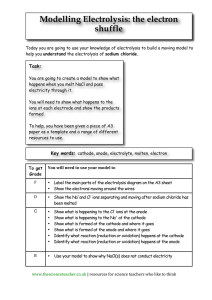

The x-ray tube - Dr. Mohsen Dashti

advertisement

The x-ray tube By Dr. Mohsen Dashti 357 Radiologic Imaging & Processing Lecture notes # 3 Lecture outline • The cathode assembly. • The anode assembly. • The glass envelope. • Protective housing. The cathode assembly • It is a fact that in order to produce x-rays three major elements MUST take place: 1. A source of electrons. 2. An appropriate target material. 3. A high voltage and vacuum presence. - The x-ray tube is the environment that permits these conditions to exist and with it allow x-ray photons to come into existence. The cathode assembly • The x-ray tube consists of cathode and an anode enclosed within glass envelope and then encased in a protective housing making up the necessary elements to produce x-rays. • The cathode: - The cathode is the negative side of the x-ray tube that consists of filament(s), focusing cup and loops of wires. The cathode assembly • The cathode has three major functions: 1. Produce thermionic cloud. 2. Conduct the high voltage to the gap between cathode and anode. 3. Focus the electron stream as it heads for the anode. - The filament within the focusing cup of the cathode assembly is a small coil of thin tungsten wire. Why tungsten? -- Because it has high melting point (3,370oC) and very difficult to vaporize or turn into gas. The cathode assembly - The high melting point available in the tungsten wire permits the filament to operate at the high temperatures required of an x-ray tube. - Tungsten wires make the filament which provides sufficient resistance to the flow of electrons so that heat produced will cause thermionic emission to occur. - And since a tungsten filament do not exhibit significant thermionic emission below 2,200oC then this will cause electrons to leave the surface of the filament wire and form the necessary thermionic cloud that will be driven towards the anode target where x-ray photons will be produced. The cathode assembly • Continuous production of thermionic clouds by the filament will eventually cause vaporization of the tungsten wires that contribute to the reduction of vacuum capability of an x-ray tube. • Vaporization of tungsten wires is also gradually deposited on the inner surface of the glass envelope, causing old tubes to have mirrored appearance and high-voltage arcing that eventually will destroy the x-ray tube. • Vaporization will cause the filament to break over time similar to a light bulb with continuous usage. The cathode assembly • The filament is housed in a shallow depression in the cathode assembly known as focusing cup. • Focusing cup is made of nickel and its main purpose is to narrow the thermionic cloud as it is driven toward the anode. • Focusing cup helps the negative electrons to travel into straight line toward the anode instead of diverging into different lines because of their similar charges. The anode assembly • The anode is the positive side of the x-ray tube and has three major functions: 1. Serves as a target surface for the high-voltage electrons from the filament, thereby becoming the source of the x-ray photons. 2. Conducts the high-voltage from the cathode back into the x-ray generator circuitry. 3. Serves as the primary thermal conductor. The anode assembly • The anode assembly consists of the anode, stator and rotor. 1. The anode: - Anodes are divided into stationary and rotating. The rotating anodes turn during the exposure, thus presenting a much larger target area. The faster the anode rotates, the better the heat dissipation that help in preserving a longer tube life. How?... - Stationary anodes have become of less use and limited to low-power functions, such as dental units. The anode assembly • Rotating anode disks range from 5-12 cm in diameter and are composed of molybdenum. • Molybdenum is a group of 6 chemical element that does not occur as free metal in nature and has the ability to stand high-voltage. • For the reason it is used in the make up of anode disks to help dissipate heat in heavy load situations. • Specialized x-ray tubes for mammography utilize molybdenum as the primary material due to its ability to emit a more uniform range of lower energy photons. The anode assembly • One major problem in the anode assembly is the use of line-focus principle, which in fact permits the best resolution of detail while permitting as large an actual area as possible to increase thermal conductivity. So where is the problem? - Anode Heel Effect. - Because of the geometry of an angled anode target, the radiation intensity is greater on the cathode side. - This allows the cathode end to have 20% more photons and 25% less photons at the anode end, a total of 45% variation exists parallel to the anode-cathode axis. The anode assembly • Anode Heel Effect: - The 45% variation is significant enough to cause a visible difference in film density during radiographic examinations when large film sizes are used at short distances. - Because the cathode end of the x-ray tube has a more intense beam, it should be positioned toward the denser (thicker) part of the body. The anode assembly 2. The stator: - The stator is the induction-motor electromagnet that turns the anode and is the only part of the cathode or anode assemblies that is located outside the vacuum of the glass envelope. - If the stator fails, the rotor will cease to turn the anode, resulting in immediate melting of a spot on the target that will damage the anode. 3. The Rotor: - The rotor is located inside the stator and inside the glass envelope. It is composed of a hallow copper cylinder attached to the anode disk and affected by the electromagnetic field of the stator, causing the anode to turn. The anode assembly • The rotor contains silver plated steel ball bearings that help the anode to turn. When these bearings go bad caused by long use at high temperature, they become imperfectly round. This leads to grinding noise and wobbling of the rotor that eventually throws the focal track of the anode off center and tube efficiency drops dramatically. • Another effect of stator or rotor failure is that the electron stream overheats the target area of the anode focal track. The glass envelope • The entire cathode and anode assemblies except the stator are enclosed within a glass envelope commonly called the tube. The glass envelope • A common glass envelope is made by sculpting several different types heat-resistant Pyrex glass. • The primary function of the glass envelope is to maintain the vacuum between the cathode and the anode. • After construction, the air is removed from the tube by the use of special vacuum and then permanently sealed. • The removal of air permits electrons to flow from cathode to anode without encountering the gas atoms of air and greatly increases the efficiency of x-ray tube operation. Protective housing • Modern x-ray tubes must be mounted inside a protective housing that controls leakage and scatter radiation as well as isolates the high voltages and provides a means to cool the x-ray tube. A: anode B: Expansion bellows (provide space for oil to expand) C: cathode (and heating-coil) E: tube envelope (evacuated) H: tube housing O: cooling dielectric oil R: rotor S: induction stator T: anode target W: tube window Time to relax