Decommissioning in the North Sea

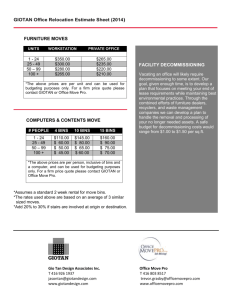

advertisement