Comprehensive Maintenance Plan

advertisement

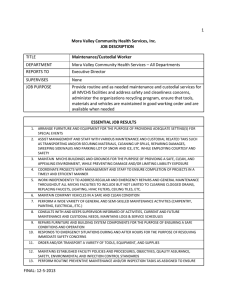

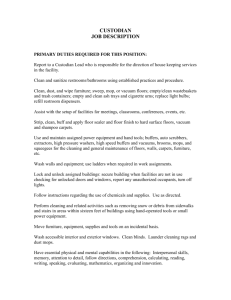

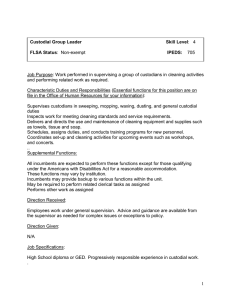

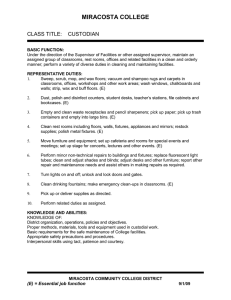

P.O. Box 1029 Easton, Maryland 21601-1029 Phone (410) 822-0330 Fax (410) 820-4260 COMPREHENSIVE MAINTENANCE PLAN 2014/2015 SUBMITTED BY: Kelly L. Griffith, Superintendent Gayle Secrist, Director of Support Services Bruce Horvath, Manager of Plant Operations Rick Walls, Maintenance Supervisor Ralph Potter, Plant Operations Supervisor Table of Contents Page § Purpose of Plan 1 § Objectives 1 § Personnel Organization 2 § Plant Operations Organization Chart 4 § Maintenance Programs 5 § Maintenance Frequency Chart 15 § General Building Statistics 17 § Vehicle Replacement Schedule 18 § Building Maintenance Survey 19 PURPOSE OF PLAN This comprehensive maintenance plan is established to develop, maintain, and/or improve the maintenance program of Talbot County Public Schools. It is designed to support the delivery of educational programs and services and to provide a safe and healthy environment as effectively and efficiently as possible. The maintenance and operation of plant personnel have an unwavering commitment of delivering quality service in construction, maintenance, operations, and grounds, as well as to address environmental areas. The entire staff strives for excellence, individual responsibility, and caring about others with the belief that they are an integral part of the educational process for the students of the Talbot County Public Schools. Research conducted regarding school facilities clearly indicates a strong correlation between the school environment and student achievement. Securing adequate funding and qualified personnel to deliver these services remain a top priority. OBJECTIVES OF THE PLAN The primary objective of the maintenance program is the maintenance of buildings, grounds, and fixed equipment through repairs or replacement during the life expectancy of the buildings. Specifically this can be further broken down as follows: 1. To provide buildings which function at top efficiency. 2. To maintain the plant buildings and grounds and fixed equipment in such a manner as to eliminate accidents and safety hazards. 3. To provide continuous use of facilities without disruptions to the educational program. 4. To protect public property by planned, scheduled, and repair/preventive maintenance. 5. To conserve energy by insuring that the maximum results are obtained with minimum expenditure of energy. 6. To provide maintenance programs which will produce the maximum amount of maintenance for the minimum dollars expended. 7. Provide effective support and response time to the schools. 8. Increase the productivity of the maintenance work force by the implementation of support staff educational programs which consist of in- house and professional training. PERSONNEL ORGANIZATION This section describes the organizational units that form the Plant Operations Department. Manager of Plant Operations Serves as the principal advisor to the Director of Support Services in all matters related to facilities including budgeting, capital improvements, building alterations, and maintenance and operations. Directs the work of the support personnel in all aspects of facility maintenance and custodial services. Supervisor of Plant Operations (Custodial) Directly responsible for the operation of custodial services in all buildings. These duties include personnel scheduling, product inventories, training, integrated pest management plan, inspections, and the coordination of activities that require custodial support. This person reports to the Plant Operations Manager. Maintenance-Supervisor Responsible for all major maintenance, renovation and addition projects. Reports to the Manager of Plant Operations and is directly responsible for maintenance and care of all buildings and grounds. These duties include personnel scheduling, product inventories, training, inspections and the coordination of all activities that require maintenance staff. Skilled Tradesman and Related Staff These positions report to the Manager of Plant Operations or the Maintenance Supervisor. A brief description of their duties follows: Electrician: Provides normal and emergency repair or replacement of electrical controls, fixtures, motors and/or circuits. Plumber: Provides normal and emergency repairs, including boiler maintenance and repair in preparation for yearly inspections. HVAC Mechanic: Provides normal and emergency repair of air conditioning, refrigeration, ventilation, and heating systems. Motor Mechanic: Maintains an orderly warehouse and assists on preventive maintenance, emergency repairs and general repairs as requested. Maintains all vehicles such as fleet vans and grounds equipment. Carpenter: Provides normal and emergency carpentry repairs and painting. Installs such items as bookshelves and other specialty needed wood items. Maintenance Worker: Works with the mechanic on emergency and general repairs. Performs all aspects of ground maintenance, including snow removal grass cutting, athletic fields and provides manpower for special custodial projects. Head Custodian: Provides leadership and guidance to custodians. Supervises and participates in overall cleaning and maintenance of the school building. Custodian: Provides students, parents and teachers with a safe, attractive, clean, comfortable place in which to learn and obtain an education. Administrative Assistant: Maintains data base, records, filing system, answers phone, provides service support and answers questions. Coordinates work order assignments and status of the assignment. MAINTENANCE PROGRAMS Maintenance - The recurring, day-to-day periodic or scheduled work required to preserve or restore a school or its equipment to such a condition that it may be effectively utilized for its designated purposes. The following are categories of the maintenance program used in Talbot County: A. Scheduled Maintenance Scheduled maintenance has a goal of keeping the facilities in proper operating condition through regular service of equipment and facilities. It is, therefore, imperative that a schedule be established to insure proper budgeting. The schedule itself is not an exact time table because the exact month or even year of failure or breakdown cannot be determined in advance. Rather, it is a prediction indicating that over a period of time a piece of equipment must be replaced or serviced if it is expected to function properly. The frequencies used are those based on local experiences and conditions. Repairs or replacements are not made strictly by the schedules, but are made based on the necessity of corrective action. The schedule or replacement must be flexible but will be accurate from a long range budget planning standpoint. The subcategories of scheduled maintenance are as follows: (1) Preventive Maintenance Preventive maintenance is the action taken by users, operators, and maintenance personnel to prevent expensive repairs and breakdowns before they occur. It is a planned program which includes lubricating, cleaning, adjusting, painting, replacement of expendable parts and other activities designed to maintain the buildings and fixed equipment in a condition as near to original as possible. All work is scheduled and documented using a computerized maintenance system. a) Fire extinguisher and kitchen ansul hoods are inspected, serviced, hydro tested, and replaced by a licensed fire and equipment specialist on an annual basis. Custodians inspect extinguishers monthly and make calls for service as needed. b) Sprinkler systems are tested quarterly by a licensed fire and equipment specialists. c) Fire alarms, smoke detectors, and schedule clocks are inspected twice a year and serviced by a licensed specialist. d) The State Fire Inspection is held during National Fire Prevention Week in every school in the county. e) Emergency generators are located at Easton High School, St.Michaels High, St. Michaels Elementary School, Easton Middle, Easton Elementary Moton Building, Easton Elementary Dobson Building, Tilghman Elementary and Chapel District Elementary School. They are tested weekly by pre-set time clock and serviced monthly through the preventive maintenance work order system. f) Safety inspections are made daily as part of the custodian’s normal duties. The Talbot County Health Department conducts inspections that are in addition to the annual inspections made by Manager of Plant, Supervisor of Plant and Maintenance – Construction Manager. g) The plumber cleans and inspects all oil burners and “punches” all boiler tubes annually. At that time, both ends of the boiler are opened, gaskets checked/replaced and controls checked and cleaned. Boilers are inspected every two years by insurance company representatives. h) Pest control is provided by private licensed pesticide applicator. Current regulation is adhered to by the approved Pest Control Management Program that is in place. i) Roofs are inspected semi-annually by maintenance mechanics. Roofs are cleaned at least twice a year. Roof drains are cleared of debris at least once per month by the custodians. j) Blinds are replaced/repaired continuously and cleaned annually. k) Maintenance services all air compressors, central air conditioning units and controls, air handling units and unit ventilators, motors and pumps connected to these units, cooling towers, and system controls on a year round basis. l) Oil burners, boilers, motors, pumps and oil tanks are checked weekly by Maintenance personnel and monitored by custodians daily. m) Return louvers and grills are cleaned by custodians on a monthly schedule. n) Condenser coils on all refrigerators, freezers, and window air conditioning units are cleaned annually by custodial staff and maintenance mechanics. o) Asbestos inspections for friable materials are conducted bi-annually by the State Certified Industrial Hygienist. All records are on file at the Plant Operations office and at the school. p) (2) Environmental concerns such as asbestos, lead in drinking water, indoor air quality and underground storage tanks are monitored closely to assure all local, state, and federal laws are adhered to. Accurate records are maintained to assure that all Talbot County Public Schools are in compliance, “Talbot County Public Schools Asbestos Management plan,” is in effect for the safety of our students and staff. Scheduled Repairs Scheduled repairs are actions which involve a more sizeable effort than preventive maintenance to maintain a facility in good condition. Scheduled repairs usually occur at or near the end of the specified life of an item or system. They include such items as roof replacements or renovations, carpet replacements, and boiler overhauls. a) Boiler Inspection/Overhaul Replacement Schedule Maintenance mechanics clean and inspect boilers annually. Repair or replacement depends upon the age of the boiler and the cost of repair. b) Roof Replacement Schedule Talbot County Public Schools five year maintenance program provides for semi-annual roof inspections to determine if repair and replacement is required. c) Septic Tank and Grease Trap Cleaning Grease traps are cleaned annually or as often as needed. An automated enzyme injection system was installed in the kitchen at Easton Middle School. The septic system at Chapel District Elementary School is cleaned on an as-needed basis. d) Bleacher Repair/Replacement Schedule All bleachers are inspected and repaired annually by licensed specialist. e) Tile Floor and Carpet Replacement Schedule Tile floors are replaced on an as needed basis. Carpet is scheduled for replacement on a 10 year cycle. f) Maintenance Vehicle Replacement Schedule There is no standard replacement schedule. The vehicles are replaced when the repair costs become prohibitive. (See page 18) g) Oil Tank Pressure Testing Schedule The oil storage permit is approved by the Maryland State Department of the Environment. All testing is done to meet Federal and State compliance based on the age of the tank. 3. Modernization and Alterations Modernizations and alterations are actions where labor and materials are expended to improve the buildings original condition. This includes code corrections, renovations, and repair work but does not include construction of new building additions or adapting building to major changes in use. a) Unscheduled Maintenance Unscheduled maintenance includes repair activities which cannot be programmed or foreseen. It includes corrections of dayto-day routine breakdowns or failures and emergency repairs, based on request from principals and school managers. 1) Unscheduled Repairs Unscheduled repairs are actions to correct unforeseen breakdowns or failures of building systems or equipment. They include routine repairs such as failure of light fixtures and emergency repairs such as broken water pipes. In most instances these repairs are mechanically or electrically related. 2) Vandalism and Security Related Repairs A vandalism or security related repair is one which requires the expenditure of labor and material to restore the building to its original condition after it has been damaged, or to provide temporary protection in some manner from vandals. It does not include modifications of facilities for the purpose of improving building security such as installation or enlargement of intrusion systems. Most cases deal with broken windows, jammed door hardware, or replacing security lights. o b) Deferred Maintenance Deferred maintenance includes maintenance and repairs which have been delayed due to lack of funds, personnel or decisions on major renovations, disposal, or change of use. The following categories are additional responsibility of custodial and maintenance personnel: OUTSIDE GROUNDS Outside grounds of all entrances will be monitored daily, during the work week. CLASSROOMS AND OFFICES - Monday through Friday Main cleaning of floors - daily, during the work week. Thoroughly clean all traffic areas using a dust mop or vacuum where appropriate. Wet cleaning of floors - weekly Wet clean hard surface floors with an appropriate floor chemical designed to extend the life of the floor finish. The wet cleaning of floors will be provided once per week. Shampoo carpeted floors as needed. Spot cleaning of floors Remove spots from spillage on hard surface and carpeted floors as needed. Check and spot clean - daily, during the work week. Spot clean walls, doors and electric switch plates. Clean interior of glass doors and glass partitions. Remove graffiti. Adjust shades or blinds to a uniform height throughout the building. Trash Receptacles - daily, during the work week. Empty and clean wastepaper baskets. Wet wipe with an odor controlling solution as needed. Reline wastebaskets where necessary. Wet Wipe - weekly/on a project basis All office and classroom desks are dusted and/or wet cleaned once per week when cleared. All desks, including student desks are cleaned on a project basis annually. Chalkboards, chalk trays, slate blackboards and pencil sharpeners - when needed/daily/weekly Dust and wet clean chalk trays and slate blackboards, empty pencil sharpeners, and erase chalkboards. Slate blackboards and chalkboards are washed on a project basis. NON-CLASSROOM AREAS Custodial and Maintenance Closets - as required Clean and maintain all custodial and maintenance closets. Metal Work - as required Clean, polish and maintain all bright metal work. Drinking fountain - daily, during the work week; twice daily during the flu season. Wet clean and disinfect drinking fountain with a germicidal solution. Public telephones - daily, during the work week. Wet clean and disinfect telephones with a germicidal solution. Stairways - daily, during the work week. Dust down, dry mop and spot wet mop once per day. Corridors - daily, during the work week. Thoroughly dry mop with a chemically treated mop and spot wet mop as needed. Wet clean all hard surface corridors thoroughly once a week. Thoroughly vacuum all carpeted corridors five times a week. Remove spots as necessary. Public Entrances - daily, during the work week. Spot clean glass doors and clean entrance floor area as needed. Vacuum walk off mats. Sweep exterior steps and sidewalks in front of main entrances. Kitchen and kitchen storerooms - daily, during the work week. Custodians will remove trash and garbage from kitchen areas. Cleaning of equipment is performed by food service personnel. Floors are cleaned by the custodians once a day. Dishes, silverware, and pots are received/washed by food service. Cafeteria – daily, during the work week. Thoroughly wet clean floor area once daily. Cleaning of tables and chairs are completed by custodial personnel. Cafeteria and Kitchen - annually The cafeteria and kitchen walls, vents and hoods are thoroughly cleaned. All cleaning of food preparation equipment is the responsibility of food services personnel. Bathrooms - daily, during the work week. Checked and cleaned as needed during school day am/pm, cleaned nightly. Completely clean and disinfect washrooms including: a. Wet wipe fixtures, shelves and ledges with a germicidal solution. b. Clean and disinfect both the inside and outside of urinals and toilet bowls. c. Replenish the supply of dispenser items such as toilet tissue, soap, and paper towels. d. Wet clean and disinfect floors with a germicidal solution. e. Clean and polish mirrors. f. Provide daily spot checking and cleaning as needed Locker rooms and showers - daily, during the work week Monitor areas. Wet clean floor with a germicidal solution. Daily maintenance of lockers to be done by students. Cleaning of inside of lockers to be done annually by custodial personnel. Conditioning area - weekly Dry and wet mop floors with a germicidal solution. Vacuum carpets and sanitize mats on a scheduled basis. Athletic Program - daily, during the work week/on project basis Gymnasium - perform dry mopping and/or sweeping of floors once per day and prior to, as well as following, all interscholastic sporting events. Clean bleachers and grandstand areas after use and as needed. Prepare floor surfaces with proven finishes and cleaners of a project basis. OTHER CUSTODIAL/MAINTENANCE DUTIES Cleaning and replacing of light fixtures - as needed Light fixtures will be cleaned once per year. Replacing light bulbs is provided by custodial personnel. Window cleaning - annually All cleaning of exterior windows are performed during annual summer cleaning. The interior of exterior windows are cleaned by custodial personnel on a weekly basis. Window repair is completed as needed. Security - as needed The custodial and maintenance personnel have the responsibility of opening building per the administration’s direction. The opening of facilities for pre-shift extracurricular practices or activities is the responsibility of the sponsoring party/employees. Turn off all lights and lock all doors after extra-curricular activities and provide weekend supervision for community events when assigned by administrators. Trash removal - daily, during the work week. Remove trash from all areas of the school and take to dumpster area. Floor finishing Follow a carefully planned program of applying correct finishes and maintaining the floor surfaces throughout the school. Refinish floors on a scheduled program that will take into account the different use conditions, traffic, types of floors and activities in each area of school. Carpet/furniture cleaning and repair Service carpet and furniture on a scheduled program that will take into consideration the different use conditions, traffic, types of floors and activities in each area of school. Grounds care and snow removal Scheduled grounds care and snow removal will be provided for the lawns, trees, shrubs, sidewalks, and roadways to provide a safe and attractive environment. This includes cutting grass, trimming and fertilizing of grass and shrubbery. Other miscellaneous projects of a cleaning nature will be done such as: Removal of graffiti Cleaning of grills and vents Delivery of general supplies from central warehouse to other schools (includes mail on an arranged schedule). Machine scrubbing of all ceramic tile floors in showers and lavatories to remove odors, grease and reduce the possibility of bacterial and fungal growth. Minor ceiling repair and replacement is done on an as needed basis. Minor repairs of doors are the responsibility of the Maintenance Department. Minor electrical plumbing repairs are the responsibility of the Maintenance Department. Custodial service is provided for community and extracurricular activities on school premises as approved by school administration. A recycling program has been implemented in all our buildings. Oil Burners Air Compressors Check operation X Check operation, oil level, belt X tension, drain tank X X X X X X X X Air Conditioning Units Air Handling Units and Ventilators Check operation X Check dampers, change filters clean and vacuum X X X X X X Refrigerators, Freezers and Water Coolers Clean and vacuum condenser coils X Return Grilles and Louvers Motor Pumps Clean Check belt tension grease/oil Check packing, seals, float switches, lubricate bearings couplings and strainers X X X Cooling Towers Check belts, fans, sump treatment, drain seasonally Oil Tank Roof Inspection Lighting Stick level Inspect visually Clean & check all lamps and fixtures Temperature Control Glass & Glazing Fire Extinguisher Elementary Schools Check and Calibrate Temp. Replace glass and reglaze Check, change and location X Middle & High Schools Check, change and location X X X X X X X X X X X X X Other Weekly Monthly Quarterly Semi-Annual Annual Daily Maintenance Mechanical Equipment Contractor PROCEDURE Operations ITEM X X X X X X X X X X X X X X X X X Sprinkler Inspections Kitchen Hood Ansul System Emergency Generators Health Inspection Inspection Test run one-half hour Health Department Inspection Oil Burner Cleaning and Inspection Disassemble burner, clean, set clearances, start & check X Boiler Tube Cleaning Pest Control Inspections Roof Cleaning Venetian Blind Repairs Boiler Inspection Maintenance Vehicles Special Project Vehicles Brush clean boiler tubes Spray for insects Remove debris, clean Check operation Inspection Change oil and filters Change oil and filters X X X X X X X X X X X X X X X X X X X X X Other Weekly Monthly Quarterly Semi-Annual Annual Daily Maintenance Mechanical Equipment Contractor PROCEDURE Operations ITEM X X X X X GENERAL BUILDING STATISTICS (Excluding Classroom Trailers) School Tilghman St. Michaels Elementary Easton Elementary Moton Easton Elementary Dobson HeadStart Grade Built Original Renov. Total Sq. Use Acres Sq. FT. Addition Feet Energy square Cost @ sq. Ft. K-6 1958 2003 PreK- 1953 6 1961 1977 2010 2-5 1953 1957 1965 1991 PreK- 1958 1 1965 1992 2012 14,848 28,684 1.09 8.80 159 94 10 2 17,050 3,565 56,590 77,205 1.22 5 393 386 23 1 578 5,245 23,753 12,702 77,783 84,237 1.17 12 779 710 33 7 7,585 12,355 40,797 1.04 8 388 396 21 4 5,700 46,497 43,465 1.03 10 328 342 23 1 46,070 .93 23 431 374 25 1 106,985 .84 20 903 792 45 2 7-12 1971 76,072 76,072 .80 45 691 372 27 3 2010 9-12 1966 105,08 1971 5 1976 1997 1998 1999 126 76,198 25,768 186,829 31,446 17,020 4,210 3,320 .92 36.2 1283 1071 57 3 1.64 22 N/A N/A N/A N/A 42,537 20,857 PreK- 1957 16,333 5 1971 1998 2001 14,877 10,965 1,290 Chapel District PreK- 1952 12,748 5 1994 2000 2001 30,477 1456 1,200 1,645 Easton Middle 6-8 1953 76,619 1957 1979 2002 6,487 22,124 1,755 Easton High School Central Office 2013/2014 # of # of Enrollment Classroom Sp. Rms. teaching stations 14,200 White Marsh Elementary St. Michaels Middle High School Rated Capacity 1958 25,515 1987 2,240 27,755 Director of Support Services Manager of Plant Operations Administrative Assistant Supervisor of Plant Operations Custodial Supervisor of Maintenance Tilghman Elementary Head Custodian Maintenance Worker (3) St. Michaels Head Custodian HVAC Technician (3) Custodians (6) Plumber (1) Easton High Head Custodian Motor Mechanic (1) Custodians (6) Carpenter (1) Easton Middle Head Custodian Custodians (5) Easton Elementary Head Custodian Custodians (5) White Marsh Elementary Head Custodian Custodians (2) Chapel District Elementary Head Custodian Custodians (2) TCEC Head Custodian Building Maintenance Survey - Inspection Report & Justification Roadways & Parking Lots Site Appearance Site Utilities, Secure Exterior Appearance Playground Equipment Ext. Struct. Condition Gutters & Downspouts Windows & Caulking Sidewalks Entryways & Ext. Doors Roof Conditions Flashing & Gravelstop Roofdrains Equipment On Roof Skylights Interior Appearance Floors Walls Interior Doors Ceilings Elect. Distribution Lighting FCU's/Radiators Fire & Safety Equipment Equipment Rooms, Gen. Boilers/Water Heaters Air Conditioning Ventilation Equipment Electrical Service Steam Distribution Hot Water Distribution Chill Water Distribution Plumbing Int., Sub., Struct. CD B B A A A B B C B B C B B C C B B B B B B B C C B B A B B N/A B B B B DO C B A A B B A C C B A A B C B B C B C C C D C C C C B C C C B B C C EH D B A A N/A B N/A C D C C C B C N/A B D B B C C B B B B A B C B N/A A C B B EM B B A A A B N/A B A B C C C B N/A B B B B B B B B B B B B B B N/A A B B B MO C B A B A C N/A D B C D D D C N/A C C C C C C D C C C B C C C C C B C C SM C A A A B A N/A A A B D B C A N/A A A A A A A A A A A A A A A N/A A N/A A A SH C A A A N/A A N/A A A A C B C A B A A A A A A A A A A A A A A N/A A N/A A A TM A A A A A A B A A A B N/A N/A N/A N/A A A B A A A B B B B B B B B N/A B N/A B B County WM Averages B 79.44 A 89.44 A 95.00 A 93.89 A 92.14 A 88.33 B 87.50 B 82.78 A 87.22 B 85.00 C 76.11 B 81.25 C 77.50 B 82.50 B 110.00 A 88.33 A 85.00 C 85.00 B 86.11 A 86.11 A 86.11 B 82.78 B 83.89 B 83.89 B 85.00 B 87.22 B 87.22 B 83.89 B 85.00 N/A 75.00 B 88.33 B 83.33 B 85.00 B 85.00 Factor A x 95 380 475 380 475 190 2,280 2,375 1,330 950 Factor B x 85 1,955 935 1,190 1,955 425 255 170 1,190 1,700 Factor C x 75 450 1,275 675 225 1,500 150 225 0 225 Factor D x 65 0 65 195 0 325 65 0 0 0 Factor E x 55 0 0 0 0 0 0 0 0 0 Total Sum (Lines 35a through 35e) 2,785 2,750 2,440 2,655 2,440 2,750 2,770 2,520 2,875 Maximum Possible Items Evaluated 34 34 34 34 34 34 34 34 34 Less Items Not Applicable 1 0 4 3 2 4 5 6 3 Total Items Evaluated 33 34 30 31 32 30 30 28 33 Total Score (Line 36 divided by Line 39) 84.4 80.9 81.3 85.6 76.3 91.7 92.3 90 87.1 Overall Rating: B B B B C A A A B A = Superior B = Very Good C = Good NUMBER OF PORTABLE CLASSROOMS 0 0 D = Fair E = Poor N = N/A 0 0 0 0 0 0 0 982 1,086 525 72 0 2,665 34 3 31 86 B MAINTENANCE VEHICLE REPLACEMENT SCHEDULE VEHICLE NUMBER YEAR MAKE & STYLE CONDITION 1FTFE24YXRHA85998 1994 Ford Van A ANTICIPATED REPLACEMENT DATE 2015 1GBHG31K75F152863 1995 Chevy StepVan A 2015 1FTCR11U5TTA25991 1996 Ford Ranger PU A 2015 1GCFG25X231137379 2003 Chevy Van A 2015 IGCGG25V151112771 2005 Chevy Van S 2016 1GCGG25V151113029 2005 Chevy Van S 2016 1GCGG25C581143346 2008 Chevy Van S 2018 1GBE4C1286F408820 2006 Chevy DS S 2018 1GBHC24K88E216568 2008 Chevy Truck S 2018 1GCGG25C791143253 2009 Chevy Van S 2019 1GZGFBA3A1109138 2010 Chevy Van S 2020 1FTMFIEW3AKA16508 2010 Ford F150 S 2020 1FDBF2A61EEA43595 3G7WDNBL9CG296562 2014 2012 Ford F-250 Ram 5500 Heavy Duty S S 2024 2024 Vehicles are evaluated each year to determine whether it is economically in the best interest of the district to continue to repair them or if replacement is necessary. S- Superior A- Average BL- Below Average • R – 7/14