PHYSICAL MECHANISMS OF BREAKDOWN IN

PHYSICAL MECHANISMS OF BREAKDOWN IN MULTICRYSTALLINE SILICON SOLAR CELLS

O. Breitenstein

1

, J. Bauer

1

, J.-M. Wagner

1

, H. Blumtritt

1

, A. Lotnyk

1,2

, M. Kasemann

3

, W. Kwapil

3

, W. Warta

3

1

Max Planck Institute of Microstructure Physics, Weinberg 2, D-06120 Halle, Germany

2 now: Christian-Albrechts-University, Technical Faculty, Kaiserstr. 2, D-24143 Kiel, Germany

3

Fraunhofer Institute of Solar Energy Systems, Heidenhofstr. 2, D-79110 Freiburg, Germany

ABSTRACT

We have identified at least five different local breakdown mechanisms according to the temperature coefficient (TC) and slope of their characteristics and electroluminescence

(EL) under reverse bias. These are (1) early prebreakdown (strongly negative TC, low slope), (2) edge breakdown (positive TC, low slope, no EL), (3) weak defect-induced breakdown (zero or weakly negative TC, moderate slope, 1550 nm defect luminescence), (4) strong defect-induced breakdown (zero or weakly negative TC, moderate slope, no or weak defect luminescence), and (5) avalanche breakdown at dislocation-induced etch pits

(negative TC, high slope). The latter mechanism usually dominates at high reverse bias. In addition to the local breakdown sites there is evidence of an areal reverse current between the dominant breakdown sites showing a positive TC. Since defect-induced breakdown shows a zero or weakly negative TC and also leads to weak avalanche multiplication, we propose defect level-induced avalanche instead of trap-assisted tunneling to be responsible for this breakdown mechanism.

INTRODUCTION

Local junction breakdown at low reverse biases has become an important technological problem especially in multicrystalline silicon solar cells. Theoretically, cells with a base doping concentration of 1x10

16

cm

-3

should break down at about -50 V reverse bias by avalanche breakdown, but in reality breakdown often begins already below -5 V. The appearance of local hot spots at breakdown sites may lead to permanent damage of modules under certain operating conditions of these cells.

If on cell of a string is shadowed, the other cells may reverse-bias this cell. The mechanisms behind local junction breakdown, and especially their relation to material defects, are not well understood yet. However, this understanding becomes increasingly important since the trend in solar cell industry goes towards enabling the production of silicon solar cells from high-impurity

(upgraded metallurgical grade; UMG) feedstock. There are clear indications that high impurity concentrations are leading to breakdown at even lower voltages.

EXPERIMENTAL

The results presented in this contribution are based on various physical methods for investigating breakdown phenomena, most of them being imaging techniques. They were applied to a set of industrial acidically etched multicrystalline cells made from closely neighbored wafers from the same brick, which were free of ohmic shunts.

Besides temperature-dependent current-voltage (I-V) characteristic measurements, mostly dark lock-in thermography (DLIT) under reverse bias has been used for localizing the breakdown sites. Since DLIT images can be scaled quantitatively in units of a local current density, the results of DLIT images taken under different reverse biases and temperatures allow the creation of images of the local temperature coefficient (TC) and the steepness

(slope) of the reverse current (TC-DLIT and slope-DLIT

[1]). In these techniques thermally measured local current densities belonging to different temperatures or biases, respectively, are pairwise subtracted from each other and normalized to the local average current density and the temperature or bias difference, respectively. Thereby the resulting TC or slope images show the values of the

relative TC or slope at the breakdown sites in units of "% current change per K" (or per V, respectively), independent of the absolute value of the breakdown current. These magnitudes are appropriate to distinguish different types of breakdown from each other. The local avalanche multiplication factor (MF) was imaged by a special variant of illuminated lock-in thermography (MF-

ILIT [1]), which is based on imaging the local pulsed heat dissipation at a constant reverse bias for pulsed weak homogeneous illumination. At low reverse bias this image is essentially homogeneous and displays the local photocurrent. If the reverse bias is increased above the avalanche limit, in local avalanche sites the photocurrent is locally increased. By relating the pulsed photocurrent under avalanche condition to that at low reverse bias, a quantitative image of the avalanche multiplication factor is obtained [1]. Moreover, the local lifetime and the presence of recombination-active defects in the base material was detected by forward-bias electroluminescence (EL) imaging at 1100 nm, and defect (dislocation) induced luminescence was imaged by forward-bias EL-imaging at

1550 nm. High-resolution imaging of breakdown sites was performed by EL-imaging under reverse bias. The avalanche sites were imaged also microscopically by reverse-bias lock-in electron beam-induced current in comparison with secondary electron imaging in the scanning electron microscope. By applying transmission electron microscopy (TEM) at the dominant breakdown sites, the origin of avalanche breakdown has been identified.

978-1-4244-2950-9/09/$25.00 ©2009 IEEE 000181

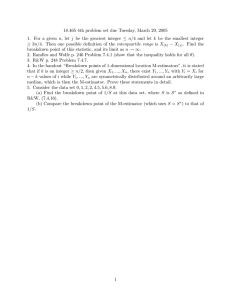

RESULTS

Current-voltage (I-V) characteristics

Fig. 1 (a) shows typical reverse-bias I-V characteristics of our solar cells at two temperatures. There is a crossover at about 13.4 V; at lower reverse bias the current shows a positive TC and at higher bias a negative TC. The latter is typical for avalanche breakdown, which, however, for monocrystalline material is expected to appear only beyond -50 V. A positive TC is expected for internal field emission breakdown, which, however, is expected for monocrystalline material only for doping concentrations many orders of magnitude higher than 10

16

cm

-3

. Since our cells are made from multicrystalline material, it can be expected that this early breakdown is connected with crystal defects. The transition from positive to negative TC points to the fact that different breakdown mechanisms exist in different bias regions. Fig. 1 (b) shows room temperature I-V characteristics of different separated regions containing different breakdown sites, see next sub-section and sub-section "Reverse-bias EL imaging". a) b)

40

T = 25°C

35

30

stage I

stage II

25

stage III

no breakdown

20

15

10

5

0

-16 -14 -12 -10 -8 -6 -4 -2 0

U [ V ]

Fig. 1. (a): Reverse-bias current-voltage (I-V) characteristic of a typical cell at two temperatures, (b): I-V characteristics of different separated regions (see text).

1100 nm EL and bias-dependent DLIT

For distinguishing different breakdown mechanisms and relating them to grown-in crystal defects, biasdependent DLIT investigations have been made and compared to forward-bias EL images. Since these EL images were obtained by using a thermoelectrically cooled

CCD camera, they display the luminescence due to electron-hole recombination at a wavelength of about 1100 nm. This EL signal diminishes in the presence of grown-in recombination-active crystal defects like dislocations and grain boundaries [2]. Fig. 2 shows a set of DLIT images made at room temperature at different biases, in comparison with a 1100 nm EL image of the same sample.

According to their very different signal height, the DLIT images are differently scaled. First weak breakdown sites appear at -5 V. They are mostly located at the edge and do not correlate with recombination-active defects. Some of them are also found in the cell area. In the following, we will call these sites in the area "early pre-breakdown" sites

(labeled as " I " in Fig. 2 (b)) and the sites at the edges

"edge breakdown" sites. At higher reverse biases (c, d) the breakdown sites more and more correlate with the grownin defects visible in the EL image (a). Thereby defects with a darker EL contrast seem to cause stronger breakdown sites. Such a site is labeled " II " in Fig. 1 (c). At -15 V (d) new breakdown sites appear, showing a very steep current increase with voltage (hard breakdown) in positions where nearly no recombination-active defects are visible in EL (see e.g. circle). Such a site is labeled in

(d) as " III ". a) EL, 1100 nm b) -5 V, 0.5 mK

II

2 cm c) -12 V, 15 mK

I d) -15 V, 800 mK

III

Fig. 2. Forward-bias 1100 nm EL image (a) and DLIT images of the leakage current measured at -5 V (b), -12 V

(c), and -15 V (d). The maximum scaling limits

(corresponding to the scaling bar in b) are indicated.

One of the cells containing all these typical breakdown sites was cut into small pieces so that each piece contained only one type of breakdown site. The I-V characteristics of these pieces were measured with the results shown in Fig. 1 (b). While the early pre-breakdown site " I " shows an almost linear characteristic, that of the defect-induced breakdown " II " starts conducting at about

-6 V and shows a moderate slope, whereas the new breakdown site " III " starts conducting at -13 V and then steeply increases its current.

1550 nm EL and TC-DLIT

Fig. 3 (a) shows a collection of other physical investigation techniques performed on the same and on a neighboring cell. The forward-bias EL image at 1550 nm was taken by using an InGaAs camera with a corresponding interference filter. It does not image the defects causing non-radiative recombination, as the 1100 nm image does, but rather a special defect-induced luminescence band [2]. Some regions where the strongest

978-1-4244-2950-9/09/$25.00 ©2009 IEEE 000182

1100 nm EL contrast and the strongest -12 V DLIT signal appeared in Fig. 2 (a) and (c) are highlighted in Fig. 3 (a).

The strongest 1550 nm radiation is generated not in these regions but in other defect regions, which show a weaker

1100 nm EL contrast and a weaker -12 V DLIT signal [2].

The image of the normalized temperature coefficient of the leakage current measured at -13 V (Fig. 3 b) shows that nearly all breakdown sites (especially those highlighted in the 1550 nm EL image) show a negative or close to zero

TC. Only the edge breakdown sites show a positive TC.

For effectively cancelling the strong noise between the breakdown sites, which arises due to the normalization to the average DLIT signal, all regions with an average DLIT signal below a certain value have been blanked to zero

(red) in this and the next image (c). This TC-DLIT image, measured at -14 V at the same cell, shows significantly more regions of negative TC. They appear mostly in regions where new breakdown sites have appeared at higher reverse bias. In (b) and (c) many breakdown regions are surrounded by a bright edge. It turned out that this is the influence of the region between the breakdown sites, which has been blanked out in (b) and (c). Indeed, in the TC-DLIT image (d), where these regions are not blanked to zero, they show a strongly positive TC of up to

+10 %/K. Note the different scaling ranges of Fig. 3 (b) and (c) vs. (d). For obtaining a sufficiently good signal-tonoise ratio also in these regions, 3x3 pixel binning has been applied to the data used for image (d). a) EL, 1550 nm b) TC -13 V, blanked

-3 to +3 %/K c) TC -14 V, blanked

-3 to +3 %/K d) TC -10 V unblanked

-10 to +10 %/K

Fig. 3. Forward-bias EL image at 1550 nm (a), TC-DLIT images taken at -13 V (b, blanked [see text], scaled from

-3 to +3 %/K), at -15 V (c, blanked, scaled from -3 to +3

%/K), and at -10 V (d, not blanked, scaled from -10 to +10

%/K).

Slope-DLIT

Fig. 4 compares two slope-DLIT images obtained by using two different pairs of images measured at different reverse biases. In image (a) measurements taken at -11.5 and -13 V have been used, hence this slope refers to the average bias of -12.25 V, and for (b) measurements taken at -13 and -14 V were used, corresponding to an average bias of -13.5 V. Comparing Fig. 4 (a) and (b) to Fig. 2 (c) and (d), the new breakdown sites appear in both cases above -13 V. Note that Fig. 4 (a) and (b) are differently scaled. While (a) displays mostly sites of recombinationactive lattice defects according to Fig. 2 (a) with a moderate slope of about 70 %/V, in (b) the breakdown sites newly appearing above -13 V are visible with a very high slope above 200 %/V. Therefore these sites are the dominating breakdown sites at high reverse bias. a) b)

Fig. 4: (a) Slope image at -12.25 V, scaled from zero to

100 %/V, (b) slope image at -13.5 V, scaled from zero to

200 %/V

Avalanche multiplication factor imaging a) MF at -14 V b) MF at -15 V

Fig. 5. MF-ILIT images scaled from MF = 1 to 3 showing the MF at -14 V (a) and -15 V (b)

By evaluating ILIT images measured at pulsed homogeneous weak illumination under two different constant reverse biases, images of the local avalanche multiplication factor (MF) can be obtained [1]. Any breakdown sites which are not influenced by the lightinduced photocurrent are not displayed in this image. Only if the (essentially homogeneous) photocurrent is amplified in certain positions, these positions appear bright in the

MF-ILIT image. As long as the higher reverse bias is

978-1-4244-2950-9/09/$25.00 ©2009 IEEE 000183

below -13 V, the MF-ILIT images shows a nearly homogeneous value of 1 across the whole image, hence no measurable carrier multiplication occurs. Fig. 5 (a) shows an MF-ILIT image of a cell used in this work, which used ILIT images taken at -13 V (below avalanche) and

-14 V. This image displays the multiplication factor at -14

V. Here in some positions a weak multiplication is visible, while most of the area remains black (MF = 1). These are mostly the positions of breakdown sites newly appearing above -13 V. In (b), which used images taken at -13 and

-15 V and displays the MF at -15 V, the local multiplication factor exceeds MF = 3 in some positions. Here a weak amount of carrier multiplication (M > 1) is visible in most regions, especially in the regions containing recombination-active defects.

Reverse-bias EL imaging a) EL 1100 nm, -14 V

I

III b)

II

Fig. 6. Reverse-bias EL image (a) and bias-dependent EL intensities in different positions (b)

Most breakdown sites become visible as light spots under reverse bias [2]. Spectral investigations have shown that this luminescence is physically very different to that appearing under forward bias. While forward-bias EL is spectrally centered around 1100 nm and is due to electron-hole recombination (sometimes also called excitonic recombination), reverse-bias EL shows a broad emission band extending into the visible range. Indeed, this reverse-bias luminescence can be seen in the dark with the naked eye or in a light microscope. The origin of this luminescence is most probably bremsstrahlung, hence it is generated by the acceleration of carriers in the breakdown sites. Fig. 6 (a) shows a reverse-bias EL image of an adjacent cell of that used for Fig. 2 taken at -14 V.

Here equivalent breakdown sites marked " I ", " II ", and " III " as in Fig. 2 are clearly visible. However, the edge breakdown at the bottom right edge is not visible. The bias dependence of the luminescence intensity of these sites is shown in (b). It is visible that the early pre-breakdown site

" I " indeed starts luminescing already at -5 V, the defectinduced breakdown " II " starts at about -11 V, and the steep breakdown " III " at -13 V. We do not believe that the light intensity is strictly proportional to the flowing current I, since it may depend non-linearly on I and probably depends on many other parameters, especially on the local temperature. This inevitable temperature increase may be the reason why the luminescence in position " I " starts only at -5 V, then saturates, and even reduces with increasing reverse bias. Nevertheless, this measurement may be used to distinguish different breakdown mechanisms from each other by comparing the different bias dependences of their EL signal. The result in Fig. 6

(b) may be compared with directly measured I-V characteristics shown in Fig. 1 (b). In these directly measured characteristics, the early pre-breakdown " I " shows a nearly linear characteristic instead of the onset at

-5 V, but the onsets of the defect-induced breakdown " II " and the steep breakdown " III " roughly correspond to those in Fig. 6 (b). It cannot be excluded that the small pieces used for Fig. 1 (b) still contain different breakdown sites, like e.g. edge breakdown due to the newly-cut edges.

Electron microscopy results

Fig. 7. Lock-in EBIC image at 0 V (a) and at -15 V (b) at low magnification, Lock-in EBIC image at -15 V (c) and corresponding SE image (d) at higher magnification [3]

For investigating the physical nature of the steep breakdown appearing above -13 V, which leads to avalanche multiplication, microscopic imaging of the avalanche sites would be desirable. Unfortunately, the spatial resolution of thermal imaging of the multiplication factor by MF-ILIT is limited by the inevitable lateral heat spreading in the silicon material. Therefore local avalanche sites have been imaged in the scanning electron microscope (SEM) in EBIC mode (Electron Beam-

Induced Current) under high reverse bias. Since under this condition, even without any irradiation, the breakdown sites generate a strong current noise signal and may overload the current amplifier, beam pulsing at about 1 kHz as well as ac-coupling to the current amplifier and lock-in processing of the EBIC signal have been used [3].

These investigations were made on material of the region framed in Fig. 5 (b), which showed especially high avalanche multiplication. Fig. 7 shows a lock-in EBIC image at 0V at low magnification (a) together with lock-in

EBIC images taken in the region framed in (a) at -15 V at different magnifications (b and c), in comparison with a secondary electron (SE) image (d) of the region of (c). In the 0V EBIC image (a) only the surface structure and a

978-1-4244-2950-9/09/$25.00 ©2009 IEEE 000184

grain boundary are visible. Under -15 V (b) in one grain bright lines appear, which in higher magnification (c) can be resolved as rows of single bright spots. These spots are also called "microplasma" and are due to avalanche multiplication of the beam-induced current. The SE image

(d) shows that in the positions of these microplasma dark spots are visible, which are proven below to be etch pits.

These etch pits are even better visible in the higher resolution SEM images in Fig. 8 (a) and (c). In (c) the region framed in (a) is shown with the object inclined, so that the SEM is looking vertically into the etch pits. It is visible that this pair of pits is lying within a planar defect, which is probably a stacking fault. Between the two arrows in (c), a transmission electron microscopy (TEM) crosssection specimen was cut out of the material by focused ion beam (FIB) preparation. A bright field TEM image of this specimen is shown in (d). This image shows a dislocation which proves that these are indeed etch pits. A higher magnification dark field TEM image of another tip is shown in (b). Also this image demonstrates that these pits are really dislocation-induced etch pits. Here also other dislocations can be seen, which did not lead to etch pits.

Obviously, under the acidic etching conditions used for these cells, only certain types of dislocations are leading to etch pits. The high magnification TEM image (b) shows that the tip radius is about 20 nm.

Fig. 8. (a) SEM image of a region containing etch pits, (c) enlarged view of region marked in (a), (d) cross-sectional bright field TEM image of same region, and (b) high magnification dark field TEM image of a similar etch pit [3].

DISCUSSION

From all these investigations the following physical picture of breakdown in acidically etched multicrystalline silicon solar cells emerges: At low voltages (here below

-10 V) some very soft pre-breakdown sites appear which are not correlated to any recombination-active crystal defects, since in neighboring cells they appear in different positions. They show a strongly negative TC and a low slope (not shown here). According to the curve of "I" shown in Fig. 1 (b) their characteristic is essentially linear so that they are not very dangerous. At biases beyond -14

V they are negligible. Their physical origin is not identified yet. At intermediate reverse bias (here up to -13 V) also relatively soft breakdown with moderate slope occurs mainly at sites of recombination-active crystal defects, which are most probably dislocations or grain boundaries.

These sites are the same in neighboring cells, hence they are due to grown-in crystal defects. Two groups may be distinguished: Defects with a weaker 1100 nm forwardbias EL contrast, which show a strong 1550 nm defectinduced EL signal, seem to be only weakly contaminated by impurities and also show weaker breakdown sites.

More strongly contaminated defects show only weak 1550 nm luminescence, most probably due to stronger nonradiative recombination in these sites, and lead to stronger breakdown sites. It had been shown that these breakdown sites even appear at a flat surface, then just at a somewhat higher reverse bias [4]. Therefore we propose that the physical mechanism being responsible for these defect-induced breakdown sites is a kind of breakdown implying defect states in the gap. A well-known mechanism of this type is trap-assisted tunneling.

However, since the gap energy reduces with increasing temperature, trap-assisted tunneling should show a positive TC of the current, just as internal field emission

(Zener breakdown) does. However, we have observed nearly zero or even negative TCs in these sites. Moreover, at least at higher biases, the regions of recombinationactive crystal defects also show a weak avalanche multiplication. Therefore it is also possible that a kind of

"trap-assisted avalanche" breakdown mechanism is responsible for this defect-induced breakdown.

At higher reverse biases, here above -13 V, very hard

(steep) breakdown occurs in new sites outside of recombination-active defects. Mostly in these regions and only in this bias range strong avalanche multiplication occurs. Microscopic investigations have proven that this hard breakdown is due to avalanche effects at the tips of etch pits, many of them being arranged in lines. At these tips the p-n junction should be bowl-shaped with a radius of 300 nm, which according to literature [5] quantitatively explains the reduction of the breakdown voltage from -50

V to -13 V. Actually the acidic etchant used industrially is selected not to produce etch pits at dislocations. However, obviously some of the dislocations lead to etch pits also for this etchant. TEM investigations (not shown here) have shown that this material contains twin boundaries and stacking faults which contain parallel running straight dislocations, which maybe are the reason for these etch pits being arranged in lines. It is understandable that avalanche appears only at clean dislocations showing no

EL contrast, since impurity scattering would prevent avalanche multiplication.

This work can be summarized as follows:

978-1-4244-2950-9/09/$25.00 ©2009 IEEE 000185

(1) The edge region shows a weak leakage current with a low slope and positive TC. It can be expected that this edge current under reverse bias is due to hopping conduction which, due to its characteristic temperature dependence, has been proposed also to be responsible for scratch-induced reverse-bias leakage [6].

(2) At low reverse bias also some early pre-breakdown sites in the area appear that show a weak slope and a strongly negative TC. Their origin is not known yet, but they are obviously not very harmful.

(3) The recombination-active defects visible in the 1100 nm forward-bias EL image are sources of relatively soft breakdown, probably caused by a trap-assisted mechanism. This mechanism is dependent on the degree of impurity contamination, hence it should become stronger if UMG material is used. As any other breakdown effect, it becomes also stronger with increasing doping concentration, which is also usually higher in UMG material. It still has to be investigated why this type of breakdown shows a negative or close to zero TC and not a positive one as internal field emission and trap-assisted tunneling does. Maybe a trap-assisted avalanche process is responsible for this mechanism.

(4) At higher reverse bias, classic avalanche breakdown occurs at the tips of certain etch pits, which appear due to acidic texture etching at the sites of certain types of dislocations. The reduction of the avalanche breakdown voltage from -50 V for 10

16

cm

-3

material to -13 V can be explained quantitatively by the tip effect. It still has to be investigated which dislocation types and grain orientations lead to these etch pits.

The etchant solution should be improved to avoid the appearance of these etch pits.

(5) The positive TC of the reverse current at low reverse bias is not only due to the edge current but obviously also due to a more or less homogeneous current flowing between the local breakdown sites. Since the breakdown sites occupy only a small fraction of the whole area, the homogeneous current, though showing a very low current density, may be responsible for most of the pre-breakdown current showing a positive TC. The nature of this current is not clear yet. It seems to be too large for being a diffusion saturation current. If it would be a recombination saturation current, it should quantitatively correlate with the density of recombination-active defects, which has not been proven yet.

This investigation still leaves many open questions:

What is the exact mechanism of the defect-induced breakdown? Which kind of dislocations and which grain orientation lead to the etch pits being responsible for the avalanche breakdown? How can the appearance of these etch pits be avoided? What is the nature of the early prebreakdown and the weak homogeneous leakage current?

How does the breakdown behavior change if UMG material is used? These and other open questions provide a wide field for further physical research on breakdown mechanisms.

This work was financially supported by the German

Federal Ministry for the Environment (BMU) and all the industry partners within the research cluster SolarFocus

(project No. 0327650; www.solarfocus.org). The content of this publication is the responsibility of the authors.

REFERENCES

[1] O. Breitenstein, J. Bauer, J.-M. Wagner, A. Lotnyk,

"Imaging physical parameters of pre-breakdown sites by lock-in thermography techniques", Prog. Photovolt: Res.

Appl. 16, 2008, pp. 679-685, DOI 10.1002/pip.848

[2] M. Kasemann, W. Kwapil, M. C. Schubert, H.

Habenicht, B. Walter, M. The, S. Kontermann, S. Rein, O.

Breitenstein, J. Bauer, A. Lotnyk, B. Michl, H. Nagel, A.

Schütt, J. Carstensen, H. Föll, T. Trupke, Y. Augarten, H.

Kampwerth, R. A. Bardos, S. Pingel, J. Berghold, W.

Warta, S. W. Glunz, "Spatially resolved silicon solar cell characterization using infrared imaging methods", Proc.

33rd IEEE Photovoltaic Specialists Conference, San

Diego, CA, 11-16 May 2008, No. 148

[3] J. Bauer, J.-M. Wagner, A. Lotnyk, H. Blumtritt, B. Lim,

J. Schmidt, O. Breitenstein, "Hot spots in multicrystalline solar cells: avalanche breakdown due to etch pits", Phys.

Status Solidi RRL 3, 2009, pp. 40-42, DOI

10.1002/pssr.200802250

[4] D. Lausch, K. Petter, H. v. Wenckstern, M. Grundmann,

"Correlation of pre-breakdown sites and bulk defects in multicrystalline solar cells", Phys. Status Solidi RRL 3,

2009, pp. 70-72, DOI 10.1001/pssr.200802264

[5] S. M. Sze and G. Gibbons, "Effect of Junction

Curvature on Breakdown Voltage in Semiconductors",

Solid-State Electronics 9, 1966, pp. 831-845

[6] O. Breitenstein, P. Altermatt, K. Ramspeck, A. Schenk,

"The origin of ideality factors n > 2 of shunts and surfaces in the dark I-V curves of Si solar Cells", Proc. 21st

European Photovoltaic Solar Energy Conference,

Dresden, 4.-8. September 2006, pp. 625-628

978-1-4244-2950-9/09/$25.00 ©2009 IEEE 000186