EXAMPLE CONSTRUCTIONS

advertisement

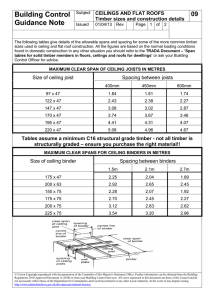

BUILDING STANDARDS DIVISION EXAMPLE CONSTRUCTIONS AND GENERIC INTERNAL CONSTRUCTIONS FOR USE WITH SECTION 5: NOISE OF THE TECHNICAL HANDBOOKS CONTENTS Page Introduction Status of document Background Aims 3 Example Constructions Section 1 – Example Constructions 1.a Design of Example Constructions 1.b Separating wall details – links to wall types 1.c Separating floor details – links to floor types 4 Section 2 – Design and specification considerations 2.a Design and specification 2.b On-site construction practices – separating walls 2.c On-site construction practices – separating floors 10 3.a 3.b 3.c 3.d 3.e Section 3 – Component specification and acoustic performance requirements Wall ties for blockwork cavity walls Bonded Resilient Covers (BRC’s) over isolated screeds Floating Floor Treatments (FFT’s) Resilient ceiling bars Downlighters (recessed lighting) Generic Internal Constructions 4.a Internal walls and intermediate floors 4.b Internal wall details 4.c Intermediate floor details 13 17 Annex A – Explanation of terms 21 Annex B – Laboratory test procedures for building products and components for manufacturers 24 B1 General requirements for the selection of Bonded Resilient Coverings (BRC’s) and Floating Floor Treatments (FFT’s) 25 B2 Determination of the acoustic performance of Bonded Resilient Coverings (BRC’s) used with concrete core floors 25 B3 Determination of the acoustic performance of requirements of Floating Floor Treatments (FFT’s) used with timber joist or lightweight frame core floors 27 B4 Determination of the acoustic performance of resilient ceiling bars 29 B5 Determination of the influence on the acoustic performance of timber separating floors due to the presence of downlighters (recessed lighting) 31 B6 Determination of the acoustic performance of downlighters and recessed lighting used with timber core floors 34 Version Date 1.0 1 October 2010 Notes New Document 2 INTRODUCTION Status of this document This document provides guidance on one way of meeting some of the requirements of the functional standards set out in Regulation 9 of the Building (Scotland) Regulations 2004, as amended. However, it is acceptable to propose alternative solutions provided they fully satisfy the functional standards. Background A reduction in sound transmission passing through a separating wall or floor is achieved by limiting airborne sound, such as that from speech or television, and impact sound such as that from footsteps by providing sound insulation measures. Sound insulation involves a “system approach” using a combination of products and components. The wide range of acoustic product testing and the logarithmic approach for sound insulation performance does not lend itself to a straightforward design process. A non-acoustician will find this complex. Past experience has shown that one of the most common causes of failure to meet the sound insulation performance levels was the specification or subsititution of unsuitable products. Aims The main aim of this document is to provide examples of the most commonly used separating wall, separating floor, internal wall and intermediate floor constructions. These examples offer a prepared solution to meeting certain aspects of Standard 5.1 and Standard 5.2. When built correctly, and taking into account the flanking elements, they should meet the sound performance levels given in 5.1.2 and 5.2.1 of the Technical Handbooks. Annex B of this document contains the relevant test information sought by manufactures to demonstrate that their products are suitable to be used in an Example Construction specification. 3 EXAMPLE CONSTRUCTIONS SECTION 1 1.a Design of Example Constructions The Example Constructions have been designed with the following in mind: x to reduce horizontal impact sound transmission through separating wall constructions from sound caused by switches, inserting plugs into sockets or cupboard doors closing; x to provide suitable measures to reduce impact sound transmission through separating floor constructions which incorporate wood based floor coverings; x to reduce flanking sound transmission through other construction elements which are not part of the separating wall or floor, such as inner leafs of external walls. The common factors which are illustrated in each detail are: x core wall or floor construction; x wall linings; x isolating, resilient or floating floor layers; x interaction with other building elements; - junction with the external wall - junction with separating wall or floor - junction for the ground floor - junction with internal walls or floors - junction with the ceiling and roof space x lining details for vertical soil vent pipes and wall mounted service penetrations; x separating walls between a dwelling and a common area (e.g. stairway for flats and maisonettes). Other requirements of the Scottish building regulations which are not illustrated by these details, but which should be considered by the designer include: x structure; x fire resistance and flame spread; x damp-proofing arrangements; x precipitation; x ventilation; x thermal performance of elements; x thermal bridging and air leakage. 4 1.b Separating wall details SEPARATING WALLS Wall Type 1 Masonry solid walls (dense blockwork) for use in attached houses, flats and maisonettes DETAILS 1.00 DENSE BLOCK SOLID WALL 1.01 Isometric and construction detail 1.02 External wall junction 1.03 Separating floor junction: Floor Type 2A 1.04 Separating floor junction: Floor Type 2B 1.05 Ground floor junction: Floating Floor Treatment (FFT) 1.06 Ground floor junction: isolated screed 1.07 Ceiling and roof junction 1.08 Separating wall: dwelling to common area 2.00 DENSE BLOCK CAVITY WALL 2.01 Isometric and construction detail 2.02 External wall junction 2.03 Separating floor junction: Floor Type 2A 2.04 Separating floor junction: Floor Type 2B 2.05 Ground floor junction 2.06 Internal floor junction: floor joists on hangers 2.07 Internal floor junction: floor joists built-in 2.08 Ceiling and roof junction 2.09 Separating wall: dwelling to common area Wall Type 2 Masonry cavity walls (dense blockwork) for use in attached houses, flats and maisonettes 5 SEPARATING WALLS DETAIL 3.00 TIMBER FRAME TWIN STUD WALL 3.01 Isometric and construction detail 3.02 External wall junction 3.03 Separating floor junction: Floor Type 3A Wall Type 3 3.04 Separating floor junction: Floor Type 3B Timber frame twin stud walls (with and without sheathing) for use in attached houses, flats and maisonettes 3.05 Ground floor junction 3.06 Ground floor junction: raft foundation 3.07 Internal wall junction 3.08 Internal floor junction 3.09 Ceiling and roof junction 3.10 Services and sockets 3.11 Separating wall: dwelling to common area 4.00 METAL FRAME TWIN STUD WALL 4.01 Isometric and construction detail 4.02 External wall junction: metal stud framing 4.03 External wall junction: in-situ concrete framing Wall Type 4 4.04 Separating floor junction: Floor Type 1A Metal frame twin stud walls for use in attached metal frame houses and in-situ concrete frame, flats and maisonettes 4.05 Separating floor junction: Floor Type 1B 4.06 Ground floor junction 4.07 Ground floor junction: raft foundation 4.08 Internal wall junction 4.09 Internal floor junction 4.10 Ceiling and roof junction 4.11 Services and sockets 4.12 Separating wall: dwelling to common area 6 1.c Separating floor details SEPARATING FLOORS Floor Type 1A In-situ concrete slab with isolating screed and Bonded Resilient Cover (BRC) DETAIL 5.00 IN-SITU CONCRETE: with isolated screed and Bonded Resilient Cover (BRC) 5.01 Isometric and construction detail 5.02 Isolated screed and Bonded Resilient Cover (BRC) 5.03 Ceiling treatment 5.04 External wall junction: metal stud inner leaf 5.05 External wall junction: dense block inner leaf 5.06 Separating wall junction: Wall Type 4 5.07 Services: vertical soil vent pipes (SVP's) 6.00 IN-SITU CONCRETE: with Floating Floor Treatment (FFT) 6.01 Isometric and construction detail 6.02 Floating Floor Treatment (FFT) 6.03 Ceiling treatment 6.04 External wall junction: metal stud inner leaf 6.05 External wall junction: dense block inner leaf 6.06 Separating wall junction: Wall Type 4 6.07 Services: vertical soil vent pipes (SVP's) Floor Type 1B In-situ concrete slab with Floating Floor Treatment (FFT) 7 SEPARATING FLOORS Floor Type 2A Precast concrete slab with isolating screed and bonded resilient cover Floor Type 2B Precast concrete slab with floating floor treatment DETAIL 7.00 PRECAST CONCRETE SLAB: with isolated screed and Bonded Resilient Cover (BRC) 7.01 Isometric and construction detail 7.02 Isolated screed and Bonded Resilient Cover (BRC) 7.03 Ceiling treatment 7.04 External wall junction: dense block inner leaf 7.05 Separating wall junction: Wall Type 1 7.06 Separating wall junction: Wall Type 2 7.07 Services: vertical soil vent pipes (SVP's) 8.00 PRECAST CONCRETE SLAB: with Floating Floor Treatment (FFT) 8.01 Isometric and construction detail 8.02 Floating Floor Treatment (FFT) 8.03 Ceiling treatment 8.04 External wall junction: dense block inner leaf 8.05 Separating wall junction: Wall Type 1 8.06 Separating wall junction: Wall Type 2 8.07 Services: vertical soil vent pipes (SVP's) 8 SEPARATING FLOORS Floor Type 3A Timber frame floor with solid joists DETAIL 9.00 TIMBER FRAME FLOOR: with solid joists 9.01 Isometric and construction detail 9.02 Floating Floor treatment (FFT) 9.03 Ceiling treatment 9.04 External wall junction: timber frame inner leaf 9.05 Separating wall junction: Wall Type 3 9.06 Internal wall junction: loadbearing 9.07 Internal wall junction: non-loadbearing 9.08 Services: vertical soil vent pipes (SVP's) 10.00 TIMBER FRAME FLOOR: with engineered Ijoists 10.01 Isometric and construction detail 10.02 Floating Floor Treatment (FFT) Floor Type 3B Timber frame floor with engineered I-joists 10.03 Ceiling treatment 10.04 External wall junction: timber frame inner leaf 10.05 Separating wall junction: Wall Type 3 10.06 Internal wall junction: loadbearing 10.07 Internal wall junction: non-loadbearing 10.08 Services: vertical soil vent pipes SVP's 9 SECTION 2 DESIGN AND SPECIFICATION CONSIDERATIONS 2.a Design and specification At the design stage of any development the design and specification are important as in the past this has found to be the most common cause of sound performance failure. Design and specification consideration should include: x the minimum block density; x the Floating Floor Treatment (FFT) achieves the performance requirements in 3c; x the resilient ceiling bar achieves the performance requirements in 3d; x the wall tie type for blockwork cavity separating walls should always be wall tie Type A, see 3a; x the minimum cavity width or floor cavity depth; x the minimum gypsum board density (to achieve a high enough level of mass); x the use of mineral wool based boards (as they have acoustic absorption properties) and not rigid insulation boards (as they have very low acoustic absorption properties). 2.b On-site construction practices (separating walls) Generally, the approved design and specification should be adhered to and the substitution of products should be avoided. Past experience has shown the following on-site construction practices will assist in achieving the sound insulation performance; Wall Type 1 - Dense block solid wall x using a dense block as specified; x laying the 215 mm block full width on its side; x fully filling perpends and bed joints with mortar; x achieving external wall inner leaf continuity with the separating wall; x installing independent metal frame studs at a minimum 30 mm offset from the blockwork face; x fully filling the metal frame stud width and height with quilt insulation. Wall Type 2 - Dense block cavity wall x using a dense block as specified; x fully filling perpends and bed joints with mortar; x using Wall Tie Type A in the separating wall leafs, see 3a; x keeping the wall ties free of mortar and debris at the base of the wall cavity (to help prevent bridging of the cavity wall leafs); 10 x x achieving a minimum 75 mm cavity width; scratching the wet render (to increase the mechanical bond for the dab and gypsum based board). Wall Type 3 - Timber frame twin stud wall x achieving the minimum cavity width between linings; x achieving a minimum of 50 mm between sheathed stud walls; x fully covering the wall face of the stud bay with quilt insulation; x staggering the joints of gypsum board linings; x achieve the minimum gypsum board density; x avoid spanning joists into the wall cavity (to prevent bridging of the twin frame) x using a rigid cavity stop fixed to one frame only (to prevent bridging of the twin frame). Wall Type 4 - Metal frame twin stud wall x building a 200 mm minimum cavity width between linings; x fully covering the wall face of the stud bay with quilt insulation; x staggering the joints of gypsum board linings; x achieve the minimum gypsum board density; x using a rigid cavity stop fixed to one frame only (to prevent bridging of the twin frame). 2.c On-Site construction practices (Separating Floors) Generally, the approved design and specification should be adhered to and the substitution of products should be avoided. Past experience has shown the following on-site construction practices will assist in achieving the sound insulation performance; Isolated screeds x installing both isolating layers; x isolating the screed (to prevent the screed bridging the core slab); x isolating the screed (to prevent the screed bridging the perimeter wall, wall linings and skirting) ; x achieving the minimum depth of 65 mm sand:cement screed. Bonded Resilient Covers (BRC) x using a resilient cover that achieves the performance requirements in 3b. Floating Floor Treatments (FFT) x using the minimum FFT depth specified; x using a FFT that achieves the performance requirements in 3c; x installing the perimeter flanking strip (to isolate flooring boards from skirtings and wall linings); x using the correct screw length (to prevent screws or nails bridging the resilient layer); x taking care installing services (to prevent them bridging the resilient layer). 11 Suspended ceiling treatments x using a metal frame ceiling where required; x building to the correct ceiling void depth; x achieving the minimum mass per unit area of the ceiling board. Resilient ceiling bars x using resilient ceiling bar that achieve the performance requirements in 3d; x using the correct screw length (to prevent the ceiling board screw fixings touching the joist). 12 SECTION 3 COMPONENT SPECIFICATION AND ACOUSTIC PERFORMANCE REQUIREMENTS 3.a Wall ties for blockwork cavity walls Specification of the correct wall tie is important. A wall tie will transmit sound and can affect the sound insulation performance. For example if the wall tie is too thick or too stiff, or a build up of mortar or debris on the wall tie has been allowed to form, this will increase sound transmission leaf to leaf (acoustic bridging). Therefore, it is important that wall ties and cavities are protected during construction and kept clear of mortar or debris. Particular attention should be paid to Section 1: Structure of the Technical Handbooks. Separating walls – wall tie Type A All wall ties used in separating walls involving cavity blockwork should be tie Type A. Tie Type A should achieve an appropriate measured dynamic stiffness for the cavity width. The specification for wall ties dynamic stiffness, KXmm in MN/m with a cavity width of X mm and n ties/m2 is n.kXmm<4.8 MN/m3. A wall tie manufacturer will be able to provide product specification details which achieve the stiffness for wall tie Type A. External walls - wall tie Type A or B Wall ties used in external blockwork cavity walls can be tie Type A (as above) or tie Type B (depending on strength requirements), which have an appropriate measured dynamic stiffness for the cavity width. The specification for wall ties of dynamic stiffness, KXmm in MN/m with a cavity width of X mm and n ties/m2 is n.kXmm<4.8 MN/m3 (tie Type A) or <113 MN/m3 (tie Type B). A wall tie manufacturer will be able to provide product specification details to achieve these requirements for tie Type A or tie Type B for external walls. 3.b Bonded Resilient Covers (BRC’s) over an isolated screed A resilient cover is a thin resilient layer used below a floor covering, which can be bonded to a concrete floor or to the surface of an isolated screed. When bonded it is referred to as a Bonded Resilient Cover (BRC). The use of a BRC does not generally affect airborne transmission but can reduce impact sound transmission. Isolated screed The resilient layer can also be used as an isolating layer underneath a screed, as in floor detail 1A and 2A, to improve airborne and impact sound transmission. However, the isolating layer on its own is not sufficient to repeatedly achieve the required impact performance against 13 impact noise such as footsteps. There has been an increase in the use of wood based floor coverings, such as laminate flooring, laid directly on a screed finish without a resilient layer (underlay, between a wood based floor covering and a screed). This will increase sound transmission into the dwelling below, therefore a BRC should be used and cover the entire floor surface of the room. Where BRC’s are used for concrete core floors they should be tested with a wood based floor covering laid over the resilient layer. This would provide a more realistic performance for how these components may perform for impact sound insulation in buildings with hard floor finishes. The BRC used in concrete core floors should: x be tested for impact performance in an acoustic laboratory, as outlined in Annex B; and x achieve the required minimum sound insulation performance as described in the table below. Minimum performance requirements of BRC’s used with concrete core floors [1- 3] Impact ÷Lw 17 dB Notes: 1) The above performance requirement is based on a resilient floor covering which has been tested in a laboratory in accordance with Annex B under a wood based floor covering. Any material adopted for use in the Example Constructions should also have been tested under a wood based floor covering. Testing directly onto the resilient cover will lead to an exaggerated performance which does not reflect its true performance under a wood based floor covering when built. 2) Annex B outlines the laboratory test requirements for resilient floor coverings with concrete core floors. 3) BRC’s should only be used with concrete core floors. 3.c Floating Floor Treatments (FFT’s) A floating floor treatment (FFT) is a timber floating floor system, normally timber, which may utilise battens, cradles or a platform base. All of these use a resilient layer to provide isolation from the base floor and adjacent wall elements. FFT’s can increase the airborne and impact performance for both concrete core floors and lightweight frame floors (such as timber joist separating floors). FFT’S are referred to in terms of FFT1, FFT2 or FFT3, which relates to their structure type, design depth and their acoustic performance. These FFT’s apply to resilient battens and cradle systems which support a timber based tongue and grooved (t&g) floor board. All FFT’s require acoustic isolation flanking strips at the room perimeter. The flanking strip should be installed such that it isolates the floor board edge form the perimeter wall, wall linings and skirtings. Further descriptive 14 information relating to the relative FFT is provided in each Example Construction. FFT1 and FFT3 - the composite resilient batten used is composed of a timber batten with a pre-bonded, continuous resilient material to provide isolation between the flooring surface layers and floor base or core. FFT2 - the cradle / saddle is used as an intermediate support system (with a resilient layer base, either pre-bonded or already integral) using levelling packer pieces to support a timber batten, isolating it from the floor base. Cradles should not be used on timber joist floors unless the supporting deck has sufficient stiffness and strength properties to cope with concentrated point loads. The incorporation of Ctr (measurement criteria for low frequency noise) within the laboratory test requirements for FFT’s for timber joist floors or lightweight frame floors will enhance the low frequency performance of these structures. The FFT’s used in concrete core floors, timber joist or lightweight frame core floors should: x be tested in an acoustic laboratory, as outlined in Annex B; and x achieve the required airborne and impact sound insulation performance as described in the tables below. Minimum performance requirements of FFT’s used with concrete core floors FFT1, FFT2 and FFT3 [1] Airborne ÷Rw Impact ÷Lw 5 dB 22 dB Note: 1) Annex B outlines the laboratory test requirements for FFT’s on concrete core floors. Minimum performance requirements of FFT’s used with timber joist or lightweight frame floors FFT1 [1] Airborne ÷Rw Airborne ÷Rw + Ctr Impact ÷Lw 17 dB 13 dB 16 dB Note: 1) Annex B outlines the laboratory test requirements for FFT’s when used with timber joist or lightweight frame floors 3.d Resilient ceiling bars Resilient ceiling bars are generally metal based and can increase both airborne and impact sound insulation performance. Resilient ceiling bars are used to support ceiling board linings and mounted perpendicular to the joist span for timber frame and lightweight frame floors. They can improve both the airborne and the impact performance of the separating 15 lightweight frame floor. Resilient ceiling bars vary in thickness and are used to support ceiling board linings and mounted perpendicular to the joist span. To obtain the best acoustic performance for both airborne and impact sound insulation the ceiling board fixings into the resilient bar should not come into direct contact with the joists. Care should be taken to ensure the correct screw length is used for fixing. The incorporation of Ctr within the laboratory test requirements for resilient ceiling bars for timber joist floors or lightweight frame floors will enhance the low frequency performance of these structures. The resilient ceiling bars for timber joist floors should: x be tested in an acoustic laboratory, as outlined in Annex B; and x achieve the required impact sound insulation performance as described in the table below Minimum performance requirements of resilient ceiling bars used with timber joist or lightweight frame floors [1] Airborne ÷Rw Airborne ÷Rw + Ctr Impact ÷Lw 16 dB 14 dB 16 dB Note: 1) Annex B outlines the laboratory test requirements for resilient ceiling bars with timber joist or lightweight frame core floors. 3.e Downlighters (recessed lighting) Downlighters (or recessed lighting) are often mounted such that they penetrate the ceiling board lining. The junction between the ceiling board and downlighter perimeter should be well sealed. It is recommended that downlighters should: x be at centres of not less than 0.75m; x have openings no greater than 100 mm diameter or 100x100 mm; x be installed at no more than one downlighter per 2m2 of total ceiling area in each room. Downlighters may be installed at a greater density than 1 per 2m2 if the light fittings are supported by test evidence undertaken in accordance with Annex B. Particular attention should be paid to Section 2: Fire of the Technical Handbooks. 16 GENERIC INTERNAL CONSTRUCTIONS The following internal constructions are provided for internal walls and intermediate floors. 4.a Internal walls and intermediate floors INTERNAL WALLS DETAIL LINK 1.0 Timber or metal frame with gypsum based board linings on each side of frame 2.0 Timber or metal frame with gypsum based board linings on each side of frame and absorbent material 3.0 Concrete block wall, plaster or gypsum based board finish on both sides 4.0 Aircrete block wall, plaster or gypsum based board finish both sides Wall Type 1 - 4 INTERMEDIATE FLOORS Floor Type 1 - 3 DETAIL LINK 1.0 Timber or metal joist, with wood based board and gypsum based board ceiling and absorbent material 2.0 Concrete beams with infilling blocks, bonded screed and ceiling 3.0 Concrete planks 17 4.b Internal wall details Type 1 Timber or metal frame with gypsum based board linings on each side of frame x Each lining to be 2 layers of gypsum based board, total minimum mass per unit area 10 kg/m2 each layer; x Linings fixed to timber frame 75 x 38 mm at 600 mm centres with a minimum distance between linings of 75 mm, or metal ‘C’ type frame at 600 mm centres with a minimum distance between linings of 48 mm; x All joints staggered and well sealed. Type 2 Section Timber or metal frame with gypsum based board linings on each side of frame and absorbent material x Single layer of gypsum based board of minimum mass per unit area 10 kg/m2; x Linings fixed to timber frame 75 x 38 mm at 600 mm centres with a minimum distance between linings of 75 mm, or metal ‘C’ type frame at 600 mm centres with a minimum distance between linings of 48 mm; x An absorbent layer of mineral wool batts or quilt (minimum thickness 25 mm and minimum density 10 kg/m3) that may be wire reinforced and suspended in the cavity; x All joints well sealed. Type 3 Timber or metal frame Timber or metal frame Section Concrete block wall, plaster or gypsum based board finish on both sides x Minimum mass per unit area, excluding finish 120 kg/m2; x All joints well sealed; x Plaster or gypsum based board on both sides. Section 18 Type 4 Aircrete block wall, plaster or gypsum based board finish both sides x Plaster finish, minimum mass per unit area, including finish 90 kg/m2; x Gypsum based board finish, mass per unit area, including finish 75 kg/m2; x All joints well sealed. Note 1: this wall type should only be used with separating walls included in Example Constructions where there is no recommended mass on the internal masonry walls. Note 2: this wall type should not be used as a load-bearing wall connected to a separating floor included in Example Constructions. 19 Section 4.c Intermediate floor details Type 1 Concrete slab x Minimum mass per unit area 180 kg/m2; x Regulating screed optional; x Ceiling finish optional. Section Type 2 Concrete beams with infilling blocks, bonded screed and ceiling x Minimum mass per unit area of beam and block 220 kg/m2; x Bonded screed. Sand cement screeds should have a minimum thickness of 40 mm. For proprietary bonded screed products, screed thickness should be as recommended by the manufacturer; x Ceiling finish - single layer of gypsum based board, minimum mass per unit area 10 kg/m2; x Fix using timber battens or proprietary resilient channels. If resilient channels are used, incorporate an absorbent layer of mineral wool, minimum density 10 kg/m2 that fills the ceiling void. Type 3 Section Timber or metal joist, with wood-based board and gypsum based board ceiling and absorbent material x Floor surface of timber - or wood-based board, minimum mass per unit area 15 kg/m2; x 47 x 200 mm joists at 450 mm centres; x Ceiling treatment of two layers of gypsum based board, minimum mass per unit area 10 kg/m2 and fixed using any accepted fixing method; x An absorbent layer of mineral wool, minimum thickness 100 mm, minimum density 10 kg/m3 and laid in between the joists. 20 Timber or metal joist Section Annex A Explanation of terms The following terms are provided for clarity, and are for use with the Example Constructions and Generic Internal Constructions. It is not the intention that any of these terms relate to proprietary products. Absorption is the conversion of sound energy into heat, often by the use of a porous material. Absorbent material is a material that absorbs sound energy, such as mineral wool. Airborne sound is sound which is propagated from a noise source through the medium of air. Examples of these are speech and sound from a television. Airborne sound transmission is direct transmission of airborne sound through walls or floors. When sound energy is created in a room, for instance by conversation, some of the energy is reflected or absorbed by room surfaces but some may set up vibrations in the walls and floor. Depending on both the amount of energy and the type of construction, this can result in sound being transmitted to adjacent parts of the building. Air path is a void in construction elements, which adversely affects the performance of sound resisting construction. Examples of air paths include incomplete mortar joints, porous building materials, gaps around pipes and shrinkage cracks. Bonded resilient cover (BRC) is a thin resilient floor covering normally of minimum 3 mm thickness which is bonded to the isolated screed surface to reduce impact sound transmission such as footfall noise. Cavity stop is a proprietary product or material such as mineral wool (fibre) used to close the gap in a cavity wall. Composite resilient batten this is composed of a timber batten with a pre-bonded resilient material to provide isolation between the flooring surface layers and floor base. Cradle/Saddle is an intermediate support system (with a resilient layer base, either pre-bonded or already integral) using levelling packer pieces to support a timber batten, isolating it from the floor base. Decibel (dB) is the unit used for different acoustic quantities to indicate the level with respect to a reference level. Density (kg/m3) is the mass per unit volume, expressed in kilograms per cubic metre (kg/m3). Blockwork is commonly referred to by industry in terms of strength (in 21 Newtons). However, it is the density that has the important role in terms of sound insulation. Direct transmission refers to the path of either airborne or impact sound through elements of construction. DnT,w is the weighted standardized level difference. A single-number quantity (weighted) which characterises the airborne sound insulation between two rooms, in accordance with BS EN ISO 717-1:1997 Flanking element (flanking wall) is any building element that contributes to the airborne sound or impact transmission between rooms in a building which is not the direct separating element (i.e. not the separating wall or separating floor). Flanking strip or edge strip is a resilient strip using foamed polyethylene normally 5 mm thick, which is located at the perimeter of a floor to isolate the floor boards from the walls and skirtings. Flanking transmission is airborne or impact transmission between rooms that is transmitted via flanking elements and/or flanking elements in conjunction with the main separating elements. An example of a flanking element is the inner leaf of an external wall that connects to the separating ‘core’ of a wall or floor. Flexible closer is a flexible cavity stop or cavity barrier which seals the air path in cavities linking adjoining dwellings. Floating floor treatment (FFT) is a timber floating floor system which may use battens, cradles or platform base, all of which use a resilient layer to provide isolation from the base floor and adjacent wall elements. Gypsum based board is a dry lining board applied to walls, ceilings and within floating floor treatments which has gypsum content. It may also have fibre reinforcement within the board. Impact sound is sound which is propagated from a noise source through a direct medium. An example of this is footfall on a floor. Impact sound transmission is sound which is spread from an impact noise source in direct contact with a building element. Isolation is a strategy to limit the number and type of rigid connections between elements of construction. L’nT,w is the weighted standardized impact sound pressure level. A single-number quantity (weighted) to characterise the impact sound insulation of floors, in accordance with BS EN ISO 717-2: 1997. Mass is a physical quantity that expresses the amount of matter in a body. Walls and floors may be described in terms of the surface density (mass per unit area, kg/m2) of the wall face or the floor surface, which is the sum of the surface densities 22 of each component of the construction. The density of materials is expressed as mass per unit volume, kg/m3, which can be provided via the core structure and linings such as in-situ concrete or solid dense block walls. Mass per unit area (or surface density) is expressed in terms of kilograms per square metre (kg/m2). This is often used to describe boards, panels, flooring and dry linings (see gypsum based board). Resilience can reduce structural vibration transmission and still maintain material performance and overall dimensions, examples include floating floor treatments such as resilient battens or cradles, or resilient ceiling bars. Resilient ceiling bars are generally metal based and vary in thickness from 11 mm to 30 mm. They are mounted perpendicular to the joist span direction and can increase both airborne and impact sound insulation. Care should be taken to ensure that the ceiling board fixings into the resilient bar do not come into contact with the joists and reduce the potential performance. Resilient noggin a small section of resilient ceiling bar which is used to assist in bracing non load bearing partitions. Rw a single-number quantity (weighted) which characterises the airborne sound insulation of a building element from measurements undertaken in a laboratory, in accordance with BS EN ISO 717-1: 1997 Stiffness can improve low frequency sound insulation, for example in floors, by reducing the potential for deflection or movement of the primary structure, therefore the correct spacing and depth of joists is important. 23 Annex B Laboratory test procedures for building products and components Annex B is aimed at manufacturers of acoustic products and outlines the laboratory test procedures and methodologies for the acoustic testing of building components which may be used as part of the Example Constructions. The weighting terms (as the name suggests) used in this annex applies a focus or weighting of how the wall or floor is performing for certain types of frequencies and sounds. Such terms are applied to reflect the location the wall or floor may be situated within / adjacent to and the type of noise source the wall has to insulate against. The building components which may be assessed by laboratory testing are described in the following sections: B1 General requirements for the testing of Bonded Resilient Covers (BRC’s), Floating Floor Treatments (FFT’s) and resilient bars B2 Determination of the acoustic performance of Bonded Resilient Floor Coverings (BRC’s) used with concrete core floors B3 Determination of the acoustic performance of Floating Floor Treatments (FFT’s) used with concrete core floors B4 Determination of the acoustic performance of Floating Floor Treatments (FFT’s) used with timber core floors B5 Determination of the acoustic performance of resilient bars used with timber core floors B6 Determination of the acoustic performance of downlighters and recessed lighting used with timber core floors 24 B1 General requirements for the testing of Bonded Resilient Coverings (BRC’s), Floating Floor Treatments (FFT’s) and resilient bars Test facility accreditation The test facility must have UKAS Accreditation (or European equivalent) for the measurement of sound insulation in the laboratory for both airborne sound insulation and impact sound transmission. Test facility requirements The test measurement should be undertaken in accordance with: x BS EN ISO 140-3: 1995 for FFT’s and resilient bars only; x BS EN ISO 140-6: 1998 for FFT’s and resilient bars only; x BS EN ISO 140-8: 1998 for BRC’s only. The performance of each measurement should be rated in accordance with: x BS EN ISO 717-1: 1997 (for airborne sound), and x BS EN ISO 717-2: 1997 (for impact sound). The measurements should be undertaken in a laboratory with suppressed flanking transmission and in accordance with: x BS EN ISO 140-1: 1998; and x BS EN ISO 140-2: 1991. B2 Determination of the acoustic performance of Bonded Resilient Coverings (BRC’s) used with concrete core floors To determine the acoustic performance of BRC’s used with concrete core separating floors impact measurements should be undertaken in an acoustic test laboratory. The measurement and performance rating criteria are outlined below. Test facility accreditation and requirements – in accordance with B1. Core floor Testing should be undertaken on a core (or base) floor which consists of an in-situ concrete slab 140 mm thick. The tapping machine should not be placed directly onto the resilient floor cover as this leads to exaggerated performance values which are not representative of real buildings with hard floor finishes. The test sample resilient floor cover should be tested with a wood based floor covering laid over the test sample area. The test sample area and wood based floor covering should be of sufficient size to permit a tapping machine to be placed on top of the test materials. The wood based floor covering should be 8 mm (min) to 16 mm (max) thickness with a nominal density of 600 kg/m3 (+/- 30 kg/m3). 25 The floor test samples should be measured with a uniformly distributed load of 25 kg/m2 with at least one weight per square metre of the flooring area as described in BS EN ISO 140-8. Testing required Impact Test 1 - Determination of Ln,w for the core (or base) concrete floor. Test 2 - Determination of Ln,w for the core (or base) concrete floor with the resilient cover applied to the core floor surface. Expression of performance The impact sound transmission performance of the resilient covering should be expressed as the weighted reduction in impact sound transmission/pressure level (÷Lw) as a result of the application of the resilient covering to the core floor (÷Lw = Test 1 – Test 2). 26 B3 Determination of the acoustic performance of Floating Floor Treatments (FFT’s) used with concrete core floors To determine the acoustic performance of FFT’s used with concrete core separating floors airborne and impact measurements should be undertaken in an acoustic test laboratory. The measurement and performance rating criteria are outlined below. Test facility accreditation and requirements – in accordance with B1. In addition to B1, the R’max value of the laboratory test facility should be at least 10 dB greater than the sound insulation of the structure under test. Core floor The airborne and impact performance for FFT’s can be determined by using an insitu concrete floor in accordance with B2 or the pre-cast concrete core floor below. CORE (BASE) Concrete floor with FFT’s Testing should be undertaken on a core (or base) floor which consists of the following construction: Screed 10 mm (min) – 25 mm (max) levelling screed min. 80 kg/m2 with bonding agent applied such that it is directly bonded to the entire floor surface of the slab (planks). 150 mm deep hollow-core precast concrete slab (plank) of mass per unit area 295-305 kg/m2. Precast slab (plank) The hollow segments of the precast slab (plank) should be located at regular centres and should be distributed over a minimum of 80% of the slab (plank) width. The precast concrete hollow-core slab (planks) should be mounted in the test aperture to cover the entire test aperture area. Core floor construction The slab (planks) should be tightly abutted and all joints should be filled with grout including top and bottom joints. No voids should remain at the floor perimeter junction with the test aperture border. No ceiling treatments or layers should be applied. 27 The FFT should cover the entire test area of the core floor surface and should be constructed in accordance with the manufacturer’s instructions. Floating Floor Treatment (FFT) All FFT’s require a resilient flanking strip to isolate the edge of the floor board from the perimeter walls. The manufacturer should use the flanking strip, which they would normally use on site, in the laboratory measurements. The flanking strip design and specification should be consistent with the Example Constructions. Testing required (FFT) For the purposes of evaluating the performance of a FFT for concrete core floors four different measurements are required (two airborne and two impact). Airborne Test 1 – Determination of Rw for the core (or base) concrete floor. Test 2 – Determination of Rw for the core (or base) concrete floor with the FFT applied to the core floor surface. Impact Test 3 – Determination of Ln,w for the core (or base) concrete floor. Test 4 – Determination of Ln,w for the core (or base) concrete floor with the FFT applied to the core floor surface. Expression of performance The airborne sound insulation performance of the FFT should be expressed as the improvement in airborne sound insulation (÷Rw ) as a result of the application of the FFT to the core floor (÷Rw = Test 2 – Test 1) The impact sound transmission performance of the FFT should be expressed as the reduction in impact sound transmission (÷Lw) as a result of the application of the FFT to the core floor (÷Lw = Test 3 – Test 4). 28 B4 Determination of the acoustic performance requirements of Floating Floor treatments (FFT) used with timber core floors To determine the acoustic performance of floating floor treatments used with timber joist or lightweight frame separating floors airborne and impact measurements should be undertaken in an acoustic test laboratory. The following sections outline the measurement and performance rating criteria. Test facility and accreditation – in accordance with B1. In addition to B1, the R’max value of the laboratory test facility should be at least 10 dB greater than the sound insulation of structure under test. CORE (OR BASE) Timber joist floor with FFT Testing should be undertaken on a core (or base) floor which consists of the following construction construction: Floor decking 15 mm OSB timber decking board (or equivalent timber based board) with mass per unit area of 10-11 kg/m2 Joists 235 mm x 50 mm solid timber joists at least SC3 grade timber Insulation 100 mm glass based mineral wool insulation with a density of 10-11 kg/m3 Ceiling Two layers of 12.5 mm gypsum based board with a mass per unit area for each layer of 8-8.5 kg/m2 The timber joists should be mounted on joist hangers at 450 mm centres and the 100 mm (deep) glass based mineral wool insulation should be placed in the cavities between the joists and also between cavities formed between the joists and the test aperture border. Core floor construction The floor decking should be mounted on the timber joists with screws at 300 mm centres. All junctions between the floor surface perimeter and test aperture should be sealed with a flexible or acoustic sealant. The ceiling layers should be mounted with joints staggered and the first layer (inner layer) should be fixed to the underside of the joists with screws, at 300 mm centres within the field of the boards and at 150 mm centres at the board ends. The second layer (outer layer) should be fixed with screws, at 230 mm centres within the field of the boards and at 150 mm centres at the board ends. The perimeter of the ceiling should be sealed with flexible or acoustic mastic sealant and all joints and screwheads taped with self adhesive tape. 29 The FFT should cover the entire test area of the core floor surface and should be constructed in accordance with the manufacturer’s instructions. Floating Floor Treatment (FFT) All FFT’s require a flanking strip to isolate the edge of the floor board from the perimeter walls. As such the manufacturer should also use the resilient layer and flanking strip which they would normally use on site in the laboratory measurements. The flanking strip design and specification should be consistent with the Example Constructions. Testing required For the purposes of evaluating the performance of a FFT for timber separating floors four different measurements are required (two airborne and two impact). Airborne Test 1 – Determination of Rw and Rw +Ctr for the core (or base) timber floor. Test 2 – Determination of Rw and Rw+Ctr for the core (or base) timber floor with the floating floor treatment applied to the core floor surface. Impact Test 3 – Determination of Ln,w for the core (or base) timber floor. Test 4 – Determination of Ln,w for the core (or base) timber floor with the floating floor treatment applied to the core floor surface. Expression of performance The airborne sound insulation performance of the FFT should be expressed as the improvement in airborne sound insulation for two categories of performance (÷Rw and ÷Rw+Ctr) as a result of the application of the FFT to the core floor (÷Rw = Test 2 – Test 1) and (÷Rw+Ctr = Test 2 – Test 1). The impact sound transmission performance of the FFT should be expressed as the reduction in impact sound transmission (÷Lw) as a result of the application of the FFT to the core floor (÷Lw = Test 3 – Test 4). 30 B5 Determination of the acoustic performance of resilient bars used with timber core floors To determine the acoustic performance of resilient bars for use within separating floors airborne and impact measurements should be undertaken in an acoustic test laboratory. The performance of the resilient bars is calculated from the improvement in airborne and impact performance by a ceiling connected via resilient bars as opposed to a direct fix ceiling. The ceiling linings should be identical in both tests. Test facility and accreditation – in accordance with B1. Direct fix ceiling versus resilient bar ceiling Testing should be undertaken on a floor with a direct fix ceiling which consists of the following construction specification: Floor Decking 15 mm OSB timber decking board (or equivalent timber based board) with mass per unit area of 10-11 kg/m2 Joists 235 mm x 50 mm solid timber joists SC3 grade timber Insulation 100 mm glass based mineral wool insulation with a density of 1011 kg/m3 Ceiling Two layers of gypsum based board with an overall mass per unit area of 23-25 kg/m2. The timber joists should be mounted on joist hangers at 450 mm centres and the 100 mm (deep) glass based mineral wool insulation should be placed in the cavities between the joists and also between cavities formed between the joists and the test aperture border. The floor decking should be mounted on the timber joists with screws at 300 mm centres. All junctions between the floor surface perimeter and test aperture should be sealed with a flexible or acoustic mastic sealant. Floor construction with direct fix ceiling The direct fix ceiling is composed of two layers of gypsum based board which have an overall mass per unit area of 23-25 kg/m2 and have a minimum overall thickness of 30 mm. The ceiling layers should be mounted with joints staggered and the first layer (inner layer) should be fixed to the underside of the joists with screws, at 300 mm centres within the fields of the boards and 150 mm centres at the board ends, and the second layer (outer layer) should be fixed with screws, at 230 mm centres within the fields of the boards and at 150 mm centres at the board ends. The perimeter of the ceiling should be sealed with flexible or acoustic mastic sealant and all joints and screwheads taped with self adhesive tape. 31 Floor construction with the ceiling connected via resilient bars The floor construction and components used should be identical to the Direct Fix test structure except that the ceiling is only connected to the joists via the resilient bars. The resilient bars should be directly connected to the joists at 400 mm centres using metal screws, mounted perpendicular to the joist direction span and in accordance with the manufacturer’s instructions. The gypsum based board ceiling layers should be identical in their material properties to those used for the Direct Fix ceiling. Testing Required For the purposes of evaluating the performance of resilient bars for four different measurements are required (two airborne and two impact measurements). The following measurements are required: Airborne Test 1 – Determination of Rw and Rw+Ctr for the floor with a direct fix ceiling. Test 2 – Determination of Rw and Rw+Ctr for the floor with a ceiling connected with resilient bars. Impact Test 3 - Determination of Ln,w for the floor with a direct fix ceiling. Test 4 - Determination of Ln,w for the floor with a ceiling connected with resilient bars. Expression of performance The airborne sound insulation performance of resilient bars should be expressed as the improvement in airborne sound insulation for two categories of performance 32 (Rw and Rw+Ctr) as a result of the application of the resilient bar connected ceiling as opposed to the direct fix ceiling (Rw = Test 2 – Test 1) and (Rw+Ctr = Test 2 – Test 1). The impact sound transmission performance of resilient bars should be expressed as the reduction in impact sound transmission (Lw) as a result of the application of the resilient bar connected ceiling as opposed to the direct fix ceiling (Lw = Test 3 – Test 4). 33 B6 Determination of the acoustic performance of downlighters and recessed lighting used with timber core floors This test procedure may also be used where a manufacturer may wish to test closer spacing or increased density of downlighters (i.e. less than 1 per 2m2). To determine the influence on the acoustic performance due to the presence of downlighters for use within timber separating floors airborne and impact measurements should be undertaken in an acoustic test laboratory. The influence on the acoustic performance of the timber floor is calculated from airborne and impact measurements on a timber floor structure with and without downlighters present. The timber floor structure must be identical in both sets of tests (for airborne and impact) except for the presence of the downlighters. Test facility and accreditation – in accordance with B1. In addition to B1, for downlighters to qualify the difference in performance with the downlighters present should be no worse than 1 dB for both airborne measurements and impact measurements. Core timber floor with and without downlighters Testing should be undertaken on a floor with the following construction specification: Floor Decking 15 mm OSB timber decking board (or equivalent timber based board) with mass per unit area of 10-11 kg/m2 Joists 235 mm x 50 mm solid timber joists SC3 grade timber Insulation 100 mm glass based mineral wool insulation with a density of 10-11 kg/m3 Two layers of gypsum based board with an overall mass per unit area of 23-25 kg/m2. Construction of The timber joists should be mounted on joist hangers at 450 mm initial timber centres and the 100 mm (deep) glass based mineral wool floor (no insulation should be placed in the cavities between the joists and also between cavities formed between the joists and the downlighters) test aperture border. The floor decking should be mounted on the timber joists with screws at 300 mm centres. All junctions between the floor surface perimeter and test aperture should be sealed with a flexible or acoustic mastic sealant. Ceiling The direct fix ceiling is composed of two layers of gypsum based board which have an overall mass per unit area of 23-25 kg/m2 and have a minimum overall thickness of 30 mm. The ceiling layers should be mounted with joints staggered and the first layer (inner layer) should be fixed to the underside of the joists with screws, at 300 mm centres within the fields of the boards 34 and 150 mm centres at the board ends, and the second layer (outer layer) should be fixed with screws, at 230 mm centres within the fields of the boards and at 150 mm centres at the board ends. The perimeter of the ceiling should be sealed with flexible or acoustic mastic sealant and all joints and screwheads taped with self adhesive tape. Construction of The floor construction and components used should be identical timber floor with to the Initial Timber Floor test structure except that downlighters have been installed into the ceiling. The downlighters must be downlighters spaced at 1 downlighter per 2m2 of ceiling area and at not less than 0.75m spacings (e.g. 10m2 of ceiling area equates to 5 downlighters) Testing required For the purposes of evaluating the influence on performance due to downlighters for timber separating floors, four different measurements are required (two airborne and two impact measurements). Airborne Test 1 – Determination of Rw and Rw+Ctr for the initial timber floor. Test 2 – Determination of Rw and Rw+Ctr for the initial timber floor plus downlighters. Impact Test 3 – Determination of Ln,w for the initial timber floor. Test 4 – Determination of Ln,w for the initial timber floor plus downlighters. Expression of performance The influence on airborne sound insulation performance as a result of the installed downlighters should be expressed as two categories of performance (÷Rw = Test 2 – Test 1) and (÷Rw+Ctr = Test 2 – Test 1). The influence on impact sound transmission performance as a result of the installed downlighters should be expressed as the (÷Lw = Test 3 – Test 4). 35 Note: Downlighters which qualify for the above performance requirements should also be of suitable integrity. Particular attention should be paid to Section 2: Fire of the Technical Handbooks. 36