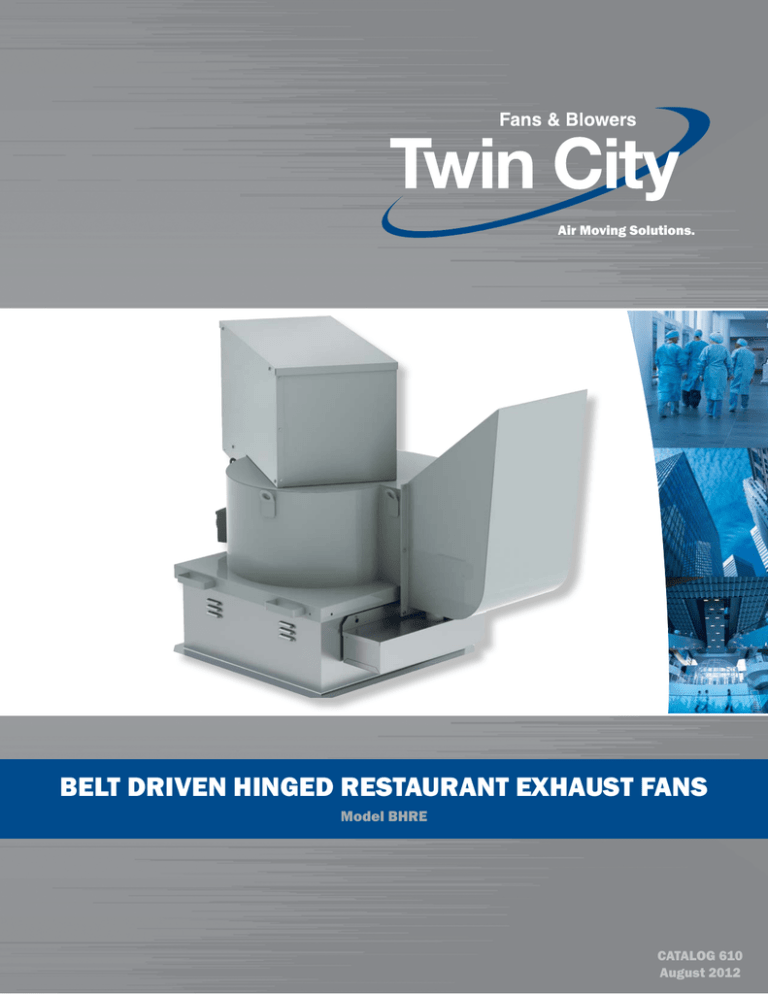

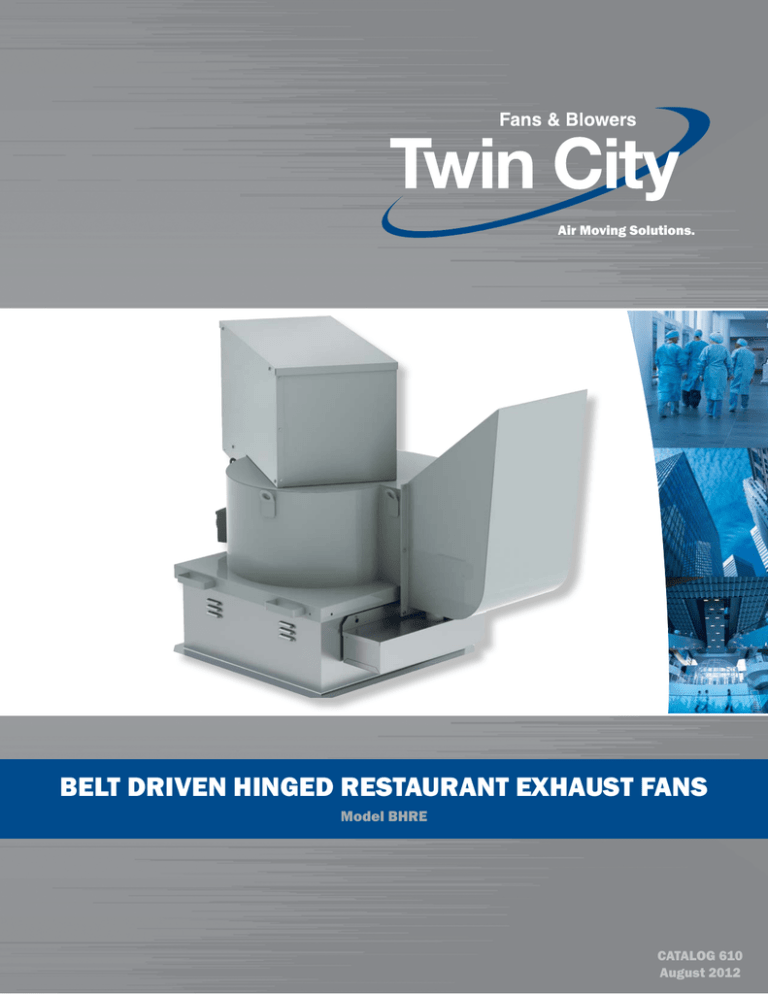

Air Moving Solutions.

Belt driven hinged Restaurant Exhaust Fans

Model BHRE

CATALOG 610

August 2012

RestaurantExhaustFans

Model BHRE

Hinged Restaurant Exhaust Fans

Twin City Fan’s belt driven hinged rooftop exhaust

fan, model BHRE, is designed specifically for roof

mounted applications handling grease laden air and

elevated temperatures from kitchens, restaurants,

cooking and dishwasher hoods. The compact, low

profile design hinges on the roof curb to provide easy

access for cleaning and maintenance of the unit.

BHRE fans feature fully welded, non-overloading backward inclined centrifugal wheels designed for maximum efficiency and quiet operation. All wheels are

statically and dynamically balanced. Units are manufactured under strict quality assurance standards to

ensure catalogued performance and years of troublefree operation.

Capabilities

BHRE fans are available in 9 sizes, ranging from

10.5” through 24.50” wheel diameters. Performance

capabilities include a broad capacity range from 300

to 9,000 CFM and static pressure capabilities up to

5 inches w.g. The BHRE is capable of handling airstream temperatures of 400oF continuous.

Sizes

10.5" to 24.50" wheel diameters

Performance

Airflow to 9,000 CFM

Static pressure to 5 inches w.g.

Drive Configuration

Available in belt driven configuration

Model BHRE is UL/cUL 705 listed for electrical,

File No. E158680. Model BHRE is UL/cUL 762

listed for the exhaust of grease-laden air, File

No. E158680.

2

Twin City Fan Catalog 610

Twin City Fan & Blower certifies that the

Model BHRE Hinged Restaurant Exhaust

Fans shown herein are licensed to bear

the AMCA Seal. The ratings shown are

based on tests and procedures performed

in accordance with AMCA Publication 211

and AMCA Publication 311 and comply with the requirements of the AMCA

Certified Ratings Program. See Twin City

Fan & Blower Fan Selector© Program for

sound ratings.

ConstructionFeatures

Housing

Housing is constructed of heavy gauge steel and is

continuously welded on top and bottom to prevent

grease leakage. Lifting lugs are welded to the housing

as standard.

Drive Assembly

Adjustable pitch V-belt drives with cast iron sheaves

and heat resistant belts are selected at 150% of the

driven motor horsepower.

Discharge Scoop

The discharge scoop is sealed to the fan housing with

a high temperature gasket to prevent grease leakage

onto the roof. It can be easily removed for cleaning

and maintenance. A 2” NPT drain is welded to the

bottom of the scoop to allow for grease to be collected in a grease trough or piped and collected at

remote location (local codes may vary).

Drive Assembly

Motor Cover

Encloses the motor, drives and bearings from the

elements. Vents allow ambient air in to cool motor,

drives and bearings. The top panel of the motor cover

is removed with simple hand tools for maintenance

and inspection of motor and drive components.

Curb Cap

The curb cap is constructed of heavy gauge steel and

is continuously welded. Mounting holes in the curb

cap are prepunched to ensure correct attachment to

the roof curb. A curb hinge is provided as standard.

Curb caps are complete with stops at the corners to

prevent over rotation and handles to assist with lifting.

Motor Cover

Discharge Scoop

Disconnect Switch

Standard on all units. Fans are provided with a NEMA-3R

type disconnect switch mounted to the outside of the

fan housing. Switches are prewired from the motor.

Drive Frame

Vibration isolators support and isolate the motor, shaft,

bearings and wheel assembly from the unit, reducing

noise transmission into the ductwork.

Curb Cap & NEMA-3R Disconnect Switch

Wheel

Backward inclined wheel is non-overloading and constructed of heavy gauge steel. Wheel is fully welded

and includes fins on the backplate to draw cool air

across the motor, drives and bearings.

Bearings

Heavy duty grease lubricated pillow block bearings

complete with zerk fittings for simple and easy lubrication. Bearings have been selected to have an L-10

life in excess of 100,000 hours.

©2012 Twin City Fan Companies, Ltd., Minneapolis, MN. All rights

reserved. Catalog illustrations cover the general appearance of Twin City

Fan & Blower products at the time of publication and we reserve the right

to make changes in design and construction at any time without notice.

www.tcf.com

3

ProductAccessories

Swingout Wheel Design

Available as an optional construction, the swingout

wheel design allows for the wheel to pivot out of the

fan housing for simple cleaning and maintenance. A

rod prop is standard with the swingout wheel option

to keep the assembly open as well as a lockable

hasp. See page 5 for more details on the swingout

wheel option.

Scroll Access Door

A bolted access door on the fan scroll is available to

provide access to the wheel for cleaning and inspection.

A high temperature gasket seals the access door to

the scroll.

Grease Box

The heavy gauge galvanized grease box is designed

to trap the grease in and allow the water to run off

onto the roof.

Grease Box

Auto Belt Tensioner

The auto belt tensioner keeps constant tension on

the belt which reduces slippage and extends belt life.

Available with single-groove drives only.

NEMA-4 Weatherproof Disconnect Switches

A NEMA-4, water and dust tight disconnect is available mounted and prewired from the motor.

Vented Curb Extension

NEMA-4 Disconnect Switch

Prefabricated Roof Curbs

Extensions work to extend the height of the roof

curb and fan discharge. Extensions are sized to meet

NFPA discharge height requirements of 40” above the

roof with an 12” tall roof curb. Standard curb extension is galvanized steel.

Extended Discharge

For applications where it is required to increase the

discharge height of the unit due to local codes or

close proximity to the inlets of supply units, an extended discharge is available. On fan sizes 150 and

above, an access door on the top of the fan housing

is standard to provide access to the inside of the

housing for cleaning.

Prefabricated Roof Curbs

Extended Discharge

Prefabricated roof curbs are available in heavy duty

galvanized steel or aluminum construction, in heights

of 8", 12", or 18". The standard curb (vented self

flashing) is provided with a 3/16" polystyrene gasket.

The standard self flashing curb design features continuously welded seams for added rigidity and moisture

protection. Prefabricated curbs are also available in

raised cant, pitched and peak models. Refer to Catalog 4910 for complete details on roof curb options.

Special Coatings

Available coatings include air-dried enamel, air-dried

epoxy, and Heresite (air-dried phenolic). Contact your

Twin City Fan & Blower representative for more information on available coatings and colors.

4

Twin City Fan Catalog 610

ProductAccessories

BHRE

Swingout Wheel

Swingout wheel assembly

is sealed to fan housing

with high temperature

gasketing

Lifting handle assists in raising the

counter-balanced swingout wheel

assembly

Rod prop supports the wheel

and keeps it open during

cleaning and inspection

Swingout wheel is secured

to fan housing on welded

studs, and wingnuts make

for simple removal without

the need for hand tools

Security hasp for use

with padlock (by others)

Complete access to

wheel and inside of fan

housing for cleaning

www.tcf.com

5

PerformanceData

Size 105

CFM

OV

261

392

522

653

784

914

1045

1175

1306

1437

1567

1698

400

600

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

0.25" SP

RPM BHP

874 0.02

1032 0.03

1220 0.05

1431 0.08

1653 0.13

1879 0.19

2111 0.26

2344 0.36

2582 0.48

2821 0.62

3061 0.79

3303 1.00

Wheel Diameter: 10.50"

0.5" SP

RPM BHP

1150 0.04

1258 0.06

1417 0.08

1597 0.12

1797 0.17

2009 0.23

2229 0.32

2452 0.42

2680 0.54

2912 0.69

3145 0.87

3381 1.08

Size 122

CFM

OV

344

516

688

860

1032

1204

1376

1548

1720

1892

2064

2236

400

600

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

0.25" SP

RPM BHP

719 0.02

836 0.04

990 0.07

1152 0.10

1323 0.16

1501 0.23

1684 0.32

1870 0.43

2058 0.57

2248 0.75

2439 0.95

2630 1.19

CFM

OV

418

626

835

1044

1253

1462

1670

1879

2088

2297

2506

2714

400

600

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

1960

2041

2153

2300

2467

2645

2831

3031

3240

3452

3671

0.18

0.22

0.28

0.35

0.43

0.53

0.65

0.80

0.98

1.18

1.41

2241

2301

2396

2517

2667

2835

3010

3195

3390

3593

0.25

0.30

0.37

0.44

0.54

0.65

0.79

0.94

1.12

1.33

Wheel Diameter: 12.25"

2496

2538

2619

2725

2854

3011

3179

3355

3539

0.32

0.39

0.46

0.55

0.65

0.78

0.92

1.09

1.28

2759

2826

2922

3036

3176

3336

3507

0.48

0.56

0.66

0.77

0.91

1.06

1.24

2966

3022

3107

3212

3338

3486

3651

0.57

0.67

0.77

0.90

1.04

1.20

1.39

Outlet Area: 0.86 ft2

1034

1149

1296

1454

1617

1787

1962

2142

2324

2509

2696

0.07

0.10

0.15

0.21

0.28

0.38

0.50

0.65

0.83

1.04

1.29

1438

1543

1671

1821

1979

2140

2304

2473

2646

2823

0.19

0.24

0.31

0.41

0.52

0.66

0.82

1.02

1.24

1.50

1703

1771

1876

1999

2142

2297

2456

2617

2781

2948

0.29

0.35

0.43

0.53

0.66

0.82

1.00

1.21

1.45

1.72

1984

2067

2174

2298

2438

2591

2749

2909

3070

0.47

0.56

0.67

0.81

0.97

1.17

1.40

1.66

1.95

Wheel Diameter: 13.50"

2195

2246

2341

2451

2576

2717

2869

3026

0.60

0.70

0.82

0.96

1.14

1.35

1.59

1.87

2423

2498

2600

2713

2841

2983

3135

3162

3207

3283

3381

3496

3631

0.67

0.78

0.89

1.02

1.18

1.35

3348

3385

3451

3542

3650

0.77

0.89 3554 1.01

1.01 3613 1.14

1.16

1.32

Fan Efficiency Grade = FEG71

0.85

0.97

1.13

1.31

1.53

1.78

2.08

2599

2650

2741

2847

2965

3096

1.01

1.14

1.30

1.49

1.72

1.98

Outlet Area: 1.04 ft2

2802

2877

2977

3087

1.32 2953 1.50 3103 1.70

1.48 3010 1.67 3142 1.87

1.68 3101 1.88

1.92

Fan Efficiency Grade = FEG71

0.5" SP

1" SP

1.5" SP

2" SP

2.5" SP

3" SP

3.5" SP

4" SP

4.5" SP

5" SP

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

938

1042

1175

1320

1467

1620

1780

1943

2108

2276

2445

0.08

0.12

0.18

0.25

0.35

0.46

0.61

0.79

1.01

1.27

1.57

1305

1400

1516

1652

1795

1941

2090

2243

2401

2560

0.22

0.29

0.38

0.49

0.63

0.80

1.00

1.23

1.51

1.82

1546

1607

1702

1814

1943

2084

2228

2374

2523

2674

0.35

0.42

0.52

0.65

0.80

0.99

1.21

1.47

1.76

2.09

1800

1876

1973

2084

2212

2351

2494

2639

2785

0.57

0.68

0.81

0.98

1.18

1.42

1.70

2.02

2.37

1992

2038

2124

2224

2337

2465

2603

2746

0.73

0.85

0.99

1.17

1.38

1.64

1.93

2.27

2199

2267

2358

2461

2577

2706

2844

Maximum outlet velocity for restaurant applications is 1800 fpm.

Performance certified is for installation Type A: free inlet, free outlet.

Power rating (BHP) does not include transmission losses.

Performance ratings include the effects of a discharge scoop.

6

Fan Efficiency Grade = FEG71

1.5" SP

2" SP

2.5" SP

3" SP

3.5" SP

4" SP

4.5" SP

5" SP

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

0.5" SP

1" SP

1.5" SP

2" SP

2.5" SP

3" SP

3.5" SP

4" SP

4.5" SP

5" SP

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Size 135

0.25" SP

RPM BHP

653 0.03

758 0.05

898 0.08

1045 0.12

1200 0.19

1362 0.27

1527 0.38

1696 0.52

1867 0.70

2039 0.90

2212 1.15

2386 1.44

1" SP

RPM BHP

1581 0.08

1642 0.11

1747 0.15

1894 0.19

2065 0.25

2245 0.33

2442 0.42

2648 0.53

2863 0.67

3082 0.83

3304 1.02

3530 1.24

Outlet Area: 0.65 ft2

Twin City Fan Catalog 610

1.03

1.18

1.37

1.59

1.85

2.16

2.52

2358

2405

2487

2583

2690

2808

1.23

1.39

1.58

1.81

2.09

2.40

2542

2610

2700

2800

1.60 2679 1.82 2815 2.06

1.80 2731 2.03 2851 2.28

2.04 2813 2.28

2.32

CFM

OV

516

773

1031

1289

1547

1805

2062

2320

2578

2836

3094

3351

400

600

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

0.25" SP

RPM BHP

587 0.03

682 0.06

808 0.10

941 0.15

1080 0.23

1226 0.34

1375 0.47

1527 0.65

1680 0.86

1835 1.12

1991 1.42

2147 1.78

Wheel Diameter: 15.00"

CFM

OV

624

936

1248

1560

1872

2184

2496

2808

3120

3432

3744

4056

400

600

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

844

938

1058

1188

1321

1458

1602

1748

1898

2049

2201

0.10

0.15

0.22

0.31

0.43

0.57

0.76

0.98

1.25

1.57

1.94

CFM

OV

772

1158

1544

1930

2316

2702

3088

3474

3860

4246

4632

5018

400

600

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

1175

1260

1365

1487

1616

1747

1881

2019

2161

2305

0.28

0.36

0.47

0.61

0.78

0.99

1.23

1.52

1.86

2.25

1391

1446

1532

1633

1749

1876

2006

2137

2271

2407

0.43

0.52

0.64

0.80

0.99

1.23

1.50

1.81

2.17

2.58

1620

1688

1776

1876

1991

2116

2245

2375

2507

0.70

0.83

1.00

1.21

1.46

1.76

2.10

2.49

2.93

Wheel Diameter: 16.50"

1792

1834

1912

2001

2103

2218

2342

2471

0.91

1.04

1.22

1.44

1.70

2.02

2.38

2.80

1979

2040

2123

2215

2320

2435

2560

1.27

1.46

1.69

1.96

2.29

2.67

3.11

2123

2164

2238

2325

2421

2528

1.52

1.71

1.95

2.24

2.58

2.97

Outlet Area: 1.56 ft2

2288

2349

2430

2520

1.98 2411 2.25 2534 2.55

2.22 2458 2.51 2566 2.81

2.52 2532 2.82

2.87

Fan Efficiency Grade = FEG67

0.5" SP

1" SP

1.5" SP

2" SP

2.5" SP

3" SP

3.5" SP

4" SP

4.5" SP

5" SP

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

767

853

962

1080

1201

1326

1456

1590

1725

1862

2001

0.13

0.18

0.27

0.38

0.52

0.69

0.91

1.19

1.51

1.89

2.34

Size 182

0.25" SP

RPM BHP

473 0.05

558 0.08

657 0.14

766 0.22

881 0.32

999 0.47

1121 0.66

1244 0.90

1369 1.19

1495 1.54

1621 1.96

1748 2.45

Fan Efficiency Grade = FEG67

0.5" SP

1" SP

1.5" SP

2" SP

2.5" SP

3" SP

3.5" SP

4" SP

4.5" SP

5" SP

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Size 165

0.25" SP

RPM BHP

534 0.04

620 0.07

735 0.12

855 0.19

982 0.28

1115 0.41

1250 0.57

1388 0.78

1528 1.04

1669 1.35

1810 1.72

1953 2.16

Outlet Area: 1.29 ft2

PerformanceData

Size 150

1068

1146

1241

1352

1469

1588

1710

1836

1964

2096

0.34

0.43

0.57

0.74

0.95

1.20

1.49

1.84

2.25

2.73

1265

1315

1393

1484

1590

1705

1824

1943

2064

2189

0.52

0.63

0.78

0.96

1.20

1.48

1.82

2.19

2.63

3.13

1473

1535

1614

1706

1810

1924

2041

2159

2279

0.85

1.01

1.21

1.46

1.77

2.13

2.54

3.01

3.54

Wheel Diameter: 18.25"

0.5" SP

RPM BHP

634 0.10

681 0.14

767 0.21

862 0.31

965 0.43

1075 0.60

1189 0.80

1306 1.05

1425 1.36

1547 1.73

1669 2.17

1793 2.68

1630

1668

1738

1820

1912

2017

2130

2247

1.10

1.27

1.48

1.75

2.06

2.44

2.89

3.39

1799

1854

1930

2014

2109

2214

2327

1.54

1.76

2.04

2.38

2.77

3.23

3.76

1930

1967

2035

2114

2201

2298

1.83

2.07

2.36

2.71

3.12

3.59

Outlet Area: 1.93 ft2

2080

2136

2210

2291

2.39 2192 2.73 2304 3.08

2.69 2234 3.04 2333 3.40

3.05 2302 3.41

3.47

Fan Efficiency Grade = FEG71

1" SP

1.5" SP

2" SP

2.5" SP

3" SP

3.5" SP

4" SP

4.5" SP

5" SP

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

901

947

1024

1117

1213

1314

1421

1532

1645

1761

1879

0.30

0.38

0.50

0.66

0.86

1.10

1.38

1.73

2.13

2.59

3.14

1088

1113

1166

1243

1335

1429

1527

1630

1738

1848

1961

0.48

0.59

0.72

0.89

1.13

1.40

1.72

2.09

2.53

3.03

3.61

1251

1268

1302

1362

1442

1534

1628

1725

1826

1931

2039

0.68

0.81

0.98

1.15

1.40

1.71

2.06

2.47

2.94

3.48

4.08

1407

1432

1477

1544

1627

1720

1814

1910

2010

2114

1.05

1.24

1.45

1.69

2.01

2.41

2.85

3.35

3.92

4.57

1536

1555

1588

1645

1717

1804

1897

1991

2088

1.31

1.52

1.76

2.02

2.33

2.75

3.24

3.77

4.38

1655

1670

1697

1742

1806

1885

1974

2068

1.57

1.81

2.08

2.37

2.69

3.10

3.62

4.20

1779

1801

1838

1894

1964

2048

2.12

2.41

2.74

3.08

3.48

4.00

1882

1902

1931

1979

2043

2.43

2.75

3.11

3.48

3.89

1980

1997

2022

2063

2.76

3.10

3.48

3.90

Maximum outlet velocity for restaurant applications is 1800 fpm.

Performance certified is for installation Type A: free inlet, free outlet.

Power rating (BHP) does not include transmission losses.

Performance ratings include the effects of a discharge scoop.

www.tcf.com

7

PerformanceData

Size 200

CFM

OV

927

1391

1854

2318

2782

3245

3709

4172

4636

5100

5563

6027

400

600

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

0.25" SP

RPM BHP

432 0.06

510 0.10

599 0.16

699 0.26

804 0.39

912 0.56

1023 0.79

1135 1.07

1249 1.43

1364 1.85

1479 2.35

1595 2.94

Wheel Diameter: 20.00"

CFM

OV

1148

1721

2295

2869

3443

4017

4590

5164

5738

6312

6886

7459

400

600

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

1" SP

1.5" SP

2" SP

2.5" SP

3" SP

3.5" SP

4" SP

4.5" SP

5" SP

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

0.5" SP

RPM BHP

520 0.15

559 0.21

629 0.32

707 0.46

792 0.65

882 0.89

975 1.19

1071 1.57

1169 2.03

1269 2.58

1369 3.22

1471 3.98

1" SP

1.5" SP

2" SP

2.5" SP

3" SP

3.5" SP

4" SP

4.5" SP

5" SP

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

CFM

OV

1391

2087

2782

3478

4174

4869

5565

6260

6956

7652

8347

9043

400

600

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

822

864

934

1019

1106

1199

1296

1398

1501

1607

1715

0.36

0.46

0.60

0.80

1.03

1.32

1.66

2.07

2.55

3.12

3.77

993

1016

1064

1135

1218

1304

1394

1488

1586

1686

1790

0.58

0.71

0.86

1.07

1.35

1.68

2.07

2.52

3.04

3.64

4.34

1141

1157

1188

1243

1316

1400

1485

1574

1666

1762

1861

0.81

0.98

1.17

1.38

1.68

2.05

2.47

2.97

3.53

4.18

4.91

Wheel Diameter: 22.25"

Size 245

0.25" SP

RPM BHP

353 0.09

416 0.15

489 0.25

570 0.39

656 0.58

744 0.85

835 1.19

927 1.61

1020 2.14

1113 2.77

1207 3.53

1302 4.41

739

777

840

916

995

1078

1165

1256

1350

1445

1541

0.45

0.57

0.74

0.98

1.28

1.63

2.05

2.56

3.16

3.86

4.66

893

913

957

1020

1095

1172

1253

1337

1425

1516

1608

0.71

0.88

1.07

1.33

1.67

2.08

2.56

3.11

3.76

4.51

5.36

1026

1040

1068

1117

1183

1258

1335

1415

1497

1584

1.01

1.21

1.45

1.71

2.08

2.54

3.06

3.68

4.37

5.17

Wheel Diameter: 24.50"

0.5" SP

RPM BHP

472 0.18

507 0.26

571 0.38

642 0.56

719 0.78

801 1.08

886 1.45

973 1.90

1062 2.46

1152 3.12

1243 3.90

1336 4.83

1284

1306

1348

1409

1485

1569

1655

1743

1835

1929

1.26

1.49

1.74

2.03

2.42

2.89

3.42

4.03

4.72

5.48

1401

1419

1449

1501

1567

1646

1731

1817

1905

1.57

1.82

2.11

2.42

2.80

3.30

3.89

4.53

5.26

1510

1524

1548

1590

1648

1720

1802

1887

1.89

2.17

2.50

2.85

3.23

3.73

4.35

5.04

Outlet Area: 2.87 ft2

1154

1174

1212

1267

1335

1411

1488

1567

1.56

1.84

2.16

2.51

2.99

3.58

4.24

4.99

1260

1276

1303

1349

1409

1480

1556

1.94

2.26

2.62

3.00

3.47

4.09

4.81

1357

1370

1392

1429

1482

1546

1620

1623

1644

1677

1728

1792

1869

2.54

2.89

3.29

3.69

4.18

4.81

1717

1735

1762

1806

1864

2.92

3.30

3.73

4.18

4.67

1807

1822

1845

1882

3.31

3.72

4.18

4.68

Fan Efficiency Grade = FEG71

2.34

2.69

3.09

3.52

4.00

4.61

5.38

Outlet Area: 3.48 ft2

1459

1478

1507

1553

1611

3.14

3.58

4.07

4.57

5.17

1544

1560

1584

1623

3.61 1624 4.10

4.09 1638 4.61

4.62 1659 5.18

5.17

Fan Efficiency Grade = FEG71

1" SP

1.5" SP

2" SP

2.5" SP

3" SP

3.5" SP

4" SP

4.5" SP

5" SP

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

671

705

763

832

903

979

1058

1141

1226

1312

1400

0.54

0.69

0.90

1.19

1.55

1.98

2.49

3.11

3.84

4.68

5.66

811

829

869

926

994

1065

1138

1214

1294

1376

1461

0.86

1.07

1.30

1.61

2.03

2.52

3.10

3.77

4.56

5.46

6.51

932

944

970

1015

1074

1142

1212

1285

1360

1438

1519

1.22

1.47

1.76

2.08

2.51

3.07

3.71

4.46

5.30

6.26

7.36

1048

1066

1101

1150

1212

1281

1351

1423

1498

1575

1.90

2.23

2.62

3.04

3.62

4.34

5.14

6.05

7.08

8.23

1144

1158

1183

1225

1279

1344

1413

1483

1555

Maximum outlet velocity for restaurant applications is 1800 fpm.

Performance certified is for installation Type A: free inlet, free outlet.

Power rating (BHP) does not include transmission losses.

Performance ratings include the effects of a discharge scoop.

8

Fan Efficiency Grade = FEG71

0.5" SP

RPM BHP

578 0.12

622 0.17

700 0.26

787 0.37

881 0.52

981 0.72

1085 0.96

1192 1.27

1301 1.64

1411 2.08

1523 2.60

1636 3.21

Size 222

0.25" SP

RPM BHP

388 0.07

458 0.12

539 0.20

628 0.32

722 0.48

820 0.70

919 0.98

1020 1.33

1123 1.77

1226 2.29

1330 2.91

1434 3.64

Outlet Area: 2.32 ft2

Twin City Fan Catalog 610

2.35

2.73

3.17

3.63

4.20

4.96

5.83

6.80

7.89

1233

1244

1264

1298

1346

1404

1471

1540

2.84

3.26

3.75

4.27

4.85

5.59

6.52

7.56

1325

1342

1369

1411

1463

1525

3.81

4.34

4.93

5.55

6.27

7.21

1402

1416

1438

1474

1522

4.38

4.95

5.59

6.27

7.01

1475

1487

1506

1537

4.97

5.58

6.27

7.03

DimensionalData

Model BHRE - Belt Driven

D

A

MAX

H

F

C

G

2.00

B

E SQ.

INSIDE

2" NPT DRAIN

SIZE

A

B

C

D

E

F

G

H

105

122

135

150

165

182

200

222

245

25.74

26.87

28.93

30.05

31.30

32.68

34.08

35.77

38.63

11.57

13.24

14.43

15.86

17.28

18.94

20.62

22.76

24.89

21.14

24.44

26.76

29.58

31.85

35.08

38.14

42.52

46.61

11.21

13.02

14.34

15.90

17.43

19.40

21.21

23.59

25.93

20.00

23.00

25.00

27.50

29.00

31.50

34.00

38.00

41.50

17.69

20.13

22.11

24.36

26.69

29.38

32.09

35.45

38.83

12.05

12.12

14.10

14.35

14.74

14.75

15.28

16.04

19.60

26.90

29.29

32.61

34.72

36.17

38.11

40.38

43.98

50.09

AVG. SHIP

WT. (LBS)*

173

193

251

267

294

348

380

446

573

*Consult Fan Selector Program for specific ship weights.

www.tcf.com

9

DimensionalData

Self-Flashing Vented Roof Curb

3

/16" Polystrene Gasket

A SQ.

4" x 1/2"

Vent

Slots

A – 3"

Curb

Height

SIZE

A SQ

105

18.50

122

21.50

135

23.50

150

26.00

165

27.50

182

30.00

200

32.50

222

36.50

245

40.00

2"

A + 4"

Vented Curb Extension

3/16"

Polystrene Gasket

A SQ.

Outside

4" x 1/2"

Vent Slots

13"

2.75"

B SQ.

Inside

10

Twin City Fan Catalog 610

SIZE

A SQ

B SQ

105

19.50

19.25

122

22.50

22.25

135

24.50

24.25

150

27.00

26.75

165

28.50

28.25

182

31.00

30.75

200

33.50

33.25

222

37.50

37.25

245

41.00

40.75

PERFORMANCE — Performance ratings shall conform to AMCA Standard 205 (fan efficiency grade), 211 (air

performance) and 311 (sound performance). Fans shall be tested in accordance with ANSI/AMCA Standard 210

(air performance) and 300 (sound performance) in an AMCA accredited laboratory. Fans shall be licensed to

bear the AMCA certified ratings seal for both sound and air, and fan efficiency grade (FEG).

Fans shall have a sharply rising pressure characteristic extending through the operating range and continuing to

rise beyond the peak efficiency to ensure quiet and stable operation. Fans shall have a non-overloading design

with self-limiting horsepower characteristics and shall reach a peak in the normal selection area. All fans shall

be capable of operating over the minimum pressure class limits as specified in AMCA Standard 99.

Model BHRE shall be UL 762 listed for the exhaust of grease-laden air. Fans shall bear a permanently attached

nameplate displaying model and serial number of the unit for future identification.

CONSTRUCTION — Fan housings shall be heavy gauge, continuously welded construction. Housings with lock

seams or partially welded construction are not acceptable. Housings shall be suitably braced to prevent vibration or pulsation. Housings shall have tapered spun, aerodynamically designed inlet cones or shrouds providing

stable flow and high rigidity. The curb cap shall include prepunched mounting holes for ease of installation.

Lifting lugs shall be welded to the fan housing for ease of handling and installation. Vibration isolators support and isolate the motor, shaft, bearings and wheel assembly from the unit, reducing noise transmission into

the ductwork.

TypicalSpecifications

Fans shall be Model BHRE Belt Driven Hinged Restaurant Exhaust Fans, as manufactured by Twin City Fan

& Blower, Minneapolis, Minnesota.

WHEELS — Backward inclined wheels shall be single thickness plate type designed for maximum efficiency and

quiet operation and shall be of the non-overloading type. BHRE wheels shall be constructed of heavy gauge

steel with welded (not riveted) blades. All wheels shall be statically and dynamically balanced.

SHAFT — Shafts shall be AISI 1040 or 1045 hot rolled steel, accurately turned, ground, polished, and ring

gauged for accuracy. Shafts shall be sized for the first critical speed of at least 1.43 times the maximum speed.

BEARINGS — Bearings shall be heavy duty, grease lubricated, anti-friction ball, self-aligning, pillow block type

and selected for a minimum L-50 life in excess of 200,000 hours at the maximum fan RPM.

DRIVE — Motor sheaves shall be cast iron, and supplied as either variable pitch or fixed pitch. BHRE drives

and belts shall be rated for a minimum of 150% of the required motor HP.

FINISH AND COATING — The entire fan assembly, excluding the shaft, shall be thoroughly degreased and

deburred before application of a rust-preventative primer. After the fan is completely assembled, a finish coat

of paint shall be applied to the entire assembly. The fan shaft shall be coated with a petroleum-based rust

protectant.

ACCESSORIES — When specified, accessories such as swingout wheel, extended discharge, grease box, roof

curb, etc., shall be provided by Twin City Fan & Blower to maintain one source responsibility.

FACTORY RUN TEST — All fans prior to shipment shall be completely assembled and test run as a unit

at operating speed or maximum RPM allowed for the particular construction type. Each wheel shall be statically and dynamically balanced in accordance with ANSI/AMCA 204-96 "Balance Quality and Vibration Levels

for Fans" to Fan Application Category BV-3, Balance Quality Grade G6.3. Balance readings shall be taken by

electronic type equipment in the axial, vertical and horizontal directions on each of the bearings. Records shall

be maintained and a written copy shall be available upon request.

GUARANTEE — The manufacturer shall guarantee the workmanship and materials for its BHRE fans for at

least one (1) year from startup or eighteen (18) months from shipment, whichever occurs first.

www.tcf.com

11

Industrial & Commercial Fans

Centrifugal Fans | Utility Sets | Plenum & Plug Fans | Inline Centrifugal Fans

Mixed Flow Fans | Tubeaxial & Vaneaxial Fans | Propeller Wall Fans | Propeller Roof Ventilators

Centrifugal Roof & Wall Exhausters | Ceiling Ventilators | Gravity Ventilators | Duct Blowers

Radial Bladed Fans | Radial Tip Fans | High Efficiency Industrial Fans | Pressure Blowers

Laboratory Exhaust Fans | Filtered Supply Fans | Mancoolers | Fiberglass Fans | Custom Fans

Twin city fan & blower | www.tcf.com

TwinCity

City FanFan

Companies,

Ltd.

A Twin

Company

1.5MWG8/12

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7600 | Fax: 763-551-7601