Comparison of Hybrid Asymmetric and Conventional Multilevel

advertisement

Comparison of Hybrid Asymmetric and

Conventional Multilevel Inverters for Medium

Voltage Drive Applications

Master of Science Thesis in the Master’s programme Electric Power Engineering

AMIR SAJJAD BAHMAN

Department of Energy and Environment

Division of Electric Power Engineering

CHALMERS UNIVERSITY OF TECHNOLOGY

Göteborg, Sweden 2011

MASTER’S THESIS 2011

Comparison of Hybrid Asymmetric and

Conventional Multilevel Inverters for Medium

Voltage Drive Applications

Master’s Thesis in the Master’s Programme Electric Power Engineering

AMIR SAJJAD BAHMAN

Department of Energy and Environment

Division of Electric Power Engineering

CHALMERS UNIVERSITY OF TECHNOLOGY

Göteborg, Sweden 2011

Comparison of Hybrid Asymmetric and Conventional Multilevel Inverters for

Medium Voltage Drive Applications

Master’s Thesis in the Master’s Programme in Electric Power Engineering

AMIR SAJJAD BAHMAN

© AMIR SAJJAD BAHMAN, 2011

Department of Energy and Environment

Division of Electric Power Engineering

Chalmers University of Technology

SE-412 96 Göteborg

Sweden

Telephone: + 46 (0)31-772 1000

Cover:

A medium-voltage frequency converter, the ABB PCS 6000 Wind,

Reference: http://www.windpowerengineering.com/tag/abb

Göteborg, Sweden 2011

Comparison of Hybrid Asymmetric and Conventional Multilevel Inverters for

Medium Voltage Drive Applications

Master’s Thesis in Master’s Programme in Electric Power Engineering

AMIR SAJJAD BAHMAN

Department of Energy and Environment

Electric Power Engineering

Chalmers University of Technology

ABSTRACT

Power electronic converters are becoming more and more popular for

various industrial applications. To overcome the limitation of semiconductors

current and voltage ratings in high power applications, series and parallel

connection of switches is often considered an effective solution. In addition,

stepped waveform in the output of inverter has better harmonic spectrum

than 2-level waveform in low switching frequencies. So, in recent years

multilevel inverters have gained great interest in industry. Among the

different solutions available for multilevel converters, the asymmetric

topologies allow to generate more voltage levels with less number of

semiconductors and thus increase of output performance and system

reliability. For these reasons, this kind of topology has attracted a lot of

attention both from the customers and from the manufacturers. Application of

appropriate semiconductor switches in the different cells of the inverter leads

to increase of inverter efficiency. This inverter is typically known as hybrid

inverter.

In this work, different topologies of multilevel inverters consisting

cascaded symmetric, diode-clamped, flying-capacitor, and hybrid asymmetric

are investigated. It will be shown that hybrid asymmetric inverter has more

reliable topology than others, due to less number of power semiconductor

switches and higher voltage levels. Also different multilevel modulation

techniques will be studied form voltage waveforms and harmonic spectra

aspects. This study proves that Phase Disposition Pulse Width Modulation

shows less harmonic distortion than other techniques.

Comparison of hybrid asymmetric inverter with conventional multilevel

inverters will be lead in two states of constant frequency and constant

efficiency. The results indicate that, hybrid asymmetric topology has better

performance in power losses, total harmonic distortion and first distortion

factor than other topologies that leads to energy saving, better power quality

and reduce in size, weight and volume of its LC filter.

Key words: Hybrid asymmetric multilevel inverter, medium voltage drive,

modulation techniques, power losses.

I

II

Acknowledgment

This work has been carried out at the Division of Electric Power

Engineering, Department of Energy and Environment at Chalmers University

of Technology, Gothenburg, Sweden.

I would like to thank first and foremost my examiner Dr. Massimo

Bongiorno for his valuable and constructive suggestions during this work and

advices in revising the thesis manuscript extensively to give it a better shape.

I would also like to express my deep and sincere gratitude to my

supervisor Dr. Ghasem Aghdam for his patience, encouraging, stimulating

and critical comments regarding the work.

I express my sincere appreciation to Mohammadreza Derakhshanfar,

Mehdi Javdani Erfani, Shahab Shariat Torbaghan, Ali Mehdipour, and Saeid

Haghbin my dear friends at division for their help, suggestions, and

friendship throughout my time at Chalmers and for all the great memories

away from the research.

Finally, I’d like to dedicate this work to the love of my life, Mona, for her

deep love, patience, and encouragement from a long distance and my dear

family, my parents, Manouchehr and Nafiseh, my sister and brother, Sara and

Ali, for their encouragement, support, and love which always warms my

heart in the darkest moment.

Göteborg March 2011

Amir Sajjad Bahman

III

IV

Contents

ABSTRACT

I

ACKNOWLEDGMENT

III

CONTENTS

V

1

1

2

INTRODUCTION

1.1 High-power medium-voltage drives classification

2

1.2 Multilevel inverters, features, advantages and applications

4

1.3 Hybrid and asymmetric multilevel inverters

6

1.4 Thesis topics

7

MULTILEVEL INVERTER TOPOLOGIES

2.1 2-level and 3-level voltage source inverters

3

4

5

8

9

2.2 Multilevel inverters

2.2.1 Symmetric multilevel inverters

2.2.2 Asymmetric multilevel inverter

10

10

15

2.3 Hybrid multilevel inverters

17

2.4 Conclusions

19

MODULATION TECHNIQUES

20

3.1 Carrier based PWM

3.1.1 2-level PWM

3.1.2 Multilevel PWM

21

21

23

3.2 Conclusion

34

DRIVE SYSTEM AND PERFORMANCE INDEXES

36

4.1 Inverter specification

4.1.1 Dc-link voltage

4.1.2 Power semiconductor selection

36

37

38

4.2 Performance indexes

4.2.1 THD

4.2.2 DF1

4.2.3 Semiconductor power losses

4.2.4 Efficiency

38

38

39

40

43

4.3 Conclusion

44

COMPARISON OF DIFFERENT MULTILEVEL INVERTERS

45

5.1 Simulation environment

45

5.2 Simulation results

48

V

5.2.1 Comparison at constant carrier frequency

5.2.2 Comparison at constant efficiency

6

CONCLUSION AND FUTURE WORK

48

51

54

6.1 Results

54

6.2 Future work

54

7

VI

REFERENCES

56

1

Introduction

The increasing demand for electrical energy, depleting fossil energy

reserves and the increase in energy prices have necessitated to use the current

energy resources more efficiently. Power electronic converters as the essential

equipments to convert and control of electrical power in the wide range of

milliwatts to gigawatts with the help of semiconductor devices are finding

increased attention. Hence, highly efficient power electronic technologies and

reliable control strategies are needed to reduce the waste of energy and to

improve power quality. One of the most significant potentials to improve the

efficiency of electrical energy in industry is electric motor drive systems.

Today, medium voltage drives have found extensive application in various

industries, such as oil, gas and petrochemical industry, the cement industry,

water pumping stations, metal industry, rolling mills, traction applications,

wind power generation, marine drives, reactive power compensation, high

voltage direct current (HVDC) transmission as well as many other

applications [1]. On the other hand, several industries have increased their

power-level needs, urged mostly by economy of scale (production levels and

efficiency), causing the development of new power semiconductors, converter

topologies, and control methods. Currently, medium voltage drives cover a

power range of 0.2 MW to 40 MW at voltage level of 2.3 kV up to 13.8 kV [2].

However, at present 97% of the currently installed medium voltage motors

operate at fixed speed; and only 3% of these are controlled by variable-speed

drives [1]. One of the major markets for medium voltage drives is retrofit

applications. For instance, when fans or pumps are driven by fixed speed

motor, air or liquid flow are controlled normally by conventional mechanical

methods, such as throttling control, inlet dampers, and flow-control valves,

resulting in large amount of energy loss [3].

Therefore, there is a huge scope for developing adjustable speed drives for

industrial applications. The installation of controlled medium voltage

variable-speed drives reduces the energy loss and leads to a significant

savings on energy cost and improving the power quality [2]. The power

quality of medium voltage drives is affected by the applied converter

topology, the load characteristics, the size and the type of the utilized filter,

the level of switching frequency, and the control method [1].

Nevertheless, the design of these drives is faced with a number of

challenges related to topologies and control of power line side converter (e.g.

power quality, resonance, and power factor) and motor side converter (e.g.

dv/dt, torque ripples, motor derating caused by generated harmonics and

travelling wave reflections), as well as power semiconductor devices

(semiconductor losses)[1]. Essential requirements for medium voltage drives

are high efficiency, high reliability, low cost, small size and in some

applications, high dynamic performance and regeneration capability [1].

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

1

1.1

High-power

power medium-voltage

medium voltage drives classification

Fig. 1.1 shows a simplified classification of converters used in high-power

high

medium-voltage

voltage applications, which have a main division into direct and

indirect connections of power supply and load. The former usually connects

the load to the source directly through power semiconductors and suitable

control method. The latter transfers the power indirectly in two stages of

rectification and inversion via an energy-storage

energy storage component [3].

For direct conversion, cycloconverters are the most used topology in high

power applications, which use a series of semiconductor switches to connect

directly the high power supply to the load. Cycloconverters convert a threethree

phase ac voltage with a fixed magnitude and frequency to a three-phase

three

ac

voltage with variable magnitude and variable frequency. Matrix converters

are included in this category but they are not listed in classification, since the

technology is not available for high-power

high power ranges, reaching only up to 150

kVA [4].

In the other side of this classification, indirect converters are divided

basically into current-source

source and voltage-source

voltage source topologies, depending on the

dc-link energy-storage

storage component.

MediumVoltage Drives

Direct conversion

ac-ac

Cycloconverter

Indirect conversion

(DC-Link) ac-dc-ac

Current Source

Voltage Source

PWM Current

Source Inverter

Load

Commutated

Inverter

Multilevel

Inverters

Single DC

source

NPC

Flying

Capacitor

High Power

2-level VSI

Multiple

Isolated DC

sources

Cascaded

H-Bridge

Bridge

Symmetric

(Equal DC

sources)

Asymmetric

(Unequal DC

sources)

Fig. 1.1 Classification

Classi

of converters topologies for high-power

power drives

2

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

Fig. 1.2 shows a typical view of an indirect medium-voltage drive.

Depending on the system demands and the type of converters applied, the

line and motor side filters are optional. A phase shifting transformer with

multiple secondary windings is often utilized mainly for the line current

distortions. The rectifier converts the power supply voltage to a dc voltage

with a fixed or variable magnitude. The generally used rectifier topologies

include multi-pulse diode or thyristor rectifiers and pulse width modulation

(PWM) rectifiers. The dc link can simply be a capacitor that supplies a stiff dc

voltage in voltage-source inverters or an inductor that smoothes the dc

current in current-source inverters [3].

Fig. 1.2 Typical block diagram of medium voltage variable speed drives

For current-source drives, two topologies have found industrial

applications in high power ranges: the load-commutated inverter (LCI) and

the PWM-CSI. The LCI has been utilized for many years presenting simple

converter topology, low manufacturing cost, and reliable operation. Its main

problems include low input power factor and distorted input current

waveforms, which these problems are overcame by the newer technology of

PWM-CSI [5].

On the other hand, high-power voltage-source inverters (VSI), have

attracted more markets and developed significantly over the last decades,

compared to current-source topologies. The voltage-source drives are divided

in two groups of high-power two-level and multilevel inverters. The simplest

topologies of VSIs are single-phase half-bridge inverter which generates a 2level square-wave voltage and full-bridge inverter which generates 3-level

waveform. These classical inverters were limited to low or medium power

applications due to the limitations on the power semiconductor voltages and

currents. The series connection of semiconductor switches enabled high twolevel VSIs for high-power applications.

However, the addition of some other power components, like diodes or

capacitors, and utilization of more complex switching methods permitted a

more interesting use of these additional components to enhance the quality of

input and output currents and voltages, originating the family of multilevel

VSI technology.

Although multilevel inverters were basically developed to reach higher

voltage operation, before being restricted by semiconductor limitations, the

extra switches and dc sources (supplied by dc-link capacitors) could be used

to generate different voltage levels, enabling the generation of stepped

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

3

waveform with less harmonic distortion, reducing dv/dt and common-mode

voltages. These characteristics have made them popular for high-power

medium-voltage applications but the large number of semiconductor switches

in these inverters, result in a reduction both of the reliability and efficiency of

the drive [18]. Therefore, many power electronic researchers have made great

effort in developing multilevel inverters with the same benefits and less

number of semiconductor devices.

1.2

Multilevel inverters,

applications

features,

advantages

and

In 80s, many power electronics researches were focused on increase of the

current and voltage ratings of semiconductor devices. To obtain higher

voltage levels, a group of researchers started to study new inverter topologies

that were able to operate at high voltages. In 1981, A. Nabae, I. Takahashi and

H. Akagi presented a new inverter topology, which was named “neutralpoint-clamped PWM inverter (NPC-PWM)”. In fact, this topology was an

improved circuit of the classical 2-level inverter [13]. Although the new

topology was just 3-level inverter, it had the potential to be extended to Nlevels. Today, this inverter is known as “diode-clamped multilevel inverter”

[15].

Currently, in terms of topology, multilevel inverters can be mainly divided

into three major groups:

•

“Cascaded multilevel inverters”: These inverters include several Hbridge cells (Full-bridge inverters) connected in series. One leg of a

cascaded multilevel inverter is shown in Fig. 1.3. In the same figure, it

is possible to observe the structure of one individual cell.

Vdc

4

Cell 4

Vdc

4

Cell 3

Va

Vdc

4

Cell 2

Vdc

4

Cell1

Fig. 1.3 Cascaded multilevel inverter

4

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

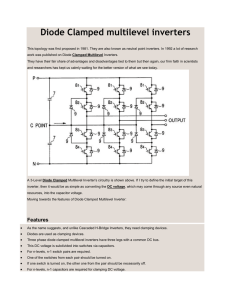

•

“Diode-clamped multilevel inverters”: These inverters use clamped

diodes and dc capacitors in order to generate ac voltage. This inverter

is manufactured in 3, 4 and 5-level structures. The 3-level structure is

known as “neutral-point clamped (NPC)” and is widely used in

medium voltage, high power drives. One leg of an NPC inverter can be

seen in Fig. 1.4.

SW1

Vdc

2

SW2

D5

SW3

Vdc

2

D6

Va

SW4

Fig. 1.4 NPC inverter

•

“Flying-capacitor multilevel inverter”: In this topology, semiconductor

devices are in series and their connecting points are clamped by extra

capacitors, as it can be seen in Fig. 1.5.

SW1

Vdc

2

SW2

C5

SW3

Vdc

2

Va

SW4

Fig. 1.5 Flying-capacitor inverter

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

5

Together with the converter topology, great effort has been addressed from

the research community in investigating different switching methods for

these inverters. This is mainly due to the fact that the adopted switching

strategy impacts the harmonic spectrum of output waveforms as well as the

switching and the conduction power losses. In case of multilevel converters,

three switching methods are usually used [14]:

•

“Selective Harmonic Elimination”. In this method, each switch is

turned on and turned off once in a switching cycle and switching

angles are usually chosen based on specific harmonics elimination or

minimization of output voltage Total Harmonic Distortion (THD).

•

“Carrier-Based PWM”. In this method, drive signals of switches are

derived from comparison of reference signal with carrier signals.

•

“Space-Vector PWM”. The space vector modulation technique is based

on reconstruction of sampled reference voltage with help of switching

space vectors of a voltage source inverter in a sampling period.

1.3

Hybrid and asymmetric multilevel inverters

The topologies mentioned before are typically called “symmetric multilevel

inverters”, because the dc link capacitors have the same voltages. Asymmetric

multilevel inverters have the same topology as symmetric ones; the only

difference is in the dc link voltages. However, the asymmetric multilevel

inverters can generate higher number of output voltage levels with the same

number of semiconductor switchers in symmetric ones. Therefore, in these

inverters the efficiency is improved by using less semiconductor devices and

more complicated switching algorithms; while, output filters are very small or

even removed [14, 15]. One leg of an asymmetric multilevel inverter is shown

in Fig. 1.6.

3 × Vdc

4

Cell 2

Va

Vdc

4

Cell1

Fig. 1.6 Asymmetric multilevel inverter

Since the different cells of asymmetric inverter work with different dc link

voltages and different switching frequencies, it is more efficient to use

appropriate semiconductor devices in different cells. For example, using IGCT

(Integrated Gate-Commutated Thyristor) switches which are suitable for high

voltage low frequency applications, in higher voltage cells decreases the

6

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

power losses. These inverters are called “hybrid multilevel inverters”. A

hybrid inverter which uses several types of semiconductors has many

advantages [17, 18]. Active power is transferred by semiconductors with low

losses and high reliability and the output harmonic spectrum is improved by

other semiconductors.

1.4

Thesis topics

This thesis investigates hybrid asymmetric multilevel inverters for medium

voltage drive applications. In addition, it presents some comparisons of this

type of inverters with conventional multilevel inverters in terms of harmonic

distortion, power losses and efficiency. The inverter consists of a main cell

with IGCT switches and a sub cell with IGBT (Insulated-Gate Bipolar

Transistor) switches. Main and sub cells are connected in series in each phase

[19]. IGCT is a device with high reverse voltage, high reliability and low

losses which is used in the main cell [20-22], while IGBT is a device with high

switching frequency which is used in the sub cell to obtain low harmonic

spectrum in the output of inverter.

In the second chapter of this thesis, a brief overview of different multilevel

inverter topologies and new research topics in this field are presented and

their advantages and disadvantages are discussed briefly. In addition, these

topologies are compared in different aspects. At the end, the hybrid

asymmetric multilevel inverter topology is derived.

In Chapter 3, different modulation techniques in voltage source inverters

are explained. Also, the carrier-based multilevel PWM, which is applied in

hybrid asymmetric multilevel inverters extensively, is analyzed briefly and

different multilevel PWM techniques are compared from voltage waveforms

and harmonic spectra aspects and the most appropriate modulation technique

is derived.

In Chapter 4, the inverter specifications, semiconductor devices, and the

performance indexes consisting power losses, harmonic distortions, and

efficiency that will be compared in different topologies will be studied.

In Chapter 5, the simulation environment and results of comparison

between hybrid asymmetric and conventional multilevel inverters in two

methods of constant carrier frequency and constant efficiency will be

presented.

In the last chapter, a summary of works which have been done on

multilevel inverters in this work are presented; finally, future works that can

be followed in continue of this thesis, are mentioned.

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

7

2

Multilevel Inverter Topologies

In recent years, industry has demanded for high power equipments, which

today reaches to megawatts. Adjustable ac drives which operate in high

power range are usually connected to the medium voltage network. Hence,

medium and high voltage ac drive systems have been considered widely.

Today, due to limitation of semiconductor devices to operate in high current

and voltage ratings, it is difficult to connect a semiconductor switch directly

to medium voltage networks (2.3 – 6.9 kV). To achieve this problem, a family

of multilevel inverters has been emerged for working in medium and high

voltage levels [23].

Multilevel inverters consist of a series of power semiconductor devices and

capacitors, which generate voltages with stepped waveforms in the output.

Fig. 2.1 shows one phase leg of multilevel inverters. In this schematic

diagram, operations of semiconductors are shown by an ideal switch with

several states. The switching algorithms of switches and commutation of them

allow the addition of the capacitor voltages as temporary dc voltage sources,

whereas the semiconductors should withstand limited voltages of capacitors.

VC

a

VC

Va

VC

0

Fig. 2.1 One phase leg of a multilevel inverter

The large number of semiconductors in the multilevel inverters has a

negative impact on the reliability and on the overall efficiency of these types

of converters. On the other hand, using inverters with the low number of

semiconductors needs large and expensive LC filters to limit insulation stress

of motor windings or can be applied for motors that can withstand this stress

[6-12].

In this chapter, first the structure of inverter is briefly explained and then

different topologies of multilevel inverters, their advantages, disadvantages

and comparison in different aspects are discussed. In this case, first the

topologies of symmetric multilevel inverters are investigated and then

asymmetric multilevel inverters are discussed. Finally, based on these

inverters, the topology of hybrid asymmetric multilevel inverter is derived.

8

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

2.1

2-level and 3-level voltage source inverters

Generally inverters can be divided in two major groups: “single-phase

inverters” and “three-phase inverters”. The simplest inverter structure is halfbridge single-phase inverter which generates 2-level square waveform,

whereas output waveform of a full-bridge single-phase inverter is 3-level

square waveform. Full-bridge inverters are known as H-bridge inverter due

to their structure shape. These two structures are shown in Fig. 2.2 and Fig.

2.3.

In half-bridge single-phase inverter, two switches are needed which should

not be turned on simultaneously to prevent short-circuit of the dc source. In

first half-cycle, is on and is off, so load voltage is equal to /2. In

second half-cycle, is off and is on so load voltage is equal to /2. In

full-bridge inverter when (, ) are on and ( , ) are off, load voltage is

equal to whereas, in the case of (, ) are off and ( , ) are on, is

seen on load. To apply zero voltage on load, (, should be on and ( , )

should be off or vice versa.

Similar to the half-bridge case, in full-bridge inverter the pairs of (, )

and ( , ) should not be on simultaneously. The output voltage waveforms

of half-bridge and full-bridge inverter are shown in Fig. 2.4 and Fig. 2.5.

Vdc / 2

S1

vo

io

Vdc / 2

S2

Fig. 2.2 Half-bridge inverter power circuit

S1

S4

vo

Vdc

io

S3

S2

Fig. 2.3 Full-bridge inverter power circuit (H-bridge)

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

9

vo

Vdc / 2

− Vdc / 2

Fig. 2.4 Half-bridge inverter output voltage waveform

vo

Vdc

− Vdc

Fig. 2.5 Full-bridge inverter output voltage

2.2

Multilevel inverters

Multilevel inverters are being used widely in static VAr compensators,

active power filters and adjustable speed drives (ASDs) for medium voltage

induction motors [23]. Usually the inverters which generate more than two

phase potentials are known as multilevel inverters. By increase of the voltage

levels to infinite value, THD of voltage waveform decreases to zero, since the

waveform will be more sinusoidal; but, in practice the accessible voltage level

is limited because of voltage unbalancing problems and power losses [23]. In

this part, the most important topologies of multilevel inverters and their

characteristics will be discussed.

2.2.1

Symmetric multilevel inverters

There are three decades that multilevel inverters are being used in the

world of power electronics [8]. They are named by the number of voltage

levels that generate and different topologies they have. Usually the number of

output voltage levels is odd instead of even. It means that the definition of a

zero voltage level in the output of inverter like in 3-level or 5-level inverters

makes it more sinusoidal and less harmonics are made. This issue will be

discussed later in this chapter. As discussed in the introductory part of this

10

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

thesis, the most conventional topologies of multilevel inverters are listed

below [23]:

•

Cascaded H-Bridge multilevel inverter

•

Diode-clamped multilevel inverter

•

Flying-capacitor multilevel inverter

These inverters are known as symmetric multilevel inverters, since their

DC link capacitors have the same voltages and all the semiconductor devices

should be able to block these voltages in the off state.

2.2.1.1 Cascaded HH-bridge multilevel inverter

inverter

Fig. 2.6 shows the power circuit of a 5-level cascaded H-bridge inverter [6,

10, 24]. For clarity of the figure, only one phase is shown in the figure. In this

topology power cells are in series and the number of phase voltage levels that

can be obtained at the converter terminals is proportional to the number of

cells. In other words, in this topology the number of phase voltage levels at

the converter terminals is 2 1, where is the number of cells or dc link

voltages.

In this topology, each cell has separate dc link capacitor and the voltage

across the capacitor might differ among the cells. So, each power circuit needs

just one dc voltage source. The number of dc link capacitors is proportional to

the number of phase voltage levels.

The ground point shown in Fig. 2.6 is a common reference point and all

phases are connected in this point. Each H-bridge cell may have positive,

negative or zero voltage. Final output voltage is the sum of all H-bridge cell

voltages and is symmetric with respect to neutral point, so the number of

voltage levels is odd.

Cascaded H-bridge multilevel inverters typically use IGBT switches. These

switches have low block voltage and high switching frequency. Cascaded Hbridge inverters have excellent input current and output voltage waveforms.

Output voltage has smooth steps, so the output filter is usually not needed or

in the case of necessity it can be very small [12].

The most important problems with the drives using this inverter are the

high number of devices to rectify ac to dc voltage, complex switching patterns

to command all the switches and need of multi-pulse input transformer that

affect the efficiency, reliability and system costs [16].

Vdc

4

Vdc

4

Va

Fig. 2.6 Cascaded H-bridge 5-level power circuit

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

11

2.2.1.2 DiodeDiode-clamped multilevel inverter

Fig. 2.7 shows the power circuit of a 5-level diode-clamped inverter [9, 13].

For clarity of the figure, only one phase is shown. In this topology,

semiconductor devices are connected in series and dc link is divided to

smaller capacitors and connects to switches by clamp diodes. The clamp

diode connections are necessary to block the current and their numbers in

each leg are selected in such a way to have the same block voltages like the

switches.

DC link capacitors are the same for all phases, so one dc voltage source is

needed for the dc link. The number of capacitors in each phase is proportional

to the number of phase voltage levels.

The ground point shown in the figure is the common reference point and is

connected to the middle of dc link. To generate N voltage levels by the aim of

the diode-clamped inverter, N-1 capacitors are needed on the dc bus [25]. For

example, in a 5-level inverter shown in fig 2.7, dc bus voltage consists of four

capacitors: , , and . If they are being fed by a dc link voltage of ,

the capacitors voltages will be /4.

Table 2.1 presents switching pattern of a 5-level diode-clamped inverter. “1”

indicates that the switch is ON and “0” indicates that the switch is OFF. It is

obvious from this table that in each cycle just four switches should be ON.

S1

Vdc

4

C1

S2

Vdc

4

S3

C2

S4

Va

S5

Vdc

4

C3

S6

S7

Vdc

4

C4

S8

Fig. 2.7 Diode-clamped 5-level inverter power circuit

12

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

Table 2.1 Diode-clamped 5-level inverter switch states

Output

V /2

V /4

0

V /4

V /2

S

1

0

0

0

0

S

1

1

0

0

0

S

1

1

1

0

0

Switch state

S

S

1

0

1

1

1

1

1

1

0

1

S

0

0

1

1

1

S

0

0

0

1

1

S

0

0

0

0

1

Since in Diode-clamped multilevel inverter topology switches should

withstand the dc link voltage, this topology uses HV-IGBT (High Voltage

IGBT) switches, but IGCT switches seem to be more suitable for this

application. Diode-clamped multilevel inverter has a simple circuit but

generates high and steep voltage steps which may impact the life time of the

motor windings; therefore, an additional filtering stage is needed to reduce

the ripple in the inverter output voltage. Theses filters are usually heavy and

expensive in comparison with the filters used in cascaded H-bridge inverters

[25].

2.2.1.3 FlyingFlying-capacitor multilevel inverter

Fig. 2.8 shows one phase leg of the power circuit for a flying-capacitor 5level inverter [23]. In this topology semiconductor devices are connected in

series and their connecting points are clamped by extra capacitors. In this

topology series connections of clamped capacitors are necessary to block the

current and their numbers in each leg are selected in such a way that all the

capacitors store the same energy. In this way large and heavy capacitors will

not be needed.

The ground point shown in the figure is the common reference point and,

similarly to the diode-clamped topology described in the previous section, is

connected to the middle point of the dc link. The output voltage is symmetric

with respect to the neutral point. When using this kind of inverter topology, if

the system generates even voltage levels, the number of dc link capacitors will

be odd. In other words, to generate N-level output voltage, N-1 dc link

capacitors are needed [25]. It is clear in Fig. 2.8 that there is not any

connections in the three interior loops between balancing capacitors ( , ,

) to the dc link sources for each phase, like the diode clamped topology.

Table 2.2 presents switching pattern of a 5-level flying-capacitor inverter.

Large number of clamped capacitors makes this inverter bulky and expensive.

Also, to balance the capacitors voltages, specific controls and accurate

measurements should be considered.

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

13

S1

Vdc

4

C1

S2

Cc

S3

Vdc

4

C2

Cb

S4

Cc

Va

Ca

S5

Vdc

4

C3

Cb

S6

Cc

S7

Vdc

4

C4

S8

Fig. 2.8 Flying-capacitor 5-level inverter power circuit

Table 2.2 Flying-capacitor 5-level inverter switch states

Output

V /2

V /4

0

V /4

V /2

S

1

1

1

1

0

S

1

1

1

0

0

S

1

1

0

0

0

Switch state

S

S

1

0

0

1

0

1

0

1

0

1

S

0

0

1

1

1

S

0

0

0

1

1

S

0

0

0

0

1

2.2.1.4 Required components for different topologies

Totally, considering the cost of semiconductors and passive components,

converter losses and simplicity of modulation schemes, cascaded H-bridge

and diode-clamped inverters are more used in large motor drive applications.

Flying capacitor inverters can be used in DC/DC converters since their phase

voltage looks like that of a full-bridge phase shift modulated DC/DC

converters [23]. In Table 2.3, required components of different N-level

topologies discussed till now are brought together [23].

14

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

Table 2.3 Required components of multilevel inverters (N-level) form different aspects

Topology

A

B

C

D

E

Even:

Cascaded

H-bridge

6(N-1)

0

0

6(N-1)

6(N-2)

(N-1)

(3N/2)-1.5

Odd:

Odd:

(3N/2)-2

(3N/2)-2

N-1

N-1

(N-2)

Flyingcapacitor

6(N-1)

0

0

3N-5

g

/(N-1)

2N-1

/(N-1)

2N-1

/(N-1)

2N-1

Even:

(3N/2)1.5

3

Diodeclamped

F

!"

1 3 #$

A: switches (including free-wheeling diodes)

B: required diodes (with different reverse voltages)

C: required diodes (if the same reverse voltage distribution on them is targeted)

D: required capacitors

E: required capacitors (if the same voltage distribution across the capacitors is targeted)

F: maximum voltage applied for each cell/dc link capacitor

G: line-to-line output voltage levels

2.2.2

Asymmetric multilevel inverter

As mentioned earlier, symmetric multilevel inverters are characterized by

the fact that the voltages across the different dc link capacitors are equal. One

interesting alternative is to have different capacitor voltages. This topology of

inverters is known as asymmetric multilevel inverter. Although the focus for

this kind of inverters has been mainly addressed in the direction of cascaded

H-bridge asymmetric multilevel [14-18], asymmetric inverters can also be

derived from diode-clamped and flying-capacitor inverters or a combination

of them either [16, 18].

Asymmetric multilevel inverters have the same circuit configuration as

symmetric ones. The only difference is the dc link capacitor voltages. Using

different dc link voltages in different power cells and application the

appropriate switching methods, the number of output voltage levels

increases. Therefore, with less number of H-bridge cells, more output voltage

levels can be obtained.

In Fig. 2.9 and Fig. 2.10 two types of 9-level symmetric and asymmetric

inverters are shown. According to these figures, in the symmetric inverter,

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

15

four cells are needed to generate 9-level voltage, whereas in the asymmetric

inverter two cells are enough to generate the same number of voltage levels.

The operation method of asymmetric inverters will be explained in Section

2.2.2.1.

The number of phase voltage levels in asymmetric multilevel inverter is

calculated by equation 2.1:

'

2. V& 1

2.1

&$

where N is the number of inverter cells and # is the normalized dc voltage of

each cell with respect to the dc link capacitor voltage. This equation can easily

be obtained by considering the derivation of asymmetric topology from

cascaded symmetric inverter. For example, for the asymmetric inverter shown

in Fig. 2.10 the number of output voltage levels is 2.(1+3)+1=9.

It of importance to mention that the switches applied in the symmetric

inverter have the same off-state voltage, but in the asymmetric inverter, due

to different voltage levels of dc link sources, the size of switches can be

different.

Vdc

Vdc

Vdc

Vdc

Va

Fig. 2.9 9-level symmetric inverter power circuit

Vdc

3Vdc

Va

Fig. 2.10 9-level asymmetric inverter power circuit

2.2.2.1 Inverter states and voltages

voltages

In a cascaded H-bridge asymmetric multilevel inverter, each cell has four

switching states. Output voltages are: , and 0 (two times). So, there

are three different states with different voltages. If the voltage of () cell is

named *, this voltage is defined as the following:

* + ,* -* , ,* / 0

1, 0, 12

where ,* is the switching state and -* is the cells capacitor voltages.

16

2.2

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

If multilevel inverter is constituted by N cells, then the output voltage with

respect to the neutral point is give by,

!

*3 + #

2.3

#$

From (2.3) it can be seen that the final output voltage is the sum of each cell

voltage.

According to the discussion above, a graph is formed and inverter states

and output voltages are specified, Fig. 2.11. It is obvious that the starting point

of this graph is the neutral point and the voltage is zero in this point. The

nodes in this graph indicate the possible voltages for each cell. It is clear from

this figure that each cell can generate three voltage levels. Therefore, by

applying different dc link voltage levels to different cells and combination of

them, more voltage levels can be obtained in the output of inverter terminals.

This combination can be done up to the () cell.

Each branch of this graph indicates a switching state of each cell, therefore

each route of these graph shows a switching state of the inverter. It should be

mentioned that it is possible for different routes to arrive in a same output

voltage.

(a)

(b)

Fig. 2.11 Inverter states and output voltages for each phase (a) 9-level symmetric inverter, (b) 9-level

asymmetric inverter

2.2.2.2 Cell voltages, switching power and frequency

frequency

In the symmetric multilevel inverters, all cells have the same voltages,

whereas in asymmetric multilevel inverters different cells may have different

voltages. In chapter 4, it will be shown that how the different dc link voltages

affects the switching power losses and frequency.

2.3

Hybrid multilevel inverters

In previous sections, symmetric inverters, asymmetric inverters and their

characteristics were discussed. In this section these topologies are synthesized

and another topology that is called “hybrid multilevel inverter” is derived.

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

17

This topology has a simple circuit with high reliability, power quality and

efficiency.

According to Section 2.1, in multilevel inverters two topologies are more

applied in medium voltage industrial applications especially in electric drives:

cascaded H-bridge inverter and diode-clamped inverter. In addition, both

topologies have some advantages and disadvantages. In fact, the important

matters are compromise in power quality of converter in both line and motor

sides, circuit complexity that affects efficiency, reliability and cost of inverter.

H-bridge cascaded inverter has excellent input current and output voltage

waveforms but it requires many devices to rectify the ac voltage to the dc

voltage, many control equipments and complexity multi-pulse transformer

design. Diode-clamped multilevel inverter has a simple circuit but needs LC

filter to drive the motor.

This compromise can be done by using asymmetric multilevel inverter.

Using asymmetric method in cascaded H-bridge inverter increases the

number of output voltage levels. As a result, by using an asymmetric

multilevel inverter, power semiconductors should withstand high reverse

voltage in the off-state. So, if the voltage ratio of cell supplying voltages is

selected 3 to 1 or more, the semiconductor switches should not be the same in

all cells. In this case, depending on the voltage level, it is suggested that an

appropriate switch used. In other words, larger cells which work in higher

voltages, transfer high active power and operate in low switching frequencies

[16-19]. HV-IGBT or IGCT switches with reverse voltages more than 4.5 kV

are used in these cells. IGCT switches works with high reliability; high reverse

voltage and low off-state power losses [20-22]; whereas smaller cells which

have lower voltages operate in higher switching frequencies. LV-IGBT

switches are used in these cells; because this switch operates in high switching

frequency and shows good performance in lower voltages.

By combination of IGBT and IGCT in a hybrid asymmetric multilevel

inverter, all the advantages of multilevel inverters can be achieved [17, 18].

This inverter is named hybrid since it uses two different types of

semiconductor devices. Since, this inverter uses different voltage levels in the

dc link capacitors, it can generate more voltage levels in the output and since,

it uses two types of semiconductors in each cell, the power losses decreases

either. This inverter is shown in Fig. 2.12.

S7

S5

S3

3Vdc

S8

S1

Vdc

S6

S4

Va

S2

Fig. 2.12 9-level hybrid asymmetric cascaded H-bridge inverter power circuit

18

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

Fig. 2.13 shows the drive power circuit of a 3-phase hybrid asymmetric

inverter. The inverter is composed of two parts: IGCT inverter or main

inverter and IGBT inverter or sub inverter and they are connected in series in

each phase. Usually in hybrid asymmetric multilevel inverters, the ratio of 3

to 1 is used between main and sub inverter capacitors in order to achieve

maximum output voltage level; so finally the output phase voltage is 9-level

[25].

Fig. 2.13 3-phase 9-level hybrid asymmetric inverter power circuit for drive applications

2.4

Conclusions

In this chapter, conventional topologies of multilevel inverters have been

investigated. First, different topologies of multilevel inverters, their

advantages and disadvantages have been discussed. Then, based on

symmetric multilevel inverter, asymmetric and hybrid multilevel inverter

have been derived. Finally, the structure of the hybrid asymmetric multilevel

inverter that is appropriate for high power, medium voltage drive

applications has been described.

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

19

3

Modulation Techniques

In many industrial applications, the output voltage of inverters should be

controlled to overcome input voltage changes and meets the need of

voltage/frequency control. It is obvious that output voltage harmonics are

depended on the selected modulation technique. A high number of

semiconductor devices and switching redundancies bring a higher level of

complexity in multilevel topologies compared with a two-level inverter.

However, this complexity can be used to improve the modulation technique,

such as, reducing the switching frequency, minimizing the common-mode

voltage or balancing the dc link voltages.

Today, there are many modulation techniques for multilevel applications

and they can be classified in two main groups, depending on their switching

frequency: 1) fundamental switching frequency, where each inverter has only

one commutation per cycle, and 2) high switching frequency, where each

inverter has several commutations per cycle. These techniques are shown in

Fig. 3.1[14-16] and can be defined as the following:

Fundamental

Switching

Frequency

Multi-Level Inverter

Modulation

Techniques

Selective Harmonic

Elimination (SHE)

Space Vector PWM

(SVM)

High Switching

Frequency

Carrier-Based PWM

Fig. 3.1 Conventional modulation techniques in multilevel inverters

•

Selective Harmonic Elimination (SHE): In this technique, the switching

angles are computed offline and are calculated in such a way that

arbitrary harmonics, usually low order, up to m-1 harmonics are

eliminated, where m is the number of switching angles. This

modulation operates at a very low switching frequency to reduce the

semiconductor losses. To minimize harmonic distortion and to achieve

adjustable amplitude of the fundamental component, the most

significant low-frequency harmonics are chosen for elimination by

properly selecting angles among different level inverters.

•

Space-Vector PWM (SVM): Each multilevel inverter has several

switching states which generate different voltage vectors and can be

used to modulate the reference. In SVM, the reference signal is

generated from its closest signals. Some vectors have redundant

switching states, meaning that they can be generated by more than one

20

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

switching state. This feature is used for balance of capacitor voltages.

Multilevel SVM must manage this behavior to optimize the search of

the modulating vectors and apply an appropriate switching sequence.

Carrier-Based PWM: This highly conventional technique is based on

•

the comparison of a sinusoidal reference with carrier signals which are

usually selected triangular and modified in phase or vertical positions

to reduce the output voltage harmonic content. Due to simplicity and

popularity of this technique, it will be analyzed in this chapter in

details and will be used as the modulator of the multilevel topologies.

3.1

Carrier based PWM

In this part, first fundamentals of PWM for 2-level converters and its

characteristics will be explained. Then, this modulation will be investigated

for multilevel inverter applications.

For all of inverters (2-level or multilevel) minimum and maximum values

of output voltages will be normalized to -1 and +1 with respect to the input dc

voltage. For 2-level inverter which has two states, this is simply

understandable, but for multilevel inverters depending on the number of

output voltage levels, other states which are equally between the minimum

and maximum, will be added.

3.1.1

2-level PWM

Inverter gain can be defined as the ratio between the output ac voltage and

the input dc voltage. There are different methods to change the inverter gain.

The most effective method to control the gain and the output voltage of

inverter is using PWM method in inverters.

Fig. 3.2 shows 2-level PWM fundamentals. In this figure a reference signal

which is usually a sinusoidal waveform, is compared with a carrier signal

which is usually a triangular waveform. Based on this figure, if we assume

that the average output voltage in switching cycle 45 is 6, we have:

4 6 4 6 + 45 6,

4 4 + 45

where 4 is the switching time where the reference signal is lower than the

carrier. 6 is the minimum voltage and is generated by subtraction of

reference and carrier signals when the reference is lower than carrier. 4 is the

switching time where the reference signal is higher than the carrier and 6 is

the maximum voltage and is generated by subtraction of reference and carrier

signals when the reference is higher than carrier.

(3.1)

If we solve the above equation for two switching times, 4 and4 , we have:

4 + 7

45

: "79

78"79

, 4 + 7

78"7:

9 "7:

45

(3.2)

The equation (3.2) shows a linear relation between switching times and

average of output voltage.

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

21

The previous equations can be rewritten based on duty cycles (;< ), i.e. the

ratio of conduction times (4< ) and total switching period (45 ):

;< +

(=

(>

, ? + 1,2

(3.3)

; 6 ; 6 + 6, ; ; + 1

; +

78"79

7: "79

, ; +

(3.4)

78"7:

79 "7:

v2

(3.5)

d1

d2

1

v

carrier

reference

v1

t1

t2

0

ts

Fig. 3.2 PWM modulation fundamentals

From equation 3.5, it can be concluded that duty cycles can be stated as

normalized form of average voltages. For example, duty cycle ; corresponds

to average voltage 6@ for mapping A6 , 6 B C A0,1B. Also, according to equation

3.2 switching times can be calculated and detected by using a timer. In

addition, desired output voltage can be compared with a linear ramp wave in

the switching period. Thus, if desired voltage is higher than ramp, higher

level of output voltage is selected; otherwise lower level is selected.

There are different methods to generate modulation signals [27]. All these

methods can be presented by similar graphic diagrams: a reference signal is

compared to a carrier signal and output state is selected based on which

signal is higher at any moment. In selection of carrier and reference signals

there are some points which are mentioned below:

•

Carrier signal is usually a symmetric triangular wave, but a saw tooth

wave can be used either. Important fact is that the symmetric signal

generates fewer harmonic [27].

•

The reference signal can be continuous or sampled synchronous with

carrier signal. The second method usually generates fewer harmonics.

Since today digital controllers are used, this method is preferred [28].

Fig. 3.3 shows an example of 2-level PWM.

22

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

+1

0

-1

0

0.005

0.01

0.015

0.02

0.015

0.02

(a)

+1

0

-1

0

0.005

0.01

(b)

Fig. 3.3 (a) Reference signal (DEF ) and carrier signal (GGH#G ), (b) output voltage of 2-level PWM

3.1.2

Multilevel PWM

Multilevel PWM is a generalized form of the 2-level PWM, described in the

previous section, applied to multilevel inverters. In this part, multilevel PWM,

its characteristics and advantages are presented.

Considering 2-level PWM, the average output voltage (6@ ) is generated by

switching of voltages 6…* in the switching cycle (45 ). In addition, considering

this modulation, to determine switching times, carrier signals are used.

According to Fig. 3.2, for each modulation band one carrier signal is needed.

Therefore, for an inverter with N output levels, N-1 modulation bands and

therefore N-1 carrier signals are needed [28].

Considering 2-level PWM, there are several methods to generate

modulation signals. Carrier signals in multilevel applications can be in the

form of level-shifted to each other or phase-shifted [23, 27, 30, 31]. In levelshifted PWM, the carrier signals have the same phase and pick-to-pick

amplitude and they are in vertical positions to each other. In phase-shifted

PWM the phase of each carrier shifts in a proper angle to reduce the harmonic

content of the output voltage. The arrangement that is used generally is

triangular waveforms which are level-shifted to each other. Some examples of

5-level and 9-level PWM are shown in Fig. 3.4 and Fig. 3.5. In this figures, all

the carrier signals have the same frequency, amplitude and phase.

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

23

1

0.75

0.5

0.25

0

-0.25

-0.5

-0.75

-1

0

0.0025

0.005

0.0075

0.01

0.0125

0.015

0.0175

0.02

(a)

1

0.75

0.5

0.25

0

-0.25

-0.5

-0.75

-1

0

0.0025

0.005

0.0075

0.01

0.0125

0.015

0.0175

0.02

(b)

Fig. 3.4 5-level inverter: a) reference and carrier signals, b) output voltage

1

0.75

0.5

0.25

0

-0.25

-0.5

-0.75

-1

0

0.0025

0.005

0.0075

0.01

0.0125

0.015

0.0175

0.02

0.015

0.0175

0.02

(a)

1

0.75

0.5

0.25

0

-0.25

-0.5

-0.75

-1

0

0.0025

0.005

0.0075

0.01

0.0125

(b)

Fig. 3.5 9-level inverter: a) reference and carrier signals, b) output voltage

24

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

The above PWM technique is called Phase Disposition PWM (PD-PWM).

Moreover, the other two modulations are defined in below:

carrier signal is out of phase with its neighbors by 180° .

•

Alternate Phase Opposition Disposition PWM (APOD-PWM) – each

•

signals above zero are in phase and are 180° out of phase with those

Phase opposition Disposition PWM (POD-PWM) – all the carrier

below zero.

In the following, each technique is explained briefly. Also it should be

mentioned that depending on the topology of multilevel inverter, the applied

modulation may be different.

For description of the three modulation techniques mentioned above, we

consider a 5-level symmetric cascaded H-bridge inverter. Also we consider

these definitions:

•

Amplitude Modulation ratio (K ), defined as K + LM /L , where LM is

the amplitude of the reference signal and L is the pick-to-pick

as K + LM / 1L .

amplitude of carrier signal. (For a N-level inverter, this ratio is defined

•

•

Frequency modulation ratio (KN ), defined as KN + O /O7 , where O7 is the

reference signal frequency and O is the carrier signal frequency.

P angle that the relative phase displacement between the carrier and

the reference signal and in this analysis it is assumed to be zero.

3.1.2.1 Alternate phase opposition disposition

disposition (APOD(APOD-PWM)

In this modulation, carrier signals are out of phase with their neighbours

by 180° . The voltage at the output of a 5-level inverter which uses APODPWM control method is as the following

•

The inverter switches to /2 if the reference signal is higher than all

The inverter switches to /4 if the reference signal is lower than

of carrier signals.

•

The inverter switches to /4 if the reference signal is lower than

two above carrier signals and higher than two below carrier signals.

•

The inverter switches to /2 if the reference signal is lower than all of

two below carrier signals and higher than two above carrier signals.

•

carrier signals.

Fig. 3.6 shows the APOD-PWM control technique for a 5-level inverter

K + 0.85 and KN + 39. In particular, it can be seen that APOD modulation

does not produce a first carrier harmonic. Instead the dominant harmonics are

channelled into the sidebands around the first carrier harmonic. Therefore,

since only the triple sidebands away from the carrier frequency cancel in a

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

25

three phase system, APOD modulation contains some considerable harmonic

energy in the line voltage spectrum. In addition, output voltage has quarterwave symmetry, if KN is even. If KN is odd, then the output waveform has

odd symmetry.

1

0.75

Magnitude (pu)

0.5

0.25

0

-0.25

-0.5

-0.75

-1

0

0.0025

0.005

0.0075

0.01

Time (s)

0.0125

0.015

0.0175

0.02

0.0125

0.015

0.0175

0.02

(a)

1

Output Voltage (pu)

0.75

0.5

0.25

0

-0.25

-0.5

-0.75

-1

0

0.0025

0.005

0.0075

0.01

Time (s)

(b)

Fundamental (50Hz) = 0.8499 , THD= 36.05%

Mag (% of Fundamental)

25

20

15

10

5

0

0

20

40

60

80

Harmonic order

100

120

140

100

120

140

(c)

Fundamental (50Hz) = 1.472 , THD= 29.46%

Mag (% of Fundamental)

25

20

15

10

5

0

0

20

40

60

80

Harmonic order

(d)

Fig. 3.6 APOD-PWM technique: a) reference and carrier signals, b) output phase voltage waveform,

c) Harmonic spectrum of output phase voltage, d) Harmonic spectrum of output line voltage

26

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

3.1.2.2 Phase position disposition

disposition PWM (POD(POD-PWM)

In POD-PWM control technique the carrier signals which are above the

zero level are in phase and the carrier signals which are below the zero level

are in phase of each other and out of phase by 180° to above signals.

Fig. 3.7 shows the POD-PWM technique for a 5-level inverter with K +

0.85 and KN + 39. In POD, the output phase voltage has quarter-wave

symmetry, if KN is even. If KN is odd, then the output waveform has odd

symmetry.

In this modulation, dominant harmonics are on the sideband of the first

carrier (KN S 1) and the phase voltage harmonic at the carrier frequency is not

considerable. Hence, similar to APOD-PWM, POD modulation contains

significant harmonics in the line voltage spectrum, especially in the first

carrier band. Comparing to APOD, this modulation has more harmonic

distribution along the harmonic orders. This is because, as long as both APOD

and POD channel the harmonic energy into the carrier sidebands, the APOD

technique still places more harmonic energy into the multiples of three away

from the carrier multiples than POD. These triple sideband harmonics cancel

on a three-phase system, hence improving the performance of the APOD

compared to the POD [35].

1

Magnitude (pu)

0.75

0.5

0.25

0

-0.25

-0.5

-0.75

-1

0

0.0025

0.005

0.0075

0.01

0.0125

0.015

0.0175

0.02

0.0125

0.015

0.0175

0.02

Time (s)

(a)

1

Output Voltage (pu)

0.75

0.5

0.25

0

-0.25

-0.5

-0.75

-1

0

0.0025

0.005

0.0075

0.01

Time (s)

(b)

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

27

Fundamental (50Hz) = 0.85 , THD= 36.05%

Mag (% of Fundamental)

25

20

15

10

5

0

0

20

40

60

80

Harmonic order

100

120

140

(c)

Fundamental (50Hz) = 1.472 , THD= 33.02%

Mag (% of Fundamental)

25

20

15

10

5

0

0

20

40

60

80

Harmonic order

100

120

140

(d)

Fig. 3.7 POD-PWM technique: a) reference and carrier signals, b) output phase voltage waveform,

c) Harmonic spectrum of output phase voltage, d) Harmonic spectrum of output line voltage

3.1.2.3 Phase disposition

disposition PWM (PD(PD-PWM)

In PD-PWM modulation, as already shown in Fig. 3.4 and Fig. 3.5, all the

carrier signals are in phase.

Fig. 3.8 shows the PD-PWM modulation technique for a 5-level inverter

with K + 0.85 and KN + 39. In this modulation, main harmonics are at the

first carrier frequency. In this technique, the odd sidebands around the even

carrier multiples, and the even sidebands around the odd carrier harmonics

can be easily seen in the output phase voltage spectrum. Also, as with all

carrier-based PWM techniques, only the multiples of three away from the

carrier multiples cancel in the line voltage. This cancelation is independent of

the absolute carrier frequency and proves that integer/triple carrier to

fundamental ratios do not affect the harmonic performance of the modulation

algorithm [35].

In PD-PWM modulation technique, the major feature of the phase voltage

spectrum is the significant first carrier harmonic. This feature gives the PDPWM excellent line voltage performance, since this carrier harmonic is a

common-mode component across the phase voltages of a three phase inverter,

and therefore cancels in the output line voltage. Consequently, with

concentration of harmonics in the first carrier, the harmonic sidebands which

of course do not fully cancel between the three phase legs have less energy

[35]. This is in contrast to the APOD- and POD-PWM techniques, which have

28

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

considerable harmonics in their line voltage spectra. In addition, when this

technique is used, an even KN will lead to both odd and even harmonics in the

output phase voltage and in the case of odd KN , the output phase voltage

spectrum will only contain odd harmonics.

1

Magnitude (pu)

0.75

0.5

0.25

0

-0.25

-0.5

-0.75

-1

0

0.0025

0.005

0.0075

0.01

Time (s)

0.0125

0.015

0.0175

0.02

0.0125

0.015

0.0175

0.02

(a)

1

Output Voltage (pu)

0.75

0.5

0.25

0

-0.25

-0.5

-0.75

-1

0

0.0025

0.005

0.0075

0.01

Time (s)

(b)

Fundamental (50Hz) = 0.85 , THD= 36.05%

Mag (% of Fundamental)

30

25

20

15

10

5

0

0

20

40

60

80

Harmonic order

100

120

140

100

120

140

(c)

Fundamental (50Hz) = 1.472 , THD= 19.24%

Mag (% of Fundamental)

25

20

15

10

5

0

0

20

40

60

80

Harmonic order

(d)

Fig. 3.8 PD-PWM technique: a) reference and carrier signals, b) output phase voltage waveform,

c) Harmonic spectrum of output phase voltage, d) Harmonic spectrum of output line voltage

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

29

As for the symmetric multilevel inverter case, APOD-PWM, POD-PWM

and PD-PWM modulations can be used in asymmetric multilevel topology.

The PD-PWM technique for the 9-level asymmetric inverter shown in Fig. 3.9,

the output phase voltage, its harmonic spectrum and line-to-line voltage are

shown in Fig 3.9. It is clear from this figure that the harmonic contents are

decreased, because the number of voltage levels is increased.

1

0.75

Magnitude (pu)

0.5

0.25

0

-0.25

-0.5

-0.75

-1

0

0.0025

0.005

0.0075

0.01

Time (s)

0.0125

0.015

0.0175

0.02

0.0125

0.015

0.0175

0.02

(a)

1

Output Voltage (pu)

0.75

0.5

0.25

0

-0.25

-0.5

-0.75

-1

0

0.0025

0.005

0.0075

0.01

Time (s)

(b)

Fundamental (50Hz) = 0.85 , THD= 17.33%

M ag (% of Fundam ental)

25

20

15

10

5

0

0

20

40

60

80

Harmonic order

100

120

140

100

120

140

(c)

Fundamental (50Hz) = 1.4722 , THD= 10.14%

Mag (% of Fundamental)

25

20

15

10

5

0

0

20

40

60

80

Harmonic order

(d)

Fig. 3.9 PD-PWM technique for a 9-level asymmetric inverter: a) reference and carrier signals, b)

output phase voltage, c) Harmonic spectrum of output phase voltage, (d) Harmonic spectrum of output

line voltage

30

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

Fig. 3.10 shows the firing signals of inverter switches shown in Fig. 2.11.

Observe that the switches in the IGBT inverter (sub inverter) are turned on

and off more frequently than the switches in the IGCT inverter (main

inverter).

1.5

1.5

1

1

0.5

0.5

0

0

-0.5

-0.5

0

0.005

0.01

0.015

0.02

0

0.005

0.01

1.5

1.5

1

1

0.5

0.5

0

0

0

0.005

0.02

(c)

(a)

-0.5

0.015

0.01

0.015

-0.5

0.02

0

0.005

0.01

0.015

0.02

(d)

(b)

Fig. 3.10 Switching signals for 9-level asymmetric inverter: (a) , , (b) , , (c) , , (d) , The output voltage waveforms of the IGBT inverter (solid lines) and IGCT

inverter (dashed lines) can be observed in Fig 3.11. It can be seen that the

maximum voltage of IGCT inverter is three times larger than the voltage of

the IGBT inverter and by adding these voltages a 9-level voltage waveform is

obtained.

1

0.75

0.5

0.25

0

-0.25

-0.5

-0.75

-1

0

0.005

0.01

0.015

0.02

Fig. 3.11 output voltages of IGBT inverter (solid lines) and IGCT inverter (dashed lines)

As it was mentioned before, APOD-, POD- and PD-PWM techniques can be

used for asymmetric inverter. In asymmetric inverter, harmonic spectrum of

output voltage depends on the frequency modulation ratio (KN ) that can be

odd or even. Fig. 3.13 and 3.14 shows THD of output voltage KN + 24 and

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

31

KN + 39 in operating range of 0.8 T K T 1.6. Total Harmonic Distortion

(THD) is defined as below:

VWX73Y(ZH +

[∑∞)$ )

3.6

It is clear that for K T 0.8 some of carrier signals will not be compared

with the reference signal and the firing signal will not be applied to some of

switches; in addition using K ] 1 results in overmodulation and increase of

THD.

where h is the harmonic order.

20

18

16

14

THD (%)

12

10

8

6

4

PD-PWM

POD-PWM

APOD-PWM

2

0

0.8

20

0.9

1

1.1

1.2

ma

1.3

1.4

1.5

1.6

Fig. 3.12 THD of output voltages for different modulation techniques, (KN + 39

18

16

14

THD (%)

12

10

8

6

4

PD-PWM

POD-PWM

APOD-PWM

2

0

0.8

0.9

1

1.1

1.2

ma

1.3

1.4

1.5

Fig. 3.13 THD of output voltages for different modulation techniques, (KN + 24

1.6

Moreover it is obvious from Fig. 3.13 and 3.14 that there are very small

differences of THDs between modulations for KN + 39, whereas in KN + 24

the differences are considerable. More discussions about even and odd KN s

are presented in [25].

All these modulation techniques are classified in the group of pure

sinusoidal PWM (SPWM), where the triangular carrier waveforms are

compared with a sinusoidal reference known as modulating signal. The other

method to improve the gain of pulse width modulator in a multilevel inverter

is Switching Frequency Optimal PWM (SFO-PWM). This modulation is

similar to previous modulations and applicable for three-phase systems but

32

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

the zero sequence (3rd harmonic) of voltage is injected to each reference

signals [29, 30]. This technique calculates the average value of maximum and

minimum of instantaneous reference voltages , , and for all the

modulation waveforms subtract this value from the reference voltage:

^_` , , ^ a , , ,

2

+ 3NN5H(

3NN5H( +

cde

3.7

3.8

cde + 3NN5H( ,

3.9

cde + 3NN5H( ,

3.10

The analogue circuit to make the reference signal of SFO-PWM is shown in

Fig. 3.14 [30].

Fig. 3.15 shows the SFO-PWM with K + 1.15 and KN + 39. Injection of a

third-harmonic into the reference waveforms would obviously achieve a 15%

increase in modulation index over Sinusoidal PWM before overmodulation

nonlinearities occur. It is simply because of the reduced height of the threephase reference envelope that is achieved by third-harmonic injection [35]. In

this technique, the 3rd harmonic is cleared in three-phase system.

Fig. 3.14 Analogue circuit to make the reference signals in SFO-PWM technique

1

0.75

Magnitude (pu)

0.5

0.25

0

-0.25

-0.5

-0.75

-1

0

0.0025

0.005

0.0075

0.01

Time (s)

0.0125

0.015

0.0175

0.02

(a)

1

Output Voltage (pu)

0.75

0.5

0.25

0

-0.25

-0.5

-0.75

-1

0

0.0025

0.005

0.0075

0.01

Time (s)

0.0125

0.015

0.0175

0.02

(b)

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

33

Output Voltage (pu)

2

1

0

-1

-2

0

0.005

0.01

0.015

0.02

Time (s)

0.025

0.03

0.035

0.04

(c)

Fig. 3.15 SFO-PWM technique for a 9-level asymmetric inverter: a) reference and carrier signals, b)

output phase voltage waveform, c) output line voltage waveform

Fig. 3.16 shows the harmonic spectrum for phase and line voltages of SFOPWM. The results indicate that the third-harmonic injection offers minimal

harmonic advantage for PWM of multilevel inverters, since the harmonic

distribution of line voltage spectrum is not improved significantly. Therefore,

this optimization only has the value to increase the available linear

modulation region if this is required.

Fundamental (50Hz) = 1.155 , THD= 28.97%

Mag (%of Fundamental)

20

15

10

5

0

0

20

40

60

80

Harmonic order

100

120

140

100

120

140

(a)

Fundamental (50Hz) = 2 , THD= 7.70%

Mag (%of Fundamental)

5

4

3

2

1

0

0

20

40

60

80

Harmonic order

(b)

Fig. 3.16 SFO-PWM technique for a 9-level asymmetric inverter: a) Harmonic spectrum of output phase

voltage, b) Harmonic spectrum of output line voltage

3.2

Conclusion

After full description of different topologies of multilevel inverters in

chapter 2, the conventional modulation techniques which are used in these

inverters, discussed in this chapter. In this thesis the focus is on the carrierbased PWM. The different operating techniques of this modulation which are

34

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

PD-PWM, APOD-PWM, POD-PWM and the optimized form of these

modulations, SFO-PWM, were applied to symmetric and asymmetric

multilevel inverters, described briefly and compared with each other. It was

shown that the PD-PWM, due to the less THD and less harmonic distortions

around the carrier frequency shows better performance than other techniques.

Moreover, the injection of third harmonic in the optimized PWM increases the

available linear modulation region to reduce the THD in three-phase systems.

CHALMERS, Electric Power Engineering, Master’s Thesis 2011

35

4

Drive System and Performance

Indexes

As mentioned earlier in this thesis, voltage source inverters have

widespread application in medium voltage drives. Fig. 4.1 shows the block