What is System in Package?

advertisement

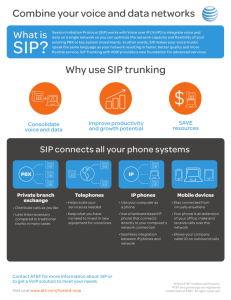

Convergence and Connectivity 2003 System in Package: Flexibility in Integration Chris Scanlan Sr. Director, System in Package Amkor Technology cscan@amkor.com Outline q q q q System in Package Definition Benefits of SiP Application examples and market drivers SOC, SiP, or SOB What is System in Package? q q An IC package containing multiple die? A fully integrated system or sub-system: Ø Ø One or more semiconductor chips plus: Passive components that would otherwise be integrated on the mother board § § § Ø Other subsystem components: § Ø Surface mount discrete passives Embedded or patterned into substrate Integrated passive components EMI shield, SAW filters, packaged ICs, connectors, antennas, mechanical housings, etc. A fully integrated functional block bridging the gap between SOC and SOB (system on board) SiP Benefits q q q q q q Simplifies product system board design and assembly. Increased functionality per unit area/volume. Improved electrical performance. Reduced system manufacturing costs. Improved interconnect reliability. Flexibility Ø Ø Can make changes to system or subsystem without changing mask-sets or mother board designs. Standardized sub-system “macros” Silicon Area Efficiency 400 Silicon Area Efficiency =Si Area / Package Area Silicon Efficiency(%) 300 Four-chip Stacked CSP 2002 Area Area Array Array Packages Packages Triple-chip Stacked CSP 2000 200 Stacked CSP 1998 100 Bare Bare Chip Chip 80 50 TSOP/QFP 1985 ‘90 Stacked TSOP/QFP 1995 Wafer-level Wafer-level CSP CSP CSP 1996 Peripheral Peripheral Packages Packages ‘95 ‘98 1st Year of Production ‘00 ‘02 ‘03 Stacked Penetrating the Handset Market Stacked CSP is being rapidly adopted in cell phones. Move from 2G to 3G Is driving need for more memory and processing power. q 3D package integration is required to fit more functionality in less space. q 700 Million units 600 500 Memory card slot 400 MEMS 300 200 100 0 '00 '01 S-CSP '02 '03 Phones '04 Source: Prismark More ASIC & memory 3D Technology – Reasons Why... q Reduce Ø System Level Costs Single Package Assembly, Test and Handling q Wafer Level Cost Optimization for Dissimilar Technologies Improved Design Time-TTM(fewer steps)-Yield-Capacity Ø Low and high density die combinations § Ø Ø Ø No Need for Finest Design Geometry for Low Density Silicon Architectures (eg: SRAM) Low and high voltage die combinations Mixed signal combinations (Memory/Logic) Flexibility of combining custom devices with off-the-shelf devices q Quicker and Easier Market Penetration Ø Ø Quickly add memory or other functionality to react to changes in market demand Greater access to niche markets through flexible integration 3D Technology – More Reasons Why... qSystem Ø 2 or More Die in 1 Package § § Ø Ø Ø Ø Level Size Reduction Flash/SRAM, Logic/Memory, etc. Double/Triple… functionality within same footprint Stacked memory die Reduced motherboard size (smaller cards) Fewer components Reduced Signal routing density, etc. Small (x-, y-axis), Thin (z-), Light Weight qConventional Surface Mount Cellular baseband module w/ 6 die including 2 stacked die Technology Ø Ø BGA & LGA Footprints and Compatibility with Thin Profile Mobile Phone Product Requirements Aligned with advanced BGA technology roadmaps § § § Pb Free/Green Cu Wirebonding Flip Chip Core Technology For 3D Packages q Thin Spacer Technology q Die overhang wirebonding q Low loop wirebonding q Wafer thinning/handling less than 75um Thin core laminates and thin die attach layers q Package Stacking q q q q Higher final test yield because each package in stack is tested before final assembly. Easier to integrate die from multiple suppliers. FA is simplified. Ideal for logic plus memory integration. CABGA, S-CSP family low cost PS-etCSP(3D) flexible substrate design good thermal performance substrate technology under development SiP Application Example: 802.11(b) Module Balun RFPA Diversity Switch RF Filter T/R Switch Transceiver Baseband To MAC Balun LNA Clock May be Integrated on Transceiver Die PLL Synthesizer Memory Power Managemet Loop Filter Transceiver section Transmit section Baseband section Courtesy of Agere Systems 802.11b IFE Module Courtesy of Agere Systems Courtesy of Agere Systems q q q Integrates 5 die and over 100 passives in a compact 25 mm x 25 mm BGA package Includes compartmentalized metal EMI shield Ø Separation of Tx/Rx sections and baseband Ø No EMI shield required on the system board. Fully integrated 802.11 IFE module Transfer Molded Integrated Shielding q Compatible with high volume assembly processes Eliminates requirement for shield at product level board assembly. Benefits are realized when the module is of high functionality q Meets required isolation levels for cell phone applications Requires 1/2 the area of traditional shields (.4-.5mm per side) q q 2 Turn Inductor #1 with Large Opening Shield Tabs -10 2 -30 I.L. (dB) q 2.5 3 3.5 4 4.5 5 5.5 6 6.5 baseline no runners baseline with runners -50 -70 one shield two shields -90 noise floor -110 -130 Freq (Mhz) 7 7.5 8 SiP Application Example: DC/DC Converters q Power One 15A DC/DC point of load converter Integrates full circuit including driver IC, Controller and 2 MOSFETS plus passives in a single 10mm x 12mm LGA package! Source: Power One data sheet DC/DC Converter SiP Current Solution q SiP Solution Benefits of SiP solution: Ø Ø Ø Ø Ø Reduces board area required for POL converter. Reduces external component count by 90% LGA format reduces assembly cost, improves reliability Lower total system cost. Can be mounted closer to point of load Application Example: Logic – Memory integration ASIC Memory (tested, burned-in) 1.0 - 1.5 mm BGA Pitch q q q q Passive High Density Build-up Substrate Integrates ASIC and memory devices in a single module. Memory is fully tested and burned-in in a standard CSP package. Ø q Cu Heat Spreader Lower risk and higher final test yield. Off-the-shelf memory Reduces board space by over 50%. Improved electrical performance – memory much closer to ASIC. Enables higher bus speeds SiP Application Example: Camera Modules 160 Source: Cahners InStat Total 140 120 Cell phone, PDA, Handheld PC, Security cameras Digital still cameras Million Units 100 Auto, Toys, other 80 60 40 20 0 2000 2001 2002 2003 2004 2005 Cell phones will become primary market for CMOS image sensors after 2003 Digital cameras will adopt CMOS sensors over the next few years Camera in a Package q CMOS Camera SiPs are IC packages plus: Ø Ø Ø Ø q IR glass Lens mount and barrel assembly Passives and control IC Flexible connector Fully integrated camera plus controller can be easily integrated in portable products. Ceramic Mount/lens holder Lens Barrel Exploded view of Source: Electronic Trend Publications ceramic camera module SiP Application Example: Memory Cards Memory Stick q MMC RS-MMC xD Picture Card 1GB memory card will hold: Ø Ø Ø Ø content of 16 music CDs (64MB per CD) 385 JPEG images in 5-megapixel quality 24 minutes of DVD-quality video (MPEG2) six hours of MPEG4 (384 Kbps) moving images SonyDUO Secure Digital (SD) mini-SD Flash Memory Card Hosts 2006 flash card market by application Digital Cameras 30% Compressed Audio 10% Other 4% PDA & PC 6% Industrial and Telecom 50% •Projected total flash card market in 2006 = 311 million units •About 55% to be SD card format Source: IDC Oct 2002 Memory Card Categories q Game Cards Ø Ø Ø Ø q Multimedia Cards Ø Ø Ø Ø q ROM-based 1 - 2 die solutions no SMT typically LF-based controller + Flash memory 2 - 7 die solutions 100% SMT ; COB + SMT ; 100% COB typically Laminate based I/O Cards Ø Ø Ø Ø controller + Flash memory + I/O functionality (e.g. GPS, WiFi, camera, etc.) 3+ die solutions COB + SMT LF/Laminate hybrid SOC, SiP and SOB WiFi example Circuit Design By Customer SOC MAC System on Board Diversity and T/R switches SiP RFPA PM Memory Switches DSP MAC?? RF Filter Transceiver RFPA + Baluns Transceiver Memory DSP Crystal Oscillator Power Management EMI shield Antenna Baluns + Crystal Oscillator MAC EMI shield Antenna Antenna SiP vs. SoC System LSI example Functionality (High) Development Cost (Low) Device Cost (Low) SiP üFlexibility üShort development cycle üCan integrate more memory üLow Noise üCost reduction for system SoC Flexibility (high) Development Period (Short) Installed memory capacity üHigh Performance üArea Shrink üLower Device Cost Adapted From: Renesas System-in-Package Catalog Summary q q The power of SiP is the ability to bring together many IC and packaging technologies to create highly integrated products with optimized cost, size and performance. SiP and SOC are not mutually exclusive! Ø Ø Most SiP products contain at least one SOC device In general, functions that can be economically integrated on chip should be integrated using SOC.