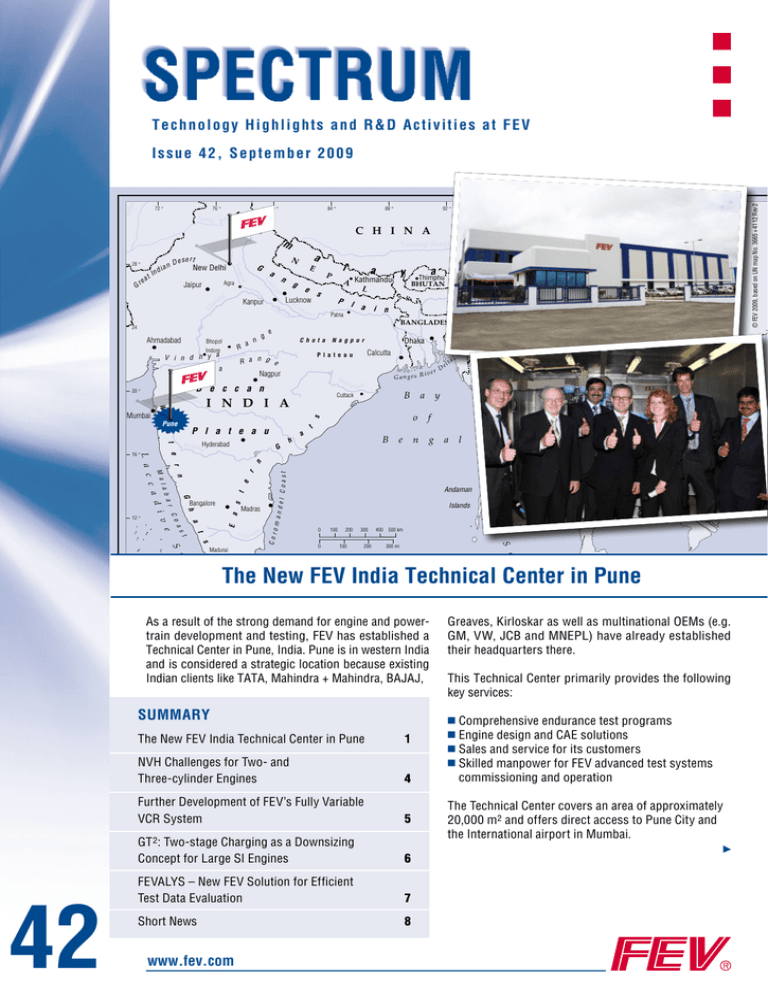

The New FEV India Technical Center in Pune

advertisement

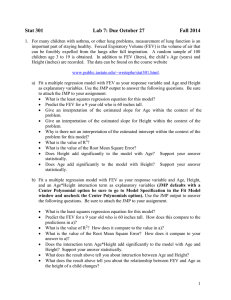

T echnology H ighlights and R&D Ac tiv ities at FEV 88 ° i In d ia n New Delhi g Ya mu n Bhopol Indore Go dav a n P l a i Patna Chota Br ahm t a ap u t r Imphal Dhaka Calcutta l ta ah a ve G anges R i n adi B Cuttack a e r D MYANMAR y f n g t o h B e a l t e n G s E a t t a s C o a h Madras Co l e ro on Madurai Andaman Islands 0 0 100 200 100 300 200 400 500 km S s S Cor om a ndel Coast r r n G a a n A n d a m e Bangalore 300 mi e e a a The New FEV India Technical Center in Pune 8° Nicobar SRI LANKA Islands Colombo 72 ° 76 ° 80 ° 84 ° 88 ° As a result of the strong demand for engine and powertrain development and testing, FEV has established a Technical Center in Pune, India. Pune is in western India and is considered a strategic location because existing Indian clients like TATA, Mahindra + Mahindra, BAJAJ, SUMMARY 42 102 ° Gauhati n Nagpur M I N D I A Krishn Hyderabad a 100 ° 28 ° s a Thimphu BHUTAN BANGLADESH Platea u D e c c a n ar i y e g P l a t e a u s 12 ° ) a A Kathmandu L e Pune a r l a b v e M a d i c a L a c 16 ° s ges l P s W Mumbai e an a R a V i n d h y a N armad a n g e R a r S a t p u Nagpur 20 ° E Lucknow (G Kanpur 98 ° Y a r l u n g Za n g bo a a bal am 24 Ahmadabad n ng Ch Ga Agra Jaipur a 96 ° C H I N A N G ana t ea 94 ° Chind wi n 28 ° e rt Des 92 ° The New FEV India Technical Center in Pune 1 NVH Challenges for Two- and Three-cylinder Engines 4 Further Development of FEV’s Fully Variable VCR System 5 GT 2: Two-stage Charging as a Downsizing Concept for Large SI Engines 6 FEVALYS – New FEV Solution for Efficient Test Data Evaluation 7 Short News 8 www.fev.com 92 ° Greaves, Kirloskar as well as multinational OEMs (e.g. GM, VW, JCB and MNEPL) have already established their headquarters there. This Technical Center primarily provides the following key services: ■ ■ ■ ■ Comprehensive endurance test programs Engine design and CAE solutions Sales and service for its customers Skilled manpower for FEV advanced test systems commissioning and operation The Technical Center covers an area of approximately 20,000 m2 and offers direct access to Pune City and the International airport in Mumbai. © FEV 2009, based on UN map No. 3665 + 4112 Rev 2 84 ° m Gr ° 80 ° H j dy 76 ° S u tl e Y am s du In 72 ° Ayeyarwa Indu s I s sue 42, September 20 09 FEV SPECTRUM Preface Dear Spectrum Reader, Preparing a vehicle to be launched in a foreign country can represent a major challenge, even when the production vehicle has been successfully launched in its home market. To ensure a successful launch, the final phase of the development process must be repeated. In addition, suppliers have to be selected, managed and qualified to consistently guarantee a high-level of quality. The influences of operating conditions and fuels have to be checked, which sometimes requires the design to be adapted as well. Market-tailored derivates are gaining increasing importance. Based on previously validated platforms, the specific requirements of the target market – in most cases also the production location – must be taken into account to be successful. India and China are examples of markets which justify an approach that includes additional development effort. FEV’s new technical center in India is ready to support you in meeting the local challenges of this emerging market. Pune is the central location for many Indian and international automotive manufacturers and is also the site of our technical center, with all the required design, calculation, testing and calibration resources at its disposal. Our local team of employees is equipped with detailed knowledge of the Indian suppliers, on-site conditions and combined with the experience of our employees in our headquarters in Aachen and the worldwide FEV technical centers. We would be glad to assist you in meeting these local challenges. Phase I of the Technical Center’s construction has been built and will be expanded to match the future requirements of the Indian OEMs. From an economic standpoint, efficient process sequencing and high plant availability are key factors for success in the construction of such a test facility. The FEV India Technical Center is equipped with our advanced testing technology that will support the endurance and development testing requirements of future engine generations. This center has attached special importance to efficient work flow as well as to the definition and organization of effective processes in the workshops and in test rig operations. All of the features of the building, the media supply services and the test rig technology were optimized for high test bench availability, including the necessary redundancies. Highly-standardized test rigs are featured that can be operated dynamically; however, the facility will also feature a design that is largely modular to accommodate conditioning units. FEV’s usual high engine and powertrain testing standards will be maintained. The test facility is configured into several interconnected wings, with a usable floor space of approximately 9,000 m2. The structure is an excellent example of state of the art test facilities, which feature containerized test benches. The well organized structure and efficient planning will ensure continuous operation of the plant, 24 hours a day / 365 days a year, with clearly defined responsibilities and work processes. Test operations started in July 2009, with two test benches. Additional test benches are currently undergoing the commissioning process and will soon be operational for clients. These test programs in the FEV India Technical Center are conducted on fullyautomated test rigs, based on the latest state of the art technology. Yours faithfully, Dr. Ernst Scheid, Executive Vice President 2 Fig. 1: P rof. Franz Pischinger, Prof. Stefan Pischinger and representatives of the Indian and European automotive industry after “Lighting Lamp”, an Indian ceremony marking the beginning of new projects FEV SPECTRUM The center was inaugurated by Prof. Dr. Franz Pischinger – Chairman FEV Group Worldwide and other top FEV officials on July 2nd. The FEV India Technical Center provides tremendous support to automotive OEMs, fuel research labs, R&D centers and component suppliers in India. This was evident by their presence in large numbers during FEV India’s Technical Center Inauguration held on July 2nd and during the “1st FEV India Day of Powertrain” held on July 3, 2009. Fig. 2: “Coconut Breaking”, a traditional Indian inauguration ceremony for good luck, celebrated by Prof. Stefan Pischinger and Sushil Berry (Managing Director FEV India) Fig. 3: Phase I of the new facility buildings in Pune, India FACTS AND HIGHLIGHTS OF THE NEW TECHNICAL CENTER The Phase I of FEV India Technical Center includes: T hree steady state engine test rigs are setup for performance Tests including emissions measurement for engines up to 400 kW ■ One transient dyno test rig for performance evaluation including emissions measurement for engines up to 250 kW ■ Two durability test rigs of up to 130 kW ■ Two Commissioning test rigs ■ Assembly / workshop / operating shops, laboratories and offices ■ Design center ■ Local construction of FEV Test Systems ■ ■ Continuous operation 24 hours a day / 365 days a year utomatic safety monitoring of defined shut-off limits A Large number of measuring channels Potential for data pick-up from the Engine Control Unit (ECU) ■ Possibility for loading auxiliary units ■ Possibility for analyzing the raw exhaust gas concentrations during the test cycle ■ Availability of independent cooling systems (hot/cold) for fast thermal cycles ■ Analysis of all operating liquids (< 24 hour response time) ■ Use of conventional fuels or special fuels ■ Extensive ratings for all tested engine parts, including photographic documentation ■ Comprehensive reporting on progress and failures, if applicable ■ ■ ■ 3