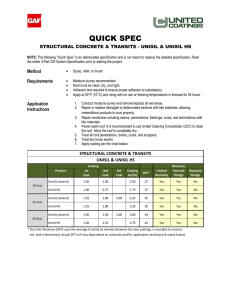

Technical Data Solvent Free Epoxy coating for Industrial coatings

advertisement

Technical Data P500 Solvent Free Epoxy coating for Industrial coatings. Description: P500 is a two component solvent free epoxy floor coating system which is designed for continous protection in light to heavy duty application. It provides a high gloss , seamless , surface that is hard wearing and durable. The system consists of pre weighed coloured base and hardener components . It cures to a semi gloss finished and easily clean.. The coating can also be applied to provide a non-slip texture and may be top coated if required Features and Benefits : o o o o o o o o o o Self leveling , penetrates and strengthen porous surfaces such as concrete. Durable and good resistance to wear and abrasion Low odour during application Adheres durably to a variety of substrates . It withstand light to heavy foot traffic. High adhesive strength and mechanical properties. Excellent adhesion, toughness, and overall chemical resistance. Seamless and complete protection Good color and finish Excellent long term protection and cost effective. Uses and Application: P500 as: o o o o o o o o provides a hard, abrasion chemical and slip resistant floor finish to areas such Chemical plant Factory Floors Dairies Food and soft drink production places warehouses Car production plants, pharmaceutical and laboratory installations Car park flooring Show rooms Recommended Systems: Concrete floors o Epoxy Primer 1coat @30~50DFT o P500 Solvent Free 1 ~ 2 coat P. O. Box No. 30303 Dubai, UAE, Tel No. +971 4 8802088, Fax No.: +971 4 8802055 Email : info@tekncoat.ae, web : www.tekncoat.net 1 Issued No. 2 March 25,2014 Technical Data P500 Parking Floor o Epoxy Primer 1 coat @30~50 DFT o P500 Basecoat 0.2 ~0.4 kg /sq. meter o Anti slip grit- high quality quartz sand of 0.3 ~0.5 mm size 0.8~ 1.2 kg/ sq. meter o P500 Top Coat of chosen color 1 ~ 2 coats Packaging: o Part A – 15 kg net drum o Part B – 2.1 kg net can Caution: This is a two component system, DO NOT use without a hardener Technical data: Color Finish Volume solid Pot Life : : : : : Coverage : To touch : Foot traffic : Heavy traffic : To cure : Compressive Strength ASTM C579 : Flexural Strength ASTM C580 : Tensile Strength ASTM C 307 : Shore D Hardness ASTM D2240:05 : Resistant to chemical : coating thickness : Shelf life : VOC : Grey, Green, Red, Blue, other colors by request smooth and glossy 100 % 3 hrs @ 25 0C 1.5 hrs @ 300C 3~ 4 m2 / kg /mm 10 hours 48 hours 96 hours 7 days 66.2 N /mm2 19.8 N / mm2 21.5 N/ mm2 D/74/1 after 7 days of coating min 1 ~ 1.5 mm 12 months unopened 15 .7 g/l ( USEPA 24 ) P. O. Box No. 30303 Dubai, UAE, Tel No. +971 4 8802088, Fax No.: +971 4 8802055 Email : info@tekncoat.ae, web : www.tekncoat.net 2 Issued No. 2 March 25,2014 Technical Data P500 Surface Preparations: Surface must be clean, dry and in good condition. Remove oil, dust, and other foreign materials to achieve food adhesion. o Poured Concrete - the surface to be laid must be flat and roughened and cured for 28 days. Remove laitance preferably by using Blast tracking machine with vacuum sucking off the dust. Oil and paints on the surface shall be removed using acid wash followed by detergent and wash water. Rinse thoroughly and allow to dry prior to coating. o Surface irregularities must be ground down or filled out with Tg 113c or suitable grout. o Iron and Steel – Remove oil and grease from the surface using solvent cleaning. For better performance, use metal blast cleaner and blast clean all surfaces. Prime the surface as it is cleaned. Application Procedure : P500 is consist of two components, and supplied in a pre weighed quantities. P 500 shall be mixed using slow speed electric mixer for 2 to 3 minutes until the mixture becomes homogenous . o Apply P500 on to already Epoxy primed surface at the rate given above. For better adhesion, apply the mixed P500 while the primed coat is tacky and touch dry. Mixed P500 can be applied using squeegee or roller brush as required. o Anti slip grit of 0.3 ~0.5 mm size shall be applied at the rate of 0.8 to 1.2 kg /m2 immediately after applying the basecoat. After 24 hours curing, excess grit shall be sweep off the surface. Apply P500 top coat of chosen color. Performance tips: o Do not apply the material beyond recommended pot life. o No reduction of material should be done as it can affect film build, appearance and adhesion. o Do not add catalyzed P500 material with new. Clean up: o Remove uncured P500 from tools and equipment using cleaning solvent such as naptha or xylene. P. O. Box No. 30303 Dubai, UAE, Tel No. +971 4 8802088, Fax No.: +971 4 8802055 Email : info@tekncoat.ae, web : www.tekncoat.net 3 Issued No. 2 March 25,2014 Technical Data P500 Shelf life : o Remain stable for at least 12 months when stored in an air tight container in a cool and dry place and no direct sun exposure. Health and Safety: o As with all chemical products, caution should always be exercised. Protective coating such as gloves, goggles should be worn. Treat any splashes to the skin or eyes with fresh water immediately. Should any of the products be accidentally swallowed, seek immediate medical assistance. o Always refer on MSDS for further safety use of the product. Available on Request: o Information contained in this product sheet conforms to the standard detail recommendation in specification is presented in good faith. TEKNCOAT assumes no liability or implied as to the architecture, engineering or any other project. For additional information, contact TEKNCOAT. P. O. Box No. 30303 Dubai, UAE, Tel No. +971 4 8802088, Fax No.: +971 4 8802055 Email : info@tekncoat.ae, web : www.tekncoat.net 4 Issued No. 2 March 25,2014