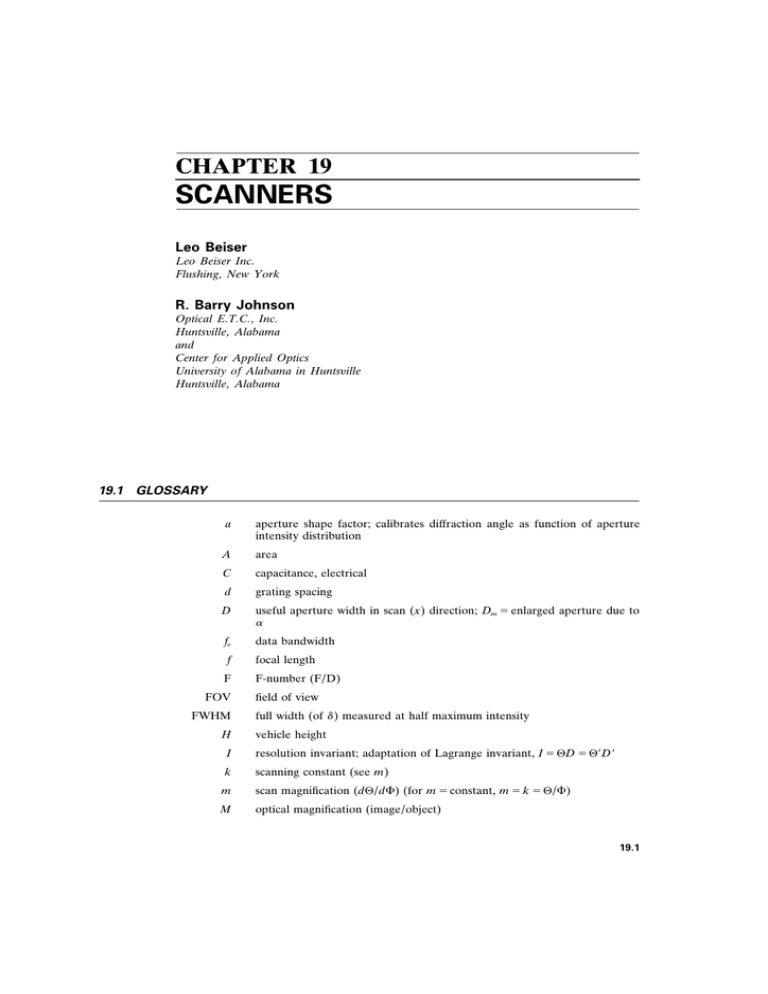

Chapter 19 - Handbook of Optics

advertisement