Cement Industry Technical Bulletin

Originally printed in WORLD CEMENT MAGAZINE, March 2010

Initial Heat Treatment and Cleaning

Castings are often annealed or normalized before cleaning. Cleaning consists of

removing fins, bumps, riser pads, in-gate stubs, etc. and blasting a second time with

abrasive shot to remove new scale and processing spatter.

Final Heat Treatment

Final heat treatment changes the molecular structure of the casting to improve its

mechanical properties. It normally increases the hardness, strength and toughness of

the casting. Castings of equal chemical composition can be given different properties by changing the heat treating process.

Crusher mantle coming out of heat

treating oven.

Machining

Many castings require machining to provide proper fit and surface finish. Dimensional changes and distortions can occur during final heat treatment so most castings

are machined after final heat treatment. Some castings, such as alloy white iron castings, are normally machined in a softened state and again after final heat treatment.

Creating Wear

Resistant Castings

An understanding of the casting process can bring

benefits to cement plant operations.

By Scott McNiven, Product Engineering Manager, Columbia Steel Casting Co., Inc.

Computer modeling of a grinding roller.

BASIC OPERATIONS TO PRODUCE

WEAR RESISTANT CASTINGS:

A FULL SERVICE FOUNDRY WITH TRAINED

SALES REPRESENTATIVES AND SPECIALIZED

Designing

PRODUCT ENGINEERS CAN OFTEN WORK

Detailing

WITH CEMENT PLANT PERSONNEL TO

DEVELOP SUPERIOR PARTS THROUGH

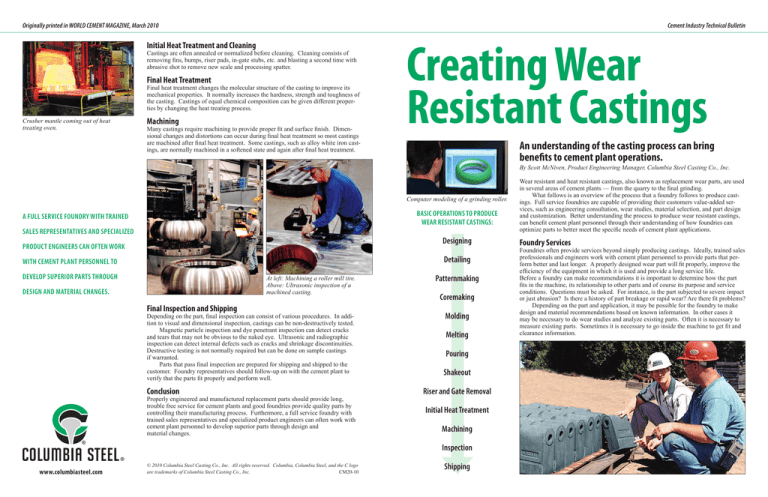

At left: Machining a roller mill tire.

Above: Ultrasonic inspection of a

machined casting.

DESIGN AND MATERIAL CHANGES.

Final Inspection and Shipping

Depending on the part, final inspection can consist of various procedures. In addition to visual and dimensional inspection, castings can be non-destructively tested.

Magnetic particle inspection and dye penetrant inspection can detect cracks

and tears that may not be obvious to the naked eye. Ultrasonic and radiographic

inspection can detect internal defects such as cracks and shrinkage discontinuities.

Destructive testing is not normally required but can be done on sample castings

if warranted.

Parts that pass final inspection are prepared for shipping and shipped to the

customer. Foundry representatives should follow-up on with the cement plant to

verify that the parts fit properly and perform well.

Conclusion

Properly engineered and manufactured replacement parts should provide long,

trouble free service for cement plants and good foundries provide quality parts by

controlling their manufacturing process. Furthermore, a full service foundry with

trained sales representatives and specialized product engineers can often work with

cement plant personnel to develop superior parts through design and

material changes.

Patternmaking

Coremaking

Molding

Melting

Pouring

Shakeout

Riser and Gate Removal

Initial Heat Treatment

Machining

Inspection

www.columbiasteel.com

© 2010 Columbia Steel Casting Co., Inc. All rights reserved. Columbia, Columbia Steel, and the C logo

are trademarks of Columbia Steel Casting Co., Inc.

CM20-10

Shipping

Wear resistant and heat resistant castings, also known as replacement wear parts, are used

in several areas of cement plants — from the quarry to the final grinding.

What follows is an overview of the process that a foundry follows to produce castings. Full service foundries are capable of providing their customers value-added services, such as engineering consultation, wear studies, material selection, and part design

and customization. Better understanding the process to produce wear resistant castings,

can benefit cement plant personnel through their understanding of how foundries can

optimize parts to better meet the specific needs of cement plant applications.

Foundry Services

Foundries often provide services beyond simply producing castings. Ideally, trained sales

professionals and engineers work with cement plant personnel to provide parts that perform better and last longer. A properly designed wear part will fit properly, improve the

efficiency of the equipment in which it is used and provide a long service life.

Before a foundry can make recommendations it is important to determine how the part

fits in the machine, its relationship to other parts and of course its purpose and service

conditions. Questions must be asked. For instance, is the part subjected to severe impact

or just abrasion? Is there a history of part breakage or rapid wear? Are there fit problems?

Depending on the part and application, it may be possible for the foundry to make

design and material recommendations based on known information. In other cases it

may be necessary to do wear studies and analyze existing parts. Often it is necessary to

measure existing parts. Sometimes it is necessary to go inside the machine to get fit and

clearance information.

Cement Industry Technical Bulletin

Mechanical Properties of Typical Alloys

Alloy

Manganese steels

High strength steels

Chromium-molybdenum steels

Alloy white irons

Heat resistant steels

Hardness (HB)

228*

260 - 512

302 - 402*

555 - 713

180

Toughness & Ductility

Very good

Fair to good

Poor to fair

Very poor

Poor

Pouring

Machineability

Poor

Poor to good

Poor to fair

Very poor

Fair

In the casting process, molten metal is

poured from a ladle into a pouring cup that

sits atop the mold. The optimum pouring temperature varies with the chemical

composition of the metal being poured and

must be tightly controlled. Metal goes

down the sprue (downspout), into runners

and through gates into the mold cavity

created by the pattern (which was removed

before the mold was closed and prepared

for pouring). Risers are reservoirs of excess metal that feed heavy sections of the

casting. They are filled during the pouring

process and feed molten metal into the

casting as it solidifies and shrinks. Most

castings would not be solid without the use

of risers.

Weldability

Good

Poor to good

Not weldable

Not weldable

Poor to good

*The hardness shown for manganese steel is “as heat treated” — manganese steel work-hardens significantly during service.

**Chromium-molybdenum-vanadium tool steel has a hardness of 555HB.

Design and Material Selection

Two common methods by which a foundry

can improve the performance and life of a

replacement wear part are improving the

part design and pouring it out of a superior material. Sometimes the foundry can

improve the performance of a part simply

by changing the manufacturing or heat

treating process.

Often the life of a part can be improved by simply adding material to the

high wear areas. Sometimes it is possible

to move material from a non wear area to

a high wear area without increasing the

weight of the part, thus keeping the price

down and reducing throw-away weight.

Part life can often be improved by

changing the chemical composition or

heat treating process. Every alloy has its

benefits and detriments. Selecting the

right alloy for a wear part is a balancing

act between properties such as toughness

and hardness. Toughness is the ability

of a material to withstand shock loading

without fracture. Hardness is the ability

of a material to resist indentation. As a

rule of thumb, the harder a casting is the

better it will resist wear. In general, hard

parts are not tough and tough parts are not

hard. Other properties to consider include

heat resistance, ductility, machineability

and weldability. Some materials cannot

be drilled, tapped or accurately machined.

Some materials cannot be welded or hardfaced without risk of cracking.

Alloy white irons are extremely hard

and provide excellent abrasion resistance

but they have limited toughness. Manganese steels are tough but are normally

limited to applications where impact

loading will allow it to work-harden. High

strength steels are more machineable than

most wear resistant steels. Air-hardened

chromium-molybdenum steels are less

prone to cracking and distortion in processing than water-quenched steels. Heat

resistant steels are resistant to oxidation

and hot gas corrosion and have superior

mechanical properties at elevated temperatures but they do not have good abrasion

resistance.

The properties of steels and irons can

be varied by changes in chemistry and

heat treatment. This is especially true for

high strength steels, wherein a wide range

of properties can be obtained by varying

the chemical composition and tempering

temperatures in the heat treatment process.

A foundry with a knowledgeable

engineering and metallurgical staff can, by

working with the customer’s maintenance

and operations personnel, recommend the

optimum part design and material selection. Furthermore, solidification software

and computerized equipment and controls

can help a modern foundry manufacture a

quality casting that will provide excellent

service.

Manufacturing Process

Castings are created by pouring molten metal into molds and allowing it to

solidify. It is important for the casting’s

designer to be familiar with foundry processes and material options.

The basic operations of producing

steel or iron castings using the sand mold-

ing process include designing, detailing,

patternmaking, coremaking, molding,

melting, pouring, shakeout, riser and

gate removal, initial heat treatment,

cleaning, final heat treatment, machining, inspection and shipping. It should

be noted that manganese steel castings

receive only one stage of heat treatment.

The designing operation, including

material selection has been discussed

previously. The remaining operations

are discussed next.

Detailing

Product engineers create part drawings

for use by the pattern shop, machine

shop and inspection departments. The

drawings specify dimensions, tolerances,

finish allowance and allowable surface

roughness. Tolerance is the allowable

deviation from the specified dimension. Finish allowance is material that is

added to the pattern so that there is extra

material on the casting for machining.

The drawings can also include

notes regarding the location of cast

product information (e.g. pattern number, material code and foundry logo)

and other information such as associated

parts, special cleaning or inspection

instructions, and material specification.

Patternmaking

Patterns are reusable replicas of castings, normally made of wood or

urethane. They are slightly larger than

the castings they produce to allow for

dimensional shrinkage that occurs in the

mold during the solidification process.

Patterns have tapered sides, known as

draft that allows them to be withdrawn

from the sand mold.

Molding and Coremaking

Wooden pattern of a roller mounting frame.

Sand molding consists of placing a pattern in a box known as a flask and ramming green sand or placing chemically

Shakeout, Riser and Gate Removal

Mold being prepared for closing.

bonded sand around it. The pattern is

then removed and cores are placed in

the resultant mold. The mold normally

consists of two halves. The top half is

called the cope and the bottom half is

called the drag. The halves are created

seperately then combined in preperation

for pouring.

Cores are placed in molds to create

holes and pockets and to accommodate

backdraft situations. Backdraft is a

condition wherein the pattern cannot be

removed without destroying the mold.

Cores are made of chemically bonded

sand that breaks down during the solidification process to allow easy removal.

Melting

Most ferrous foundries create molten

metal in electric arc furnaces or electric

induction furnaces. In an arc furnace,

the metal charge is melted by an electric

arc from large electrodes. In induction furnaces, melting is accomplished

by the heat generated as a result of the

charge’s resistance to a current that is

induced by a magnetic field generated

by a coil. The process of pouring the

molten metal from the furnace into the

pouring ladle is called tapping.

At right: Furnace being tapped.

After the casting solidifies and cools in

the mold for a specified time (known as

the dwell time) it goes to the shakeout

department. Shakeout normally consists

of placing the mold on a vibrating grizzly

and allowing the sand to fall between the

bars of the grizzly while the casting stays

on top.

After the casting is shaken out, the

gates and risers are removed and it is blasted with abrasive shot to remove adhering

sand and scale.

Above top: Molds being poured.

Above: Casting with risers after shakeout.

Cement Industry Technical Bulletin

Mechanical Properties of Typical Alloys

Alloy

Manganese steels

High strength steels

Chromium-molybdenum steels

Alloy white irons

Heat resistant steels

Hardness (HB)

228*

260 - 512

302 - 402*

555 - 713

180

Toughness & Ductility

Very good

Fair to good

Poor to fair

Very poor

Poor

Pouring

Machineability

Poor

Poor to good

Poor to fair

Very poor

Fair

In the casting process, molten metal is

poured from a ladle into a pouring cup that

sits atop the mold. The optimum pouring temperature varies with the chemical

composition of the metal being poured and

must be tightly controlled. Metal goes

down the sprue (downspout), into runners

and through gates into the mold cavity

created by the pattern (which was removed

before the mold was closed and prepared

for pouring). Risers are reservoirs of excess metal that feed heavy sections of the

casting. They are filled during the pouring

process and feed molten metal into the

casting as it solidifies and shrinks. Most

castings would not be solid without the use

of risers.

Weldability

Good

Poor to good

Not weldable

Not weldable

Poor to good

*The hardness shown for manganese steel is “as heat treated” — manganese steel work-hardens significantly during service.

**Chromium-molybdenum-vanadium tool steel has a hardness of 555HB.

Design and Material Selection

Two common methods by which a foundry

can improve the performance and life of a

replacement wear part are improving the

part design and pouring it out of a superior material. Sometimes the foundry can

improve the performance of a part simply

by changing the manufacturing or heat

treating process.

Often the life of a part can be improved by simply adding material to the

high wear areas. Sometimes it is possible

to move material from a non wear area to

a high wear area without increasing the

weight of the part, thus keeping the price

down and reducing throw-away weight.

Part life can often be improved by

changing the chemical composition or

heat treating process. Every alloy has its

benefits and detriments. Selecting the

right alloy for a wear part is a balancing

act between properties such as toughness

and hardness. Toughness is the ability

of a material to withstand shock loading

without fracture. Hardness is the ability

of a material to resist indentation. As a

rule of thumb, the harder a casting is the

better it will resist wear. In general, hard

parts are not tough and tough parts are not

hard. Other properties to consider include

heat resistance, ductility, machineability

and weldability. Some materials cannot

be drilled, tapped or accurately machined.

Some materials cannot be welded or hardfaced without risk of cracking.

Alloy white irons are extremely hard

and provide excellent abrasion resistance

but they have limited toughness. Manganese steels are tough but are normally

limited to applications where impact

loading will allow it to work-harden. High

strength steels are more machineable than

most wear resistant steels. Air-hardened

chromium-molybdenum steels are less

prone to cracking and distortion in processing than water-quenched steels. Heat

resistant steels are resistant to oxidation

and hot gas corrosion and have superior

mechanical properties at elevated temperatures but they do not have good abrasion

resistance.

The properties of steels and irons can

be varied by changes in chemistry and

heat treatment. This is especially true for

high strength steels, wherein a wide range

of properties can be obtained by varying

the chemical composition and tempering

temperatures in the heat treatment process.

A foundry with a knowledgeable

engineering and metallurgical staff can, by

working with the customer’s maintenance

and operations personnel, recommend the

optimum part design and material selection. Furthermore, solidification software

and computerized equipment and controls

can help a modern foundry manufacture a

quality casting that will provide excellent

service.

Manufacturing Process

Castings are created by pouring molten metal into molds and allowing it to

solidify. It is important for the casting’s

designer to be familiar with foundry processes and material options.

The basic operations of producing

steel or iron castings using the sand mold-

ing process include designing, detailing,

patternmaking, coremaking, molding,

melting, pouring, shakeout, riser and

gate removal, initial heat treatment,

cleaning, final heat treatment, machining, inspection and shipping. It should

be noted that manganese steel castings

receive only one stage of heat treatment.

The designing operation, including

material selection has been discussed

previously. The remaining operations

are discussed next.

Detailing

Product engineers create part drawings

for use by the pattern shop, machine

shop and inspection departments. The

drawings specify dimensions, tolerances,

finish allowance and allowable surface

roughness. Tolerance is the allowable

deviation from the specified dimension. Finish allowance is material that is

added to the pattern so that there is extra

material on the casting for machining.

The drawings can also include

notes regarding the location of cast

product information (e.g. pattern number, material code and foundry logo)

and other information such as associated

parts, special cleaning or inspection

instructions, and material specification.

Patternmaking

Patterns are reusable replicas of castings, normally made of wood or

urethane. They are slightly larger than

the castings they produce to allow for

dimensional shrinkage that occurs in the

mold during the solidification process.

Patterns have tapered sides, known as

draft that allows them to be withdrawn

from the sand mold.

Molding and Coremaking

Wooden pattern of a roller mounting frame.

Sand molding consists of placing a pattern in a box known as a flask and ramming green sand or placing chemically

Shakeout, Riser and Gate Removal

Mold being prepared for closing.

bonded sand around it. The pattern is

then removed and cores are placed in

the resultant mold. The mold normally

consists of two halves. The top half is

called the cope and the bottom half is

called the drag. The halves are created

seperately then combined in preperation

for pouring.

Cores are placed in molds to create

holes and pockets and to accommodate

backdraft situations. Backdraft is a

condition wherein the pattern cannot be

removed without destroying the mold.

Cores are made of chemically bonded

sand that breaks down during the solidification process to allow easy removal.

Melting

Most ferrous foundries create molten

metal in electric arc furnaces or electric

induction furnaces. In an arc furnace,

the metal charge is melted by an electric

arc from large electrodes. In induction furnaces, melting is accomplished

by the heat generated as a result of the

charge’s resistance to a current that is

induced by a magnetic field generated

by a coil. The process of pouring the

molten metal from the furnace into the

pouring ladle is called tapping.

At right: Furnace being tapped.

After the casting solidifies and cools in

the mold for a specified time (known as

the dwell time) it goes to the shakeout

department. Shakeout normally consists

of placing the mold on a vibrating grizzly

and allowing the sand to fall between the

bars of the grizzly while the casting stays

on top.

After the casting is shaken out, the

gates and risers are removed and it is blasted with abrasive shot to remove adhering

sand and scale.

Above top: Molds being poured.

Above: Casting with risers after shakeout.

Cement Industry Technical Bulletin

Originally printed in WORLD CEMENT MAGAZINE, March 2010

Initial Heat Treatment and Cleaning

Castings are often annealed or normalized before cleaning. Cleaning consists of

removing fins, bumps, riser pads, in-gate stubs, etc. and blasting a second time with

abrasive shot to remove new scale and processing spatter.

Final Heat Treatment

Final heat treatment changes the molecular structure of the casting to improve its

mechanical properties. It normally increases the hardness, strength and toughness of

the casting. Castings of equal chemical composition can be given different properties by changing the heat treating process.

Crusher mantle coming out of heat

treating oven.

Machining

Many castings require machining to provide proper fit and surface finish. Dimensional changes and distortions can occur during final heat treatment so most castings

are machined after final heat treatment. Some castings, such as alloy white iron castings, are normally machined in a softened state and again after final heat treatment.

Creating Wear

Resistant Castings

An understanding of the casting process can bring

benefits to cement plant operations.

By Scott McNiven, Product Engineering Manager, Columbia Steel Casting Co., Inc.

Computer modeling of a grinding roller.

BASIC OPERATIONS TO PRODUCE

WEAR RESISTANT CASTINGS:

A FULL SERVICE FOUNDRY WITH TRAINED

SALES REPRESENTATIVES AND SPECIALIZED

Designing

PRODUCT ENGINEERS CAN OFTEN WORK

Detailing

WITH CEMENT PLANT PERSONNEL TO

DEVELOP SUPERIOR PARTS THROUGH

At left: Machining a roller mill tire.

Above: Ultrasonic inspection of a

machined casting.

DESIGN AND MATERIAL CHANGES.

Final Inspection and Shipping

Depending on the part, final inspection can consist of various procedures. In addition to visual and dimensional inspection, castings can be non-destructively tested.

Magnetic particle inspection and dye penetrant inspection can detect cracks

and tears that may not be obvious to the naked eye. Ultrasonic and radiographic

inspection can detect internal defects such as cracks and shrinkage discontinuities.

Destructive testing is not normally required but can be done on sample castings

if warranted.

Parts that pass final inspection are prepared for shipping and shipped to the

customer. Foundry representatives should follow-up on with the cement plant to

verify that the parts fit properly and perform well.

Conclusion

Properly engineered and manufactured replacement parts should provide long,

trouble free service for cement plants and good foundries provide quality parts by

controlling their manufacturing process. Furthermore, a full service foundry with

trained sales representatives and specialized product engineers can often work with

cement plant personnel to develop superior parts through design and

material changes.

Patternmaking

Coremaking

Molding

Melting

Pouring

Shakeout

Riser and Gate Removal

Initial Heat Treatment

Machining

Inspection

www.columbiasteel.com

© 2010 Columbia Steel Casting Co., Inc. All rights reserved. Columbia, Columbia Steel, and the C logo

are trademarks of Columbia Steel Casting Co., Inc.

CM20-10

Shipping

Wear resistant and heat resistant castings, also known as replacement wear parts, are used

in several areas of cement plants — from the quarry to the final grinding.

What follows is an overview of the process that a foundry follows to produce castings. Full service foundries are capable of providing their customers value-added services, such as engineering consultation, wear studies, material selection, and part design

and customization. Better understanding the process to produce wear resistant castings,

can benefit cement plant personnel through their understanding of how foundries can

optimize parts to better meet the specific needs of cement plant applications.

Foundry Services

Foundries often provide services beyond simply producing castings. Ideally, trained sales

professionals and engineers work with cement plant personnel to provide parts that perform better and last longer. A properly designed wear part will fit properly, improve the

efficiency of the equipment in which it is used and provide a long service life.

Before a foundry can make recommendations it is important to determine how the part

fits in the machine, its relationship to other parts and of course its purpose and service

conditions. Questions must be asked. For instance, is the part subjected to severe impact

or just abrasion? Is there a history of part breakage or rapid wear? Are there fit problems?

Depending on the part and application, it may be possible for the foundry to make

design and material recommendations based on known information. In other cases it

may be necessary to do wear studies and analyze existing parts. Often it is necessary to

measure existing parts. Sometimes it is necessary to go inside the machine to get fit and

clearance information.