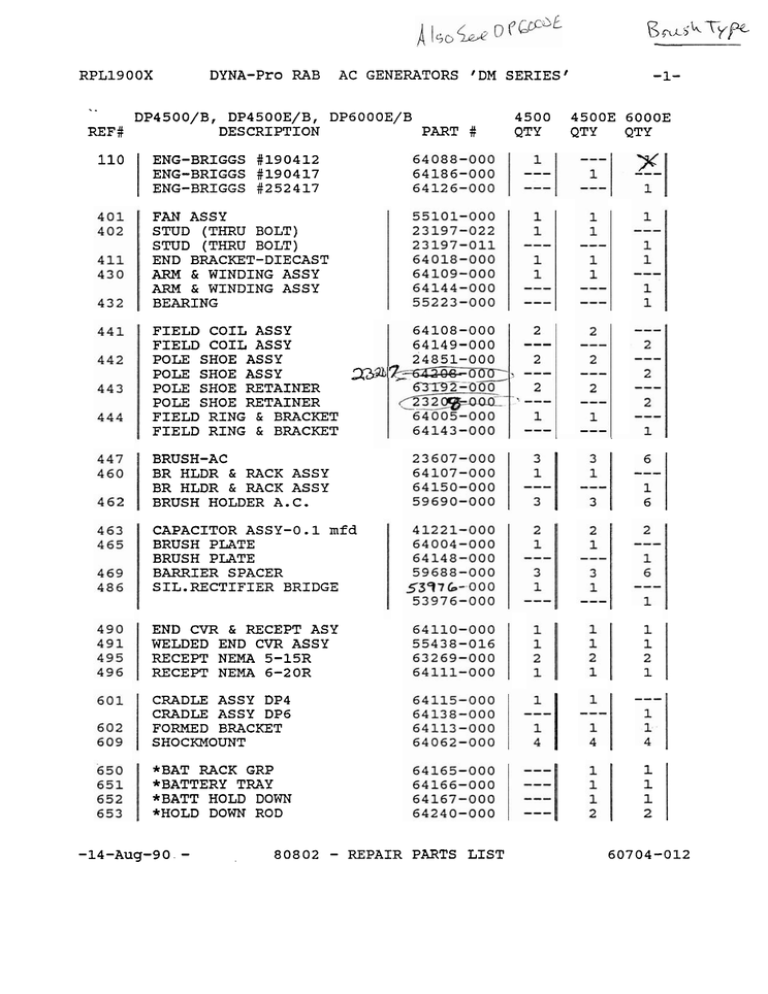

POLE SHOE ASSY

advertisement

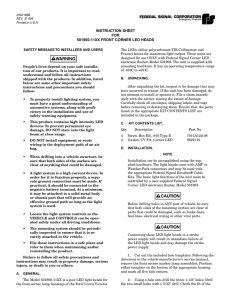

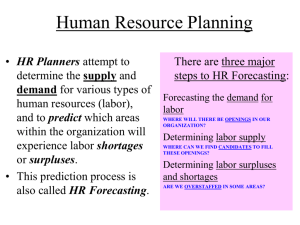

RPL1900X " REF!# 110 DYNA-Pro RAB AC GENERATORS 'DM SERIES' DP4500/Bl DP4500E/Bl DP6000E/B DESCRIPTION PART # 4500 QTY -1- 4500E 6000E QTY QTY ENG-BRIGGS #I90412 ENG-BRIGGS #I90417 ENG-BRIGGS #252417 FAN ASSY STUD (THRU BOLT) STUD (THRU BOLT) END BRACKET-DIECAST ARM & WINDING ASSY ARM & WINDING ASSY BEARING FIELD COIL ASSY FIELD COIL ASSY POLE SHOE ASSY POLE SHOE ASSY 23 POLE SHOE RETAINER POLE SHOE RETAINER FIELD RING & BRACKET FIELD RING & BRACKET BRUSH-AC BR HLDR t RACK ASSY BR HLDR & RACK ASSY BRUSH HOLDER A.C. CAPACITOR ASSY-0.1 m f d BRUSH PLATE BRUSH PLATE BARRIER SPACER SIL.RECTIFIER BRIDGE END CVR & RECEPT ASY WELDED END CVR ASSY RECEPT NEMA 5-15R RECEPT NEMA 6-20R CRADLE ASSY DP4 CRADLE ASSY DP6 FORMED BRACKET SHOCKMOUNT *BAT RACK GRP *BATTERY TRAY *BATT HOLD DOWN *HOLD DOWN ROD - -14-Aug-90. 80802 - REPAIR PARTS LIST 60704-012 -. RPL1900X .REF# DYNA-Pro RAB AC GENERATORS 'DM SERIES' DP4500/Bt DP4500E/Bt DP6000E/B DESCRIPTION PART # -2- 4500 4500E 6000E QTY QTY QTY REFERENCE DATA ONLY 64023-002 64023-006 64125-001 COMPLETE UNIT ASSY. COMMON PRT.GRP DP4 COMMON PRT.GRP DP6 1 64093-001 64093-002 1 ----- 1 -!-I COMP GEN PARTS DP4 COMP GEN PARTS DP6 SLIP RING-3 RINGS 0PR.MANUAL-DP4.5-6 PARTS LIST-DP4.5-6 INSTRUCT-BAT-RACK DP 60708-012 60704-012 60710-043 DECAL INSTAL-DP4500 DECAL INSTAL-DP6000 N.PLATE-COMPUTER BLN DECAL-WARNING DECAL-USA/ENERGX DECAL-MODEL DP4500 DECAL-MODEL DP6000 1 1 PACK GRP-DP4500 PACK GRP-DP6000 CARTON-DP4.5 SHIPPING BRKT TAG SHIPPING BRACKET POLY BAG 9 X 14 -14-Aug-90 - 80802 - REPAIR PARTS LIST --- 1 --- 1 -1-1 GROUND STRIP GROUND STRIP CONN-CONTACT SOCKET CONN-SOCKET HOUSING 901 902 902 --- 1 1 --- --- --1 I OPERATOR CARE AND MAINTENANCE (continued) CLEANING - Remove dirt and debris with a cloth or brush. DO NOT use high pressure spray to clean either the engine or the generator. This high pressure spray could contaminate the fuel system and the generator components. 1. Keep the air inlet screen on both the engine and generator free of any dirt or debris to insure proper cooling. At least yearly remove the blower housing on the engine and clean the chaff and dirt out of the engine cooling fins and flywheel. Clean more often if necessary, failure to keep these areas clean may cause overheating and permanent damage to the unit. 2. Periodically clean muffler area to remove all grass, dirt and combustible debris to prevent a fire. 3. On engine mufflers equipped with spark arresters, the spark arrester must be removed every 50 hours for cleaning and inspection. Replace if damaged. Problem Won't Start THINGS TO CHECK Sometimes problems can be easily solved by checking a few basic things. Check below before you call or take your unit to a service center. It could save you time and money. ( excitation circuit Possible Causes 'Check and clean spark plug *Check fuel level *Fuel turned on. *Dead battery *Defective start switch. Voltage too low *Check for proper engine speed *Generator overloaded *Defective rectifier *Defective Armature *Defective Field Coil Voltage too high *Engine speed is too high Generator *Overloaded overheating *Insufficient ventilation No output voltage *Short in load (disconnect) *No residual magnetisim in generator Defective armature 'Defective field coil *Defective Brushes *Shorted condenser *Shorted rectifier *Defective receptacle Battery not *Defective charging circuit re-charging on engine power circuit output DP450016000 SCHEMATIC WIRING DIAGRAM Printed in U . S . A . (3-88) C-, ' . . . .f