Review Article

Chemical Science Review and Letters ISSN 2278-6783

Review Article

Nanosilver Products - A Review

Vikas Gupta

1

and Ajay Kumar*

2

1 GTBIT, Rajouri Garden, New Delhi -110065

2 Galgotias University, Plot No-2, Sector17A, Yamuna Expressaway, Distt Gautam Budh Nagar, UP

Abstract

Review article describes the importance of nano dimensions in product development. Nanosilver EPA approved products such as silver biocidal additives, silver-impregnated water filters and silver algaecides and disinfectants historic development is described. Recent applications of silver nano particles in medical devices, silver dressings, silver coated

Exposure of nanosilver products is far less than to conventional silver products and synthetic chemical antimicrobials. textile fabrics, silver-nano particle-embedded antimicrobial paints, antimicrobial surface functionalization of plastic catheters, antimicrobial gel formulation for topical use, antimicrobial packing paper for food preservation, silverimpregnated fabrics for clinical clothing, nano silver children products and products for pets are described.

Nanosilver products safety data available in EPA’s formal incident reporting database (EPA OPP IDS) indicates that nanosilver products are safe. Nanosilver has been safely used in direct aquatic applications and dermal wound care since decades.

Keywords: Nano silver particles, microorganism, biocidal, algaecides, disinfectants, EPA

*Correspondence

Ajay Kumar

Email:ak.gupta59@rediffmail.com

Introduction

Silver has been used for disease prevention for many centuries. The earliest example is the storage of potable water in silver vessels in ancient times throughout Rome, Greece, Egypt and Phoenicia [1]. In the late 1800s the Swiss botanist

Carl vor Naegeli, observation that a low concentration of metal ions are biocidal to many different types of microorganism [2] is called oligodynamic effect. Because of oligodynamic effect the silver ion is the most bactericidal of all the metals followed by mercury, lead and copper [2]. The necessary concentra tion for antibacterial effectiveness of silver ions is only 0.3 to 2.0 ppm [3-7]. In medical treatment silver salts are used to control certain types of infections. Silver nitrate drops are placed in new born eyes at birth for the prevention of contracting gonorrhea from mother [1]. To prevent infections in burn wounds, silver sulfadiazine topical creams are applied to damaged skin [8]. Copper–silver ionization systems for water disinfection are used to eliminate the spread of

Leogionella in healthcare facilities. [9,10].

Silver nanoparticles (AgNP) are crystalline particles of Ag (0) metal with at least one dimension between 1 to 100 nm. AgNP can have spherical, prism, cubic or rod shaped morphologies. In comparison with silver ions, the nanoparticles have longer lasting biocidal properties. They are less prone to complexation and precipitation into forms unavailable to bacteria. Silver nanoparticles are easier to incorporate into matrix materials such as paper, fibers, polymers and ceramics. Due to the nanometer-sized diameter of the nanoparticles, the surface area is much greater than the bulk metal, and is therefore more bioactive. Applications of silver nanoparticles are currently of intense interest in nanotechnology. Due to their biocidal properties, the Woodrow Wilson Database lists over 313 commercial products that contain silver nanoparticles[11]. These products include textiles, cosmetics, health supplements, filters,

Chem Sci Rev Lett 2014, 3(11), 717-727 Article CS22204508 717

Chemical Science Review and Letters ISSN 2278-6783 detergents and others [11, 12]. Although silver ions/nanoparticles and other compounds have shown great success in many antimicrobial applications but are not without some problems. Some bacteria have evolved resistance to many antibiotics, including silver. Resistance refers to the ability of bacteria to reproduce in high concentra tions of a disinfectant or antibiotic [13]. Silver – resistant bacteria were first isolated from environments contaminated with silver , such as polluted soil near silver mine drainage areas, skin burn wound regions, watersheds , near photographic industry effluents etc. [5, 14-16]. Gene encoding silver resistance in bacteria are carried on plasmids, which have been found in Pseudomonas stutzeri that were isolated from silver mine [17] and E coli [18]. Differing mechanisms explain silver resistance in bacteria, which include either cell wall impermeability to metal ions or metal accumulation within the cells [15, 19]. Recently, it has been shown that hazard assessment of a silver nanoparticle in soil applied via sewage sludge because toxic effects on soil microorganisms of the terrestrial ecosystem. {20]. Silver nanoparticles are also biomagnified and effect aquatic life [21-23]. The silver can be toxic to humans [24, 25]. Therefore nanosilver product safety must be considered before using silver nano particle products. In this report we review antibacterial mechanism of action of silver, history and applications of silver nano products and their safety concerns.

Antibacterial mechanism of silver

In diagnostic laboratories, researcher uses the procedure of minimum inhibitory concentration (MIC) to determine microbial resistance to various antibiotic medications. The MIC is defined as the lowest concentration of an antimicrobial that will inhibit the visible growth of a microorganism after overnight incubation in a specified culture media [26]. The silver ions and silver nanoparticles in suspension have similar MIC values. But the MIC for ions is somewhat lower than the silver nanoparticles [3, 4, 7, 27-33]. The MIC values for Gaps in suspension are in ppm range but vary due differences in the `Gap diameters, bacteria concentration, exposure time and nutrients media composition

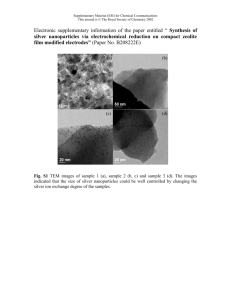

In general, the smallest particle sizes silver nanoparticles have been observed to have the largest antibacterial effects. The average diameters under 10 nm are most effective [34]. In smaller particle sizes higher proportion of atoms are on surface which results in greater reactivity and biocidal activity [34, 35]. A list of microorganism inactivated by silver ions and /or nanoparticles is listed in table-1.

The bacterial activity of silver nanoparticles is largely due to the release of silver ions from the AgNP surface [30,

36]. Silver ions bind preferentially on thiol groups in membranes proteins, and cause DNA aggregation [36]. Silver ions inhibit enzymes in nitrifying bacteria [37], block DNA transcription, and interrupt bacterial respiration a nd ATP synthesis [38]. Treatment with silver nanoparticles develop a pit in the membranes, increase membrane permeability, because of this cytoplasm leakage in E. coli occurs [28, 32]. The AgNP s in growing cultures of wild type E. coli produces superoxide radicals, which allows silver ion penetration into the cell membrane [39].

Table 1 Microorganism inactivated by silver ions and /or nanoparticles

Microbe Name

Bacillus anthracts

Bacillus cereus

Bacillus subtiles

Enterococcus faecali

Vanomycin –R E faecium

Escherichia Coli

Microbe Type : Bacteria

From of Ag

AgZn Zeolite

AgZn Zeolite

AgBRNP polymer composite

AgNPs

AgZn Zeolite

Fe

3

O

4

@AgNPs

AgNP polymer films

Ag + ions , AgNP

Ag + ions , AgNPs

Ag + ions

Reference

[40]

[40]

[41]

[42,43]

[40]

[44]

[45]

[46]

[31, 46]

[3, 7,36,46]

Chem Sci Rev Lett 2014, 3(11), 717-727 Article CS22204508 718

Escherichia Coli GFP

Escherichia Coli O157:H8

Ampicillin R E coli

Kiebsielia pneumonia

ESBL-RK pneumoniae

Legionella

Listeria monocytogenes

Micrococcus lyfae

Nitrifying bacteria

Providencia Stuartii

Proteus mirabilis

Pseudomonas aerugnose

Salmonella typhi

Serratia

Sphingomones

Staphytcoccus albus

Staphytcoccus aureus

Methicillin –R.S.aureus

Staphytcoccus-epidermis

MRS. Epidermidis

Staphytcoccus group D

Staphytcoccus mits

Staphytcoccus pyogenes

Staphytcoccus salivarus

Vibrio Cholera

Microbe Type : Fungi

Aspergillus niger

Bovine mastits

Canodida albicans

Chemical Science Review and Letters ISSN 2278-6783

AgNPs

Ag – activated carbon fibers

AgNP –granular activated carbon

Fe

3

O

4

@ AgNPs

AgNP rice paper plant stem

AgNP polymer composite

Ag + ions in ceramics

Polyethersulphone membranes with

AgNP in multilayers

AgNPs

AgNPs

AgNPs

AgNPs

Ag + ions AgNPs

Cu and Ag ionization

AgNPs on paper silicone

AgNP TiO

2

Ag + ions, AgNPS, AgCl Colloids

Ag+ ions

Ag+ ions

Ag+ ions

AgNPs

AgNP polymer films

AgNP ceramic beads

AgBr NP polymer composite

AgNPs

Ag + ions

Ag ceramic beads

Ag + ions

Ag + ions

AgNPs

AgNP polymer films

AgNP ceramic beads

Ag + ions, AgNPs

AgBr NP polymer composite

Fe

3

O

4

@ AgNPs

AgNP polymer films

AgNPs

Ag + ions

Ag + ions

Ag Zn zeolite

Ag + ions

Ag + ions

Ag + ions

AgNPs

[34,31, 42,43,46]

[49,48]

[48]

[44]

[50]

[41]

[51]

[52]

[31, 46]

[41]

[44]

[57]

[31]

[3]

[3]

[59]

[3]

[3]

[60]

[34]

[28]

[29]

[53]

[54]

[31, 46]

[9, 10]

[55]

[56]

[4]

[3]

[3]

[3]

[34, 31, 46]

[57, 45]

[58]

[41]

[14, 55]

[3]

[46]

[3]

[3,36,46]

[29,31,43,53,54]

[57, 45]

[58]

AgNP hydrogel

AgNP ceramic beads

AgNPs

AgNP hydrogel

[61]

[58]

[29]

[61]

Chem Sci Rev Lett 2014, 3(11), 717-727 Article CS22204508 719

Chemical Science Review and Letters ISSN 2278-6783

Pichia pastons

Saccharomyces cerevisiae

Microbe Type : Protozoa

Hartmannella vermiforrnis

Naegleria fowleri

Tetrahymena pyriformis

Viruses

HIV

Murine Norovirus

Reovirus

SARS Coronavirus

AgNP rice paper plant stem

AgNPs ceramic beads

Ag–activated carbon fibers

Ag–activated carbon fibers

Cu and Ag ionization

Cu and Ag ionization

Cu and Ag ionization

AgNPs

AgNPs in ceramic

AgNPs in ceramic

Ag/Al2O3 water

[50]

[58]

[61]

[47]

[62]

[63]

[62]

[64]

[65]

[51]

[66]

Nanosilver Products History

The worldwide production of silver reached approximately 28,000 metric tons in 2007 [67], approximately 500 metric tons per year are nanosilver [68]. The majority of silver is used in industry (38.2%), as jewelry and silverware

(32.5%), and in the photographic industry (23.8%). Silver biocide use (0.5% or approximately 140 metric tons) is still very small and the remainder of the silver is used for investment and coins (5%) [67] . In 1889, M. C. Lea reported the synthesis of a citrate stabilized silver colloid [69]. The average diameter for the particles obtained by this method was between 7 and 9 nm [70]. The size and the stabilization of nanoparticle prepared by citrate method are identical to recent methods used to prepare nanosilver particles using silver nitrate and citrate, [71, 72]. The stabilization of nanosilver using proteins has been described as early as 1902 [73] and a product “Collargol” containing such a kind of nanosilver has been manufactured commercially since 1897 for medical applications[74]. Collargol contains silver of particle size of 10 nm [75]. As early as 1907 its diameter was determined to be in the nano range [76]. Gelatin stabilized silver nanoparticles with 2-20 nm diameter was patented by Moudry in 1953 [77]. The silver nanoparticle impregnated carbon with a diameter of silver particles below 25 nm has been patented [78]. Long ago inventors of nanosilver formulations understood that the viability of the technology required nanoscale silver. The inventors made a statement from a patent: “for proper efficiency, the silver must be dispersed as particles of colloidal size less than

250 Å [less than 25 nm] in crystallite size” [78]. The above formulations have consistently found into the market since last over a 50-year period and their use has become widespread to treat various diseases such as syphilis and other bacterial infections. [79] There are at least three categories of EPA-registered products that employ elemental silver particles with particle sizes less than 100 nm: (a) silver biocidal additives; (b) silver-impregnated water filters;

(c) silver algaecides and disinfectants. Several examples of each category are identified below:-

Silver Biocidal Additives: EPA has registered numerous biocidal additives based on elemental silver particles. Some examples of currently registered biocidal additive products that contain metallic (elemental) silver with very small particle size (<100 nm), are Additive SSB (EPA reg. 83587-3, company NanoHorizons), Micro Silver BG-R (EPA reg.

84146-1, company Bio-Gate), and HyGate 4000 (EPA reg. 70404-10, company BASF, formerly Ciba Corp.). These silver biocides are typically used in plastic and textile applications where the silver is effectively contained within polymer substrates.

Silver Algaecides and Disinfectants: Colloidal nanosilver algaecides are elemental silver in very small particle size

(e.g., <100 nm) maintained in a stabilized solution. Some examples of currently registered biocidal products are

Silver Algaedyn (EPA reg. 68161-1, Pool Products Packaging Corp), Nu-Clo Silverside (EPA reg. 7124-101, Alden

Leeds Inc.) and ASAP-AGX (EPA reg. 73499-1, American Biotech Laboratories). It should be noted that algaecide

Chem Sci Rev Lett 2014, 3(11), 717-727 Article CS22204508 720

Chemical Science Review and Letters ISSN 2278-6783 applications have been used safely in high-exposure, direct water contact, and down-the-drain applications such as swimming pool disinfection for decades without any known damaging impact on humans or the environment.

Silver - Impregnated Water Filters : EPA has registered multiple silver-impregnated water filters since the 1970s based on activated carbon or ceramics that are impregnated with very small particle size (<100 nm) metallic

(elemental) silver. The impregnation of carbon and ceramic materials with metals is widely recognized as a standard technique for the synthesis of nanoscale metal particles. The wet impregnation methods employed in production of nanostructured industrial catalysts for decades have been reviewed [80-82]. Silver-impregnated water filters currently registered under FIFRA employ similar methods with the clear intention to produce nanoscale silver. For example, the elemental silver preferably includes at least 2% of silver crystals having crystal sizes between approximately 3nm and

10nm [82, 83]. Silver-impregnated water filters have been safely used for domestic water applications such as drinking water and swimming pool filters for decades. No reports about any health or environmental effects have been reported, although the absence of such reports does not mean that no effects occurred.

Recent Applications of Nanosilver particles

Silver coated medical devices : Silver nanoparticles can be used for the impregnation of medical devices such as surgical masks [87]. The advantage of impregnation of medical devices with silver nanoparticles is that it protects both outer and inner surfaces of devices and there is continuous release of silver ions providing antimicrobial activity

[88, 89]. Variety of methods has been used to test the efficacy of silver nanoparticles impregnated on silicon elastomer [86] and it found that the antibacterial efficiency of silver nanoparticles reduces after washing. The reason for this might be the inactivation of metallic silver when it comes in contact with blood plasma and the lack of durability of the coatings [84-86].

Silver dressings: Dressings play a major part in the management of wounds [90]. In recent times, the development of resistant strains of pathogens has become a major problem and the newly designed wound dressings have provided a major breakthrough for the treatment of infection and wounds. The antibacterial properties and the toxicity of silver to micro-organisms are well known, thus, now a day, silver is also used in wound dressing [91]. The silver dressings make use of delivery systems that release silver in different concentrations. But different factors like the distribution of silver in the dressing, its chemical and physical form, affinity of dressing to moisture influence the killing of microorganisms [92].

Silver coated textile fabrics: Researchers are developing textile fabrics containing antibacterial agents. As, silver is non-toxic and possess antimicrobial properties, it has encouraged workers to use silver nanoparticles in different textile fabrics. Silver nano composite fibers were prepared containing silver nanoparticles inside the fabric. But scanning electron microscopic studies have shown that the silver nanoparticles incorporated in the sheath part of fabrics possessed significant antibacterial property as compared to the fabrics in which silver nanoparticles are incorporated in the core part [93]. It is also reported that silver nanoparticles coated textile fabrics possess antibacterial activity against S. aureus [91].

Silver-nanoparticle-embedded antimicrobial paints: The bactericidal coatings on surface are important to protect human health and the environment. The Ag-NPs-embedded coatings are of particular interest owing to their potential bactericidal activity. John et al [94] has developed an environmentally friendly method to synthesize metal NPsembedded paint, in a single step, from common household paint. The naturally occurring oxidative drying process in oils, involving free-radical exchange, was used as the fundamental mechanism for reducing metal salts and dispersing metal NPs in the oil media, without the use of any external reducing or stabilizing agents. These well-dispersed metal

NPs-in-oil dispersions can be used directly on different surfaces such as wood, glass, steel and different polymers.

The results showed that the surfaces coated with silver-nanoparticle paint have excellent antimicrobial properties by killing both gram-positive human pathogens ( S. aureus ) and gram-negative bacteria ( E. coli ). The market potential for silver containing paints and lacquers is currently very small and is expected to be relatively insignificant when

Chem Sci Rev Lett 2014, 3(11), 717-727 Article CS22204508 721

Chemical Science Review and Letters ISSN 2278-6783 compared to other consumer products. There are few products on the market, but examples include: silver containing biocide (TINOSAN® SDC, IRGAGUARD® by Ciba Specialty Chemicals) which can be used as a plastic additive and can be used to produce coating effects. Alfred Clouth Lackfabrik produces nanosilver containing wood lacquers

(CLOUCRYL Nano-Finish ANTIBAK and WL-Nano CB ANTIBAK) sell between 3 - 5 metric tons of these per year. The lacquers contain silver particles bound in a polymer film at a concentration of 100 - 300 ppm silver/kg lacquer [67].

Antimicrobial surface functionalization of plastic catheters: Silver nanoparticles have been used to coat catheters [95]. Silver-coated catheters showed significant in vitro antimicrobial activity and prevented biofilm formation against pathogens ( E. coli, Enterococcus, S. aureus, coagulase-negative staphylococci, P. aeruginosa and

C. albicans ); most of them involved in catheter-related infections. These catheters are non-toxic. They sustained release silver at the implantation site. Because of their demonstrated antimicrobial properties, they may be useful in reducing the risk of infectious complications in patients with indwelling catheters.

Antimicrobial gel formulation for topical use: The Ag-NPs were also used in therapeutics, for treating burn wounds.

A gel formulation containing Ag-NPs (S-gel) [96] was found to be comparable to that of a commercial formulation of silver sulfadiazine the cell viability, biochemical effects and apoptotic/necrotic potential were assessed by localization of Ag-NPs in Hep G2 cell line. It was found that Ag-NPs get localized in the mitochondria and have an IC

50

value of

251

μ g ml

−1 which indicate that Ag-NPs induced apoptosis at concentrations up to 250

μ g ml

−1

. This favors scarless wound healing. Acute dermal toxicity studies on Ag-NPs gel formulation (S-gel) Sprague-Dawley in rats showed complete safety for topical application. Hence, Ag-NPs could provide a safer alternative to conventional antimicrobial agents in the form of a topical antimicrobial formulation.

Antimicrobial packing paper for food preservation: The preventing microbial growth for longer periods in food preservation can be carried out by packing the processed food in antimicrobial packing. The silver nanoparticles containing papers using ultrasonic radiation have been developed {97]. By varying the precursor concentrations a nd reaction times, the thickness of the Ag-NPs coating and the particle size was controlled. The Ag-NPs- coated papers thus produced have been shown to possess microbiocidal properties against the Gram-negative E. coli as well as against the Gram-positive S. aureus bacteria. The results showed that such Ag-NPs-coated paper has potential application in the food industry as a packing material with a long shelf life and antifouling properties.

Silver-impregnated fabrics for clinical clothing: The contamination of clinical clothing with a mixture of bacteria from the wearer and the environment is a common occurrence. The bacteria such as Enterococcus and

Staphylococcus spp. can survive for more than 90 days on clothing worn by health care workers. The surgical scrub suits (scrubs) may be contaminated by bacteria even when freshly laundered. Also these bacteria can be transferred from nurses' uniforms to patient bedding, and can infect surgical wounds. The effect of silver impregnation of surgical scrub suits on surface bacterial contamination during use in a veterinary hospital was investigated by Freeman et al.

[98]. It was found that silver-impregnated scrubs had significantly lowered bacterial colony counts (BCC) compared with suit not treated with silver nanoparticles. This showed that silver impregnation appeared to be effective in reducing bacterial contamination of scrubs during use in a veterinary hospital. Numerous silver nanotechnologies have been launched offering antimicrobial coatings including Bactiguard (Bactiguard AB, Sweden), HyProtect (Bio-

Gate AG, Germany), Nucryst’s nanocrystalline platform technology (Nucryst Pharmaceuticals Corp., USA), Spi-

ArgentTM (Spire Corp. USA), Surfacine (Surfacine Development Company LLC, USA), and Sylva Gard (AcryMed

Inc., USA) . These are used as medical antimicrobials in textiles and surface coating products including wall coating paints, self-sterilizing hospital gowns and bedding. Bioni Hygienic , created by the German based Bioni CS® GmbH

Company (see bioni.de) is an example of a nanotech-based antimicrobial nanosilver coating frequently used in hospitals. The company claims its product will create “an antimicrobial surface which prevents the growth of mould and mildew and effectively destroys even the most resistant of hospital bacteria by the use of an entirely new combination of active agents based upon nano technology”[99]. They claim that the 13nm sized nanosilver particles are safely embedded in a matrix that permanently binds the particles to the paint [100].

Chem Sci Rev Lett 2014, 3(11), 717-727 Article CS22204508 722

Chemical Science Review and Letters ISSN 2278-6783

Nanosilver children products: Nanosilver products targeted towards children and infants include: strollers, toys

(stuffed animals), wet wipes, mats and bedding, baby bottles, nipples and pacifiers. For instance, Baby Dream® is a large supplier of baby nanosilver products offering a wide variety of products, including a baby bottle [101]. Also available are stuffed animals with nanosilver treated “Memory Foam” such as Benny the Bear Plush Toy and Donny the Dog sold by Pure Plushy™ Inc.

Products for pets: The nanosilver industry has not overlooked pets in its attempt to market products. Nanosilver feeding bowls, deodorants, pet water purifiers, dog beds and pet clothing are now on the market. Saywood Inc. offers a water purifier for pets, which “serves your pet with clean & healthy water preventing bacteria through sterilization

& antibiotic effect by the Nano silver photo catalytic coating ball & photo catalytic coating”[102].

Other Applications : Silver has been known to possess strong antimicrobial properties both in its metallic and nanoparticle forms hence, it has found variety of application in different fields such as:-

The Fe

3

O

4

attached Ag nanoparticles can be used for the treatment of water and easily removed using magnetic field to avoid contamination of the environment [103]. Silver sulfadazine depicts better healing of burn wounds due to its slow and steady reaction with serum and other body fluids [104]. The nanocrystalline silver dressings, creams, gel effectively reduce bacterial infections in chronic wounds [105, 104]. The silver nanoparticle containing poly vinyl nano-fibres also show efficient antibacterial property as wound dressing (106). The silver nanoparticles are reported to show better wound healing capacity, better cosmetic appearance and scarless healing when tes ted using an animal model (107). Silver impregnated medical devices like surgical masks and implantable devices show significant antimicrobial efficacy [86]. Environmental-friendly antimicrobial nanopaint can be developed [94]. Inorganic composites are used as preservatives in various products [108]. Silica gel micro spheres mixed with silver thio-sulfate are used for long lasting antibacterial activity {108].

Silver nanoparticles can be used for treatment of burns and various infections [109]. Silver zeolite is used in food preservation, disinfection and decontamination of products

[110,111]. Silver nanoparticles can be used for water filtration [112].

Nanosilver Products Safety

Nanoscale silver products have been safely regulated since the 1950s: The nanosilver particle products have been regulated by EPA over last 50 years. There is no incident of significance on EPA’s formal incident reporting database

(EPA OPP IDS) indicating that silvernano products are safe. Every EPA silver registration between 1970 and the

1990 was in fact a colloidal nanosilver or nanosilver-composite product. An overall analysis reveals that today over

50% of all EPA registered silver products are based on nanoscale silver [113].

Nanosilver has been safely used in direct aquatic applications for decades: Since 1970 the silver products have been safely used for swimming pools and municipal and domestic drinking water purification. Both swimming pools and domestic water waste ultimately pass to soil, sewage treatment facilities and natural aquatic systems. The reason for low impact is a demonstrated by tendency of silver particles to be strongly passivated by ubiquitous natural environmental complexing agents such as sulphur, chlorides, phosphate and dust [114-118]. The ecological fate and toxicity of environmentally passivated silver, typically forming silver sulphide, is a thoroughly investigated topic, particularly from the long history and high volume of photographic use of silver [119, 120].

Nanosilver is safely used in de rmal wound care since decades: There are no ill effects when it is used directly on wounds and broken skin. FDA approved nanosilver dermal wound care ointments and bandages are used routinely in hospitals to promote skin repair by reducing inflammation and such products often save lives by preventing infections

[121].

Exposure is far less than to conventional silver products and synthetic chemical antimicrobials: An exposure analysis in comparison to conventional silver products and synthetic chemical antimicrobials shows significantly

Chem Sci Rev Lett 2014, 3(11), 717-727 Article CS22204508 723

Chemical Science Review and Letters ISSN 2278-6783 lower quantities of active substance are required for nanosilver to achieve an equivalent effect. Such analysis shows a compelling potential for fewer chemicals to be used to treat consumer products and less pollution of the environment.

References

[1] R.L. Davies , S.F. Etris , Catalysis Today , 1997, 36(1) , 107

[2] A.B.G. Landown , Silver in healthcare : its antimicrobial efficacy and safety in use: Issues in toxicology ,Royal

Society of Chemistry, Cambridge, 2010

[3] T.J. Berger , J.A.Spadaro , S.E. , Chapin, R.O. Becker , Antimicrob Agents, 1976, 9(2) , 357

[4] O. Choi , K .Deng , N. Kim , L. Rossjs , R. Surampalli , Z. Hu, Water Research , 2008, 42 (12) ,3066

[5] W. Ghandour , J.A. Hubbard , J.Deistung , M.N. Hughes , R.K. Poole , Appl Microbiol Biot, 1988, 28(6) , 559.

[6] C.Gunawan , W.Y. Tech. C.P. Marquis , J . Lifia , R. Amal , 2009, 5(3) ,341-344.

[7] G.J. Zhao , S.E.Stevens , Biometals , 1988, 11(1) , 27

[8] S. Hoffmann , Journal of Plastics and Reconstructive Surgery and Hand Surgery, 1984, 18(1), 119

[9] R. P. Vonberg , D Sohr, J. Bruderek , P. Gastmeier , BMC Infectious Diseases , 2008, 8, 133

[10] J.E. Stout , V.L. Yu , Infection Control and Hospital Epidemiology , 2003, 24 , 563

[11] Project on Emerging Nanotechnologies , Cited on November 11, 2011, Available from http://www.nanotechproject.orginventories/consumer/analysis draft /

[12] E. Fauss , The silver nanotechnology commercial inventory . Project on Emerging Nanotechnologies , 2008.

[13] N. Silverstry – Rodriguez , E.E. Sicairos – Ruelas , C.P. Gerba , K.R.Bright , Rev Environ Contam

Toxicol,2007, 191 , 23

[14] R.C. Charley , A.T. Bull , Arch Microbiol, 1979, 123(3) , 239

[15] S. Silver , Fems Microbiolgy Reviews , 2003, 27 (2-3) , 341

[16] T. Pumpel , F. Schinner , Appl. Microbiol Biot. 1986, 24, 244

[17] C. Haefeli, C. Franklin , K. Hardy , J Bact , 1984, 158, 389

[18] A.O. Summers , G.A. Jacoby , M.N. Swartz , G. Mchugh , L. Sulton , Metal cation and oxyanion resistancesin plasmids of gram –negative bacteria , p 128-131 in D. Schlessinger (ed) Microbiology, American Society for

Microbiology , Washington, D.C.,1978

[19] J.T. Trevors , K.M. Oddie, B.H. Belliveau, Fems Microbiology Reviews, 1985, 32, 39

[20] K. Schlich , T. Klawonn , K. Terytze , K. Hund-Rinke, Environmental Sciences Europe, 2013, 25 ,17

[21] A. B. G. Landsdown, Critical reviews in toxicology, 2007, 37(3), 237.

[22] T. Marija, N. Michael, Rodl. Siegfried, H. Bengt, K Wolfgang, G .W. Less, Journal of Trauma-Injury

Infection and Critical Care , 2006, 60(3), 648

[23] S. W. P. Wijnhoven, W. J. G. M.Peijnenburg, C. A.Herberts, W. I.Hagens, A. G. Oomen, E. H. W.,Heugens,

B. Roszek,J. Bisschops, I.M. Gosens, S.Dik van de, Jong, W. de Dekkers, M. van, Sips Zijverden,

J.A.M.Adriënne , R.E. Geertsma, Nanotoxicology, 2009, 3(2),109

[24] H.T. Ratte, Environmental Toxicology and Chemistry , 1999, 18, 89

[25] S.N. Luamo, Project on Emergin Nanotechnolgies. Washington D.C., (2008), 72.

[26] J.M. Andrews , Journal of Antimicrobial Chemotherapy , 2001 , 48( Suppl 1) , 5

[27] C. Beker , A.Pradhan , L. Pakstis , D. Pochan , S.Shah , Journal of Nanoscience and Nanotechnology , 2005,

5(2), 224-249

[28] S.K. Gogoi, P. Gopinath , A Paul , A. Ramesh , S.S. Ghosh , A. Chattopadhyay , Langmuir , 2006, 22(22) ,

9322

[29] J.Kim , E Kuk , K Yu, J Kim , S. Park , H. Lee , S. Kim , Y.Park , C. H. Wang , Biology and Medicine , 2007,

3(1), 95

[30] C.N. Lok , C.M.Ho, R. Chen , Q.Y. He, W.Y.Yu, H. Sun , P.K. H. Tom , J.F. Chiu , C.M. Che , J. Biol

InorgChem. 2007. 12(4), 527

[31] A. Panacek , L.Kvitek , R. Prucek , M. Kolar , R. Vecerova, N. Pizurova , V.K. Sharma , T .Neveena , R.

Zboril, J Phys Chem B, 2006, 110(33) , 16248

[32] I. Sondi , B. Salopek – Sondi , Journal of Colloid and Interface Science , 2004 , 275(1) , 177

Chem Sci Rev Lett 2014, 3(11), 717-727 Article CS22204508 724

Chemical Science Review and Letters ISSN 2278-6783

[33] P. Li, J.Li, C.Wu , Q.Wu, Nanotechnology , 2005, 16(9) ,1912

[34] J.R. Morones , J.L. Elechiguerra , A Camacho-Bragado , K. Holt , J.B. Kouri, J.T. Ramirez , M.J. Yacaman,

Nanotechnology , 2005, 16(10) , 2346

[35] J. Liu , D.A. Sonshine , S. Shervani , R.H. Hurt, ACS Nano 2010, 4 (11) , 6903

[36] Q.L.Feng, J.Wu, G.Q. Chen , F.Z. Cui, T.N. Kim , J.O.Kim , J. Biomed Mater Res, 2000, 52(4) , 662

[37] H.T. Ratte, Environmental toxicology and chemistry, 1999, 18(1) , 89.

[38] R. Kumar, S. Howdle , H. Munstedt , J Biomed Mater. Res. B, 2005, 75B(2) ,311

[39] E. Hwang, J.Lee, Y. Chae, Y. Kim , B. Sang , M.Gu, Small , 2008, 4(6) ,746

[40] Z. S. Sachin, Symposium – Review Article , Bio-inspired nanomaterials and their applications as antimicrobial agents, 2012, 3, digitool.library.mcgill.ca/thesisfile110504.pdf

[41] N. Vigneshiwaran , A. Kathe, P. Varadarajan , R. Nachane , R. Balasubramanya , Langumuir, 2007, 23(13),

7113

[42] K.Y. Yoon , J.H. Byeon , C.W. Park , J. Hwang , Environ Sci Technology , 2008, 42(4), 1251

[43] H. Jiang , S. Manolache , A.C. Wong , F.S. Denes , J Appl. Polym Sci , 2004, 93(3) ,1411

[44] S. Shrivastava, T. Bera , A.Roy , G. Singh , P. Ramachandrarao, D. Dash , Nanotechnology , 2007, 18(22),

2251

[45] J. Zhang, H..Yu , Q. Yip , K. Li, A.Kwong , A.Xu , P. Wong , Langmuir , 2003, 19(24) ,10372

[46] D. Han , M. Lee , M.Lee , M.Uzawa , J. Park , World J Microbiol Biotechnol , 2005, 21, 6(6-7),921

[47] V. Zaporojtchenko, R.Podschun, U.Schuemann, A.Kulkarni and F. Faupel , Nanotechnology , 2006, 17(19),

4904-4908

[48] T.A.Dankovich , and D.G.Gray , Environmental Science and Technology , 2011, 45 (5), 1992

[49] R. Bandyopachyaya, M. Sivaiah , P. Shankar, J. Chem Technol. Biotechnology, 2008, 83(8), 1177

[50] F. Zeng , C. Hou , S. Wu , X.Liu , Z.Tong , S. Yu, Nanotechnology, 2007, 18(5) ,055605.

[51] S. Loher , O.D. Schneider , T. Maienfisch , S, Bokorny , W.J. Stark , Small , 2008, 4(6),824

[52] F. Diagne, R. Malaisamy , V. Boddie , R.D. Holbrook, B.E. Eribo , K.L.Jones , Environ Sci Technol , 2012,

46(7) ,4025

[53] H.Le Pape , F. Solano- Serena , P. Contini , C. Devillers , A. Maftah , Leprat , Journal of Inorganic

Biochemistry , 2004, 98 (6) ,1054

[54] B. Galeano , E.Korff , W.L. Nichoson , Applied and Environmental Microbiology , 2003, 69(7) ,4329

[55] H. Hamzehei , The Quarterly journal of biological sciences , 2012, 4(3),135

[56] H. Y. Yip, J. C. M. Yu, S. C. Chan, L. Z. Zhang, P. K. Wong , Journal of Water and Environment Technology

,2005; 3(1),47 DOI:10.2965/jwet.2005.47

[57] J. Ruparelia , A. Chatterjee , S. Duttagupta , S. Mukherji , Acta Biomaterialia, 2008, 4(3) , 707

[58] P. Gong, H. Li , X . He , K. Wang , J. Hu, W.Tan , S.Zhang and X. Yang, Nanotechnology, 2007, 18, 285604

[59] O. Eksik, A. Erciyes and Y. Yagci , Journal of Macromolecular Science Part A – Pure and Applied Chemistry,

2008, 45(9) , 698

[60] L.Kvitek , A Panacek , J. Soukupova , M.Kolar, R. Vecrova, R. Prucek , M . Holecova and R. Zboril, J Phys

Chem C, 2008, 112(15) ,5825

[61] V. Sambhy , M. Macbride , B.Peterson , A. Sen , J. Am. Chem. Soc., 2006, 12B (30) ,9798

[62] P. Dibrov , J. Dzioba , K.K. Gosnik , C.C.Hase, Antimicrob Agent Ch 2002, 46(8),2668

[63] M. Hotta , H.Nakajima , K . Yamamoto , M. Aono , J Oral Rehabil, 1988, 25(7) , 485

[64] W.F. Lee , Y.C. Huang , J Appl Poly Sci , 2007, 106(3) ,1992

[65] B. De Gusseme , L.Sintubin , L. Baert , E.Thibo, T. Hennebel , G. Vermeulen, M. Uyttendaele ,W. Verstraete,

N. Boon , Applied and Environmental Microbiology , 2010 , 76(4) ,1082

[66] H. L Pape , F. Solano – Serena , P. Contini , C. Devillers , A. Maftah , P. Leprat , Carbon, 2002, 40(15) , 2947

[67] K. Hund-Rinke, F. Marscheider-Weidemann , M. Kemper ,“Beurteilung der Gesamtumweltexposition von

Silberionen aus Biozid-Produkten”.Forschungsbericht des Umweltbundesamtes, Texte, 2008, 43/08.

[68] N.C. Mueller, B. Nowack , Environmental Science Technolology , 2008, 42, 4447

[69] M.C. Lea, Am. J. Sci., 1889, 37,476

[70] G. Frens, J.T. Overbeek, C. Leas , Kolloid Z.Z. Polym. , 1969, 233 (1-2), 922

Chem Sci Rev Lett 2014, 3(11), 717-727 Article CS22204508 725

Chemical Science Review and Letters ISSN 2278-6783

[71] A. Henglein, M. Giersig, J. Phys. Chem. B, 1999, 103 (44),9533

[72] X.Y. Dong, X.H. Ji, H.L. Wu, L.L. Zhao, J. Li, W.S. Yang, J. Phys. Chem. C , 2009, 113 (16), 6573–6576.

[73] C. Paal, Ber. Dtsch. Chem. Ges., 1902, 35 (2), 2224–2236.

[74] K. Boese, Dtsch. Z. Chir., 1921, 163 (1-2),62

[75]

N.E. Bogdanchikova, A.V. Kurbatov, V.V. Tret’yakov, P.P.Rodionov, Pharm. Chem. J., 1992, 26 (9-10), 778

[76] H. Bechhold, Z. Chem. Ind. Kolloide ,1907,2, (3-9),33

[77] Z.V.Moudry, Process of producing oligodynamic metal biocides.US Patent ,1953, 2,927,052

[78] M. Manes, Silver impregnated carbon. U S Patent, 1968, 3,374,608.

[79] M.C.Fung, D.L. Bowen, Clin. Toxicol., 1996, 34 (1), 119

[80] B. Kasemo, S. Johansson, H. Persson, P. Thorm€ahlen, V.P. Zhdanov, Top.Catal. 2000, 13, 45

[81] S.K.Ryu, S.Y. Eom, T.H. Cho , D.D. Edie, Carbon Sci. 2003, 4 (4), 168.

[82] V.S.Kumar, B.M. Nagaraja, V. Shashikala, A.H. Padmasri, S.S. Madhavendra, B.D. Raju , R.S.R.Rao, J. Mol.

Catal A: Chem. 2004, 223 (1-2), 313

[83] C.F. Heinig, Method of treating water. USPatent ,1994, 5,352,369

[84] D.K.Riley ,D.C. Classen ,L.E. Stevens , J.P. Burke , Am. J. Med., 1995,98,349

[85] E.P.J.M.Everaet , B.Van de Belt-Gritter , H.C. Van der Mei , H.J.Busscher , G.J.Verkeke, F. Dijk, H.F.Mahieu

, A. Reitsman, J Mat Sci-Mat in Med.,1998,9,147

[86] F.Furno , K.S.Morley, B. Wong , B.L.Sharp , P.L.Arnold , S.M. Howdle ,J Antimicrob Chemother

2004,54,1019

[87] Y.Li , P.Leung , Q.W. Song , E. Newton , J. Hosp. Infect., 2006,62,58

[88] M.Wilcox, P. Kite , B. Dobbins, J. Hospital. Infec., 1998,40,322

[89] R.O. Darouiche , I.I. Raad , S.O. Heard , J.I.Thornby ,O.C.Wenker , A. Gabrielli, New Engl J Med 1999,340,1

[90] D.L. Leaper , Int. Wound J 2006,3(4),282

[91] N. Duran ,P.D. Marcarto , G.I.H.De Souza , O.L.Alves , E. Esposito , J Biomed Nanotechnol., 2007,3,203

[92] I. Chopra , J Antimicrob Chemother., 2007,59,587

[93] S.Y.Yeo , S.H.Jeong , Polymer International 2003,52,1053.

[94] A. Kumar , P.K.Vemula , Ajayan P M , G. John, Nature Materials, 2008,7(3),236

[95] D.Roe , B.Karandikar , N. Bonn-Savage , B. Gibbins B , J-B. Roullet , J. Antimicrob. Chemoth. ,2008, 61 869, doi: 10.1093/jac/dkn034. Epub 2008 Feb 27.

[96] J. Jain, S. Arora , J.M. Rajwade , P.Omray , S.Khandelwal S , K.M.Paknikar , Mol. Pharm. 2009, 6 1388

[97] R. Gottesman , S.Shukla , N.Perkas , L.A.Solovyov , Y. Nitzan , A. Gedanken , Langmuir 2011, 27, 720

[98] A.I. Freeman , L.J.Halladay, P.Cripps ,Vet. J., 2012, 192 489-93

[99] Bioni. (2009). “produkten program, from http://www.bioni.de/index.php?page=produktprogramm_bioni_hygienic&lang=en

[100]

Nanovations. (2009). “Paint technology, from http://www.nanovations.com.au/Press%20Release/Paint%20technology%20from%20Nanovations.pdf

[101]

Baby Dream. (2009). “Silver Nano Baby Milk Bottle”. Available at: http://babydream.en.ec21.com/(accessed

February 25, 2009).

[102] Saywood. (2009). Pepuri Water Purifi er for PET Animals. Available at:http://saywood.en.ec21.com/product_detail.jsp?group_id=GC00521340&product_id=CA00521341&product

_nm=Petpuri (accessed February 24, 2009).

[103] P.Gong , H.Li , X.He , K.Wang , J.Hu ,W.Tan , Nanotechnology, 2007,18, 604

[104] C.L.Fox , S.M.Modak , Antimicrob Agents Chemother., 1974, 5(6), 582

[105] J.W. Richard , B.A.Spencer , L.F.McCoy ,E. Carina ,J.Washington , P.Edgar , J Burns Surg Wound Care,

2002,1,11

[106] J.Jun , D.Yuan-Yuan , W.Shao-hai , Z.Shao-feng ,W.Zhong-yi, J US-China Med Sci 2007,4(2),52

[107] J.Tian ,K.K.Y.Wong, C.M.Ho , C.N.Lok , W.Y.Yu , C.M.Che , J.F.Chiu , P.K.H. Tam Chem Med Chem,

2006, 171

[108] A.Gupta , S. Silver , Nat Biotechnol, 1998,16,888

[109] Q.L. Feng ,J.Wu , G.Q.Chen , F.Z.Cui , T.N.Kim ,J.O. Kim , J Biomed Mater 2000, 52(4),662

Chem Sci Rev Lett 2014, 3(11), 717-727 Article CS22204508 726

Chemical Science Review and Letters ISSN 2278-6783

[110] T.Matsuura , Y. Abe , K.Sato , K.Okamoto , M.Ueshige , Y.Akagawa , J Dent 1997,25,373

[111] H.Nikawa , T.Yamamoto Hamada ,M.B. Rahardjo and S.Murata Nakaando , J Oral Rehabil 1997,25,30

[112] P.Jain and T.Pradeep , Biotechnol Bioeng, 2005,90(1),59

[113]

SNWG “Evaluation of Hazard and Exposure Associated with Nanosilver and Other Nanometal Oxide Pesticide

Products”, Presentation to EPA Scientific Advisory Panel (November 4th, 2009). http://www.regulations.gov/search/Regs/contentStreamer?objectId=0900006480a52512&disposition=attach ment&contentType=pdf.

[114] J.Wang, C.P.Huang , D. Pirestani, Water Research, 2003 , 37, 4444

[115] EPA “Re-registration Eligibility Document for Silver”, 1993, Case 4082

[116] C. Impellitteri, T.Tolaymat, K.Scheckel, Journal of Environmental Quality2009, 38(4) ,1528

[117] O.Choi, Z.Hu, Water Science and Technology, 2009, 59(9),1699

[118] O.Choi, T.E.Clevenger, B.Deng, R.Y.Surampalli, L.Ross , Z.Hu, Water Research ,2009 ,43, 1879

[119] M.P.Hirsch, Environmental Toxicology and Chemistry, 1998, 17(4) , 601

[120] F.Galvez , C.M.Wood, Environmental Toxicology and Chemistry, 1999, 18(1) , 84–88.

[121] M. Crosera, M.Bovenzi, G.Maina, G.Adami, C.Zanette , C. Florio, International Archives of Occupational and

Environmental Health,2009, 82(9),1043-55

Publication History

Received 22 nd Aug 2014

© 2014, by the Authors. The articles published from this journal are distributed to the public under “

Creative Commons Attribution License

”

(http://creativecommons.org/licenses/by/3.0/). Therefore, upon proper citation of the original work, all the articles can be used without any restriction or can be distributed in any medium in any form.

Revised 09 th

Accepted 15 th

Online

Sep 2014

Sep 2014

30 th Sep 2014

Chem Sci Rev Lett 2014, 3(11), 717-727 Article CS22204508 727