Effects of Inverter Control Parameters on Commutation Failure for a

advertisement

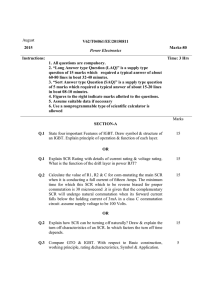

Effects of Inverter Control Parameters on Commutation Failure for a HVDC Link and on Torsional Vibrations for a Turbine Generator Chi-Hshiung Lin Abstract--In the paper, we analyze the commutation failure events caused by ac network faults happened at the rectifier and inverter sides of a HVDC link. It is found the inverter controls are significant in affecting the commutation behavior, whereas the rectifier controls are almost ineffective. For a rectifier side ac fault, the control parameters of the inverter current regulator are crucial to the commutation failure. As to an inverter side ac fault, the control parameters of the inverter voltage regulator play a non-negligible role. Further, it is found the single-phase-toground fault is the most likely one to cause the commutation failure. The three-phase-to-ground fault is less likely to cause the commutation failure than a single-phase-to-ground fault, but when it does, a repetitive commutation failure is very likely to take place and the HVDC l i nk wo n’ t recover smoothly. In addition, it is studied the torsional vibrations induced on the inverter side turbine generator due to a rectifier side ac fault. It is found there may be up to several times difference in the torsional torques induced, depending on the commutation behavior. And on certain settings of the inverter current regulator parameters, a single-phase-to-ground fault might cause a more serious impact on a turbine generator than a three-phase-to-ground fault. Index Terms—HVDC Link; Turbine Generator; Commutation Failure; Inverter; Torsional Vibration I. INTRODUCTION C OMMUTATION failure is a phenomenon that the transfer of current from the off-going valve to the on-going valve is not successful for a thyristor converter. For a HVDC system, it is a serious event and a lot of works have been done to understand such a phenomenon [1, 2]. It is shown that the basic reason for commutation failure is that the extinction angle during system disturbance is too small. When a thyristor valve is going to turn off, the internal excess charges must be removed before it can establish a forward blocking capability. If forward voltage is imposed across the turning-off valve before the storage charges have been removed completely, the thyristor valve cannot turn off successfully. As a result, commutation failure happens. Therefore, it requires a sufficient negative voltage-time area (or a sufficiently large extinction angle) for a valve to ensure the completion of a commutation process. Also, a lot of works have been done to know the cause and consequence of the commutation failure [3, 4, 5]. It is shown that commutation failure is mainly caused by the ac network C. H. Lin is with the Department of Electrical Engineering, Kao Yuan University, Kaohsiung, Taiwan. (e-mail: lin_chi_hshiung@hotmail.com) faults. When there are disturbances in the ac systems, a sudden transient reduction in the commutation voltage or a sudden rise in the dc current might be induced. And reports have revealed that commutation failures may happen during an ac system disturbance, where the voltage reduction is only as small as 10%. Once commutation failure happens, it generally causes stresses on valves, delay in restart time and, even, interruption of transmitted power. Fortunately, many approaches have been found to be helpful for alleviating the problem. For examples, larger smoothing reactors may limit the rate of rise of dc current, increasing in short circuit ratio of the inverter bus may reduce the voltage dip during faults, a greater margin angle for an inverter may provide more time for commutation, etc. Moreover, there are control approaches proposed for decreasing the commutation failure frequency [6, 7, 8]. They are generally to continuously monitor the ac system disturbances. Occasionally a dangerous situation is detected, the control system advances the firing time of thyristors. According to the survey above, the studies about the effect of control parameters of HVDC converters on commutation failure have never been found. We deem that this effect is significant because the transient response of network is crucial to the commutation time available, so studies are made in this paper. However, it is a challenge because there are interactions between the rectifier and inverter units as well as between the voltage and current regulators. The interactions are too complicated to be analyzed by analytic approach, so just the simulation analyses are adopted here. It is found that the inverter current control parameters are crucial to commutation failure when subjecting to the rectifier side ac faults. As to the inverter side ac faults, it is the inverter voltage control parameters to play a significant role. Rectifier controls are found to be ineffective, so no further discussions will be made. In another aspect, we have further studied the torsional vibrations induced at turbine generator units. For the operations of a HVDC link to impact the turbine generator units, many have been done. For examples, the torsional interactions between HVDC link and turbine generators have been studied in [9, 10]. The HVDC line faults to stress the turbine generator shafts were also studied in [11]. In [12], the impacts on rectifier side turbine generators causing by rectifier station faults were investigated. However, the paper didn’ t involve the commutation failure. In [13] and [14], the impacts of the inverter station faults on the rectifier side turbine generators and on the inverter side turbine generators were investigated, respectively. These two papers have taken into consideration the commutation failure. According to the 論文獎勵成果彙編P31 survey above, it can be seen that the impacts of rectifier side faults on inverter side turbine generators haven’ t been studied. So, the studies in the paper would make up this deficiency. It is found that, on certain settings of the inverter current regulator parameters, a single-phase-to-ground fault might cause a more serious impact on a turbine generator than a three-phase-toground fault. II. SYSTEM STUDIED A. System Descriptions The system studied is an asynchronously linked HVDC system, as shown in Fig. 1. A 1,000MW (500kV, 2kA) dc transmission line is used to transmit power from a 5,000MVA (500kV, 60Hz) network to a 10,000MVA (345kV, 50Hz) network. The converter configuration is typical, including a 12-pulse rectifier and a 12-pulse inverter. The dc transmission line is 300km long, with a 0.5H of smoothing reactor on each side. Each converter transformer, in a typical YY-and-YD winding configuration, equips with a tap changer. In normal operation, the primary voltage of the rectifier transformer is keeping at 0.90pu and the one of the inverter transformer is keeping at 0.96pu. The reactive power required by the converters is provided by a set of filters (capacitor bank plus 11th, 13th and high-pass filters, total 600Mvar on each side). depending on the firing pulse as well as the thyristor voltage and current. The switching dynamics (e.g. commutation failure) of a converter could be accurately represented by using such a model. The control strategy of the HVDC link studied is the Constant Current and Constant Voltage (CC&CV) scheme instead of the Constant Current and Constant Extinction Angle (CC&CEA) scheme. Both the rectifier and inverter have the same control structure. A detailed converter control model is adopted, of which the schematic diagram is shown in Fig. 2, with the parameters listing in Table 1. The controller has a voltage and a current regulator operating in parallel. All the regulators are typical PI controllers. Four control modes are available for the converters: 1- current control; 2- voltage control; 3- alpha minimum limitation; 4- alpha maximum limitation. I dc ref Vdc meas VDCOL 1 Vdcm arg I dcref lim 1 sTV 1 sTF Function Vdcmeas 1 I dc m arg 1 sTC I dc meas I dc dV Vdc ref max max k Current Regulator k p i s min Vdc k Voltage Regulator k p i s min ord CC ord VC min ord Tr. YY 50Hz Network to Pulse Generator Reactor Rectifier Voltage Dependent Current Order Limit Function Rectifier Controller AC Filter 60Hz Network Tr.YY I dc ref lim ( pu ) (DC Tx. Line) YD 1.0 I dc ref I dc ref 0.3 I dc ref Vdcmeas ( pu ) Inverter 0.18 0.6 (Tx. Line) Reactor YD Tr. AC Filter B2R GEN B2F LP2R LP2F Fig. 2 Schematic diagram of the converter control model Inverter Controller B1R Table 1 Parameters of the Converter Control Model B1F LP1R LP1F HP Turbine generator for torsional vibration studies Fig. 1 System studied B. System Modeling A graphic program using the Matlab/Simulink/PowerSystem-Blockset has been constructed for the entire HVDC system in order for transient simulations. The packaged models are used if available, to which we don’ t give unnecessary details. The dc transmission line is modeled as a circuit model for considering the capacitive effects. The rectifier and inverter units are composed of thyristors, and an individual thyristor is modeled as a switch in series with a resistor, an inductor and a voltage drop. The switch will be turn on/turn off (according to the preset switching characteristics) Rectifier control I dc ref 1 pu Inverter control I dc ref 1 pu Vdc ref 2 pu V dc ref 1 pu max 165 deg max 165 deg min 5 deg min 92 deg I dc m arg 0.0 pu I dc m arg 0.1 pu Vdc m arg 0.0 pu Vdc m arg 0.05 pu Current regulator k p 45 deg/ pu Voltage regulator k p 35 deg/ pu k i 4500 deg/ pu / sec k i 2250 deg/ pu / sec Measuring time constant TC 0.0003 sec TV 0.01 sec T F 0.0001 sec For the master control of a rectifier, the current order is 論文獎勵成果彙編P32 first determined, with constrains being imposed to keep the current within the maximum and minimum limits. The maximum current is determined by the Voltage Dependent Current Order Limiter (VDCOL) that is implemented for helping to recover from faults. The VDCOL automatically reduce the reference current set point when dc line voltage decreases (e.g. during a severe ac fault). The PI type of current regulator accounts for current regulating. If the current regulator doesn’ t hit any limits, the rectifier is operating in the current control mode. In case it hits the low limit the rectifier turns to operate in the alpha minimum limitation mode. In case it hits the high limit the firing angle will be larger than the one computed by the voltage regulator, thus the control mode will be changed to the voltage control mode. For the master control of an inverter, the action is reversed. Normally, the inverter operates in the voltage control mode with a PI controller to regulate the voltage. It will switch to the current control mode when the rectifier regulator touch the low limit and unable to maintain the desired dc current. instance of fault applying, with the firing angle (alpha-rec) falling down to 5 degrees. Later on, it changes positions between the current control mode and the alpha minimum limitation mode. As to the operation mode of inverter (modeinv), it changes from the voltage control mode to the current control mode during the faulty and recovery period, with the firing angle (alpha-inv) oscillating between 110 degrees and 140 degrees. It is significant to note that the current flow of HVDC link doesn’ t cease. YD side YY side 3 3 2 2 1 0 0.6 3 1 0.7 0.8 0.9 0 0.6 3 1 2 1 0 0.6 3 0.8 0.9 0 0.6 3 1 0.8 0.9 0 0.6 3 1 0.8 0.9 1 0.7 0.8 0.9 1 0 0.6 3 1 0.7 0.8 0.9 1 0.7 0.8 0.9 1 0.8 0.9 1 2 1 0.7 0.8 0.9 0 0.6 3 1 2 2 1 1 0.7 0.8 0.9 0 0.6 1 time (sec) 0.7 time (sec) 4 4 2 2 idc-inv vdc-inv Fig. 3 Inverter valves currents (in pu) without commutation failure (in sequence of 1 to 6 from top to bottom) 0 -2 0.4 0.6 0.8 0 -2 0.4 1 160 0.6 0.8 1 0.6 0.8 1 0.8 1 5 mode-inv alpha-inv 4 140 120 3 2 1 100 0.4 0.6 0.8 0 0.4 1 30 5 mode-rec alpha-rec 4 20 10 3 2 1 0 0.4 0.6 0.8 time (sec) A. Non-commutation-failure Case For the setting of (25 deg/pu, 4500 deg/pu/sec), the currents flow through the twelve inverter valves are shown in Fig. 3. It can be seen that neither the YD side nor the YY side valves occur the commutation failure. The resulting rectifier and inverter responses are shown in Fig. 4. In the steady state, the rectifier is operated in the current control mode, and the inverter in the voltage control mode. The firing angles are about 18 degrees and 141 degrees, respectively, for the rectifier and inverter. When the fault is applied, the inverter side dc voltage (vdc-inv) and current (idc-inv) start to oscillate. The operation mode of the rectifier (mode-rec) changes to the alpha minimum limitation at the 0.9 1 0 0.6 0.8 1 0.7 2 0 0.6 3 0.7 2 1 For ac faults happened in the rectifier side network, it is found the inverter current regulator will govern the commutation failure behavior. The reason is that time is a crucial factor. Too fast response may make the negative voltage-time area required by an inverter valve become insufficient for commutation to complete. So slightly differing in the settings of the proportional constant (kp) and/or the integral constant (ki) may result in wholly different commutation behaviors. Depending on the success or failure of commutation, the HVDC link will present wholly different performance in responding to the fault. We shall examine such phenomena for a single-phase-to-ground fault in the following two cases. It is assumed a ground fault occurs in the phase-A of the rectifier side network at 0.6 s and is cleared at 0.7 s. For the current regulator parameter of (kp, ki), it is set at (25 deg/pu, 4500 deg/pu/sec) in one case, and at (45 deg/pu, 4500 deg/pu/sec) in another case. In both cases, the voltage regulator parameter (kp, ki) is kept at (35 deg/pu, 2250 deg/pu/sec). For both the settings, transient simulations have confirmed the well operations of the HVDC link under the situations of load changing and reference changing. In a temporary dc line fault, the link can also recover successfully. 1 1 0.7 2 III. SIMULATION STUDIES OF THE RECTIFIER SIDE AC FAULTS 0.9 2 1 0 0.6 3 0.8 1 0.7 2 0 0.6 3 0.7 2 1 0 0.4 0.6 time (sec) Fig. 4 Converter responses without commutation failure B. Commutation-failure Case For the setting of (45 deg/pu, 4500 deg/pu/sec), the currents flow through the twelve inverter valves are shown in Fig. 5. It can be seen that, at 0.72 s or so, a commutation failure occurs in the valves 2 and 3 of YD side, and in the valves 3 and 6 of YY side. The responses for the rectifier and inverter are shown in Fig. 6. It is important to see that the HVDC link current ceases to flow (note: it is called “ collapse”in this paper) due to the commutation failure, and needs to be re-established when recovery. 論文獎勵成果彙編P33 The operation mode of converters could explain the reason for the HVDC link to collapse. It can be seen that the control action is disturbed by the commutation failure, leading to the rectifier be pushed to the inverter operation (with the firing angle changing to 130 degrees), and the inverter to the alpha maximum limitation mode (with the firing angle changing to 165 degrees). Thus, the HVDC link fails to function normally. YD side YY side 3 3 2 2 1 1 0.7 0.8 0.9 0 0.6 3 1 2 2 1 1 0 0.6 3 0 0.6 3 0.7 0.8 0.9 1 2 0.8 0.9 0 0.6 3 1 1 0.7 0.8 0.9 1 0.7 0.8 0.9 1 0.7 0.8 0.9 1 2 1 1 0.7 0.8 0.9 0 0.6 3 1 2 2 1 1 0 0.6 3 0 0.6 3 0.7 0.8 0.9 1 2 0.7 0.8 0.9 1 0.8 0.9 1 2 1 0 0.6 0.9 1 0.7 2 0 0.6 3 0.8 2 1 0 0.6 3 0.7 1 0.7 0.8 0.9 0 0.6 1 time (sec) 0.7 2 2 0 1 0 0.8 -1 0.4 1 0.6 0.8 4 160 140 120 3 2 1 0.6 0.8 0 0.4 1 150 0.6 0.8 1 0.8 1 5 mode-rec alpha-rec 4 100 50 3 2 1 0 0.4 0.6 0.8 time (sec) C B 1p-g 2p-g 3p-g 3000 A 4000 ki (deg/pu/sec) 5000 6000 1 0 0.4 Fig. 7 Parameter borderlines for the inverter current regulator IV. TORSIONAL VIBRATIONS 1 5 mode-inv alpha-inv 180 100 0.4 D To study the torsional vibrations induced at the shafts and blades of a turbine generator, a 950MW turbine generator unit is especially added to the 60Hz network. And it is assumed power is transmitted reversely from the 50Hz network to the 60Hz network. 3 idc-inv vdc-inv 4 0.6 100 90 80 70 60 50 40 30 20 10 0 2000 time (sec) Fig. 5 Inverter valves currents (in pu) with commutation failure (in sequence of 1 to 6 from top to bottom) -2 0.4 kp (deg/pu) 0 0.6 3 a double-phase-to-ground fault or a three-phase-to-ground fault, yet it will collapse when subjecting to a single-phase-toground fault. If the parameters are set at the district A, the HVDC link could wholly prevent from collapsing. That is the single-phase-to-ground fault is the most likely one to collapse the HVDC link, the three-phase-to-ground fault is the next and the double-phase-to-ground fault is the least. That is an unusual order. Thereby, it is the single-phase-to-ground fault rather than the three-phase-to-ground fault that should be examined to ensure the satisfactory setting of the inverter current regulator parameters. 0.6 time (sec) Fig. 6 Converter responses with commutation failure C. Criterion We have further examined the responses for various combinations of kp and ki parameters under the single-phaseto-ground (1p-g), double-phase-to-ground (2p-g) and threephase-to-ground (3p-g) faults. It is found there is a borderline in the parameter plane for each fault. The lower-and-left side of a borderline is a district not to cause the collapse of the HVDC link. So a smaller value of the kp and ki parameters is preferred. The borderlines for the three types of fault are shown in Fig. 7. The parameter plane is divided into the A, B, C and D districts by the borderlines. If the parameters are set at the district B, the HVDC link will not collapse when subjecting to A. Turbine generator The generator is a 4-poles/1800rpm machine with voltage rating of 23.75kV, which is driven by a steam turbine unit and supplies power to the converter bus via a step-up transformer (with power rating of 1057MVA) and two parallel transmission lines. An IEEE type-1 AVR regulates the generator terminal voltage. Again, this sub-system is constructed by the Matlab/Simulink/Power-System-Blockset packaged models. The steam turbine unit, including a highpressure stage (HP) and two low-pressure stages (LP1, LP2) steam turbines, is a close-coupled and cross-compound reheat unit that operates at a rotational speed of 1800 rpm. Each lowpressure turbine has F and R spindles, including eleven rows of blades with twisting structure and serrated type of root. B. Turbine-generator-exciter-blade model It is very difficult to characterize a complex turbine generator structure, yet it has been commonly accepted to use the lumped mass-damping-spring model for the studies on torsional vibrations. In Fig. 8, it is shown such a model for the turbine-generator-exciter-blade mechanism studied, with parameters listing in Table 2. One could refer to [15, 16] for details of how the model and its parameters were derived. According to the lumped mass-damping-spring model, dynamic equations of motion can be derived. Here, we use a 論文獎勵成果彙編P34 very particular approach, electromechanical analogy [17], to derive them. For an individual section (e.g. Rotor-j section) as shown in the upper part of Fig. 9, it can be transformed into an equivalent circuit as in the lower part of Fig. 9. By the loop analyses, one could find easily the state space equations as the followings. DB2F DLP2R/GEN DLP2R KREC/EXC JEXC JHP DHP/LP1F DLP1F/LP1R DLP1R/LP2F DLP2F/LP2R DLP1R DLP2F DHP DLP1F KGEN/REC JGEN JLP1R KLP1F/LP1R JLP1F KHP/LP1F JB2F JLP2R KB1R KB1F DB2R JB2R KB2F KB2R KLP1R/LP2F KLP2F/LP2R KLP2R/GEN JB1R JLP2F JB1F JREC DB1R DB1F DGEN/REC DGEN DREC/EXC DREC DEXC d B j Bj dt d B j Bj K Bj * j K Bj * jB D Bj * Bj / J Bj dt (3) (4) where J, K, D represent respectively the inertia, stiffness and damping of rotor or of shaft. The and are angular displacement and angular velocity respectively. For turbine rotors, is the torque delivered by the turbine. The torque is determined by the opening of the main control valves (CVs) and reheater/intercepter valves (IVs) that is dependent on turbine governor action. For the generator rotor, is the electromagnetic torque delivered to power system. As to the ones with superscript “ B” , they are the blade variables or parameters. Fig. 8 Mass-damping-spring model of the turbine-generatorexciter-blade mechanism Table 2 Parameters of the Mass-damping-spring model Rotor section HP LP1F LP1R LP2F LP2R GEN REC EXC B1F B1R B2F B2R Inertia constant (MW-s/MVA) 0.1787 0.6462 0.6410 0.6499 0.6602 1.1616 0.00344 0.00236 0.0344 0.0344 0.0344 0.0344 D Bj Bj Damping coefficient (MW-s/MVA-rad) 0.00180 0.00023 0.00021 0.00021 0.00021 0.00012 0.00000 0.00000 0.00004 0.00004 0.00004 0.00004 J jB K jB Bj j K j , j 1 K j 1 , j j-1 j1 j Jj D j 1 , j D j , j1 Dj 1 K jB j1 j Dj Jj LOOP 2 Table 2 continued Shaft section HP/LP1F LP1F/LP1 R LP1R/LP2 F LP2F/LP2 R LP2R/GEN GEN/REC REC/EXC LP1F/B1F LP1R/B1R LP2F/B2F LP2R/B2R Stiffness coefficient (MW/MVA-rad) 144.15 1595.0 Damping coefficient (MW-s/MVA-rad) 0.00 0.00 206.0 0.00 1584.9 0.00 325.28 117.16 1.61 36.2 36.2 36.2 36.2 0.00 0.00 0.00 0.00 0.00 0.00 0.00 B j 1 K j , j 1 LOOP 1 Eigen-values -1.95620262425 +/- 1806.76898690731i -0.04277156682 +/- 719.08407897187i -0.03615391816 +/- 698.19047239941i -0.06628545682 -0.06272706389 +/- 122.00368899893i -0.07436986263 +/- 232.13115405894i -1.33455883572 +/- 252.58777166885i -0.36759195240 +/- 289.60578342518i -0.08216900537 +/- 333.30197487371i -0.06376719130 +/- 326.51259771547i -0.05532705174 +/- 312.89871647952i -0.05653688675 +/- 313.05339760415i (2) LOOP 2 equations: j1 B j K j 1, j D j 1 , j Table 3 Eigen-values of the Mass-damping-spring Model D B j Fig. 9 Rotor-j section of the mass-damping-spring model and its equivalent circuit d j j (1) dt d j j D j D j , j 1 D j 1 , j j D j , j 1 * j 1 D j 1, j * j 1 dt K j , j 1 K j 1, j K Bj j K j , j 1 * j 1 K j 1, j * j 1 K Bj * jB / J j B j D j , j 1 LOOP 1 equations: -+ J 1 -+ j and Frequency (Hz) 287.55 114.44 111.12 19.42 36.94 40.20 46.09 53.05 51.96 49.80 49.82 By rewriting the torque equations to the power equations further transforming the equations into the 論文獎勵成果彙編P35 0.5 0 -0.5 6 7 8 9 0.5 0 -0.5 10 6 LP2R/GEN 0.5 0 -0.5 6 7 8 9 9 10 8 9 10 8 9 10 0 -0.5 6 7 0.05 B2F torque (pu) B2F torque (pu) 8 LP2R/GEN 0.5 -1 10 0.05 0 -0.05 7 1 torque (pu) torque (pu) 1 -1 E/M torque (pu) E/M torque (pu) 1 0.5 0 -0.5 6 7 8 9 0.5 0 -0.5 10 1 LP2R/GEN torque (pu) 0.5 0 -0.5 -1 6 7 8 9 7 8 9 10 8 9 10 8 9 10 LP2R/GEN 0.5 0 -0.5 -1 10 0.1 6 7 0.1 B2F torque (pu) 0.05 0 -0.05 -0.1 6 1 6 7 8 9 10 B2F 0.05 0 -0.05 -0.1 6 time (sec) 7 time (sec) Fig. 11 Turbine generator responses for a three-phase-toground fault (left: without commutation failure, right: with commutation failure) Table 4 Maximum-to-minimum Values of Torsional Torques Fault type Parameter district LP2R/GEN torque (pu) B2F torque (pu) 1p-g A B 0.42 1.2 0.017 0.09 3p-g B 0.8 0.03 C 2.2 0.22 1 E/M torque (pu) E/M torque (pu) 1 1 torque (pu) C. Transient simulations As indicating in the introduction, it has been studied the impact for the fault and turbine generator to be at the same side of a HVDC link. So just only the situation for an ac fault at rectifier side to stress the turbine generator at inverter side is studied here. Since the system configuration has been changed due to the addition of a generator, the inverter current regulator parameter borderlines for the three types of faults would be shifted. Nevertheless, it is the same for the parameter plane to be divided into the A, B, C and D districts. The transient simulations for a single-phase-to-ground fault and for a three-phase-to-ground fault are made here. It is assumed the ground fault is taken place in the rectifier side (50Hz side) network at 7 sec, lasts for 5 cycles, and then is cleared automatically. Neither the inverter nor the rectifier will be blocked in the simulations. The inverter current regulator parameters are set at the districts A and B for the case with a single-phase-to-ground fault, and at the districts B and C for the case with a three-phase-to-ground fault. Thus, both the HVDC link non-collapsing and collapsing situations could be achieved for the two faults. than the one induced under the non-collapsing situation, and the blade torque is about 6 times. Thus, it can be known the inverter current regulator parameters are so significant to affect the stressing of the turbine shafts and blades. torque (pu) Matlab/simulink model, the turbine-generator-exciter-blade model can thus be incorporate with the electric power system. By making an eigen-analysis on the turbine-generatorexciter-blade model, the eigen-values can be obtained as in Table 3, which reveals the natural modes of the mechanism. 6 7 8 time (sec) 9 10 0 -0.05 6 7 time (sec) Fig. 10 Turbine generator responses for a single-phase-toground fault (left: without commutation failure, right: with commutation failure) In Figs. 10 and 11, it is shown the turbine generator responses, including the generator electromagnetic torque (E/M torque) as well as the torsional torques at the LP2R/GEN shaft and B2F blade sections, for the two cases. For understanding easily, we tabulate the maximum-tominimum values of torsional torque in Table 4. It can be seen that there is a remarkable difference in torsional vibrations induced at the turbine shaft and blade. The shaft torque induced under the collapsing situation is about 3 times larger D. Discussions It is significant to make a comparison between the single-phase-to-ground and three-phase-to-ground faults in Table 4 for the parameters to be set at the district B. It is surprised to find that a single-phase-to-ground fault causes a more serious impact on the turbine generator than a threephase-to-ground fault does. The reason is that the HVDC link is collapsed for the single-phase-to-ground fault, yet it is not for the three-phase-to-ground fault. So it can be known that an un-satisfactory setting of the inverter current regulator parameters may make the stressing on a turbine generator even worsen. Furthermore, it is also significant to pay attention to the E/M torque in Fig. 11. One can observe that there occurs a repetitive disturbing phenomenon for the commutation failure situation. This is caused by the repetitive collapse in the HVDC link due to the repetitive commutation failure. A lot of cases have been examined for that, and the same results are obtained. It seems that a three-phase-to-ground fault is less likely to collapse the HVDC link than a single-phase-toground fault, but when it does, it can not recover smoothly. In practice, the converters will be blocked if more than two successive collapses in the HVDC link were detected. V. FURTHER STUDIES ON THE INVERTER SIDE AC FAULTS It has been known that the operation of a HVDC link is very sensitive to the ac network faults in inverter side. If the 論文獎勵成果彙編P36 fault is close to the inverter station, commutation failure would occur and the HVDC link would collapse without exception. Thus, in order for studies, it is assumed the fault applied to the inverter side ac network is a line-to-resistor-toground one. Here, the grounding resistance may be imagined as the distance from the inverter station to the fault. After many case studies, it is found the inverter voltage regulator, instead of the inverter current regulator, plays a significant role in affecting the link’ s commutation behavior. For a single-phase-to-ground fault with 55 ohms of grounding resistance, the relationship between commutation failure and inverter voltage regulator parameters is shown in Fig. 12. Again, it can be found that there is a borderline, dividing the parameter plane into two districts. The borderline is very nonlinear. Parameters in district A would cause the commutation failure (and the collapse in HVDC link), whereas in district B would not. So a larger value of the kp and ki parameters is preferred, that is just opposite to that for the inverter current regulator. is likely to happen and the HVDC link won’ t recover smoothly. Furthermore, it is summarized below the findings about the torsional vibrations induced on an inverter side turbine generator due to a rectifier side ac fault. 1. Depending on the commutation behaviors of the HVDC converter, there may be up to several times of difference in the shaft and blade torsional torques induced. 2. For certain settings of the inverter current regulator parameters, a single-phase-to-ground fault might cause a more serious impact on a turbine generator than a threephase-to-ground fault. REFERENCES [1] [2] [3] ki (deg/pu/sec) 3200 3000 [4] 2800 2600 B 2400 2200 2000 A [5] [6] 1800 1600 140 150 160 170 180 kp (deg/pu) 190 200 Fig. 12 Parameter borderline for the inverter voltage regulator [7] [8] [9] VI. CONCLUSIONS The collapsing of a HVDC link caused by the commutation failure is a very complicated phenomenon because the rectifier unit and the inverter unit would interact each other, and so as to the voltage regulator and the current regulator of a converter. Thus, it is hard to sophisticatedly analyze that, and there is usually not a general rule could be obtained. For the system studied, the following conclusions are found to be noteworthy for the commutation failure. 1. For the rectifier side ac faults, the control parameters of the inverter current regulator are crucial in inducing the commutation failure. 2. For the inverter side ac faults, the control parameters of the inverter voltage regulator could affect the commutation behavior. 3. It is the single-phase-to-ground fault rather than the threephase-to-ground fault to be the most likely one to cause the commutation failure. 4. A three-phase-to-ground fault seems less likely to cause the commutation failure than a single-phase-to-ground fault, but when it does, a repetitive commutation failure [10] [11] [12] [13] [14] [15] [16] Zou Gang, Zheng Jianchao, Chen Xiangxun, “ Study on Commutation Failure in an HVDC Inverter,”International Conference on Power System Technology, Vol. 1, pp. 503-506, 1998. E. Rahimi, A. M. Gole, J. B. Davies, I. T. Fernando, K. L. Kent, “ Commutation Failure in Single- and Multi-infeed HVDC Systems,” The 8th IEE International Conference on AC and DC Power Transmission, pp. 182-186, 2006. G. M. Kristmundsson, D. P. Carroll, “ The Effect of AC System Frequency Spectrum on Commutation Failure in HVDC Inverters,” IEEE Trans. on Power Delivery, Vol. 5, No. 2, pp. 1121-1128, 1990. C. V. Thio, J. B. Davies, K. L. Kent, “ Commutation Failures in HVDC Transmission Systems,”IEEE Trans. on Power Delivery, Vol. 11, No. 2, pp. 946-957, 1995. S. Tamai, H. Naitoh, F. Ishiguro, M. Sato, K. Yamaji, N. Honjo, “ Fast and Predictive HVDC Extinction Angle Control,”IEEE Trans. on Power System, Vol. 12, No. 3, pp. 1268-1275, 1997. T. Machida, Y. Yoshida, “ A Method to Detect the Deionization Margin Angle and to Prevent the Commutation Failure of an Inverter for DC Transmission,”IEEE Trans. on Power Apparatus and Systems, Vol. 86, No. 3, pp. 259-262, 1967. Arne Hansen, Henric Havemann, ”Decreasing the Commutation Failure Frequency in HVDC Transmission Systems,”IEEE Trans. on Power Delivery, Vol. 15, No. 3, pp. 1022-1026, 2000. Lidong Zhang, Lars Dofnas, “ A Novel Method to Mitigate Commutation Failure in HVDC Systems,”International Conference on Power System Technology, Vol. 1, pp. 51-56, 2002. T. J. Hammons, W. G. Mui, “ Turbine, Generator, System Modeling and Impact of Variable-frequency Ripple Currents on Torsional Stressing of Generators in Poland and Sweden: Lithuania/Poland and Sweden/Poland HVDC Links, ”IEEE Trans. on Energy Conversion, Vol. 15, No. 4, pp. 384-394, 2000. T. J. Hammons, T. C. Chua, and K. H. Chew, “ Proposed Ireland-North Wales Power Link: Steam Turbine-generator Shaft Torques due to Steady Harmonic Ripple Currents Superimposed on the HVDC Current in an Asynchronous Link,”International Journal of Power and Energy Systems, Vol. 21, No. 1, pp. 28-42, 2001. S. O. Faried, S. Abo r e s ha i d,“ Stochastic Evaluation of Turbinegenerator Shaft Torsional Torques in a HVAC/DC Power System, ” IEEE Trans. Power Systems, Vol. 17, No. 3, pp. 739-746, 2002. S. O. Faried, A. M. El-Se r a f i ,“ Ef f e c to fHVDCCo nv e r t e rSt a t i o nFa ul t s on Turbine-g e ne r a t o rSha f tTor s i o na lTo r que s , ”IEEE Trans. on Power Systems, Vol. 12, No. 2, pp. 875-881, 1997. M. R. Iravani, Z. Zhao, R. M. Hamouda, “ Impact of Inverter Station on Torsional Dynamics of Parallel HVDC-AC Power System,”IEEE Trans. on Power System, Vol. 8, No. 3, pp. 997-1003, 1993. C. K. Kim, B. M. Yang, Y. H. Ahn, J. G. Cho i ,“ Impact of Generator of Inverter Station on Torsional Dynamics of HVDC Sy s t e m, ”IEEE 2002 28th Annual Conference of the Industrial Electronics Society, Vol. 1, pp. 538-543, 2002. C. H. Lin, “ TheEf f e c t so faMOV Sur g eAr r e s t e ronBl a deVi br a t i o ns o fa La r g e Sc a l e Tur bi ne Uni t , ” Electric Power Components and Systems, Vol. 31, No. 8, pp. 757-776, 2003. C. H. Lin, “ Frequency Limitations for Disposing Natural Torsional Modes of a Large Scale Turbine Generator in an Asynchronous HVDC 論文獎勵成果彙編P37 System, ”International Journal of Electrical Engineering, Vol. 14, No. 1, pp. 51-64, 2007. [17] C. H. Lin, “ Re stricting Turbine Blade Fatigue based on Electromechanical-Ana l og yCi r c ui tAna l y s i s , ”International Journal of Power and Energy Systems, Vol. 22, No. 3, pp. 150-158, 2002. 論文獎勵成果彙編P38