S., and Pennias, J.,

“Antimicrobial Polyester-containing Articles and Process for

their Preparation”, United States Patent 7,081,139 (2006).

108.CRABYON®, A Fibre with Crab’s Pulp, http://www.swicofil.com/products/055chitosan.html (accessed June 2007).

109.Illarionova, E. L. et al., Fibre, Film, and Porous Materials

based on Chitosan, Fibre Chem., 27, 392–396 (1995).

110.Rathke, T. D., and Hudson, S. M., Review of Chitin and Chitosan as Fiber and Film Formers, J. Macromol. Sci. Rev. Macromol. Chem. Phys., C34, 375–437 (1994).

111.Worley, S. D., and Williams, D. E., Halamine Water Disinfectants, CRC Crit. Rev. Environ. Contr., 18, 133–175 (1988).

112.Sun, G., Durable and Regenerable Antimicrobial Textiles, in

“Bioactive Fibres and Polymers”, Edwards, J. V., and Vigo, T.

L. (eds), American Chemical Society, Washington, DC, 2001,

Ch. 14, pp. 243–252.

113.Sun. G., and Xu, X. J., Durable and Regenerable Antibacterial Finishing of Fabrics: Biocidal Properties, Textile Chemist

and Colorist, 30, 26–30 (1998).

114.Lin, J., Winkelman, C., Worley, S. D., Broughton, R. M., and

Williams, J. F., Antimicrobial Treatment of Nylon, J. Appl. Polymer Sci., 81, 943–947 (2001).

115.Lin, J., Winkelmann, C., Worley, S. D., Kim, J. H., Wei, C. I.,

Cho, U. C., Broughton, R. M., Santiago, J. I., and Williams, J.

F., Biocidal Polyester, J. Appl. Polymer Sci., 85, 177–182

(2002).

116.Sun, G., and Xu, X., “Durable and Regenerable Microbiocidal Textiles”, United States Patent no 5,882,357 (1999).

117.Wu, F. C., “Regenerable Antimicrobial Animal Fiber Materials”, United States Patent Application no 20020123281

(2002).

118.Qian, L., and Sun, G., Durable and Regenerable Antimicrobial Textiles: Improving Efficacy and Durability of Biocidal

Functions, J. Appl. Polymer Sci., 91, 2588–2593 (2004).

119.Luo, J., and Sun, Y. Y., Acyclic N-halamine-based Fibrous

Materials: Preparation, Characterization, and Biocidal Functions, J. Polymer Sci. Polymer Chem., 44, 3588–3600 (2006).

120.Liu, S., and Sun, G., Durable and Regenerable Biocidal Polymers: Acyclic N-halamine Cotton Cellulose, Ind. Eng. Chem.

Res., 45, 6477–6482 (2006).

121.Sun, Y. Y., and Sun, G., Novel Regenerable N-halamine Polymeric Biocides. III. Grafting Hydantoin-containing Monomers onto Synthetic Fabrics, J. Appl. Polymer Sci., 81, 1517–

1525 (2001).

122.Sun, Y. Y., and Sun, G., Novel Refreshable N-halamine Polymeric Biocides: Grafting Hydantoin-containing Monomers

onto High Performance Fibers by a Continuous Process, J.

Appl. Polymer Sci., 88, 1032–1039 (2003).

123.Li, S., “Method of Retaining Antimicrobial Properties on a

Halamine-treated Textile Substrate while Simultaneously

Reducing Deleterious Odor and Skin Irritation Effects”,

United States Patent no 6,576,154 (2003).

124.Dettenkofer, M., and Block, C., Hospital Disinfection: Efficacy and Safety Issues, Curr. Opin. Infect. Dis., 18, 320–325

(2005).

125.Huang, L. K., and Sun, G., Durable and Regenerable Antimicrobial Cellulose with Oxygen Bleach: Concept Proofing,

AATCC Review, 3, 17–21 (2003).

126.Huang, L. K., and Sun, G., Durable and Oxygen Bleach

Rechargeable Antimicrobial Cellulose: Sodium Perborate as

Downloaded from http://trj.sagepub.com at MICHIGAN STATE UNIV LIBRARIES on March 6, 2008

© 2008 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.

TRJ

TRJ

72

Textile Research Journal 78(1)

an Activating and Recharging Agent, Ind. Eng. Chem. Res., 42,

5417–5422 (2003).

127.Sun, G., and Huang, L. K., “Regenerable Antimicrobial Polymers and Fibers with Oxygen Bleaches”, United States Patent

no 6,962,608 (2005).

128.Tsukada, M., Katoh, H., Wilson, D., Shin, B. S., Arai, T.,

Murakami, R., and Freddi, G., Production of Antimicrobially

Active Silk Proteins by Use of Metal-containing Dyestuffs, J.

Appl. Polymer Sci., 86, 1181–1188 (2002).

129.Sayed, A. Z., and El-Gaby, M. S. A., Synthesis of Novel Dyestuffs Containing Sulphonamido Moieties and Their Application on Wool and Polyamide Fibres, Color. Technol., 117, 293–

297 (2001).

130.Ma, M. H., Sun, Y. Y., and Sun, G., Antimicrobial Cationic

Dyes. Part 1: Synthesis and Characterization, Dyes Pigments,

58, 27–35 (2003).

131.Sun, G., and Ma, M., “Multifunctional Antimicrobial Dyes”,

United States Patent Application no 20050011012 (2005).

132.Ma, M. H., and Sun, G., Antimicrobial Cationic Dyes. Part 3:

Simultaneous Dyeing and Antimicrobial Finishing of Acrylic

Fabrics, Dyes Pigments, 66, 33–41 (2005).

133.Han, S. Y., and Yang, Y., Antimicrobial Activity of Wool Fabric Treated with Curcumin, Dyes Pigments, 64, 157–161 (2005).

134.Singh, R., Jain, A., Panwar, S., Gupta, D., and Khare, S. K.,

Antimicrobial Activity of Some Natural Dyes, Dyes Pigments,

66, 99–102 (2005).

135.Kim, T. K., and Son, Y. A., Effect of Reactive Anionic Agent

on Dyeing of Cellulosic Fibers with a Berberine Colorant—

Part 2: Anionic Agent Treatment and Antimicrobial Activity

of a Berberine Dyeing, Dyes Pigments, 64, 85–89 (2005).

136.Russell, A. D., Biocide Usage and Antibiotic Resistance: The

Relevance of Laboratory Findings to Clinical and Environmental Situations, Lancet Infect. Dis., 3, 794–803 (2003).

Downloaded from http://trj.sagepub.com at MICHIGAN STATE UNIV LIBRARIES on March 6, 2008

© 2008 SAGE Publications. All rights reserved. Not for commercial use or unauthorized distribution.