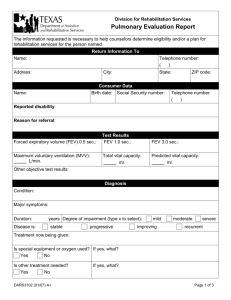

The New FEV Durability Test Center

advertisement