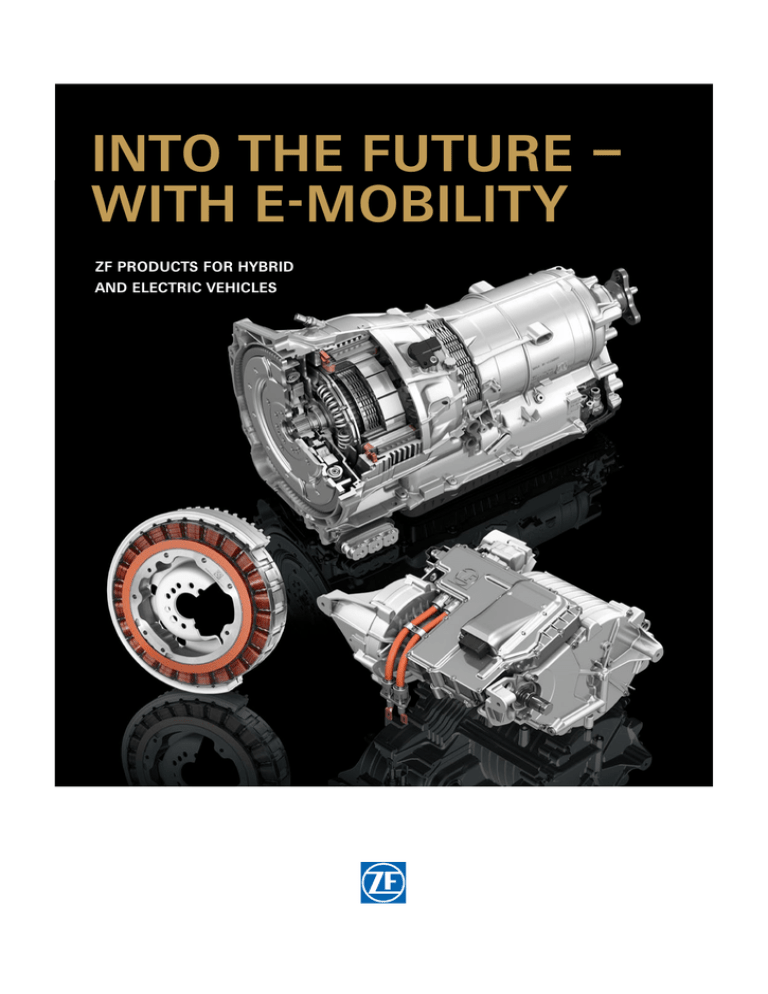

Into the Future – WIth e-MobIlIty

advertisement

Into the Future – With e-Mobility ZF PRODUCTS FOR HYBRID AND ELECTRIC VEHICLES Contents 2 Electric mobility – a megatrend with potential page4 Diversity in efficiency: electrification of the driveline page6 New features thanks to e-mobility page8 Electric Motor page10 Hybrid module page11 Hybrid Transmission page12 48V Hybrid system page13 Power Unit page14 Electric vehilce drive page15 ELECTRIC TWIST BEAM AXLE page16 Modular electric rear axle concept page17 The ZF Group page18 Research and development To secure mobility page19 INNOVATIVE AND FIT FOR THE FUTURE. Millions of people around the entire world are driving with car driveline technology from ZF – today and in the future. The products are designed for efficiency and are simultaneously setting standards when it comes to comfort and driving dynamics. Vehicles equipped with ZF technology successfully walk the challenging line between the need to shape individual mobility while also doing everything possible to preserve the environment and resources. It is impossible to imagine automobiles of the future without ZF driveline technology because, with its modern and reliable components, ZF is also paving the way for many trends, such as electrification of the driveline. This culture of innovation as well as the ability to produce components of the highest quality has made ZF a valuable partner in the international automotive industry. 3 Electric mobility – a megatrend with potential Electric drives are an important element required to make sustainable mobility concepts possible. In this context, ZF provides innovative systems and components. Already more than 100 years ago, engineers experi- and combustion-engine drives. Pure electric vehicles are motors with different power output figures for use in par- larly efficient. Customers who buy electric drive systems mented with electric drives for the early automobiles. already in use without causing any local emissions – and allel hybrid concepts. The product portfolio ranges from from ZF benefit from the Group’s overall expertise. After The fact that, in the end, a drive concept based on liquid as soon as their batteries are charged with green electric- integrated 48V solutions with 15 kW which can be used all, ZF has valuable system know-how about the entire fuel gained from fossil fuels established itself and is ity their overall carbon footprint will improve consider- in mild hybrid systems and already offer a large number driveline, including its functional and structural inte- still in use today could soon prove to be only a phase in ably. Fuel cell vehicles are also purely electrically driven. of advantages of electric drives to powerful electric mo- gration into the automobile. The Group’s expertise in automotive history. The past decades have shown us the In this case, advantages in terms of range result from the tors with up to 120 kW for plug-in hybrid transmissions. the area of mechanics derived from its well-established limits of fossil fuels: Global oil reserves will not be avail- required energy generated on the road based on hydro- Automotive manufacturers appreciate ZF’s expertise in driveline technology product portfolio is equally valu- able indefinitely, emissions caused by traffic damage the gen or methanol stored in tanks. offering complete hybrid modules in which the electric able to ZF customers. It includes topics as complex as the climate and the environment. In this context, the demand motor, a separating clutch, and torsional dampers which damping of torsional engine vibrations or efficient torque for individual mobility which is still increasing fast, ZF: Solutions from a single source balance out rotational irregularities of the combustion transmission. particularly in emerging industrialized nations or “emerg- In the context of this electrification megatrend, automo- engine are integrated in very limited space. ZF uses these ing markets”, can hardly be fulfilled based on combustion tive manufacturers can rely on the technology company hybrid modules in its own systems, for instance in the engine drive concepts. Legislators are also starting to ZF. After all, ZF has been developing electric drives for plug-in hybrid transmission based on the 8-speed auto- play an increasingly bigger role in this matter: Globally, vehicles for more than 25 years. In 2008, the company matic transmission. the automotive industry has to respect ever stricter fleet inaugurated the first industrial production facility for consumption and emission limits. Therefore, alternative electric motors for hybrid electric vehicles in Europe. drive concepts for passenger cars are now and will be For pure electric vehicles ZF supplies weight-saving electric axle drives which take up little installation space. in high demand in the future – and for many of them, Today electric drive components from ZF offer solutions These include the electric motor, a two-stage spur gear electricity as a power source plays an important role: Hy- for almost any passenger car manufacturer concept, drive, as well as the power electronics system in one brid electric vehicles combine the advantages of electric starting with the development and production of electric package. Its high speed design makes the system particu- 4 5 Diversity in efficiency: electrification of the driveline overview of electrified drive configurations HEV – Hybrid Electric Vehicles EV – Electric Vehicles Nowadays, e-mobility covers a very broad range of drive system types for which ZF is optimally prepared today and in the future. Full hybrid, parallel rear-wheel drive More cost-effectiveness and less or no emissions: This serial hybrid drives are integrated according to a differ- is the objective when it comes to implementing almost ent model: In most cases, the combustion engine drives a all electrified passenger car drives. This goal can be generator which supplies energy for one or more electric achieved in different ways. motors for the axle or wheel drive. Twice as powerful Simply great In hybrid electric vehicles or HEV, the conventional Finally, in pure electric vehicles or EV, no combustion combustion engine is supported by at least one electric engine is installed at all. The energy for the electric motor. Its respective capacity can be used for an initial motor or motors is either supplied by a battery, as is the classification: A micro hybrid can, for example, switch off case for battery electric vehicles or BEV; or a fuel cell on the combustion engine in a stationary vehicle (start/stop) board generates the electric energy by means of a chemi- as well as recuperate braking energy to a limited extent cal reaction, as is the case for fuel-cell vehicles (fuel cell but does not actively drive the vehicle. The latter is pos- (electric) vehicle – FC(E)V). ZF works intensively on elec- sible starting with the mild hybrid in which an electric tric vehicle innovations, particularly with its complete motor for instance complements the gasoline or diesel electric axle drive systems. Mild hybrid, parallel rear-wheel drive 48 V or high voltage Full hybrid, parallel front-transverse drive Battery electric vehicle Fuel Cell Full hybrid front-transverse drive with electric motor electric 4-wheel drive Mild hybrid, parallel front-transverse drive 48 V or high voltage Serial hybrid or range extender Fuel-cell (electric) vehicle engine via the boost mode; it can, however, not drive the car independently. This is possible in the full hybrid Cost-effective at 48 V which, as a plug-in hybrid electric vehicle (PHEV), can A more powerful on-board supply system in passenger also be charged using any power outlet. It already tackles cars had already been a topic in the automotive industry many everyday challenges purely electrically: A PHEV before hybrid vehicles were introduced: After all, elec- equipped with the ZF plug-in hybrid transmission even trics and electronics mean more and more consumers reaches speeds of up to 120 km/h and a range of up to 50 in the passenger car, taxing the classical 12 V network kilometers without generating any local emissions. to the limits of its capacity. An additional 48 V on-board Overview of hybrid categories Hybrid categories Main functions Micro Mild 48V Full (HEV) Plug-in (PHEV) Start/stop (Boost mode) (Recuperation) Start/stop Boost mode Recuperation (Electric maneuvering) Start/stop Boost mode Recuperation Limited electric driving Sailing Start/stop Boost mode Recuperation Electric driving Sailing 3-5 kW 10 -15 kW 20-50 kW 75-120 kW supply system is also a less costly step toward hybridizaAs an alternative, HEVs can also be categorized based on tion. A mild hybrid system based on 48 Volts already the interplay between the conventional combustion en- makes a large number of hybrid functions possible – sail- gine and the electric motor: A hybrid in which both can ing, boost mode, recuperation, electric starting, crawling, influence the same driveline simultaneously and directly, as well as start/stop. Thanks to the low-voltage system, as is the case for the mild hybrid or PHEV, is a parallel the electronic components can, however, be integrated in hybrid. And this is exactly the type of hybrid ZF focuses the vehicle at low cost. This results in fuel savings of 10 on for passenger cars. By contrast, the electric motors in to 15 percent. 6 Max. performance level 7 New features thanks to e-mobility Functions of the hybrid system Start/stop The electric drive starts the combustion engine and stops it comfortably if required. Recuperation Braking energy is converted into electric energy. Boost mode Hybrid or pure electric drives offer a number of functions which make driving more efficient. While starting or accelerating, the torque of the combustion engine is increased by the additional torque of the electric motor. Electric driving / electric maneuvering Start/stop Electric driving Switching off the combustion engine whenever it is not As soon as electric motors drive the passenger car inde- required reduces consumption. This is above all the pendently, no more emissions are caused locally while case when the vehicle is at a standstill. Today start/stop driving – and hardly any noise is generated. These are systems are therefore even integrated in vehicles without huge advantages, not least in inner city areas where strict hybrid drive. access restrictions for vehicles with conventional drives The electric drive unit drives the vehicle independently. are becoming more and more common. Recuperation When the vehicle decelerates, the electric motor is used Electric maneuvering as a generator to convert the braking energy into electric Combustion engine vehicles consume a lot of fuel when energy and to charge the battery. starting from a standstill or maneuvering at walking speed. When the electric motor takes over this task, the Boost mode Sailing Switching off and decoupling the combustion engine while driving, for instance when letting the vehicle coast to a stop. If required, the engine is switched on again by a tap on the accelerator pedal. vehicles use considerably less fuel. When full power is required in the hybrid vehicle, the electric motor supports the combustion engine. Advan- Sailing tage: For this reason, the latter can already be designed In driving situations requiring little power input, such as to be smaller and more fuel-efficient in hybrid vehicles – when driving at constant speed or slightly downhill, the keyword: downsizing. combustion engine is switched off and the electric motor takes over vehicle propulsion if required. 8 9 ELECTRIC MOTOR HYBRID MODULE PRODUCT DETAILS ELECTRIC DRIVES PRODUCT DETAILS ELECTRIC DRIVES Specification Permanent-field synchronous machine (PSM) Type Outer diameter Unit Drive configuration Specification Type AL280-32 280 mm Outer diameter 32 mm Active length approx. 150 mm Axial length module 220 – 420 Vdc Voltage range Max. power 55 kW Max. torque 250 Nm Max. speed 7,000 rpm Active length Axial length module Voltage range Permanent-field synchronous machine (PSM) Mild hybrid, parallel front-transverse drive 48 V or high voltage Full hybrid, parallel front-transverse drive Unit AL280-80 280 mm 80 mm approx. 240 mm 220 – 420 Vdc Max. power 90 kW Max. torque 400 Nm Max. speed 7,000 rpm 800 Nm Max. torque separarting clutch Consisting of Consisting of Electric motor Torsional vibration damper Rotor position sensor Housing Electric motor Torsional vibration damper Separating clutch Separating clutch actuation Housing Drive configuration Full hybrid, parallel front-transverse drive Full hybrid, parallel rear-wheel drive Electric motor Rotor position sensor Separating clutch Electric motor Interface to transmission Torsional vibration damper Torsional vibration damper Interface to transmission Interface to combustion engine Interface to combustion engine Housing Housing Separating clutch actuation 10 11 HYBRID TRANSMISSION 48V HYBRID SYSTEM PRODUCT DETAILS ELECTRIC DRIVES PRODUCT DETAILS ELECTRIC DRIVES Specification Permanent-field synchronous machine (PSM) Type Outer diameter Unit Drive configuration Specification Type IL269-70 269 mm Outer diameter 70 mm Active length approx. 150 mm Axial length module 220 – 420 Vdc Voltage range Max. power 90 kW Max. torque 250 Nm Max. speed 7,000 rpm Active length Axial length module Voltage range Permanent-field synchronous machine (PSM) Full hybrid, parallel rear-wheel drive mm 51 mm approx. 145 mm 36 – 52 Vdc Max. power 15 kW Max. torque 200 Nm Max. speed 7,000 rpm 800 Nm Consisting of Consisting of Electric motor Torsional vibration damper Separating clutch Housing Electric motor Power unit incl. rotor position sensor Housing Optional: torsional vibration damper Optional: separating element Drive configuration IL292-51 292 Max. torque separating element (optional) Separating clutch Unit Mild hybrid, parallel front-transverse drive 48 V or high voltage Mild hybrid, parallel rear-wheel drive 48 V or high voltage Interface to transmission Housing Interface to optional torsional vibration damper Interface to combustion engine Electric motor Torsional vibration damper Electric motor 12 Power unit incl. rotor position sensor Housing 13 POWER UNIT ELECTRIC VEHICLE DRIVE PRODUCT DETAILS PRODUCT DETAILS ELECTRIC DRIVES Specification Type Volume Power unit Unit Drive configuration Specification Type PUM Dimensions incl. housing 8 l Max. voltage 440 Vdc Max. current 510 Arms Axial length module Continuous current 240 Arms Voltage range C ASIL Active length Asynchronous machine (ASM) Unit Drive configuration eVD2 450 x 510 x 380 mm 150 mm approx. 450 mm 220 – 420 Vdc 150 kW 3,500 Nm 13,000 rpm Fuel Cell Safety level Max. power Fuel Cell Max. speed 7,000 rpm Max. torque at axle Max. speed Full hybrid front-transverse drive with electric motor electric 4-wheel drive Battery electric vehicle Fuel-cell (electric) vehicle Consisting of Electric motor Two-stage spur gear drive Power unit Parking lock Differential Housing Power unit Electric motor Parking lock Two-stage spur gear drive Housing Differential 14 15 ELECTRIC TWIST BEAM AXLE Modular electric rear axle concept PRODUCT DETAILS ELECTRIC DRIVES An electric drive system integrated into the axle PRODUCT DETAILS According to the customers, supplying driveline and Specification Permanent-field synchronous machine (PSM) Type Dimensions incl. damper and top mount Active length Voltage range Max. power Max. torque at axle Max. speed Unit chassis technology from a single source has always been Drive configuration ZF‘s strength. This advantage also remains in times eTB approx. 595 x 1500 x 250 (560) Drive configuration of e-mobility. For instance, ZF offers the electric drive integrated into a complete axle system. For ZF customers, mm this considerably reduces development costs because 90 ZF handles the coordination of internal interfaces. mm 220 – 420 Vdc 75 kW 1,400 Nm 21,000 rpm Fuel Cell Fuel Cell ZF develops, fine-tunes, and tests the axle including the electric drive, in accordance with the requirement specification. In the process, different axle types can be Full hybrid front-transverse drive with electric motor electric 4-wheel drive Battery electric vehicle Fuel-cell (electric) vehicle used depending on the application. For this purpose, ZF provides a modular rear axle concept which is based on essential customer requirements. Since ZF can imple- Full hybrid front-transverse drive with electric motor electric 4-wheel drive Battery electric vehicle Fuel-cell (electric) vehicle ment its experience with passenger car axle systems in the process, the electric drive is integrated seamlessly Consisting of Electric motor Two-stage spur gear drive Aluminum housing Integrated mounting of damper & spring Twist-beam axle 16 and according to the requirements. 17 The ZF Group Research and development to secure mobility Innovations are not an end in themselves, they must pay off: For manufacturers, fleet owners, and drivers, but also for the environment and society. Each new development must prove itself among the conflicting priorities of these criteria. Shaping the future responsibly Our enthusiasm for innovative products and processes and our uncompromising pursuit of quality have made us a global leader in driveline and chassis as well as active and passive safety technology. We are contributing towards a sustainable future by producing advanced technology solutions with the goal of improving mobility, increasing the efficiency of our products and systems, and conserving resources. Our customers in the automotive and industrial sectors welcome our systematic orientation towards products and services which provide great customer value. Improvements in energy efficiency, cost-effectiveness, dynamics, safety, and comfort are key to our work. Simultaneously, we are aiming for continuous improvement in our business processes and the services we provide.As a globally active company, we react quickly and flexibly to changing regional market demands with the goal of always providing a competitive price/performance ratio. The ZF Group draws upon an international network of What‘s more, the innovative power of ZF is set to development centers. Each year, ZF invests approxi- increase in the future. Proof of this is already provided mately five percent of its sales in R&D. With success, by the number of patents pending: A look at the statistics because innovative products from ZF set the standards of the German Patent and Trademark Register shows that for state-of-the-art technology – again and again. ZF is among the top ten applicants for patents – at eye level with many large automotive manufacturers. Each Development work at ZF is organized according to year, the research departments successfully complete decentralized and corporate functions. The divisions more than 10 000 projects, covering the full range from and business units focus on markets and product exper- basic research to product applications. This high project tise, ensuring customer-centered, competitive techno- volume is necessary to ensure mobility in the future. The logical product development. Corporate R&D works trend toward hybrid solutions already shows that green Our independence and financial security form the basis of our long-term business success. Our profitability enables us to make the necessary investments in new products, technologies, and markets and we thus secure the future of our company on behalf of our customers, market affiliates, employees, and ZF owners. with a strong emphasis on basic research and theory, drive technology is very complex. The same goes for pure and supports the operational development departments electric drives and lightweight design engineering. Cur- in the divisions. rently, ZF engineers are conducting pioneering work on Our tradition and values strengthen our managerial decisions. Together, they are both an obligation and an incentive to maintain a reliable and respectful relationship with customers, market affiliates, and employees. Our worldwide compliance organization ensures that locally applicable laws and regulations are adhered to. We accept our responsibility towards society and will protect the environment at all of our locations. Groundbreaking innovations alternative materials, broader approaches in design and testing, and new production processes. Over the past years, this partnership has produced product innovations that have since become benchmarks in the industry: Just some examples are the 8-speed automatic transmission for cars as well as Our employees worldwide recognize us as a fair employer, focusing on the future and offering attractive career prospects. We value the varied cultural backgrounds of our employees, their competencies, and their diligence and motivation. Their goal-oriented dedication to ZF, beyond the borders of their own field of work and location, shapes our company culture and is the key to our success. hybrid transmissions and hybrid management for cars and commercial vehicles, or the modular TraXon transmission system for commercial vehicles. Groundbreaking innovations from ZF are in use today not just in passenger cars and commercial vehicles on the road, but also in all kinds of craft on the water and in the air. 18 19 twitter.com/zf_group facebook.com/zffriedrichshafen youtube.com/zffriedrichshafenag © ZF Friedrichshafen AG - E-Mobility Cars Electric Drive Technology - 09/2015 (EN20150831) ZF Friedrichshafen AG Ernst-Sachs-Strasse 62 D-97424 Schweinfurt Germany Phone +49 9721 98-0 Fax +49 9721 98-2290 www.zf.com