INFORMATION SHEET

Metal casting

Improve cast quality and reduce production costs

CARBO Industrial Ceramics provide a range of high performance

casting media products and technologies that improve casting quality

while reducing production costs.

Our ACCUCAST ID intermediate-density and ACCUCAST LD low-density

ceramic casting media products provide higher core or mold volume,

improved casting performance, and reduced production costs compared

to specialty sand.

Engineered for performance

Technology innovation

ACCUCAST® media is an engineered product manufactured to provide performance

that equals and significantly outperform specialty and silica sand products,

respectively. Unlike sand types such as zircon and silica, our media is inert with

a non-hazardous make-up which reduces HSE concerns and associated costs.

CARBO Industrial Ceramic is constantly

developing innovative ceramic-media

based technologies for industrial

processing applications that enhance

production quality, improve efficiencies

and assure operational continuity

while lowering costs.

••

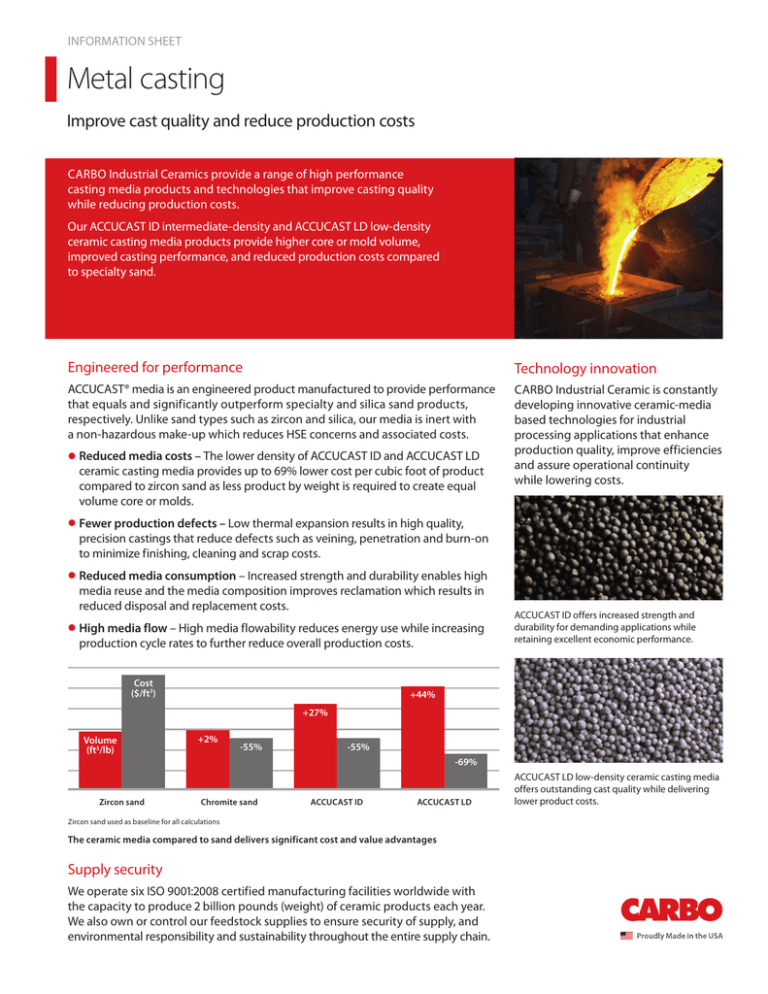

Reduced media costs – The lower density of ACCUCAST ID and ACCUCAST LD

ceramic casting media provides up to 69% lower cost per cubic foot of product

compared to zircon sand as less product by weight is required to create equal

volume core or molds.

••

Fewer production defects – Low thermal expansion results in high quality,

precision castings that reduce defects such as veining, penetration and burn-on

to minimize finishing, cleaning and scrap costs.

••

Reduced media consumption – Increased strength and durability enables high

media reuse and the media composition improves reclamation which results in

reduced disposal and replacement costs.

••

High media flow – High media flowability reduces energy use while increasing

production cycle rates to further reduce overall production costs.

Cost

($/ft3)

ACCUCAST ID offers increased strength and

durability for demanding applications while

retaining excellent economic performance.

+44%

+27%

Volume

(ft3/lb)

Zircon sand

+2%

-55%

-55%

-69%

Chromite sand

ACCUCAST ID

ACCUCAST LD

Zircon sand used as baseline for all calculations

The ceramic media compared to sand delivers significant cost and value advantages

Supply security

We operate six ISO 9001:2008 certified manufacturing facilities worldwide with

the capacity to produce 2 billion pounds (weight) of ceramic products each year.

We also own or control our feedstock supplies to ensure security of supply, and

environmental responsibility and sustainability throughout the entire supply chain.

ACCUCAST LD low-density ceramic casting media

offers outstanding cast quality while delivering

lower product costs.

Metal casting

Improve cast quality and reduce production costs

Proven performance

Our products and technologies have addressed challenges and delivered value

for our clients across a wide range of metal casting applications.

Process and metal poured

Foundry challenge

Performance result

Cast media replaced

Lost foam – aluminum

New part project jeopardized by

unacceptable dimensional capabilities.

Required tolerances met. Multibillion-dollar

project salvaged.

Olivine sand

Faced with a capital investment to add a

new production line to meet increased

production demand.

Increased production 27% per production line

(3 total). Eliminated a 9% scrap rate. Negated

the new line addition and all associated cost.

Silica sand

New foundry start-up. Owner wanted

to use the most advanced technology

available.

No start-up delays due to product. Casting quality

and capabilities met or exceeded expectation

assisted in gaining new business.

New start-up

Costly cleaning. Burn-on and veining

defects. Inconsistent dimensions.

Penetration burn-on minimized, veining

eliminated, tighter and consistent dimensions

and reduced cleaning cost.

Olivine sand

Reduce scrap and cleaning cost

with regard to dimensions, veining

and penetration. Enhance thin-wall

capabilities.

Minimized penetration, eliminated veining,

reduced casting defects and scrap, reduced

cleaning cost.

Silica sand

High cleaning cost.

Significantly reduced cleaning cost.

Competitive ceramic

Zircon sand reduced availability

and increased cost.

Matched zircon sand performance at a

lower effective cost. Met customer product

availability requirements.

Zircon sand

Shell – gray & ductile Iron

Faced with a capital investment to

add automated cleaning equipment

to reduce cleaning cost.

Reduced cleaning cost and improved dimensional

precision 10%-50% with respect to casting

complexity, negating the multimillion-dollar

purchase of new automated cleaning equipment.

Silica sand

PUCB – Gray & ductile iron

Dimensions, veining and penetration.

Improved dimensions, minimized penetration

and eliminated veining defects.

Silica sand

PUCB – steel

Zircon sand reduced availability

and increased cost.

Matched zircon sand performance at a lower

effective cost. Eliminated hot tear defect. Met

customer product availability requirements.

Zircon sand

Shell – steel

Zircon sand reduced availability

and increased cost.

Improved performance vs. zircon sand.

No burn‑in, no veins and comparable surface

finish. Improved dimensions. Improved pricing

and availability.

Zircon sand

(currently still used)

Lost foam – gray & ductile Iron

V-process – gray & white iron

Talk to CARBO to find out how we can help you

enhance your production.

carboceramics.com/industrial

© 2016 CARBO Ceramics Inc. All Rights Reserved. 1001_302