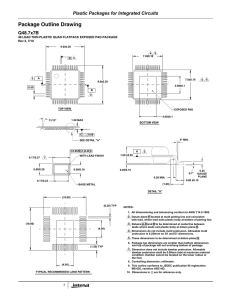

98ASA99196D, 1336-01, 1336, 52 Lead, LQFP, JEDEC MS

advertisement

4X AB 4X 13 TIPS 0.20 H A–B D X=A, B OR D X 0.20 C A–B D D AB 52 CL 40 1 39 e 48X B VIEW Y VIEW Y E1 E b1 A E1/2 13 PLATING E/2 27 14 8 26 BASE METAL 8 ÇÇÇ ÉÉÉ ÉÉÉ ÇÇÇ c c1 8 b 8 D1/2 SECTION AB–AB D/2 ROTATED 90_ CLOCKWISE D1 D H 0.08 C J b C A–B D 52X C 52X Z2 4X A SEATING PLANE 0.08 M 4X J Z3 VIEW AA S Z1 R1 A2 Z A1 R2 G L L1 VIEW AA F EXPOSED PAD VIEW J–J NOTES: 1. ALL DIMENSIONS ARE IN MILLIMETERS. 2. INTERPRET DIMENSIONS AND TOLERANCES PER ASME Y14.5M, 1994. 3. DATUMS A, B AND D TO BE DETERMINED AT DATUM PLANE H. 4. DIMENSIONS D AND E TO BE DETERMINED AT SEATING PLANE C. 5. DIMENSION b DOES NOT INCLUDE DAMBAR PROTRUSION. ALLOWABLE DAMBAR PROTRUSION SHALL NOT CAUSE THE LEAD WIDTH TO EXCEED THE MAXIMUM b DIMENSION BY MORE THAN 0.08 mm. DAMBAR CANNOT BE LOCATED ON THE LOWER RADIUS OR THE FOOT. MINIMUM SPACE BETWEEN PROTRUSION AND ADJACENT LEAD OR PROTRUSION 0.07 mm. 6. DIMENSIONS D AND E1 DO NOT INCLUDE MOLD PROTRUSION. ALLOWABLE PROTRUSION IS 0.25mm PER SIDE. D1 AND E1 ARE MAXIMUM PLASTIC BODY SIZE DIMENSIONS INCLUDING MOLD MISMATCH. 7. EXACT SHAPE OF EACH CORNER IS OPTIONAL. 8. THESE DIMENSIONS APPLY TO THE FLAT SECTION OF THE LEAD BETWEEN 0.1 mm AND 0.25 mm FROM THE LEAD TIP. DIM A A1 A2 b b1 c c1 D D1 e E E1 L L1 R1 R2 S F G Z Z1 Z2 Z3 MILLIMETERS MIN MAX ––– 1.70 0.05 0.20 1.30 1.50 0.271 0.334 0.27 0.33 0.123 0.136 0.122 0.132 12.00 BSC 10.00 BSC 0.65 BSC 12.00 BSC 10.00 BSC 0.45 0.75 1.00 REF 0.08 ––– 0.08 0.20 0.20 ––– 6.50 7.50 6.50 7.50 0_ 7_ ––– 0_ 11_ 13 _ 11_ 13 _ CASE 1336–01 ISSUE O DATE 01/11/01