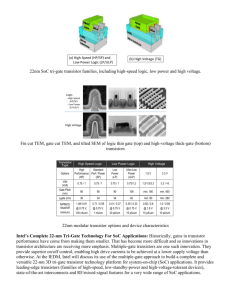

Intel`s Revolutionary 22 nm Transistor Technology

advertisement

Intel’s Revolutionary 22 nm Transistor Technology Mark Bohr Kaizad Mistry Intel Senior Fellow 22 nm Program Manager May, 2011 1 Key Messages • Intel is introducing revolutionary Tri-Gate transistors on its 22 nm logic technology • Tri-Gate transistors provide an unprecedented combination of improved performance and energy efficiency • 22 nm processors using Tri-Gate transistors, code-named Ivy Bridge, are now demonstrated working in systems • Intel is on track for 22 nm production in 2H „11, maintaining a 2-year cadence for introducing new technology generations • This technological breakthrough is the result of Intel‟s highly coordinated research-development-manufacturing pipeline • Tri-Gate transistors are an important innovation needed to continue Moore‟s Law 2 Intel Technology Roadmap Process Name P1266 P1268 P1270 P1272 P1274 Lithography 45 nm 32 nm 22 nm 14 nm 10 nm 1st Production 2007 2009 2011 2013 2015 Intel continues our cadence of introducing a new technology generation every two years 3 Traditional Planar Transistor Gate Drain High-k Dielectric Source Oxide Silicon Substrate Traditional 2-D planar transistors form a conducting channel in the silicon region under the gate electrode when in the “on” state 4 22 nm Tri-Gate Transistor Drain Gate Source Oxide Silicon Substrate 3-D Tri-Gate transistors form conducting channels on three sides of a vertical fin structure, providing “fully depleted” operation Transistors have now entered the third dimension! 5 22 nm Tri-Gate Transistor Gate Oxide Silicon Substrate Tri-Gate transistors can have multiple fins connected together to increase total drive strength for higher performance 6 22 nm Tri-Gate Transistor Gate Oxide Silicon Substrate Tri-Gate transistors can have multiple fins connected together to increase total drive strength for higher performance 7 22 nm Tri-Gate Transistor Gates Fins 8 32 nm Planar Transistors 22 nm Tri-Gate Transistors 9 Intel Transistor Leadership 2003 90 nm SiGe 2005 65 nm 2007 45 nm 2009 32 nm 2011 22 nm Invented Gate-Last High-k Metal Gate 2nd Gen. Gate-Last High-k Metal Gate First to Implement Tri-Gate SiGe Invented 2nd Gen. SiGe SiGe Strained Silicon Strained Silicon Strained Silicon High-k Metal Gate Tri-Gate 10 Std vs. Fully Depleted Transistors Bulk Transistor Gate Gate Oxide Inversion Layer Source Drain Depletion Region Silicon Substrate Silicon substrate voltage exerts some electrical influence on the inversion layer (where source-drain current flows) The influence of substrate voltage degrades electrical sub-threshold slope (transistor turn-off characteristics) NOT fully depleted 11 Std vs. Fully Depleted Transistors Partially Depleted SOI (PDSOI) Gate Floating Body Source Drain Oxide Silicon Substrate Floating body voltage exerts some electrical influence on the inversion layer, degrading sub-threshold slope NOT fully depleted Not used by Intel 12 Std vs. Fully Depleted Transistors Fully Depleted SOI (FDSOI) Gate Source Drain Extremely thin silicon layer Oxide Silicon Substrate Floating body eliminated and sub-threshold slope improved Requires expensive extremely-thin SOI wafer, which adds ~10% to total process cost Not used by Intel 13 Std vs. Fully Depleted Transistors Fully Depleted Tri-Gate Transistor Gate Oxide Silicon Fin Silicon Substrate Gate electrode controls silicon fin from three sides providing improved sub-threshold slope Inversion layer area increased for higher drive current Process cost adder is only 2-3% 14 Transistor Operation “On” Current Planar Channel Current (normalized) Threshold Voltage “Off” Current Gate Voltage (V) Operating Voltage Transistor current-voltage characteristics 15 Transistor Operation Planar Channel Current Tri-Gate (normalized) Reduced Leakage Gate Voltage (V) The “fully depleted” characteristics of Tri-Gate transistors provide a steeper sub-threshold slope that reduces leakage current 16 Transistor Operation Tri-Gate Channel Current Reduced Threshold Voltage Tri-Gate (normalized) Gate Voltage (V) Reduced Operating Voltage The steeper sub-threshold slope can also be used to target a lower threshold voltage, allowing the transistors to operate at lower voltage to reduce power and/or improve switching speed 17 Transistor Gate Delay Transistor Gate Delay Slower 32 nm Planar (normalized) Lower Voltage Operating Voltage (V) Transistor gate delay (switching speed) slows down as operating voltage is reduced 18 Transistor Gate Delay 32 nm Planar Transistor Gate Delay (normalized) 22 nm Planar Operating Voltage (V) 22 nm planar transistors could provide some performance improvement, but would still have poor gate delay at low voltage 19 Transistor Gate Delay 37% 32 nm Planar Faster Transistor Gate Delay (normalized) 22 nm Tri-Gate 18% Faster Operating Voltage (V) 22 nm Tri-Gate transistors provide improved performance at high voltage and an unprecedented performance gain at low voltage 20 Transistor Gate Delay 32 nm Planar Transistor Gate Delay (normalized) -0.2 V 22 nm Tri-Gate Operating Voltage (V) 22 nm Tri-Gate transistors can operate at lower voltage with good performance, reducing active power by >50% 21 Tri-Gate Transistor Benefits • Dramatic performance gain at low operating voltage, better than Bulk, PDSOI or FDSOI 37% performance increase at low voltage >50% power reduction at constant performance • Improved switching characteristics (On current vs. Off current) • Higher drive current for a given transistor footprint • Only 2-3% cost adder (vs. ~10% for FDSOI) Tri-Gate transistors are an important innovation needed to continue Moore‟s Law 22 22 nm Tri-Gate Circuits • 364 Mbit array size • >2.9 billion transistors • 3rd generation high-k + metal gate transistors • Same transistor and interconnect features as on 22 nm CPUs 22 nm SRAM, Sept. „09 22 nm SRAMs using Tri-Gate transistors were first demonstrated in Sept. „09 Intel is now demonstrating the world‟s first 22 nm microprocessor (Ivy Bridge) and it uses revolutionary Tri-Gate transistors 23 22 nm Manufacturing Fabs D1C Oregon Fab 28 Israel D1D Oregon Fab 32 Arizona Fab 12 Arizona 24 On-Time 2 Year Cycles 90 nm 2003 65 nm 2005 45 nm 2007 32 nm 2009 22 nm 2011 Intel continues to successfully introduce leading edge process + products on a 2 year cadence 25 Intel’s R-D-M Pipeline Research Development Manufacturing Pathfinding Copy Exactly! Bringing innovative technologies to high volume manufacturing is the result of a highly coordinated internal research-development-manufacturing pipeline 26 Key Messages • Intel is introducing revolutionary Tri-Gate transistors on its 22 nm logic technology • Tri-Gate transistors provide an unprecedented combination of improved performance and energy efficiency • 22 nm processors using Tri-Gate transistors, code-named Ivy Bridge, are now demonstrated working in systems • Intel is on track for 22 nm production in 2H „11, maintaining a 2-year cadence for introducing new technology generations • This technological breakthrough is the result of Intel‟s highly coordinated research-development-manufacturing pipeline • Tri-Gate transistors are an important innovation needed to continue Moore‟s Law 27