Minimise or prevent process loss in a retail or distribution environment

advertisement

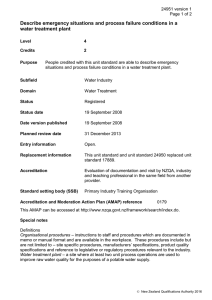

25798 April draft version 1 Page 1 of 3 Minimise or prevent process loss in a retail or distribution environment Level 3 Credits 6 Purpose People credited with this unit standard are able to: analyse process loss and use results of process loss analysis to minimise or prevent process loss. Subfield Retail, Distribution, and Sales Domain Retail and Distribution Core Skills Status Evaluation Status date April 2009 Date version published dd MMMM yyyy Planned review date dd MMMM yyyy Entry information Open Replacement information This unit standard replaced unit standard nnnnn. [Only appears if populated.] Accreditation Evaluation of documentation and visit by NZQA and industry Standard setting body (SSB) Retail Institute Accreditation and Moderation Action Plan (AMAP) reference 0225 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Definitions Retail or distribution environment refers to workplaces where the primary focus is on customers purchasing goods and/or services. Organisational procedures refer to instructions to staff on policy and procedures which are formally documented, or generally accepted within the workplace. Agreed indicates a course of action that is agreed between two or more people (including the candidate) and which follows organisational procedures. Process loss refers to loss due poor operating procedures. 2 Evidence is required for two process loss situations. 1 25798 April draft version 1 Page 2 of 3 Elements and performance criteria Element 1 Analyse process loss. Performance criteria 1.1 Methods that can be used to analyse process loss are identified in accordance with organisational procedures. Range 1.2 Causes of process loss are identified for specific situations. Range 1.3 may include but is not limited to – identify purpose of analysis, gather data, analyse data, identify causes and effects of loss, identify actions that can be taken to minimise or prevent loss, make recommendations, report, revise or update policies or procedures. may include but is not limited to - losses when selling, providing customer service, tracking orders, processing sales, staff purchasing, receiving returned goods, pricing stock, applying discounts, handling stock, ordering stock, receiving stock, storing stock, transporting stock, identifying stock, labelling stock, advertising, planning, stock taking, record keeping, using the stock control system, housekeeping, staffing, rosters, supervision and management of staff, dealing with damage and waste, allowing for seasonal changes, maintaining and using equipment and plant, health and safety, emergency procedures, administrative procedures. Purpose of process loss analysis is identified for specific situations. Range may include but is not limited to – identify known process loss; identify unknown loss; quantify loss; identify causes of loss; identify effect of loss; minimise loss; prevent loss; monitor loss; improve process; identify training needs; revise or update loss prevention policies and procedures; improve stock management; update stock control system; improve efficiency, profitability, customer satisfaction. 1.4 Procedures for analysing process loss for specific situations are identified and agreed in accordance with organisational procedures. 1.5 Analysis is used to identify the extent of process loss for specific situations. Range 1.6 may include but is not limited to – data comparison and analysis, calculation, estimation, research, tracking, use of stock control system, use of computer software, quantification of known loss, quantification of unknown loss. Effects of process loss are described in terms of impact on the organisation. 2 25798 April draft version 1 Page 3 of 3 Range may include but is not limited to – loss of sales, loss of customers, customer dissatisfaction, forced discounts, need for rainchecks, stock outage, stock shortage, stock damage, stock out-of-date, over-stocking, increased transport costs, increased storage costs, withdrawal of suppliers, bank charges, overpayments, stock damage, double handling, administration costs. Element 2 Use results of analysis to minimise or prevent process loss. Performance criteria 2.1 Procedures to minimise or prevent process loss are identified for specific situations. Range validity, practicality, timeliness, relevance. 2.2 Procedures to minimise or prevent process loss are recommended in accordance with organisational procedures. 2.3 Procedures to minimise or prevent process loss are implemented in accordance with organisational procedures. 2.4 Policies and procedures for loss prevention are updated to minimise or prevent process loss. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Retail Institute info@retailinstitute.org.nz if you wish to suggest changes to the content of this unit standard. 3